Rock crack propagation simulation testing device and testing method

A crack propagation and simulation test technology, which is applied in the field of rock crack propagation simulation test device, can solve the problems of loading process control, less use, and test cost reduction, and achieve the effect of simple test operation, low test cost and simple test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

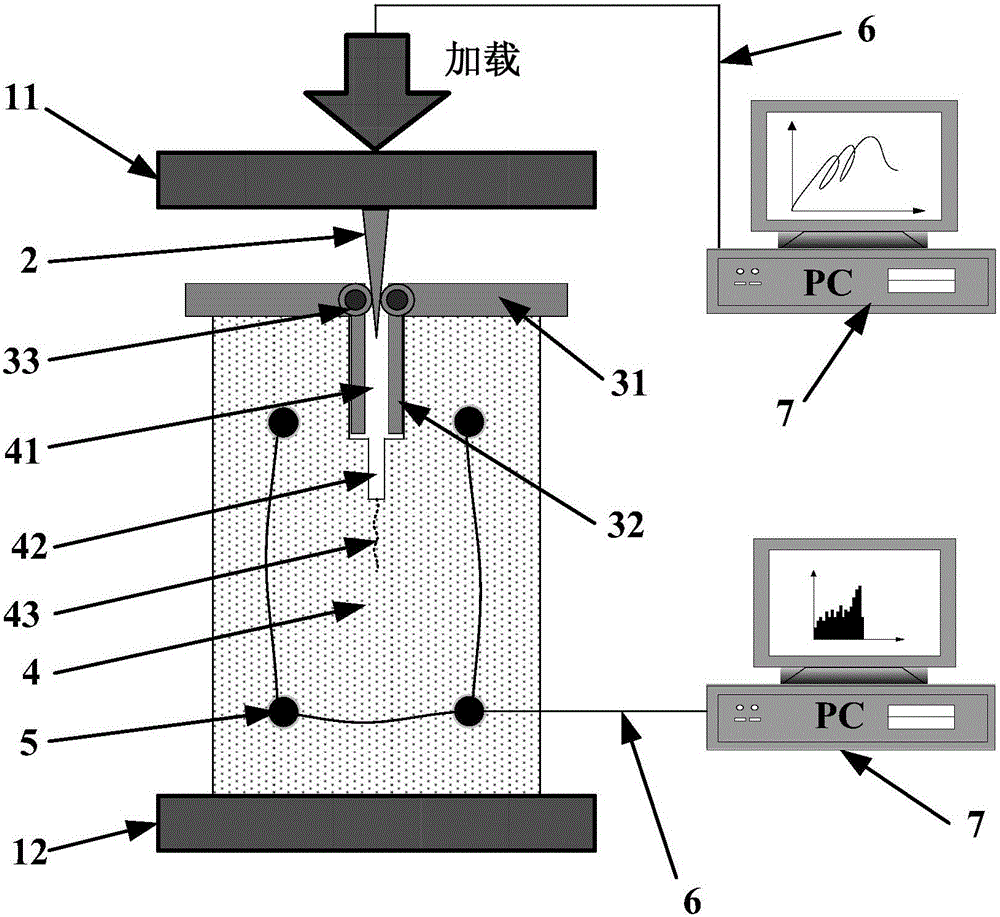

[0029] Such as figure 1 As shown, this embodiment provides a rock crack propagation simulation test device, the lower surface of the upper bearing plate 11 is fixedly connected with the extrusion head 2 made of high-strength fiber material, which is thick on the top and sharp on the bottom. The cross section of the pressure head 2 is triangular, which can facilitate the extrusion head 2 to continue to squeeze downwards from the gap between the two pulleys 33 . The rock sample 4 is placed on the upper surface of the lower bearing plate 12, the top of the rock sample 4 is provided with a groove 41, and the rock sample 4 at the bottom of the groove 41 is provided with a prefabricated crack 42, and the prefabricated crack 42 can ensure that the crack 43 The expansion proceeds along a certain direction, which is beneficial to observe the expansion process of the recording crack 43 . The upper extruding plate 31 and the lower extruding plate 32 are also made of high-strength fiber ...

Embodiment 2

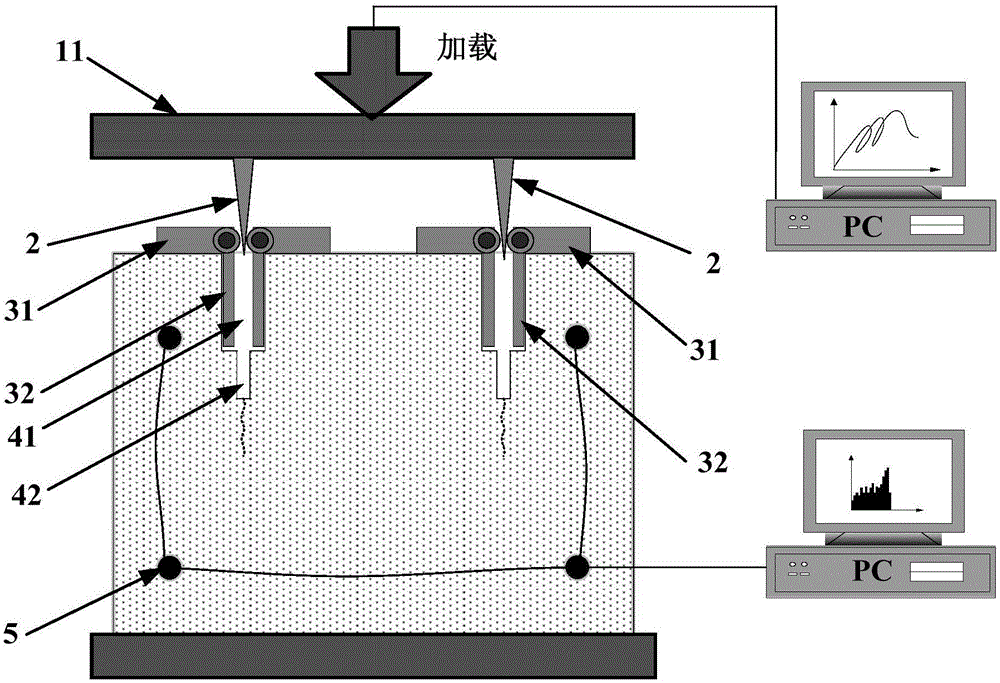

[0035] The difference between this embodiment and Embodiment 1 is that two grooves 41 are provided above the rock sample 4, and the rock sample 4 at the bottom of the two grooves 41 is provided with prefabricated cracks 42, and the upper pressure plate The lower surface of 11 is fixedly connected with two extruding heads 2 . The rock crack propagation simulation test device in this embodiment can simulate the rock crack propagation process at two places on the rock sample 4 at the same time. Certainly also can be provided with more than two grooves 41 above the rock sample 4, the rock sample 4 at the bottom of more than two grooves 41 is all provided with the prefabricated crack 42, and the lower surface of the upper bearing plate 11 is fixed. The number of extrusion heads 2 corresponding to the number of grooves 41 is connected, and more than two simulated rock crack propagation processes can be performed on the rock sample 4 at the same time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com