Method for producing round-link chain

A production method and technology of circular chain, applied in the field of mechanical processing, can solve the problems such as the bending of the circular chain cannot reach the specified deflection, the low yield point of the circular chain, the insufficient tensile load, etc., to ensure the plasticity and toughness, the electrical conductivity Good performance and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

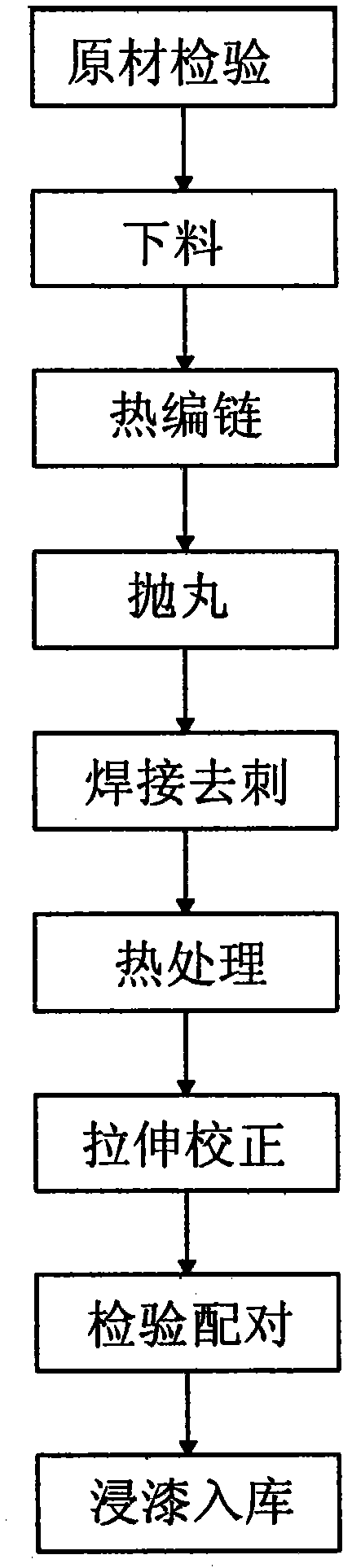

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with specific embodiments.

[0022] Raw material selection: high-quality alloy steel 23MnNiMoCr54;

[0023] Cutting:

[0024] The Q45-125A precision bar shearing machine produced by Shenyang Qiushi Precision Shearing Machine Factory adopts the principle of constrained (ie axial shearing and radial) shearing, with high shearing accuracy, end face inclination ≤ 20, and weight error ≤±0.5%, the cutting cost is low, about 1 / 3 of the band saw cutting, the production efficiency is high, about 20 times that of the band saw cutting, the equipment uses wind power, which is a material-saving and energy-saving equipment. Shear force 1250KN.

[0025] Cutting requirements: can test station, no burr chamfering, bar length error within ± 0.5mm.

[0026] Hot chaining:

[0027] The equipment adopts WEN500 type heating equipment and KBA40 type chain knitting equipment produced by Germany Mayer MYR company. The he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com