Method for predicting transverse tensile strength of coreless brittle fibers

A technology of transverse stretching and brittle fibers, applied in the direction of strength characteristics, using stable tension/pressure test material strength, measuring devices, etc., can solve the problem of not considering the influence of the internal stress distribution of the fiber, etc. High calculation accuracy, efficient and convenient calculation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

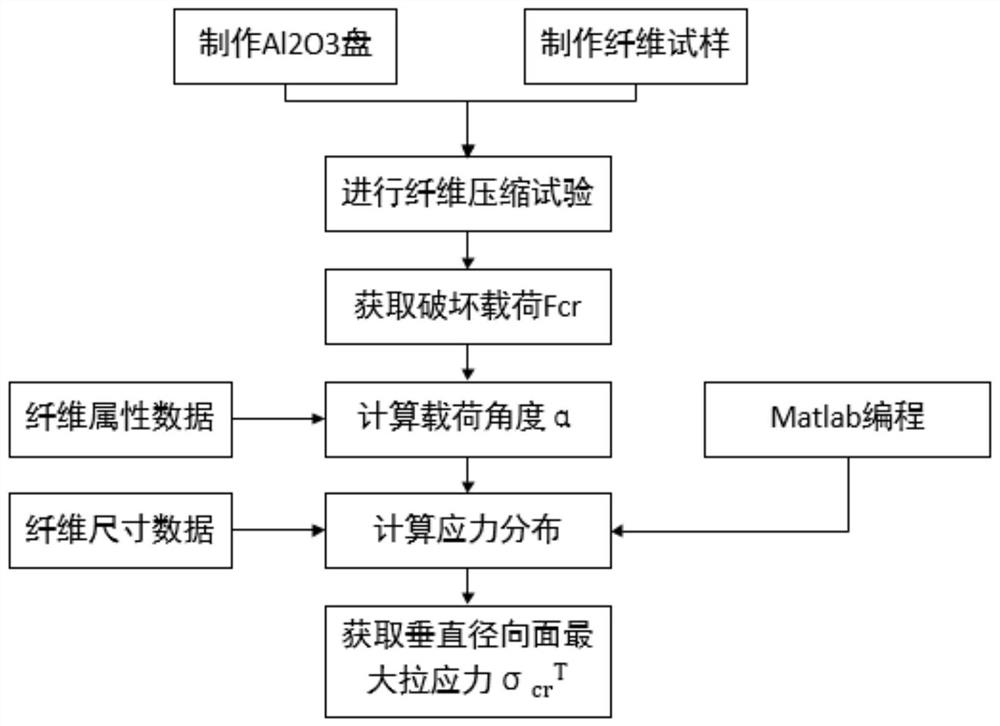

[0064] In the following, the present invention will be further described in conjunction with an example of testing the transverse tensile strength of a coreless silicon carbide fiber and the accompanying drawings, but the test object is not limited to the silicon carbide fiber.

[0065] The invention discloses a method for testing the transverse tensile strength of coreless brittle fibers. The researchers first prepared a single fiber sample with a length of about 200 μm for the brittle fiber to be tested, and performed a single fiber compression test on the sample to obtain the failure load Fcr for the fiber to undergo radial tensile failure. Then calculate the transverse tensile strength of the fiber by Fcr and fiber properties.

[0066] step 1:

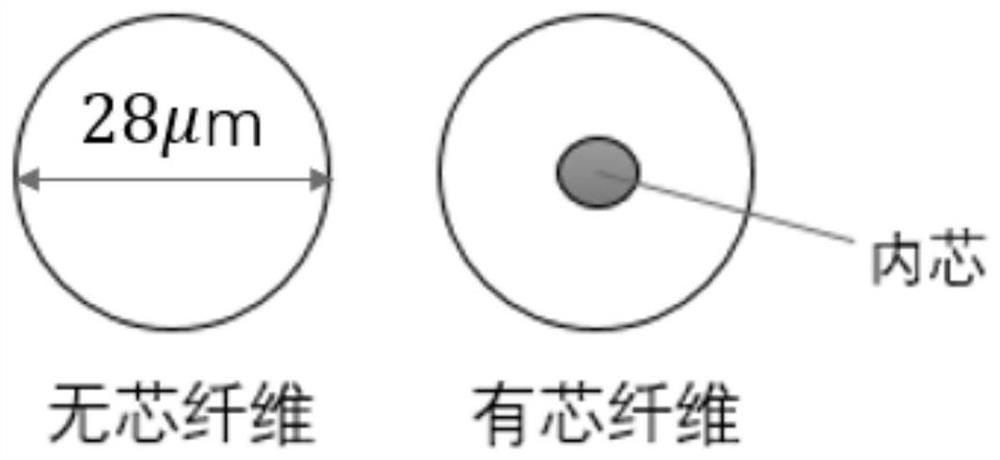

[0067] Test a coreless SiC fiber with a diameter of 28μm, such as image 3 Shown. The longitudinal elastic modulus of the fiber is 420 GPa, the transverse elastic modulus is 240 GPa, and the Poisson's ratio is 0.15. Twenty coreless SiC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com