Testing machinery cellfiber clamper and method for measuring tensile strength

A testing machine, a single fiber technology, applied in the direction of measuring devices, strength characteristics, using a stable tension/pressure test material strength, etc., can solve the problem of poor position reproducibility and accuracy, shear force in the load, relative occurrence Displacement and other issues, to achieve the effect of high position reproducibility and accuracy, scientific and accurate strain value, and convenient data storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

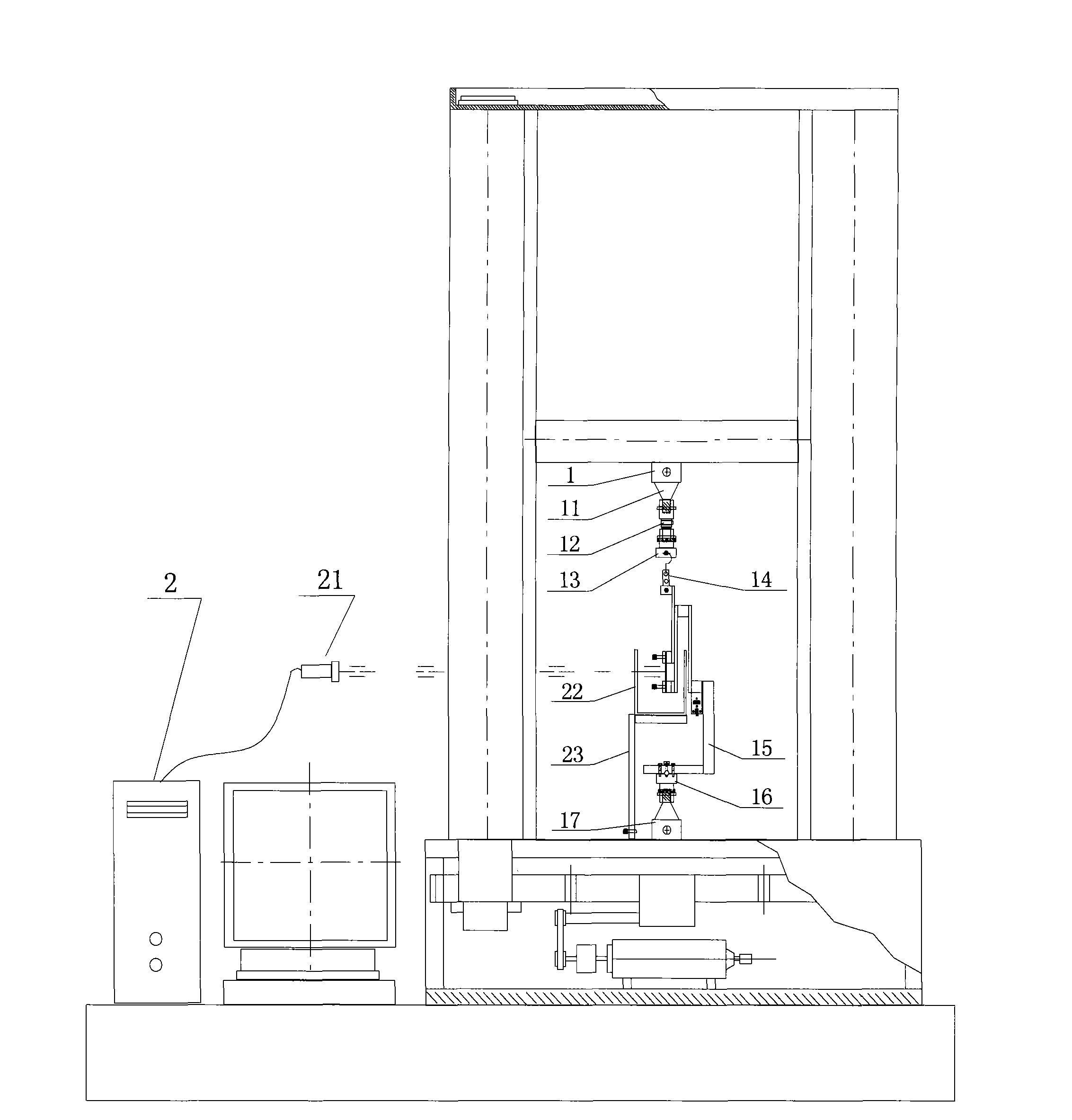

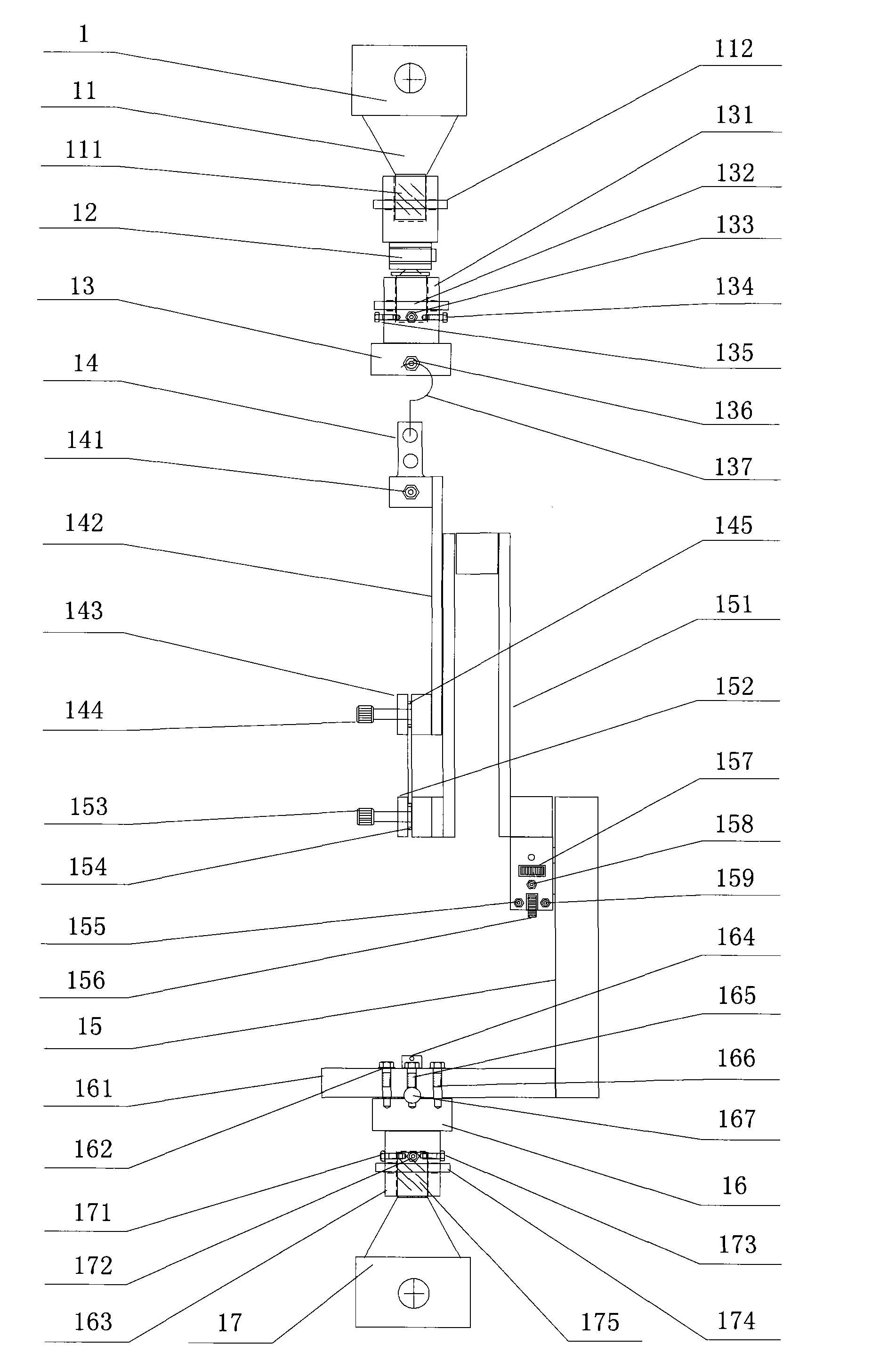

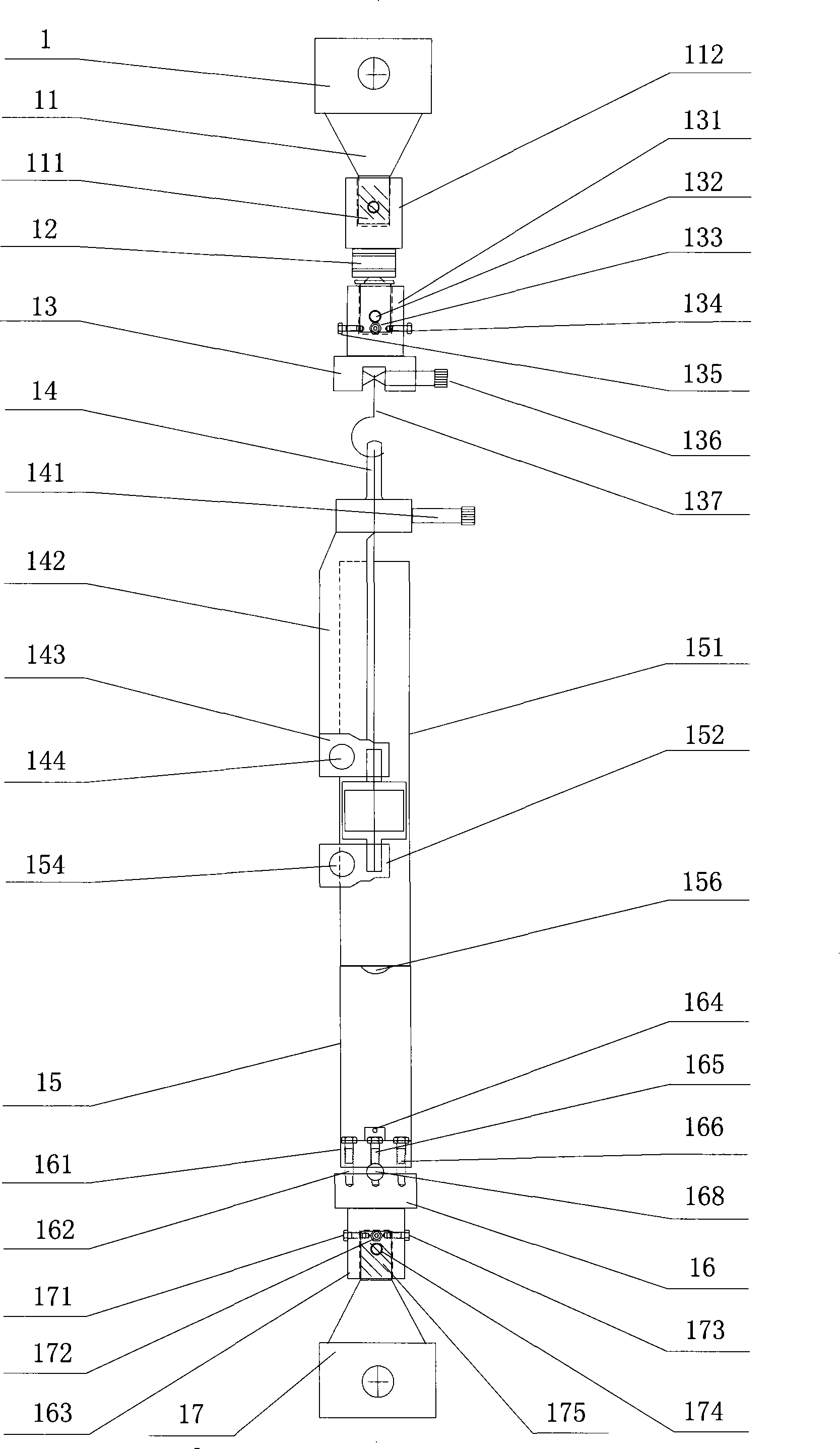

[0035] see Figure 1~3 , the measuring equipment used for the ceramic single fiber tensile test on the testing machine includes two parts: the single fiber fixture 1 of the testing machine and the strain acquisition device 2 .

[0036] The single fiber fixture 1 of the testing machine includes a lower chuck device 11 of the testing machine, a load sensor 12 , a hook holding device 13 , an upper clamping device 14 , a lower clamping device 15 , a level adjustment device 16 and a lower chuck device 17 of the testing machine. The upper chuck device 11 of the testing machine is located under the load beam of the testing machine, the load sensor 12 is connected with the upper chuck 111 through the pin 112, and the hook holding device 13 is located vertically below the load sensor 12 of the testing machine, and is connected with the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com