Patents

Literature

47results about How to "High position repeatability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

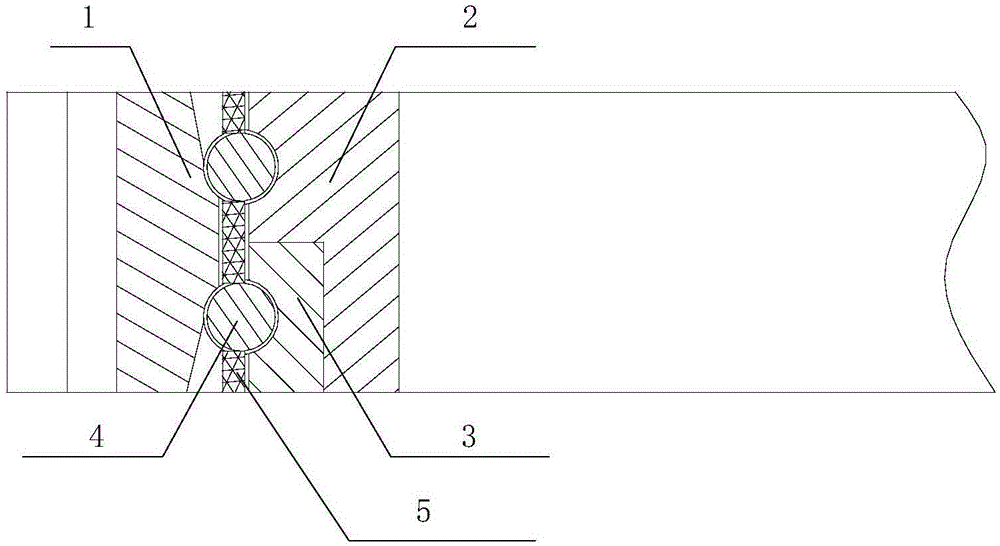

Steering system planetary gear absolute angle output corner sensor

InactiveCN101608898ALow environmental requirementsImprove performanceUsing electrical meansElectrical steeringGear wheelMagnetic poles

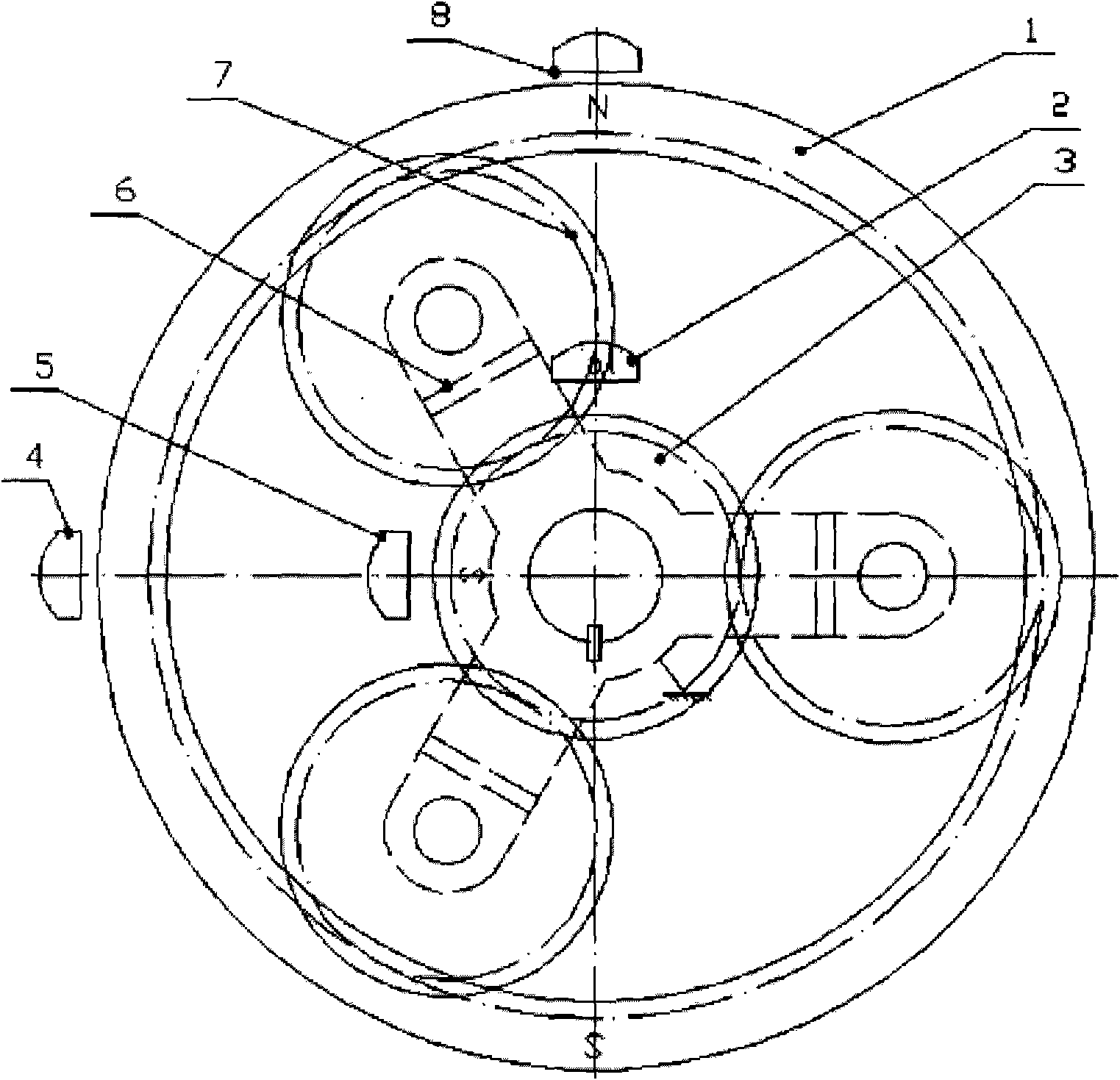

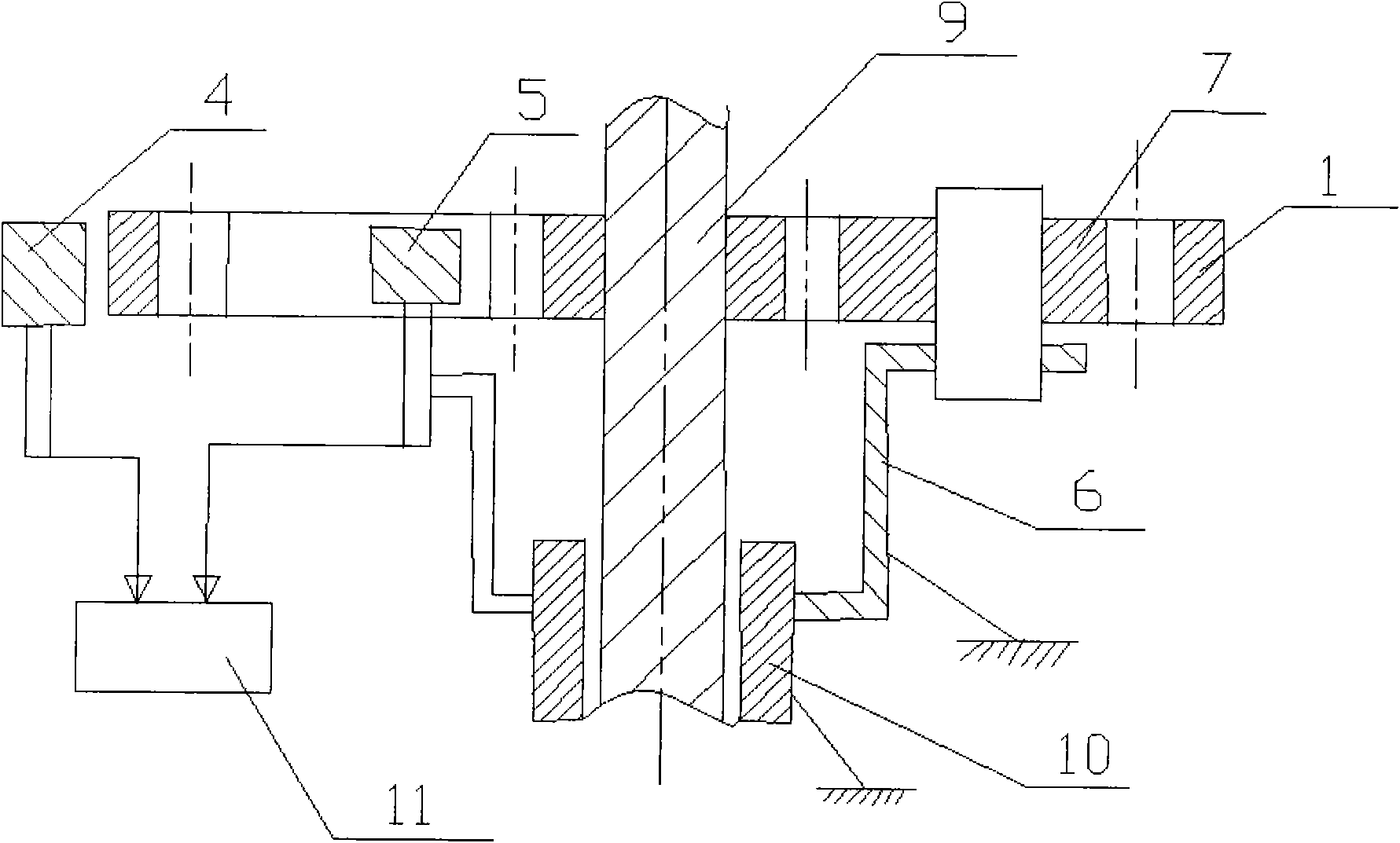

The invention relates to a steering system planetary gear absolute angle output corner sensor, mainly composed of a gear ring (1), a sun gear (3), planetary gears (7), a CPU control unit (11) and Hall sensors; wherein the sun gear is a magnetic gear, and the sun gear and the gear ring are all provided with a pair of magnetic poles; the sun gear is fixed on a steering column (9), and the steering column is fixedly connected with an auto steering wheel; the quantity of the planetary gears is three, the planetary gears are evenly distributed and fixedly arranged on a planet carrier (9) and are connected with the sun gear and the gear ring in a meshed way, and the planet carrier is fixed at the upper part of a sleeve; a pair of Hall sensors are respectively arranged near the sun gear and the magnetic poles of the gear ring, and each pair of Hall sensors are arranged in 90 degrees; and the Hall sensors are connected with the CPU control unit (11) by a data line. The invention has the advantages of low requirement on environment, high cost performance, wide measurement range, insensitivity to error caused by temperature and convenient installation.

Owner:WUHAN UNIV OF TECH +1

Electric objective table

Owner:KUN SHAN POWER STENCIL

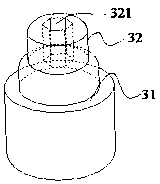

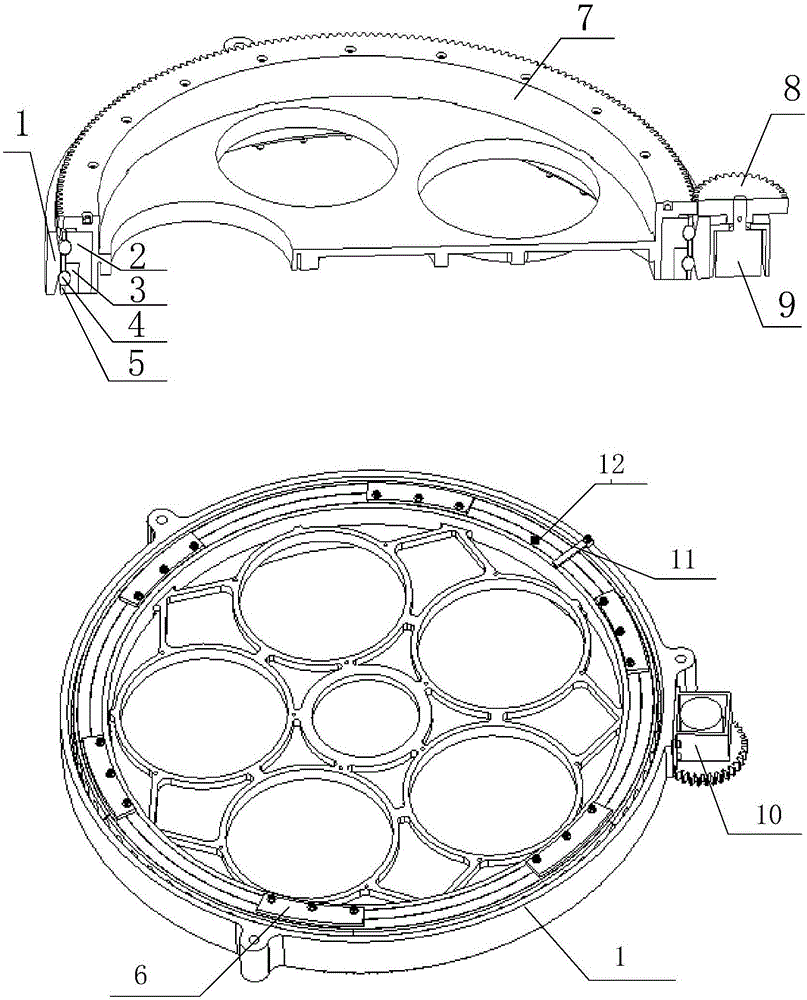

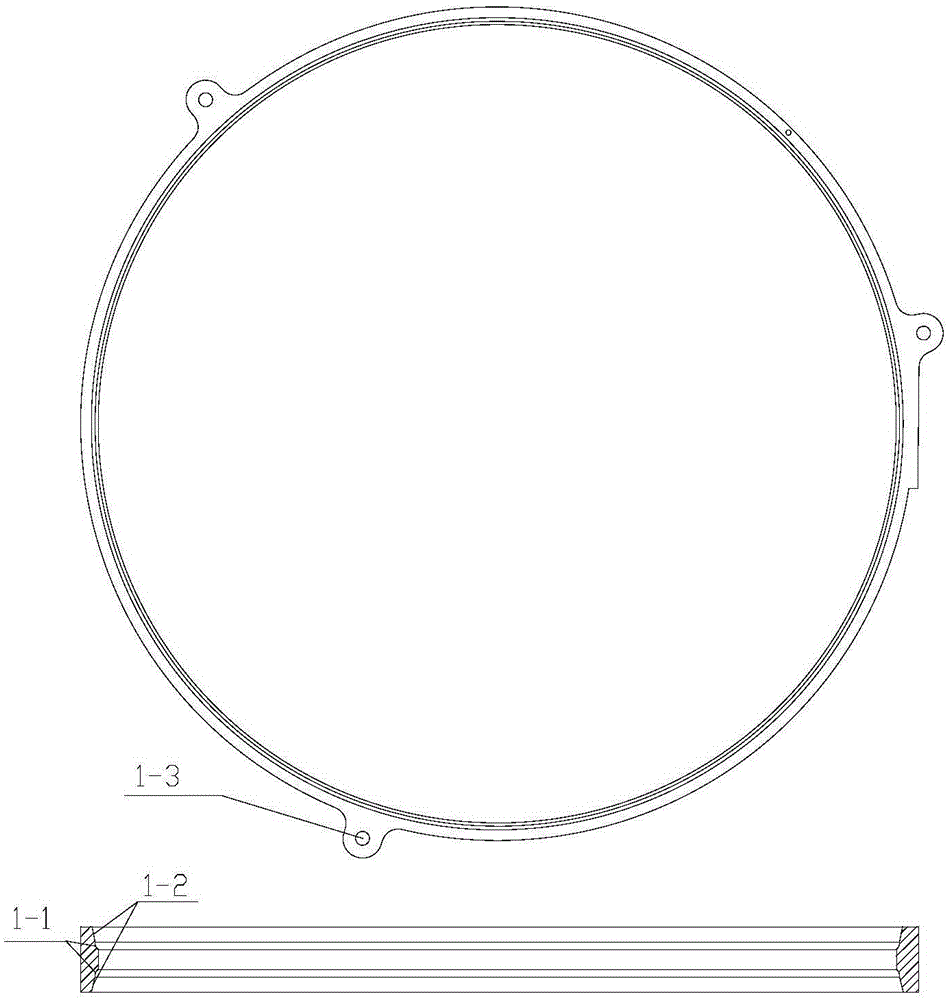

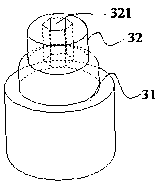

High-precision high-rigidity space camera filter switching mechanism

ActiveCN105068362AAvoid configurationIncrease stiffnessMountingsCamera body detailsMotor driveThermal deformation

The invention relates to a high-precision high-rigidity space camera filter switching mechanism, and the mechanism is used for enabling space camera filters to enter into an optical path sequentially. The mechanism consists of an integrated bearing part, a gear pair, and a drive control assembly. The integrated bearing part comprises an integrated bearing outer ring, an inner shaft ring, an embedded ring, a ball, a ball holder, and a pressure block. The gear pair consists of a filter installation disc and a small gear, and is connected with the inner shaft ring of an integrated bearing part. A driving part comprises a motor, a motor installation frame, a magnetic steel, and a Hall sensor. The motor drives the small gear to drive the filter installation disc to rotate under a control instruction. According to the invention, the mechanism employs a mode that the bearing is disposed outside and the filter installation disc is disposed inside, and increases the rigidity. The mechanism employs the integrated design of the bearing, is high in rotation precision, is excellent in axial bearing performance, and is low in assembly difficulty. The mechanism employs a stress relief design of the filter installation disc, reduces the installation stress and thermal deformation under a low-temperature working condition.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

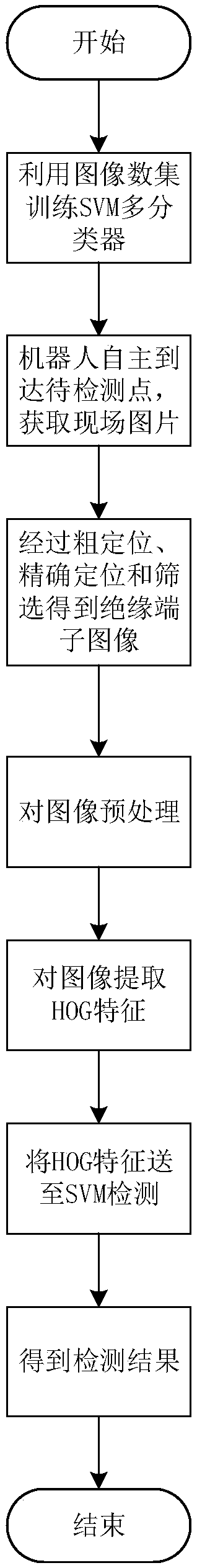

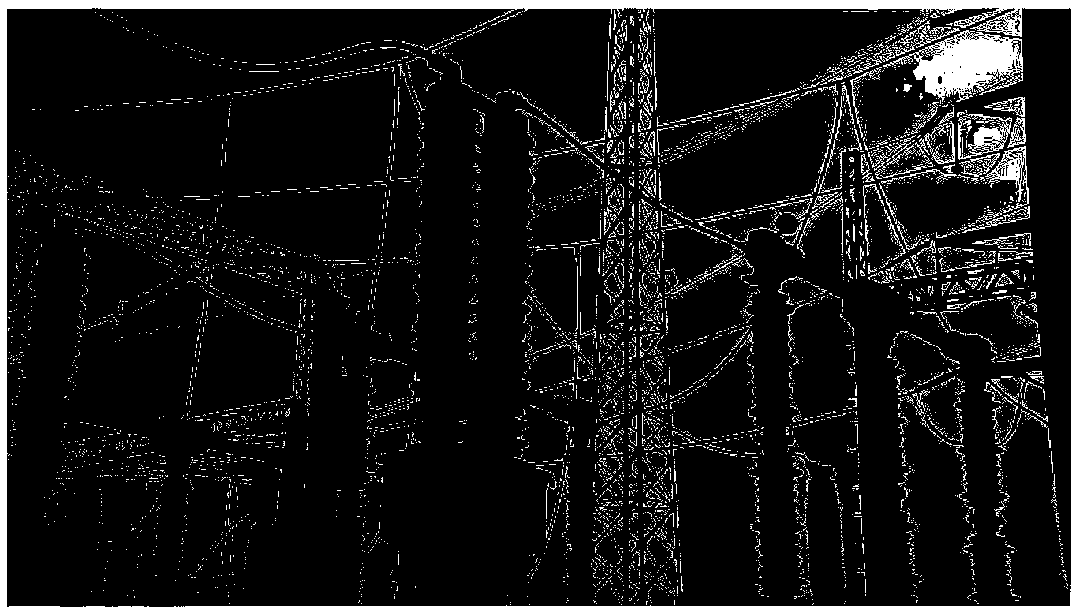

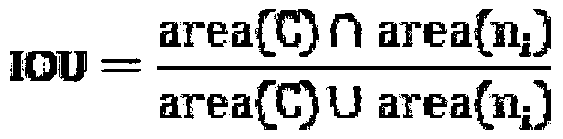

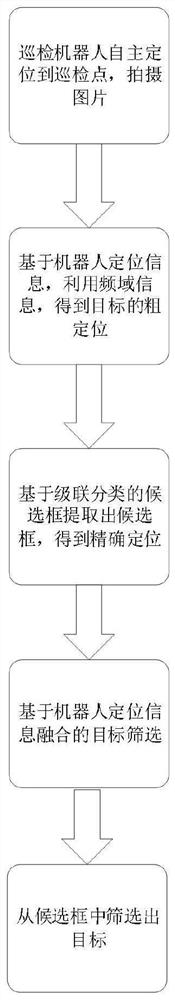

Insulation terminal defect recognition method based on patrol robot

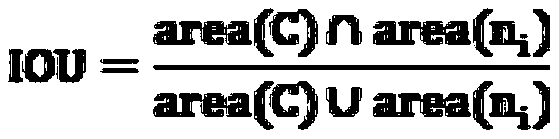

InactiveCN109447949AImprove recognition accuracyHigh position repeatabilityImage enhancementImage analysisPattern recognitionData set

The invention provides an insulation terminal defect recognition method based on a patrol robot. The method of the invention is mainly divided into five steps of (1) training the SVM multi-classifierby using the insulation terminal image data set collected in advance; 2) enabling the patrol robot to arrive at the designate patrol point, obtaining the field insulation terminal image and reading itin the form of a gray scale image; (3) coarse positioning and precise positioning of the target area to be detected, and screening the target candidate area to obtain the insulation terminal image; (4) preprocessing the obtained field insulation terminal image; (5) extracting the HOG feature from the sliding window, and sending the HOG feature operator to the SVM multi-classifier to get the recognition result. The machine learn is utilized, the insulation terminal detection and identification task can be effectively completed under different illumination and posture conditions, the automationlevel and the accuracy rate of the image identification under the complex environment are improved, and the problem of missing detection and false detection are reduced to the utmost extent.

Owner:NANJING UNIV OF SCI & TECH

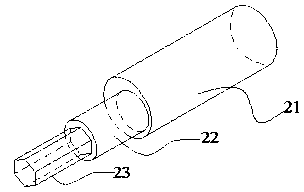

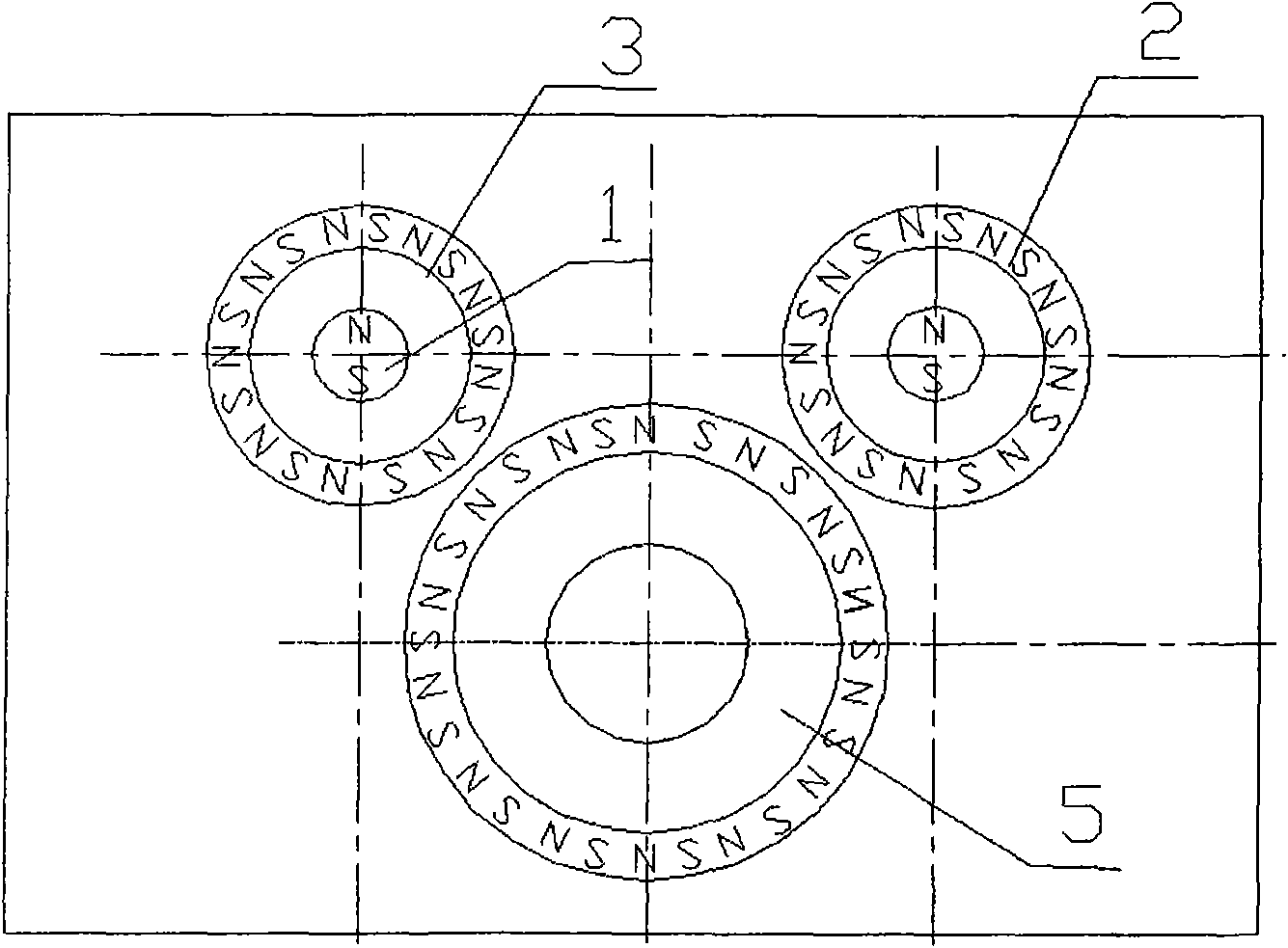

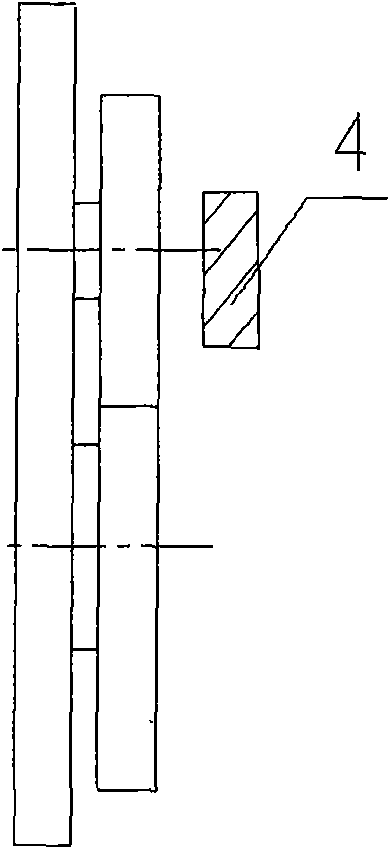

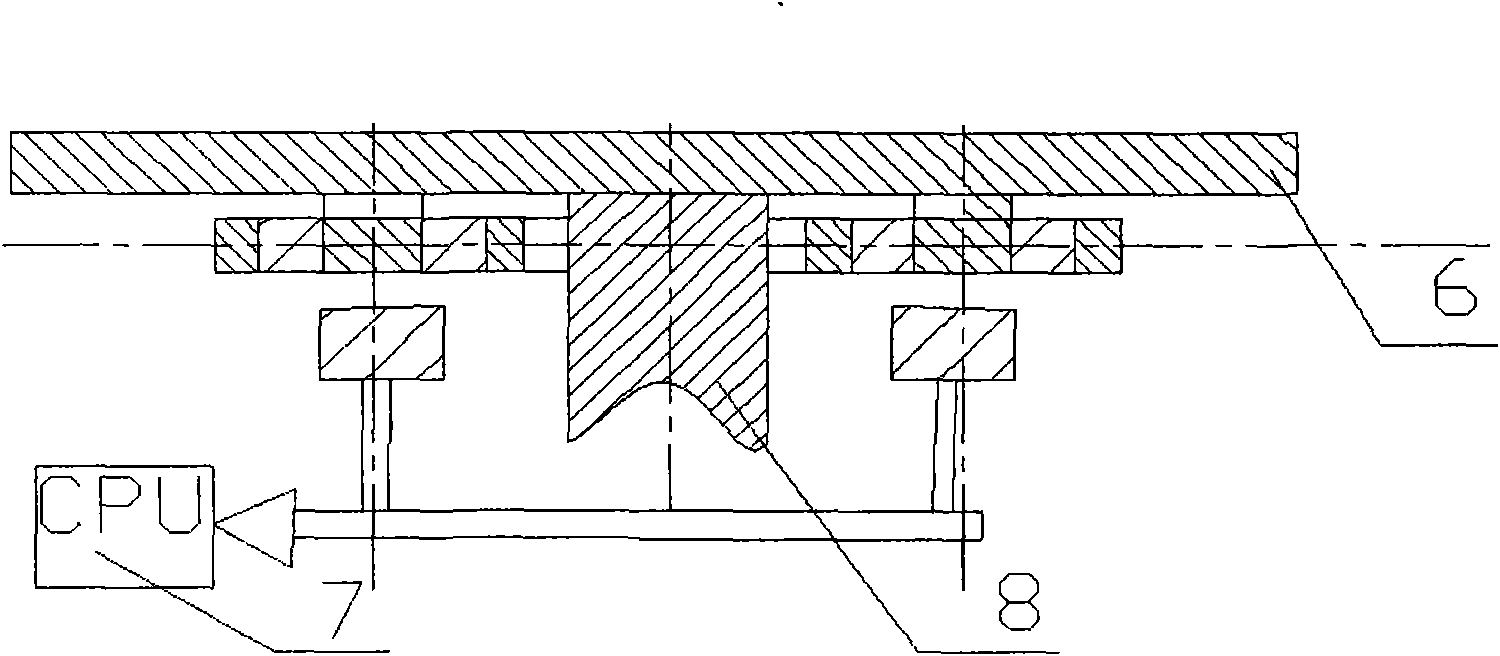

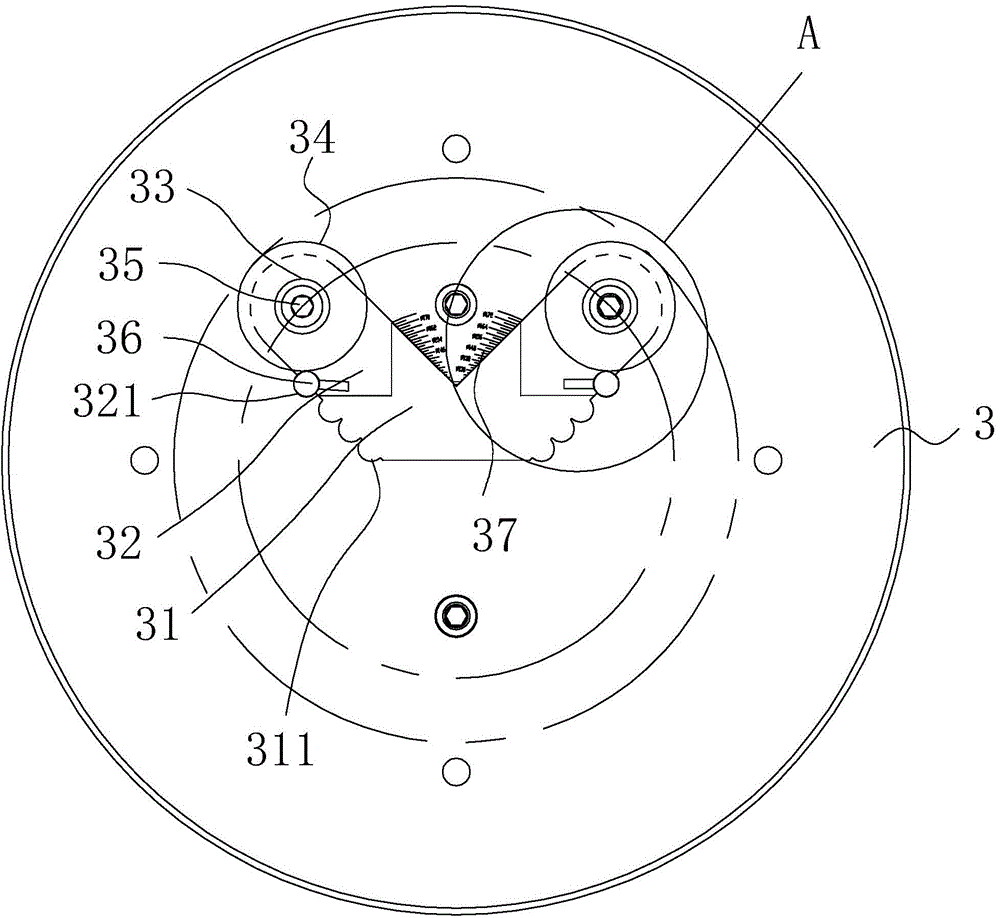

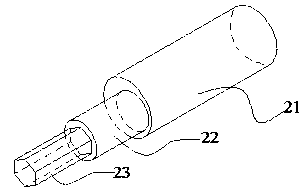

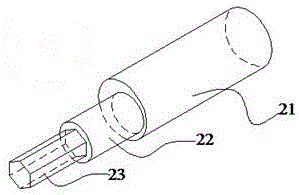

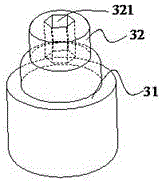

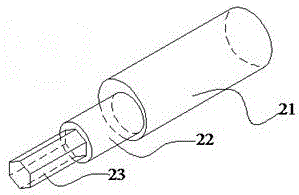

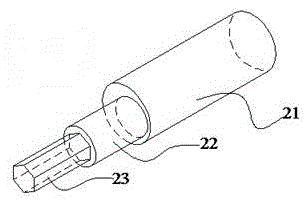

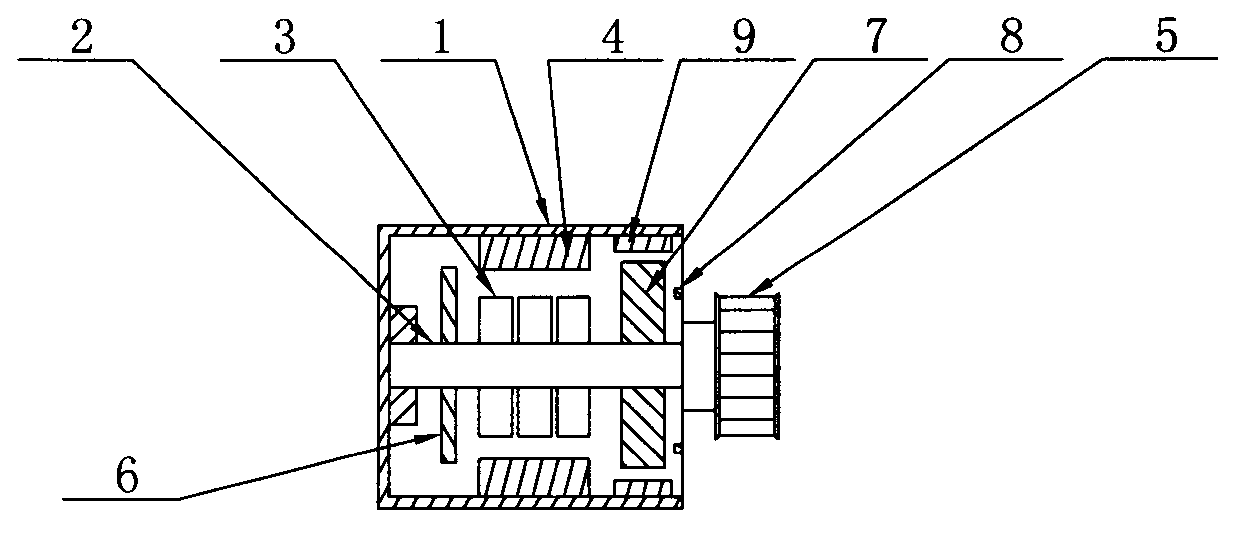

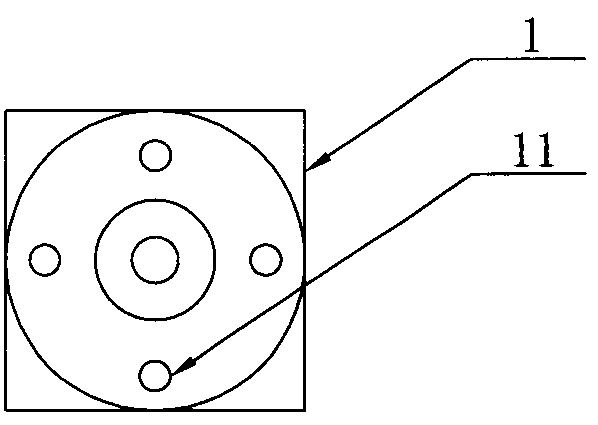

Non-contact magnetic transmission absolute angle sensor for steering system of automobile

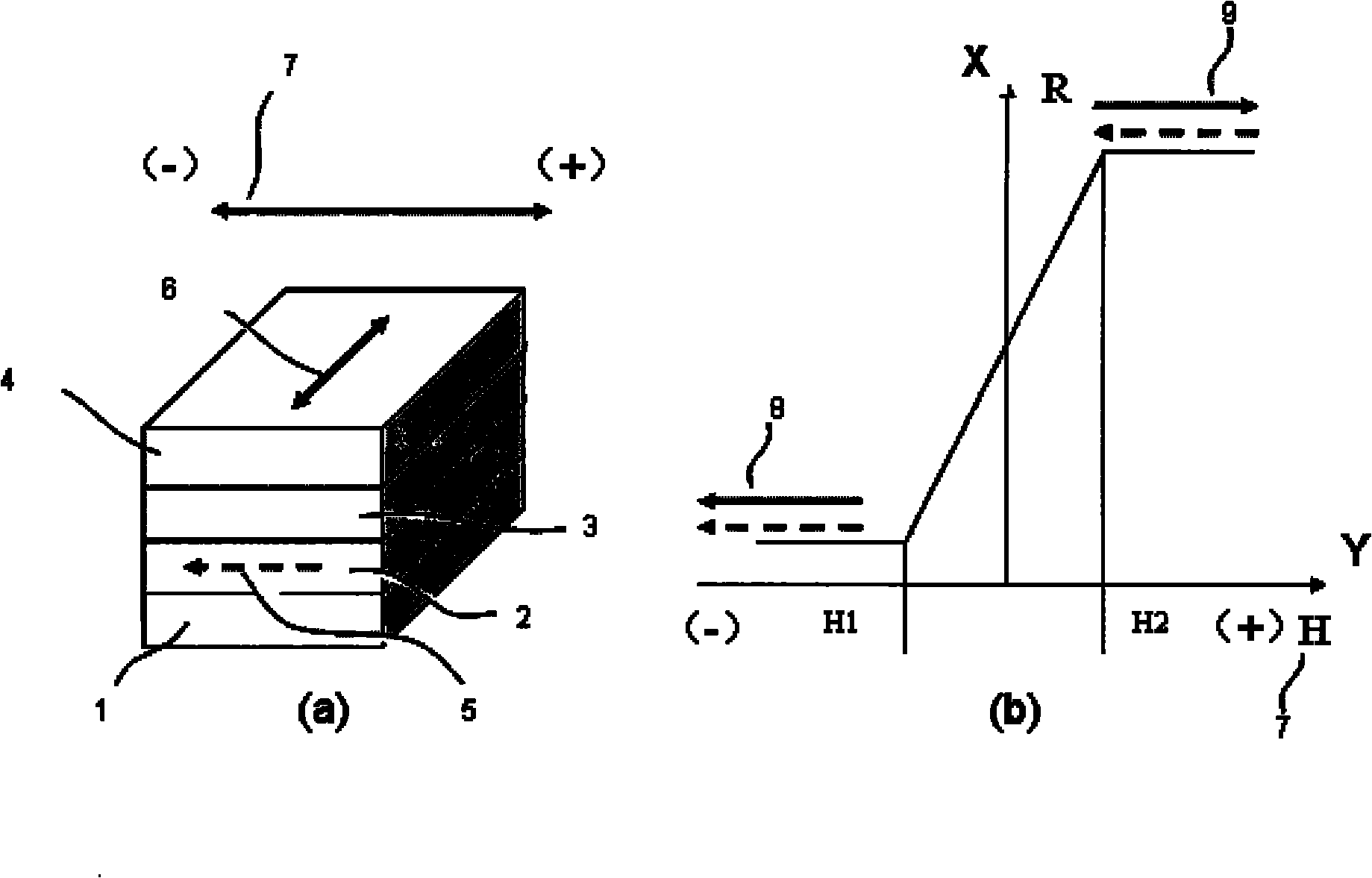

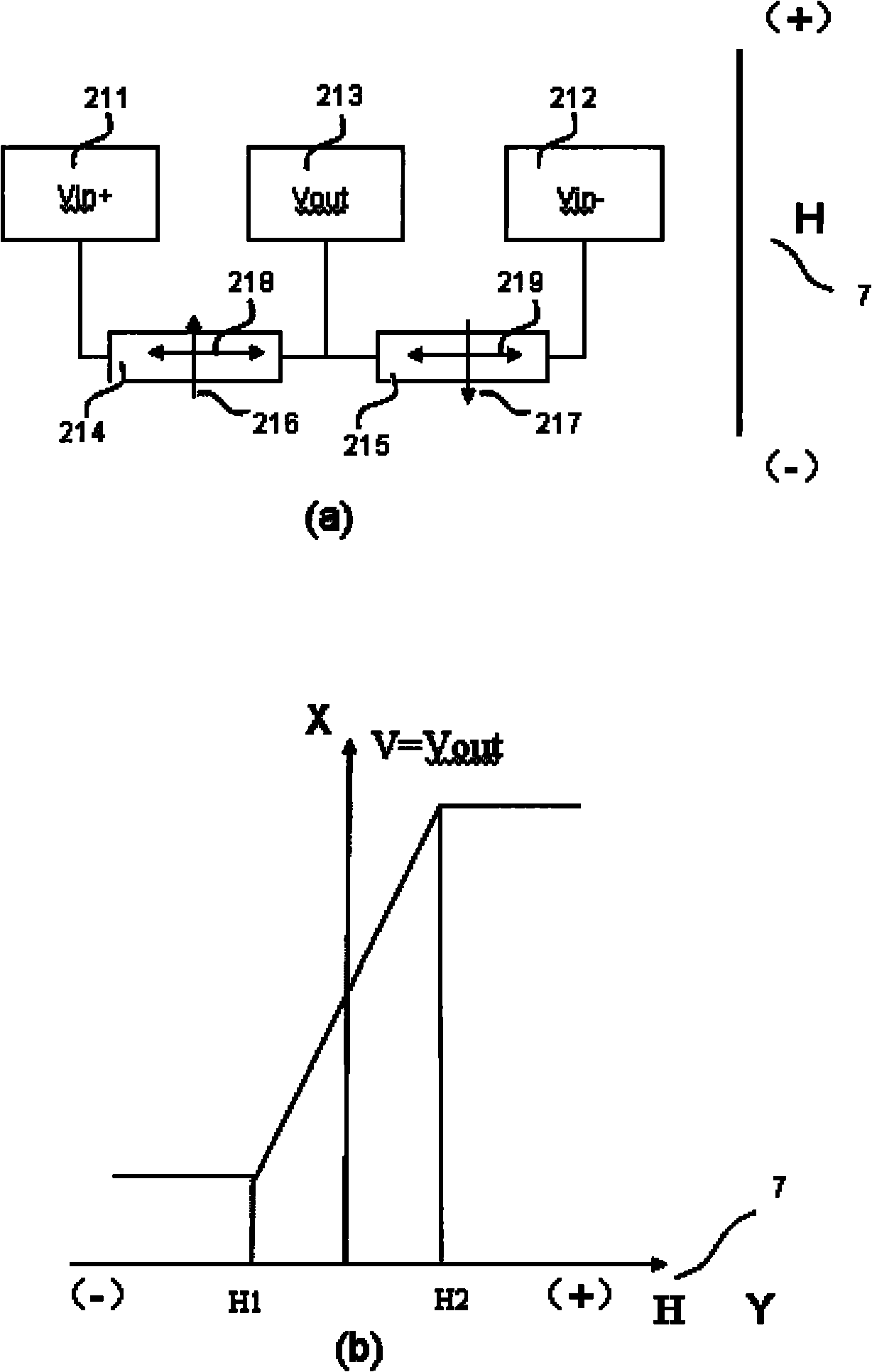

InactiveCN101603808AOvercome the disadvantages of high price and high environmental requirementsLow environmental requirementsUsing electrical meansSteering columnEngineering

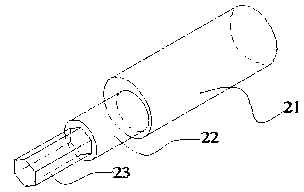

The invention relates to a non-contact magnetic transmission absolute angle sensor for a steering system of an automobile, comprising a magnetic cylinder (1), a CPU control unit (7), a magnetic wheel mechanism and Hall sensors, wherein the magnetic wheel mechanism comprises two driven magnetic gears and a driving magnet wheel (5) which is in mesh connection with the driven magnetic gears, and one magnetic steel (1) is installed on the central part of each driven magnetic gear; the driving magnet wheel is fixed on a steering column (8); and one Hall sensor is installed adjacently to each magnetic steel, and the Hall sensors are connected with the CPU control unit by data wires. The invention has the advantages of low requirement on environment, high cost performance, wide range of measurement, insensitivity to error caused by temperature, convenient installation, etc.

Owner:WUHAN UNIV OF TECH

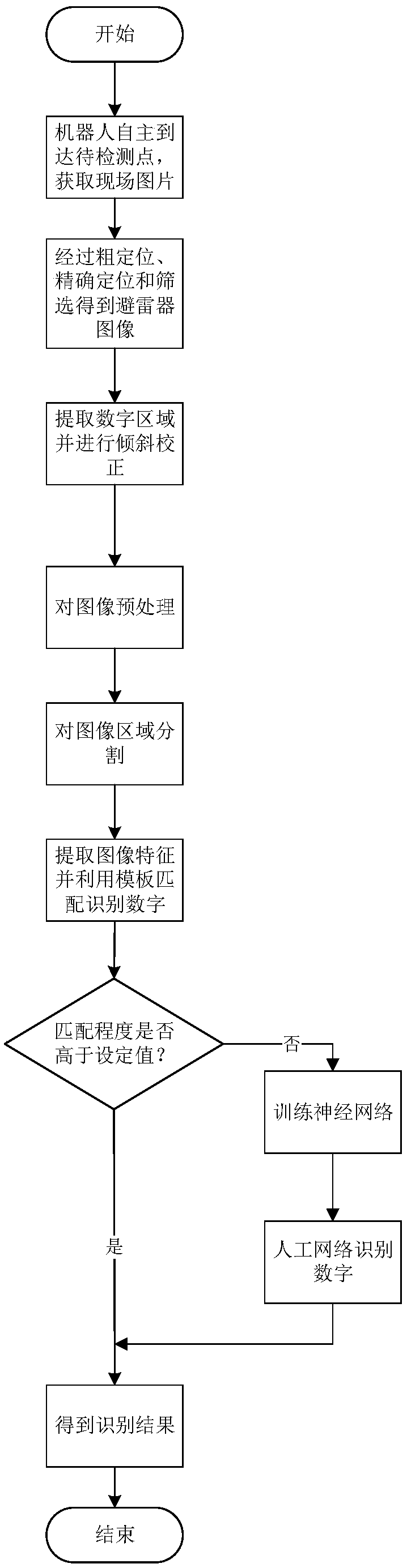

A method for identifying a lightning arrester based on a patrol inspection robot

InactiveCN109255336AImprove recognition accuracyReduce complexityCharacter and pattern recognitionTemplate matchingImaging Feature

The invention relates to a method for identifying a lightning arrester based on a patrol inspection robot, wherein the patrol inspection robot obtains an image of a field lightning arrester; the target area to be detected is roughly located and precisely located, and the target candidate area is screened to obtain the lightning arrester image. The digital region is extracted, and the tilt correction and image preprocessing are carried out on the digital region. The target region is segmented to obtain a single digital image. Image features are extracted and a template matching method is used to recognize a single digital image. ehether the matching ratio of a single digital image and a template is higher than a set threshold value is judged, if so, the recognition is completed, if not, a trained artificial neural network is called to recognize a single digital image again; the digital display part of the arrester is obtained by sorting the single digits according to their coordinates in the image. The invention can effectively complete the detection and identification task of the lightning arrester under different illumination and posture conditions, and meanwhile, the identification speed is improved on the basis of maintaining the identification accuracy.

Owner:NANJING UNIV OF SCI & TECH

Intelligent flow meter adopting TMR (Tele Meter Reading) magnetic sensor

ActiveCN101871801AReduce power consumptionReduce volumeVolume/mass flow by electromagnetic flowmetersWorking temperatureShock resistance

The invention relates to an intelligent flow meter adopting a TMR (Tele Meter Reading) magnetic sensor, comprising a TMR flow meter sensor, a flow meter shell, a rotational impeller, a rotational impeller stand, a small magnet with an upward N pole, a small magnet with an upward S pole, a flow meter inlet / outlet, a magnetic shielding layer and a protection layer isolated a flow meter chip from fluid. When fluid to be measured exists, the measured fluid drives the rotational impeller to rotate so as to drive the small magnet with the upward N pole and the small magnet with the upward S pole to rotate simultaneously, and the TMR magnetic sensor induces a magnetic field so as to achieve the purpose of metering. The invention has the advantages of tiny power consumption, wide working frequency range and working temperature range, firm structure, small size, long service life, convenient installation, shock resistance, clear output wave shape without vibration, high position repeating accuracy, simple electromagnetic shielding structure, reverse rotation error prevention calculation, and the like.

Owner:王建国 +1

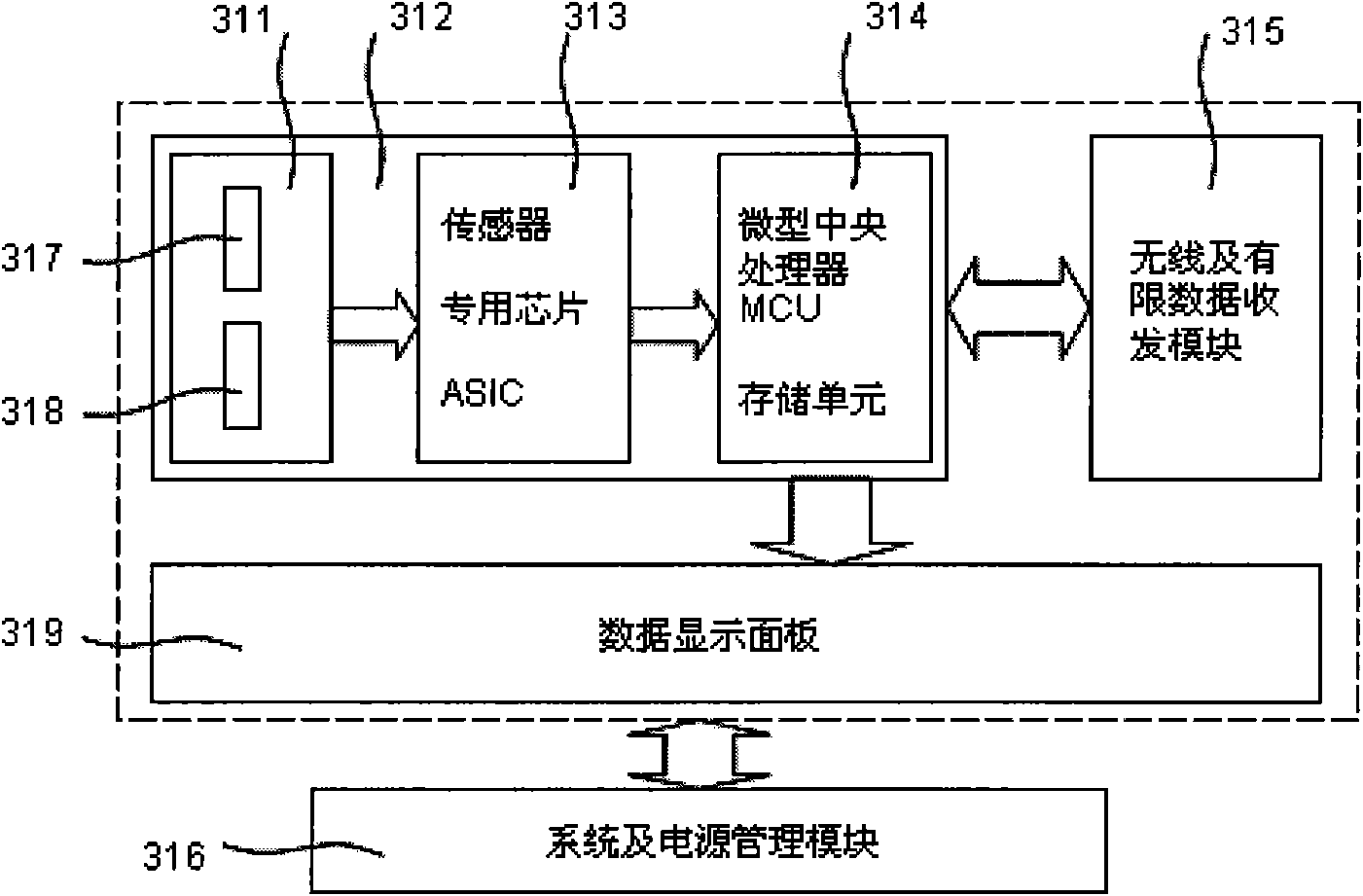

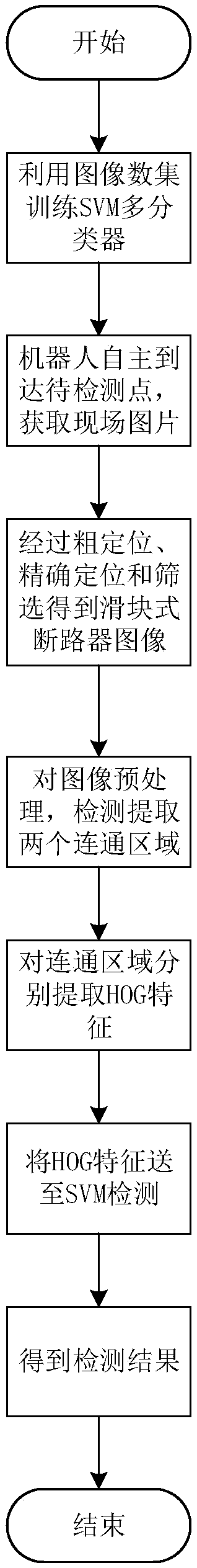

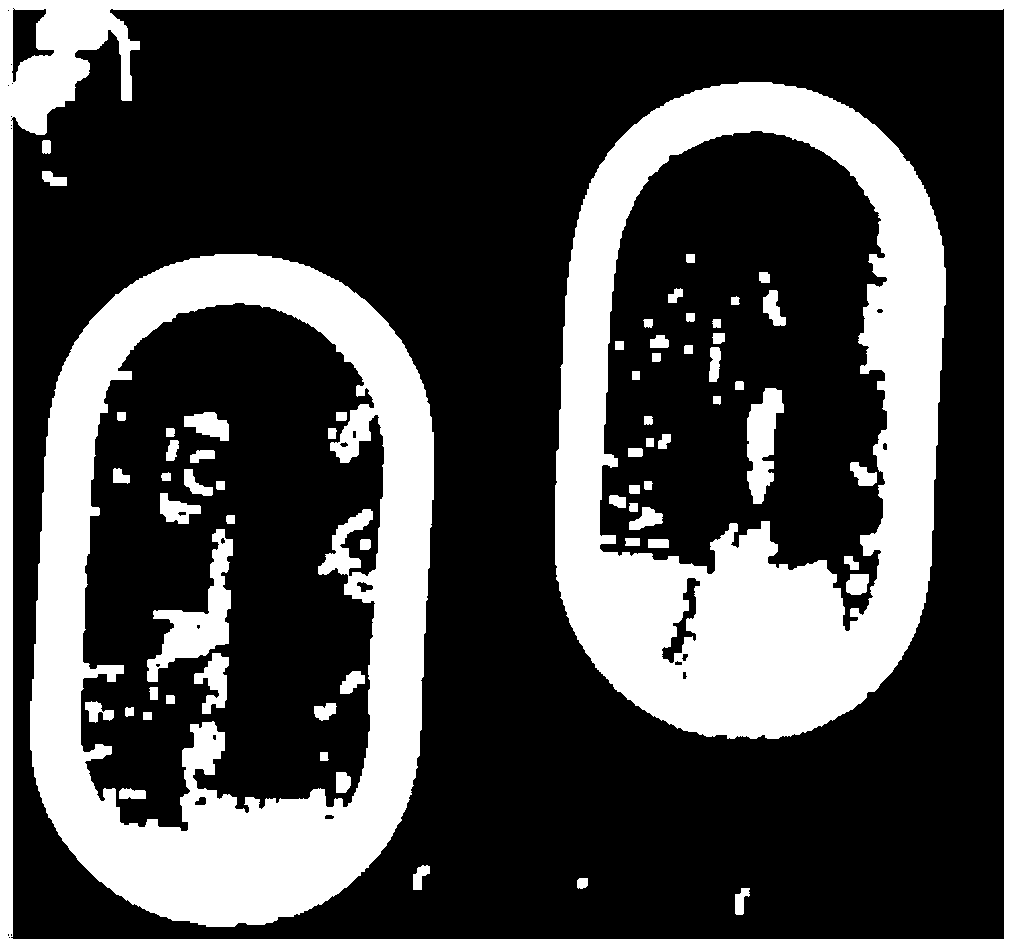

Identification method of slider circuit breaker based on patrol robot

InactiveCN109344766AReal-time monitoring captureIncrease the level of automationCharacter and pattern recognitionEngineeringCircuit breaker

The invention provides a method for identifying a slider circuit breaker based on a patrol robot. The invention is mainly divided into five steps: (1) training SVM multi-classifier by using image dataset; 2) that patrol robot arrives at the designate patrol point to obtain the pictures to be detected; 3) carry out coarse positioning and precise position on that target area, and screening the candidate area of the target to obtain a slider circuit break; 4) carry out image preprocessing on that acquire slider-type circuit breaker to extract two regions with the largest connecte area; (5) HOG features of two connected regions are extracted respectively and sent to SVM multi-classifier to get the final recognition results. As that machine learn is utilized, the detection and identification task of the slide circuit breaker can be effectively completed under different illumination and posture conditions, the automation level and the accuracy rate of the image identification unde the complex environment are improved, and the problems of missing detection and false detection are reduced to the maximum extent.

Owner:NANJING UNIV OF SCI & TECH

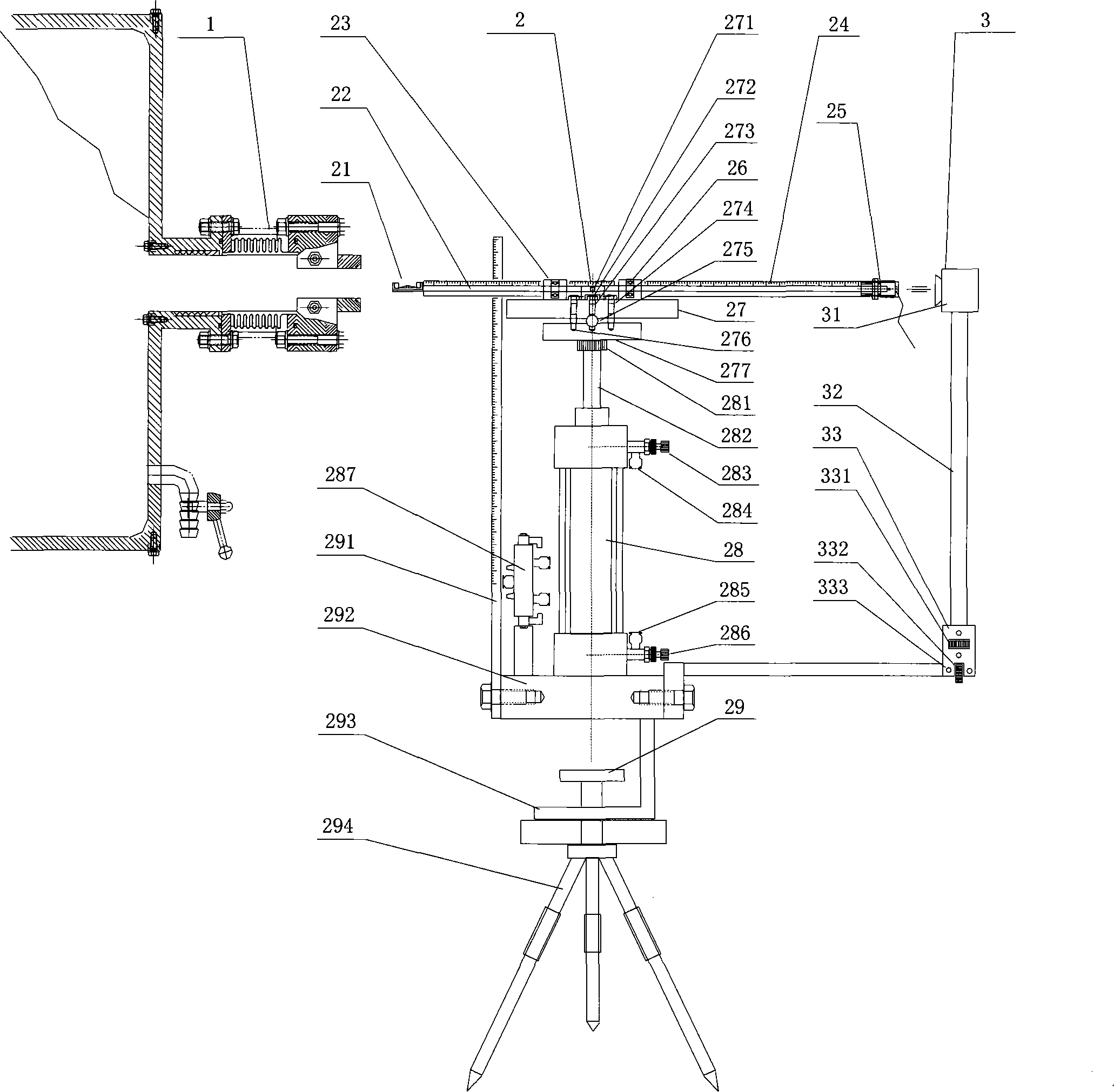

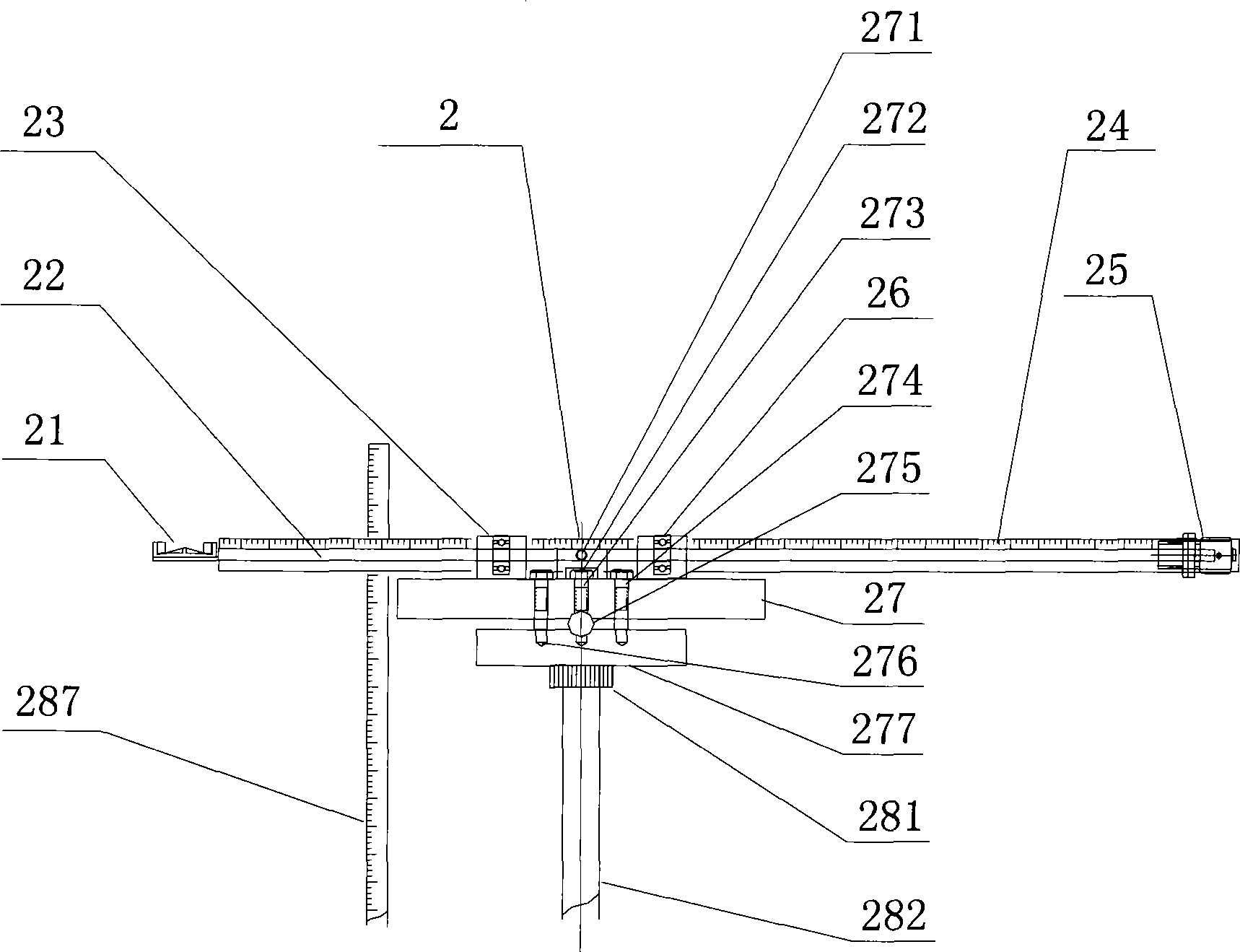

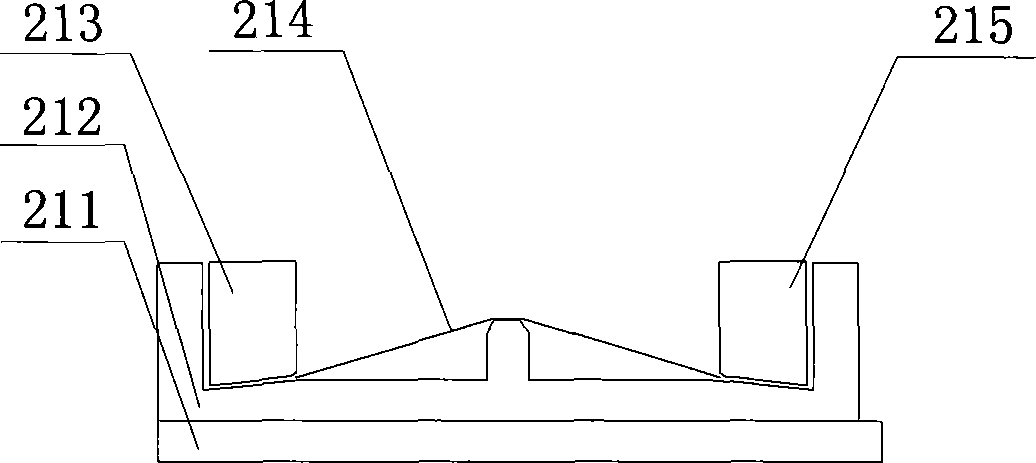

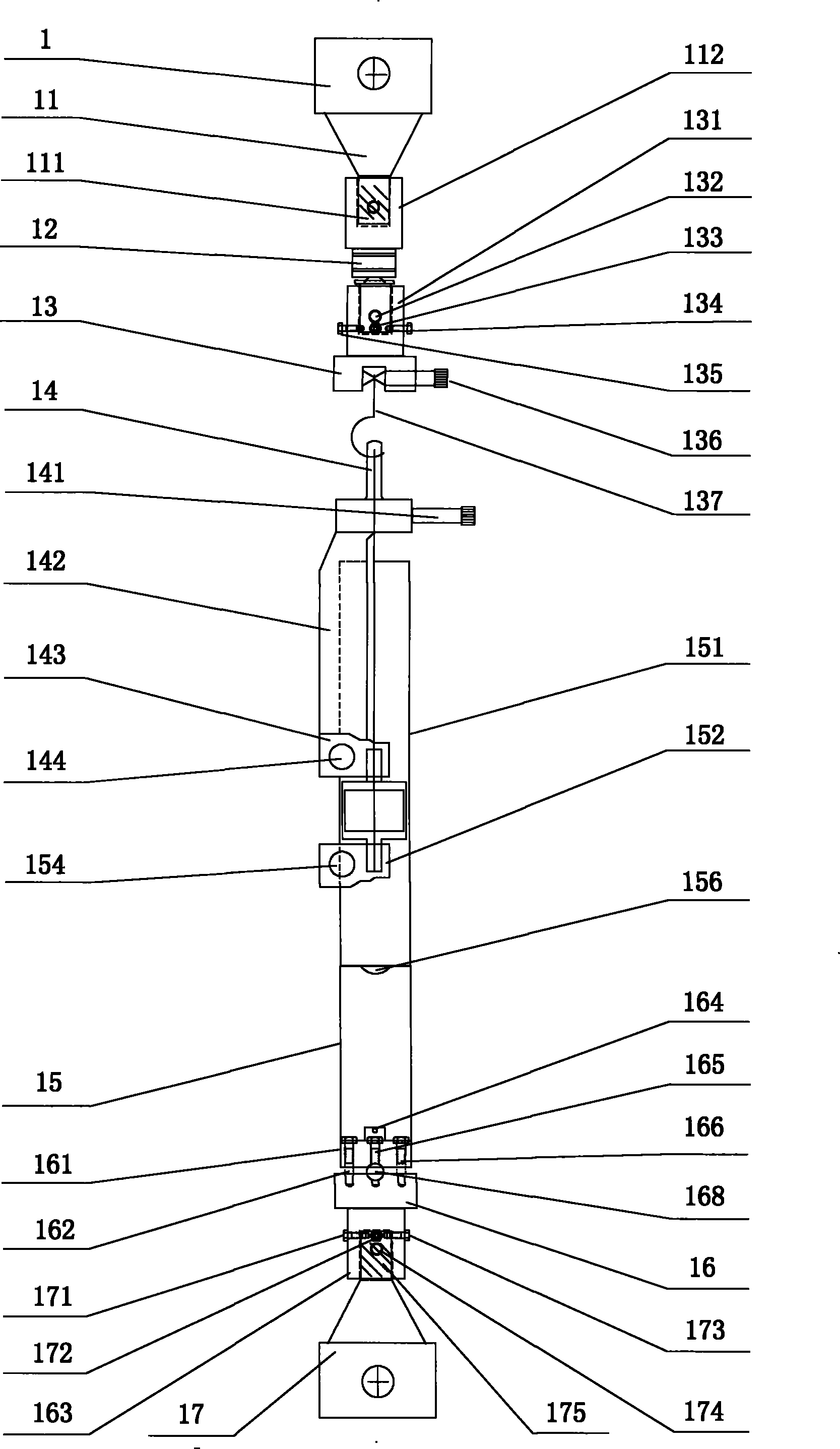

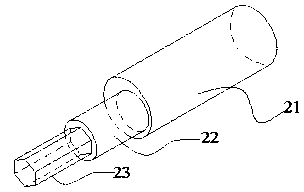

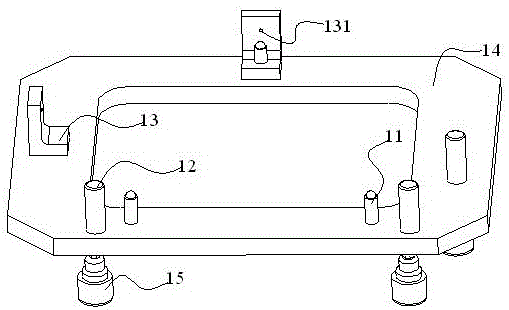

Sampler for locating and sampling ceramic filament

InactiveCN101251452AAvoid intertwiningIntertwined withoutPreparing sample for investigationSingle fibreWater level

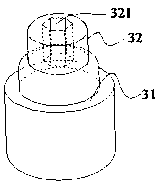

The invention relates to a positioning, sample introducing and sampling device of ceramic single fibre and provides a positioning, sample introducing and sampling device of ceramic single fibre, which comprises a sample introducing and sampling device and an optical level positioner. The sample introducing and sampling device is provided with a sample carrying station, a telescopic boom, a bearing device, a lead rail, a drive mechanism, a square horizontal stand, a cylinder and a base. The sample carrying station is connected with the telescopic boom; the telescopic boom, the bearing device and the lead rail are connected through the drive mechanism and fixed on the square horizontal stand; the telescopic boom is inserted and clings to the bearing device; the drive mechanism is fixed on the rightmost end of the telescopic boom. The square horizontal stand is fixed on the cylinder; the cylinder and the base are connected through screws and positioned on the vertical direction of the square horizontal stand. The optical level positioner is provided with an optical water level, a mounting deck and a position adjusting device. The optical water level is connected with the position adjusting device through the mounting deck.

Owner:XIAMEN UNIV

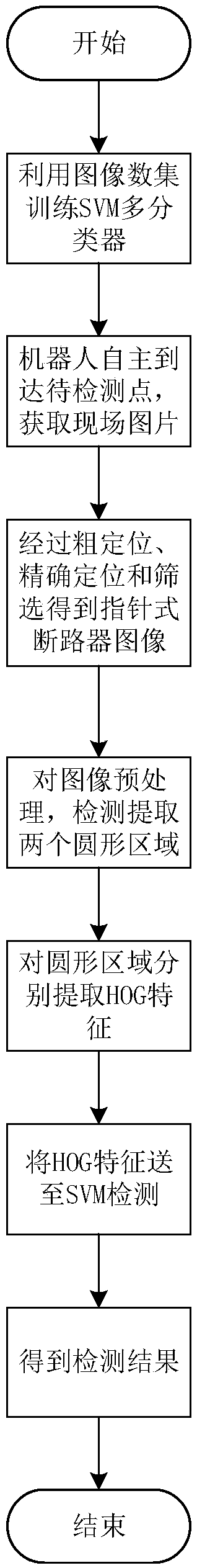

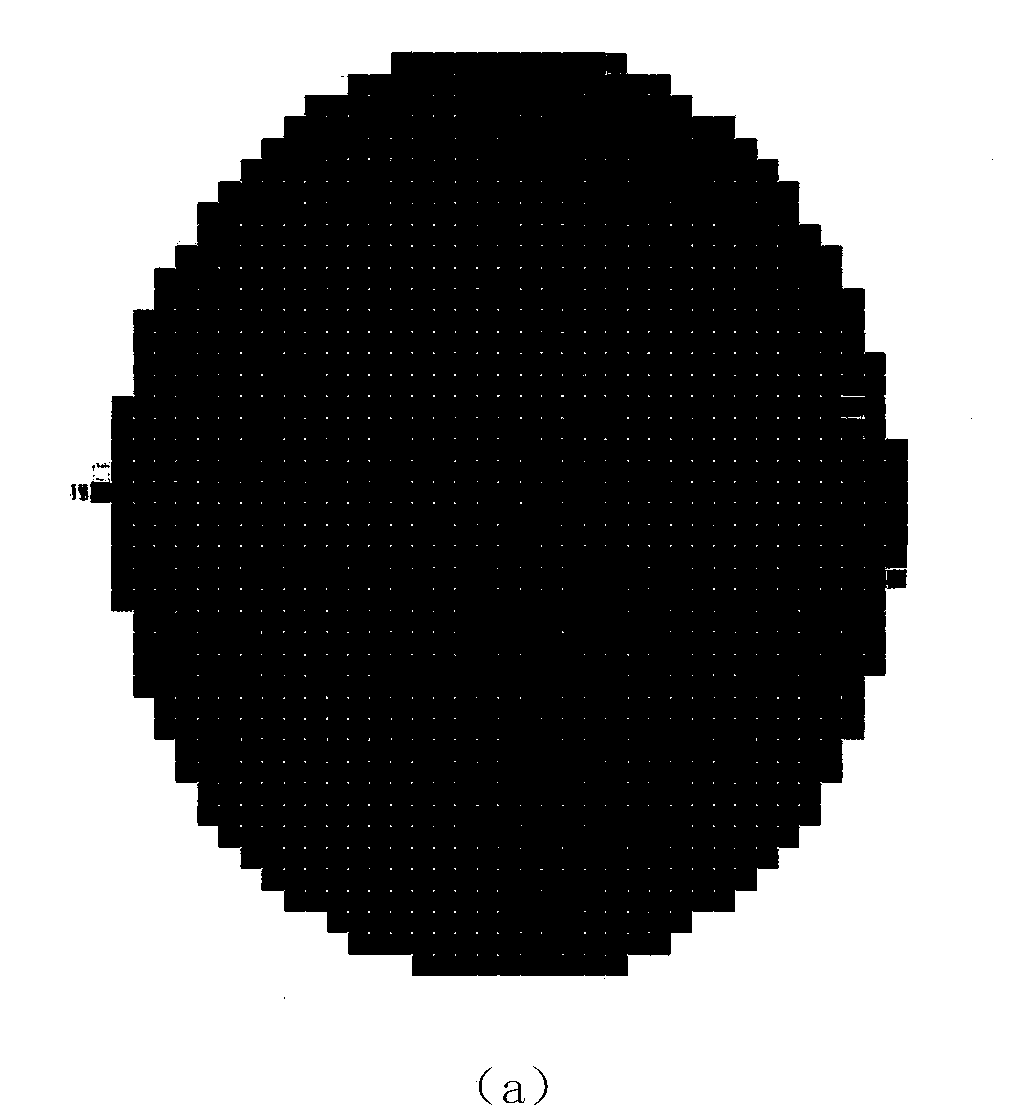

Identification method of pointer circuit breaker based on patrol robot

PendingCN109344768AIncrease the level of automationImprove recognition accuracyCharacter and pattern recognitionFalse detectionImage identification

The invention provides a pointer circuit breaker identification method based on patrol inspection robot. The invention is mainly divided into five steps: (1) training SVM multi-classifier by using image data set; 2) that patrol robot arrives at the designate patrol point to obtain the pictures to be detected; 3) carry out coarse positioning and precise position on that target area, and screening the target candidate area to obtain a pointer circuit breaker; 4) carry out image preprocessing on that acquire pointer circuit breaker, extracting a region with the largest connecte area, and detecting the upper and lower circular regions by using the Hough transform; (5) HOG features of circular region are extracted and sent to SVM multi-classifier to get the final recognition result. The invention utilizes machine learning, can effectively complete the detection and identification task of the pointer circuit breaker under different illumination and posture conditions, improves the automationlevel and the accuracy rate of the image identification under the complex environment, and minimizes the problems of missed detection and false detection.

Owner:NANJING UNIV OF SCI & TECH

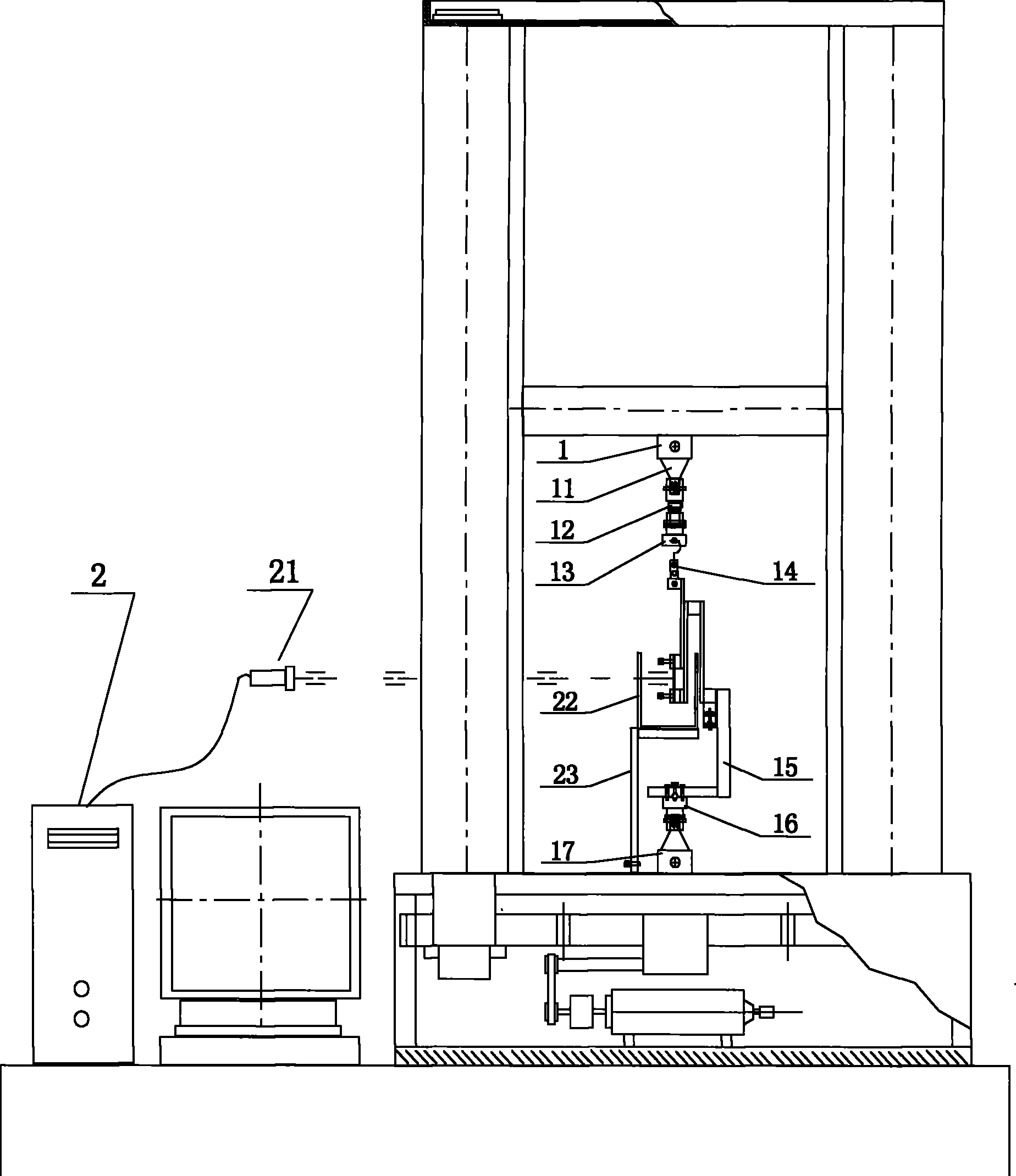

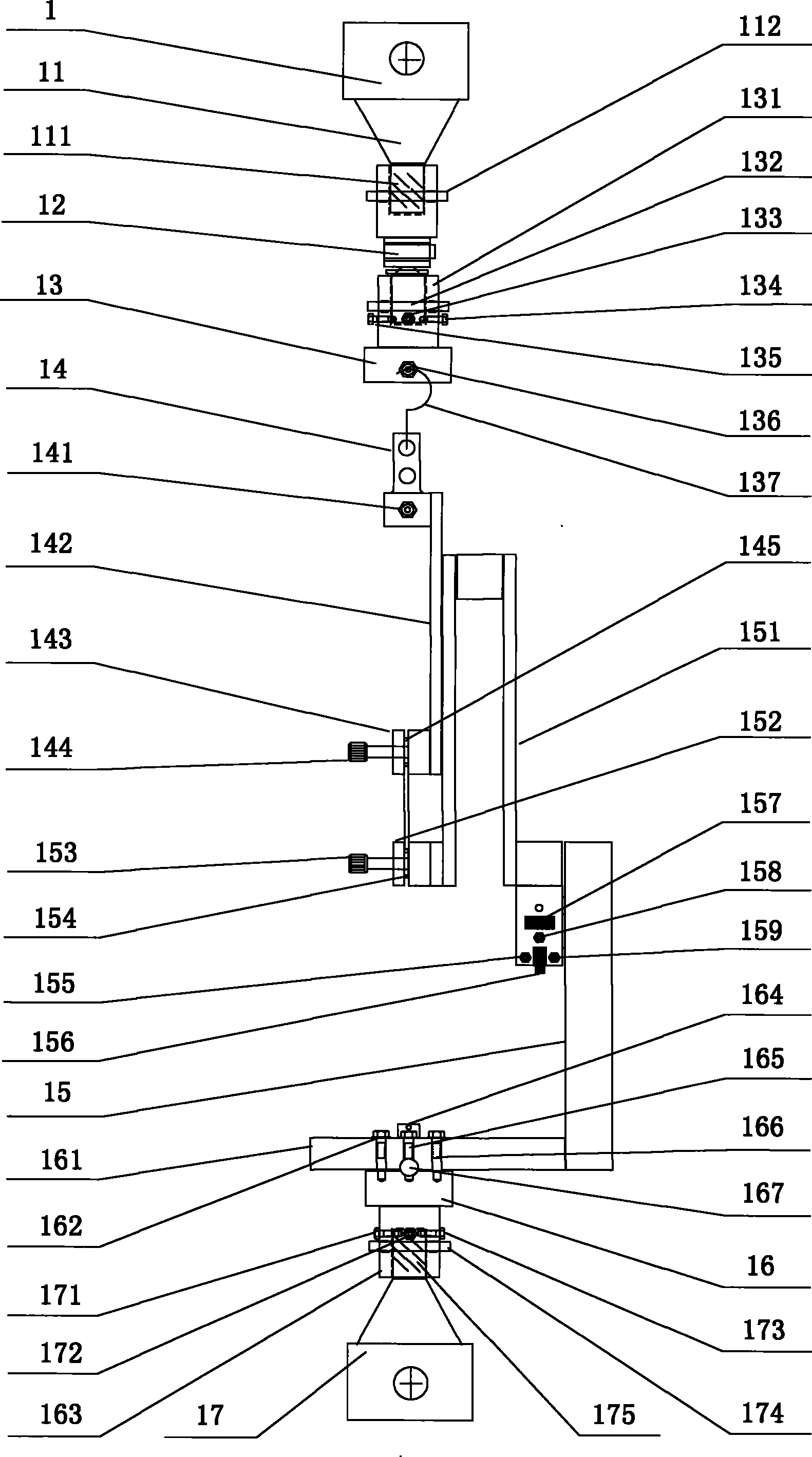

Testing machine cellfiber clamper and method for measuring tensile strength

InactiveCN101251455BGuaranteed verticalityThe strain value is scientific and accurateMaterial strength using tensile/compressive forcesSingle fibreEngineering

The invention provides a tester single fibre clamp and a tensile strength measuring method relating to a clamp and tensile strength measurement. The invention provides a tester single fibre clamp and a method for measuring the tensile strength of ceramic single fibre. The clamp is provided with an upper collet device of a tester, a load sensor, a tenaculum device, an upper and lower clamping device, a horizontal adjusting device and a lower collet device of the tester. The adjusting clamp in proper alignment measures the load linearity in vertical direction and rectifies the focus of a photoelectric extensometer; the parameters of an measuring program are set; single fibre is put on the centerline of a hole of a square paper frame, then placed in the middle of the upper and lower clampingdevice; the vertical direction of the single-fibre is adjusted; the edge of the square paper frame is burned off; a strain collecting device is started to trace the edge distance between the upper and the lower paper frames; a tensile program is started up to begin the measurement; the relation between the load and the strain is recorded to obtain a fibre fracture load value and deformation data,thereby measuring a fibre strain value; a diameter value of a fracture is observed and input to the tester in order to acquire the fracture strength of the single fiber.

Owner:XIAMEN UNIV

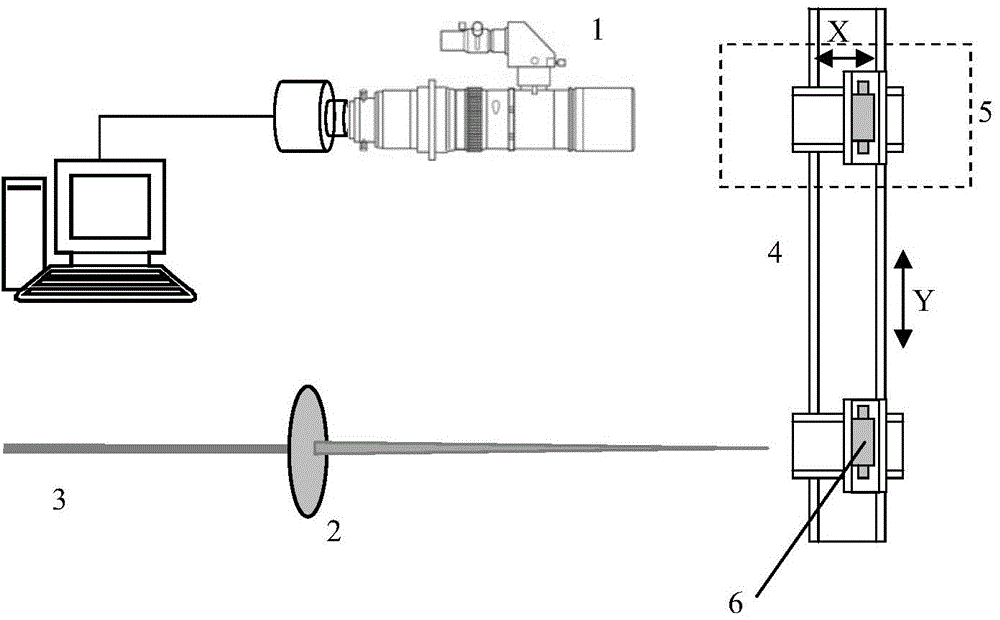

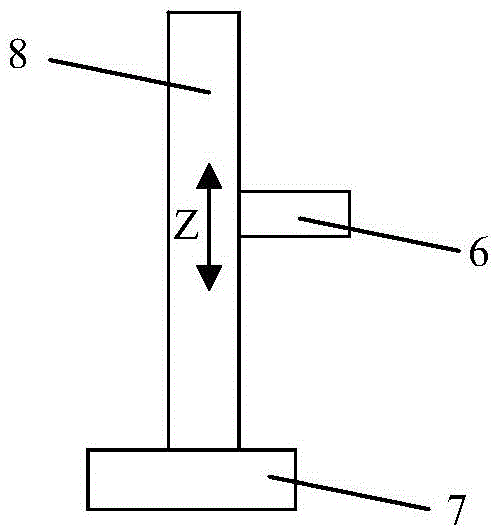

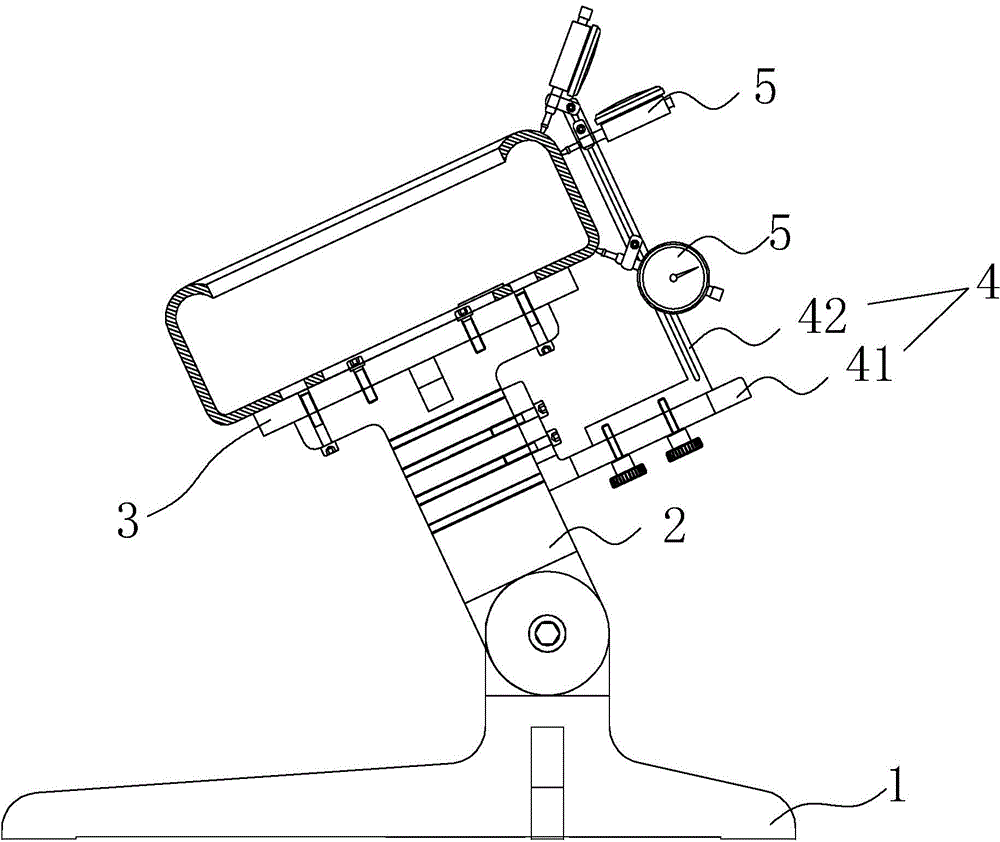

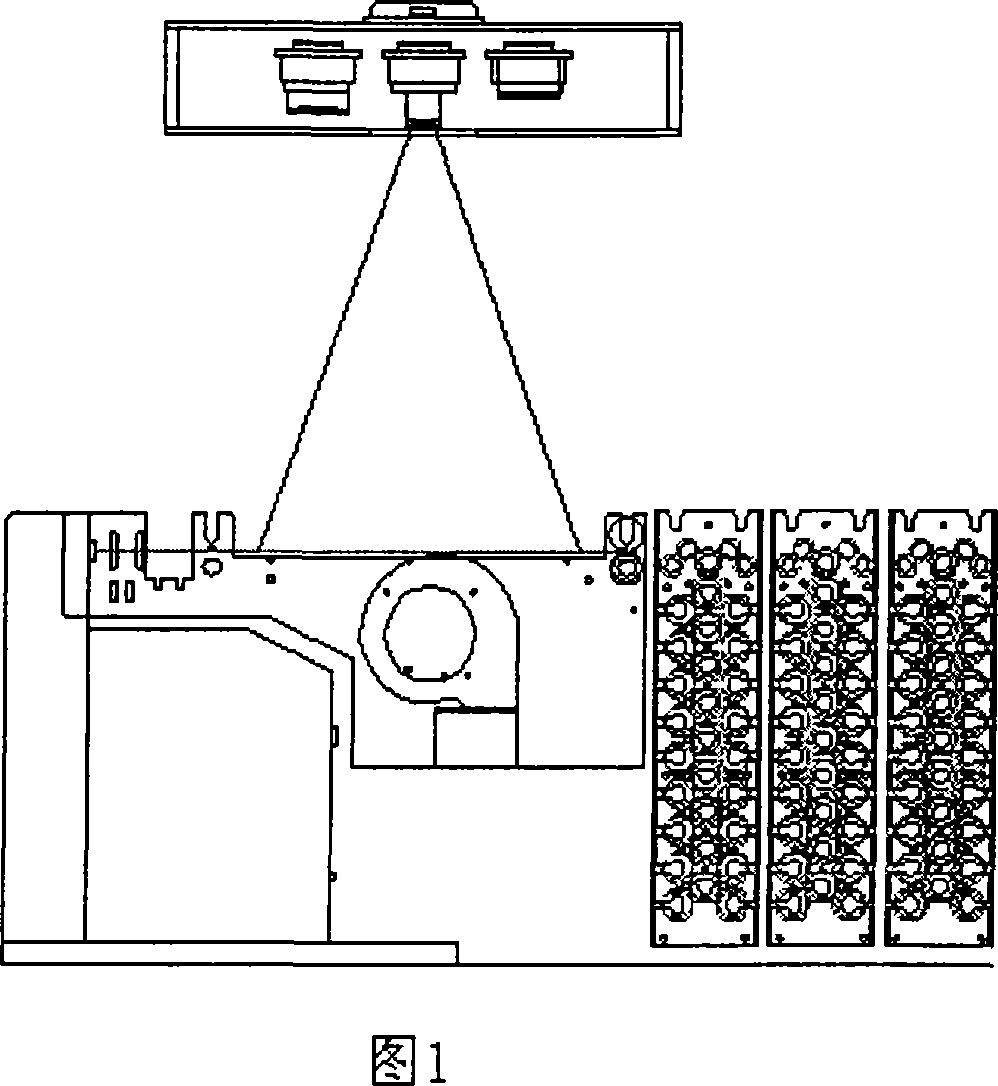

Laser focusing irradiation effect experimental device and method

InactiveCN104807742AHigh position repeatabilityGuaranteed accuracyWeather/light/corrosion resistanceMeasurement deviceLight spot

The invention discloses a laser focusing irradiation effect experimental device and method. The device comprises a focusing lens, effector fixing racks, X-Z axis direction two-dimension adjusting mechanisms, a Y-axis direction electrical control displacement platform and a video microscope. The video microscope is used for assisting in accurate positioning of positions of a light spot measuring device surface and a batch effector sample surface, meanwhile, measurement of effect ablating marks is considered, uncertainty of irradiation laser parameters due to uncertainty of the positions can be greatly reduced, and accuracy of measurement of a laser-damaged threshold and research of effect laws is improved.

Owner:NORTHWEST INST OF NUCLEAR TECH

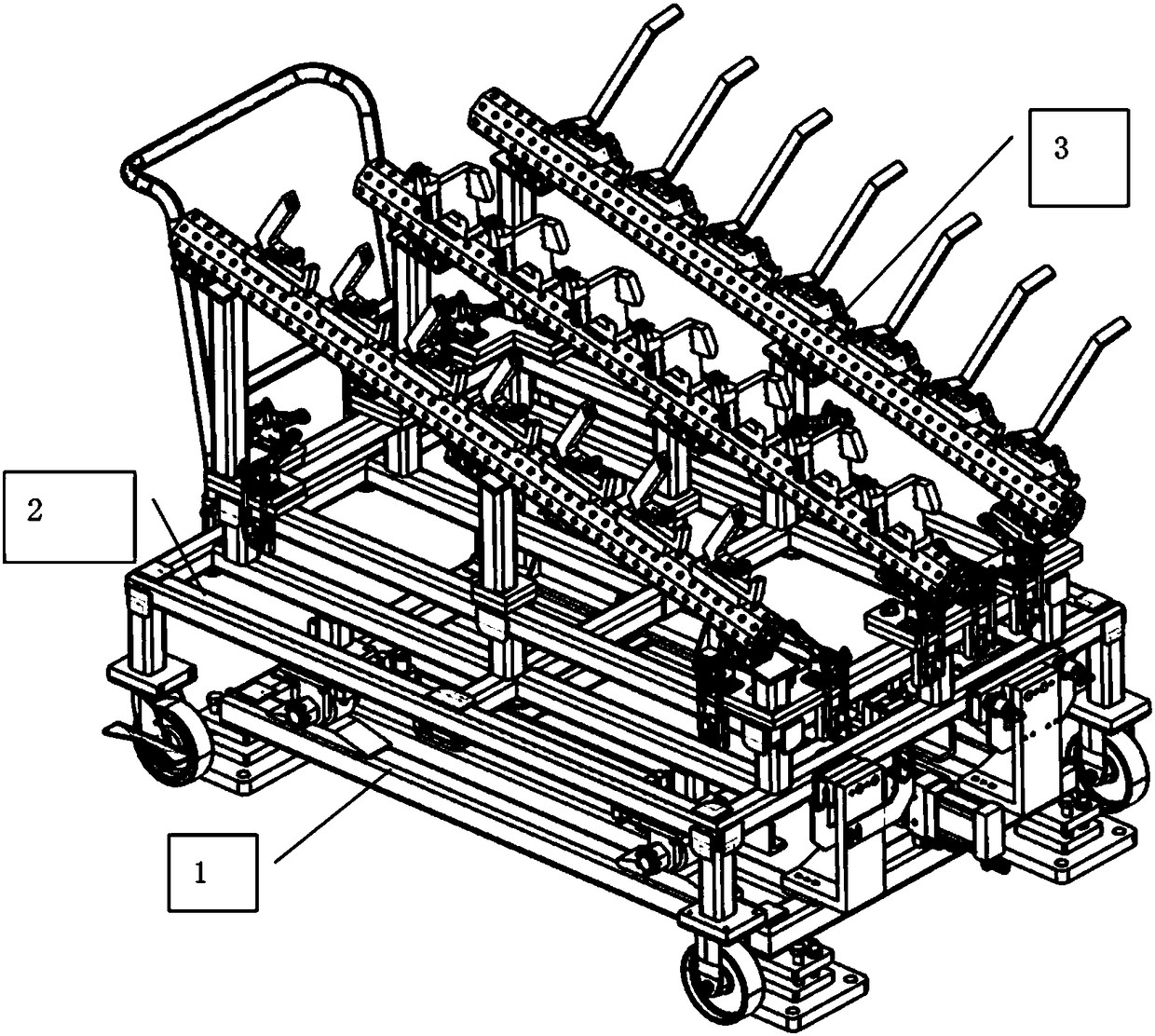

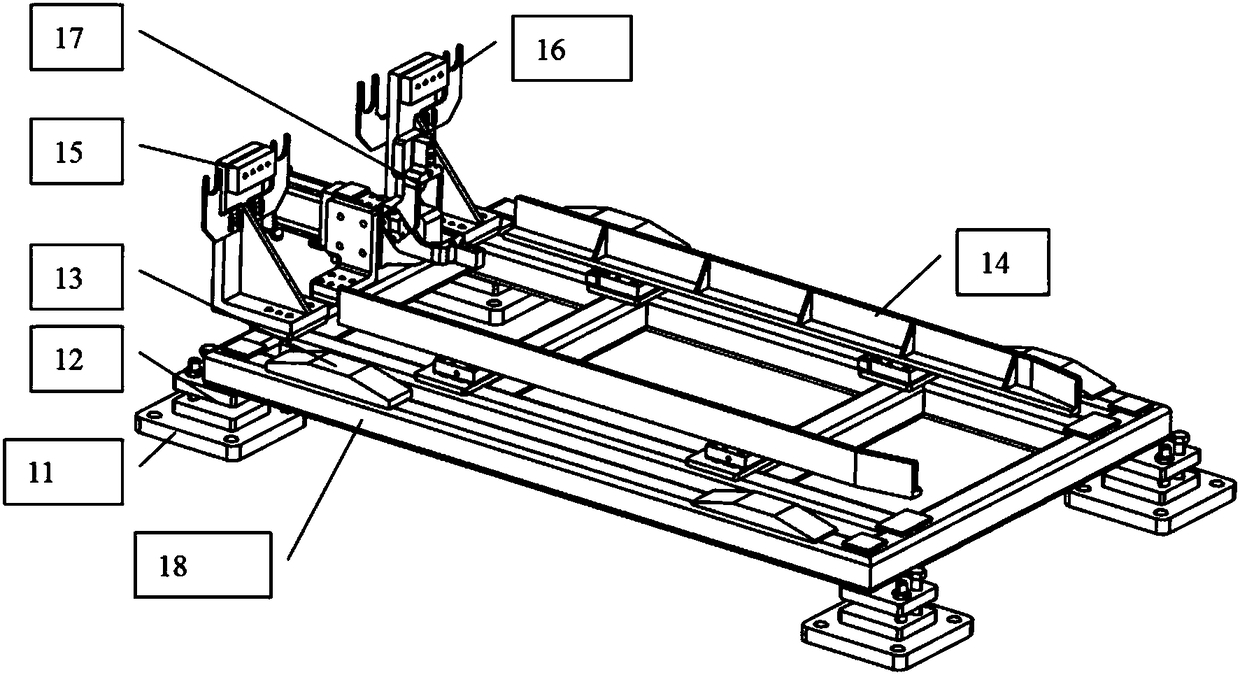

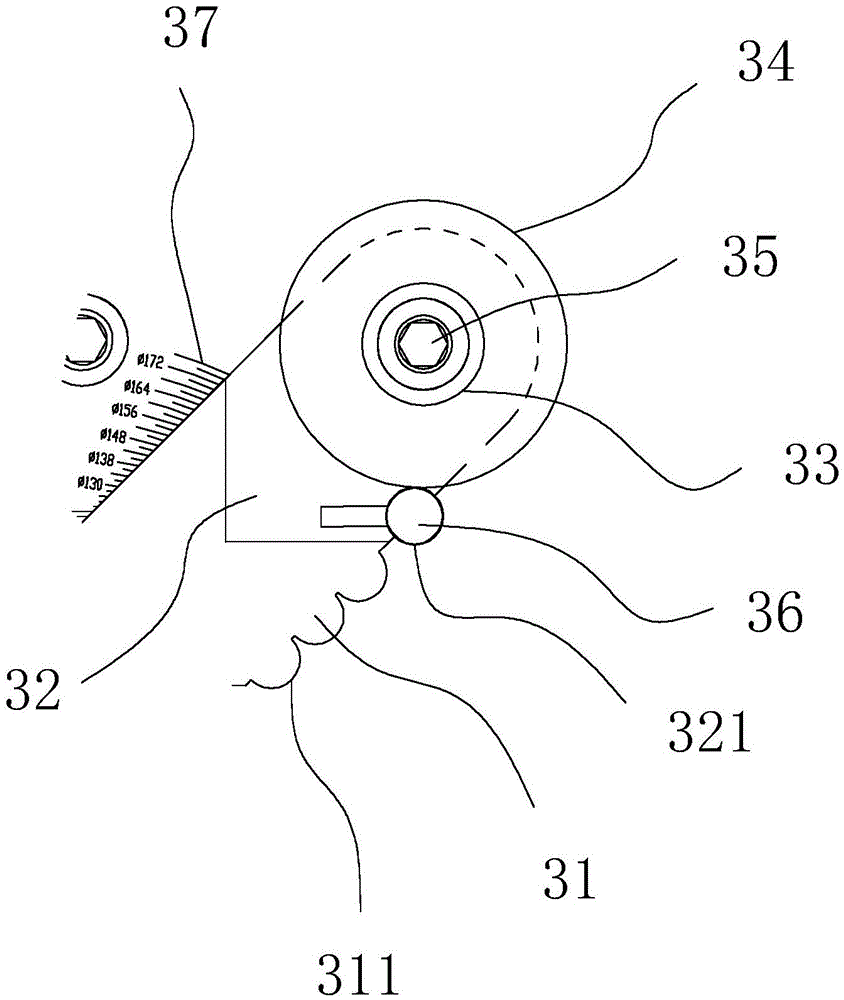

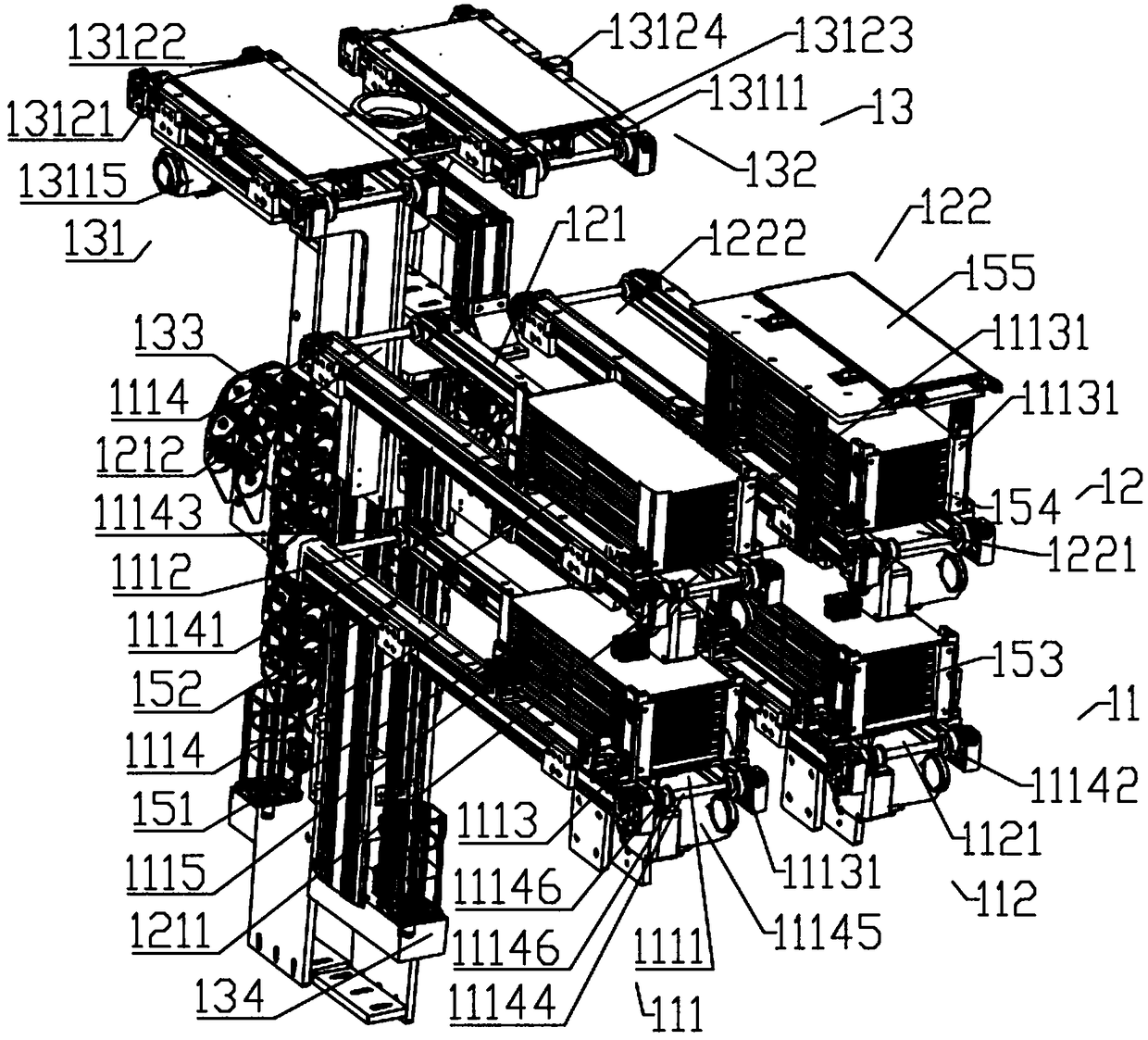

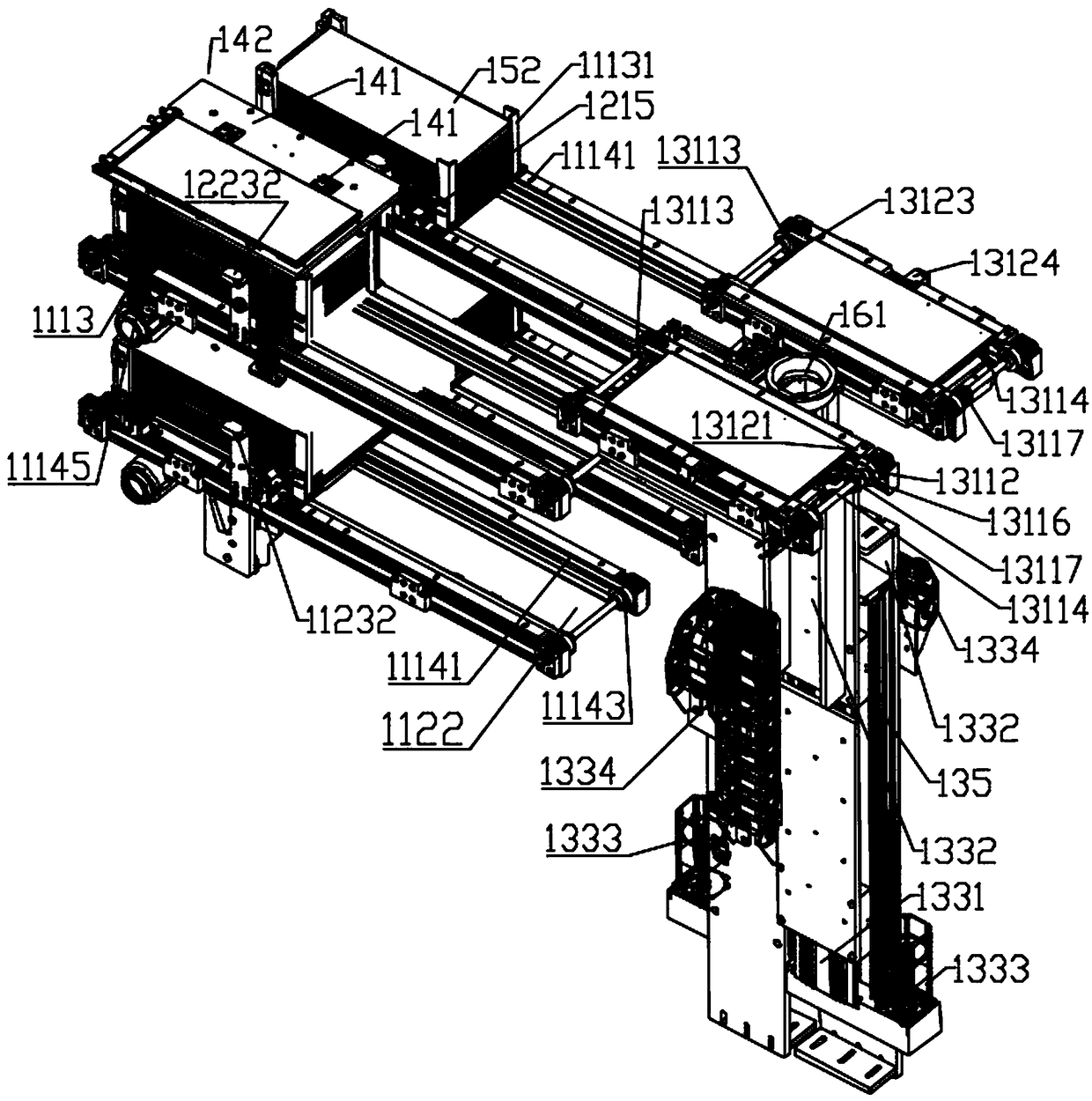

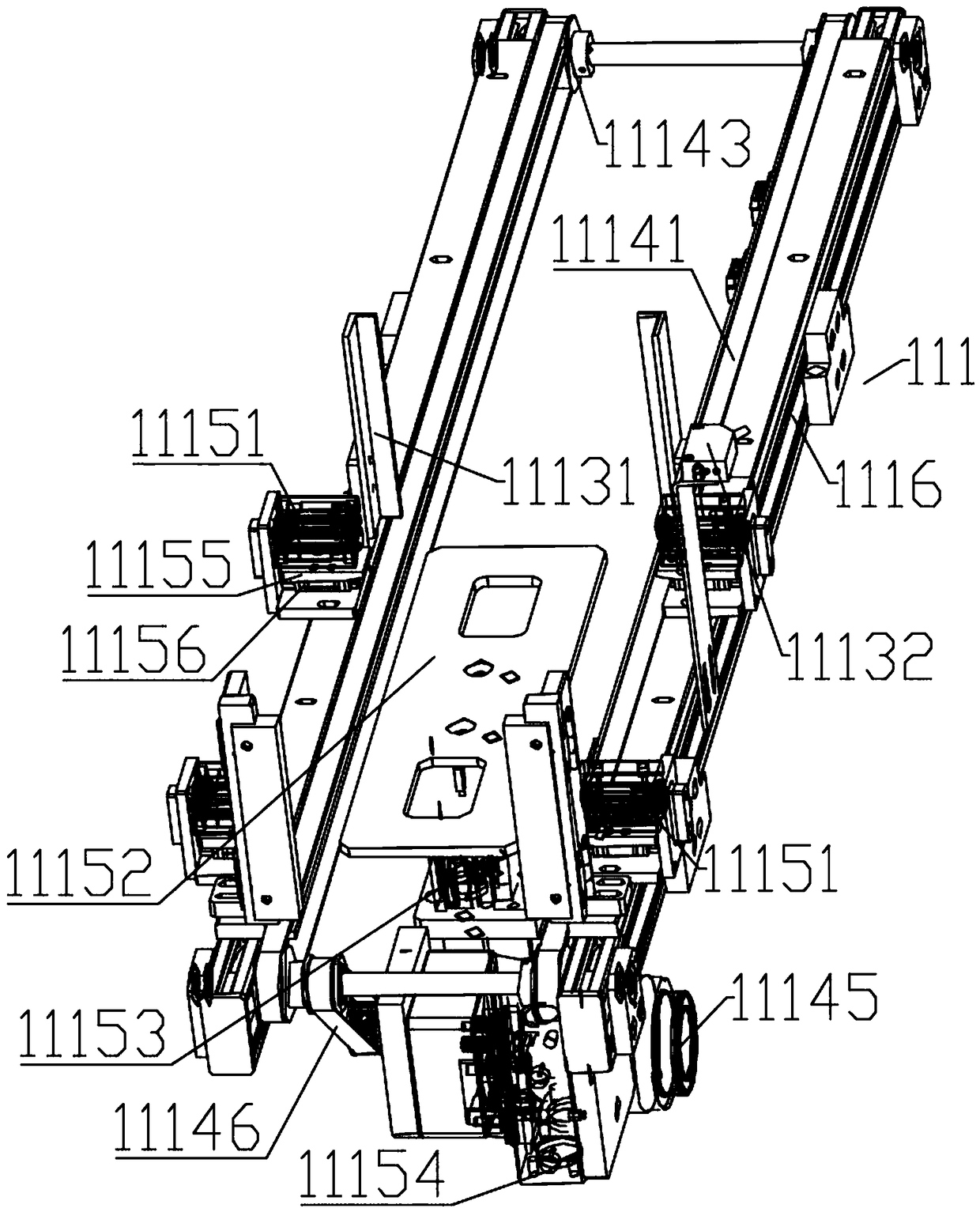

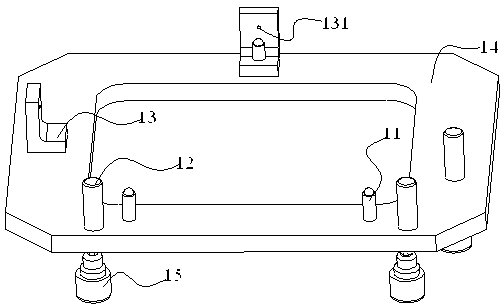

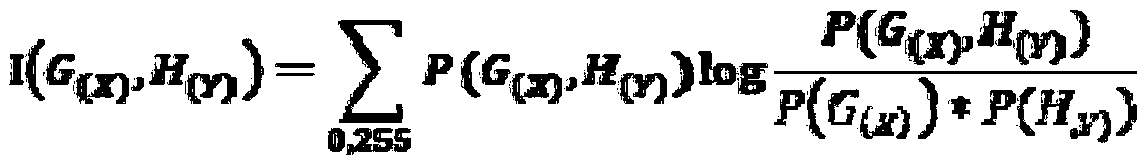

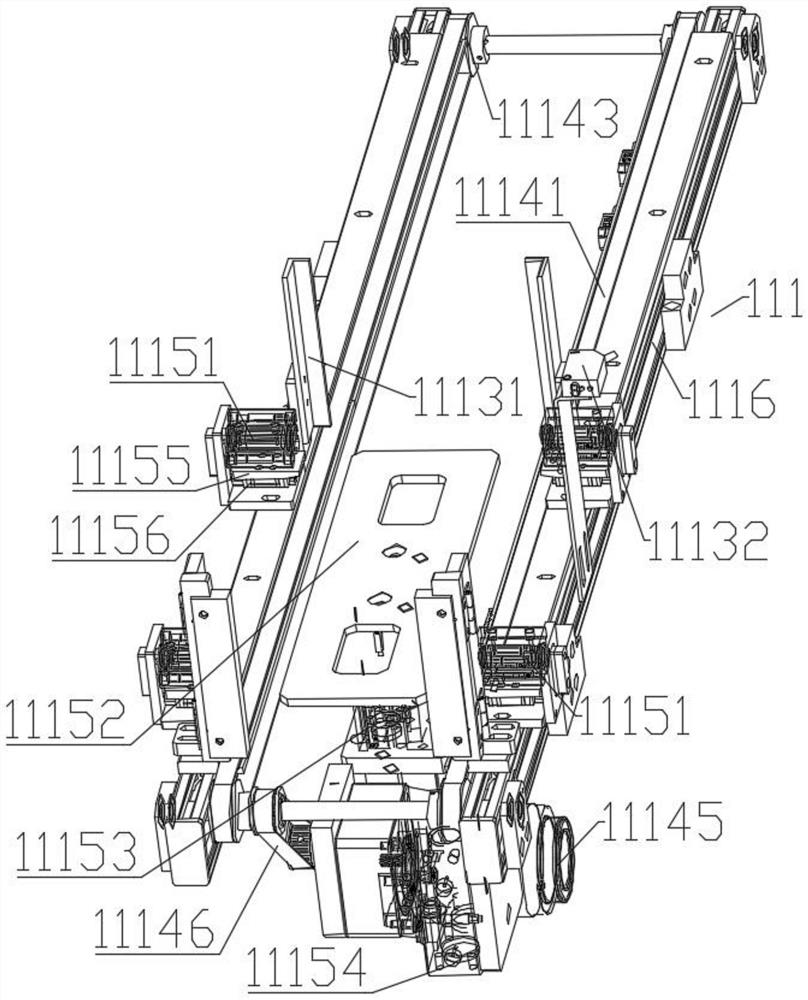

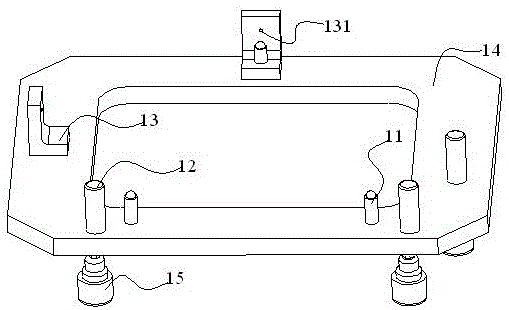

Flexible precise material frame

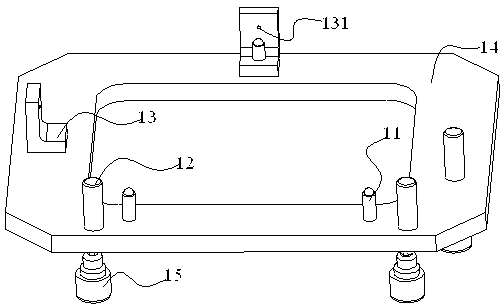

PendingCN108381270AHigh position repeatabilityMetal working apparatusHand carts with multiple axesButt jointModel switching

The invention provides a flexible precise material frame. The flexible precise material frame comprises a ground positioning mechanism, a precise material frame vehicle and a positioning flexible switching mechanism. The positioning flexible switching mechanism is arranged on the precise material frame vehicle. The precise material frame vehicle is in but joint with the ground positioning mechanism in a positioned mode. The flexible precise material frame has the beneficial effects that ground surface positioning is conducted through the ground positioning mechanism, the flexible precise material frame adapts to different vehicle models through the precise material frame vehicle, during vehicle model switching, the precise material frame vehicle serves as a common part, positioning butt joint is still conducted by the precise material frame vehicle and the ground positioning mechanism, and the part positioning repeated precision is high.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Gauge for measuring bounce flexibility

InactiveCN104089555ARestricted degrees of freedomSimple and fast operationMechanical measuring arrangementsAccuracy and precisionElectrical and Electronics engineering

Owner:泉州市双塔汽车零件有限公司

Method for locating electric object stage

InactiveCN103206971AImprove smoothnessNot easy to rolloverMeasurement apparatus componentsElectric machineEngineering

Owner:KUN SHAN POWER STENCIL

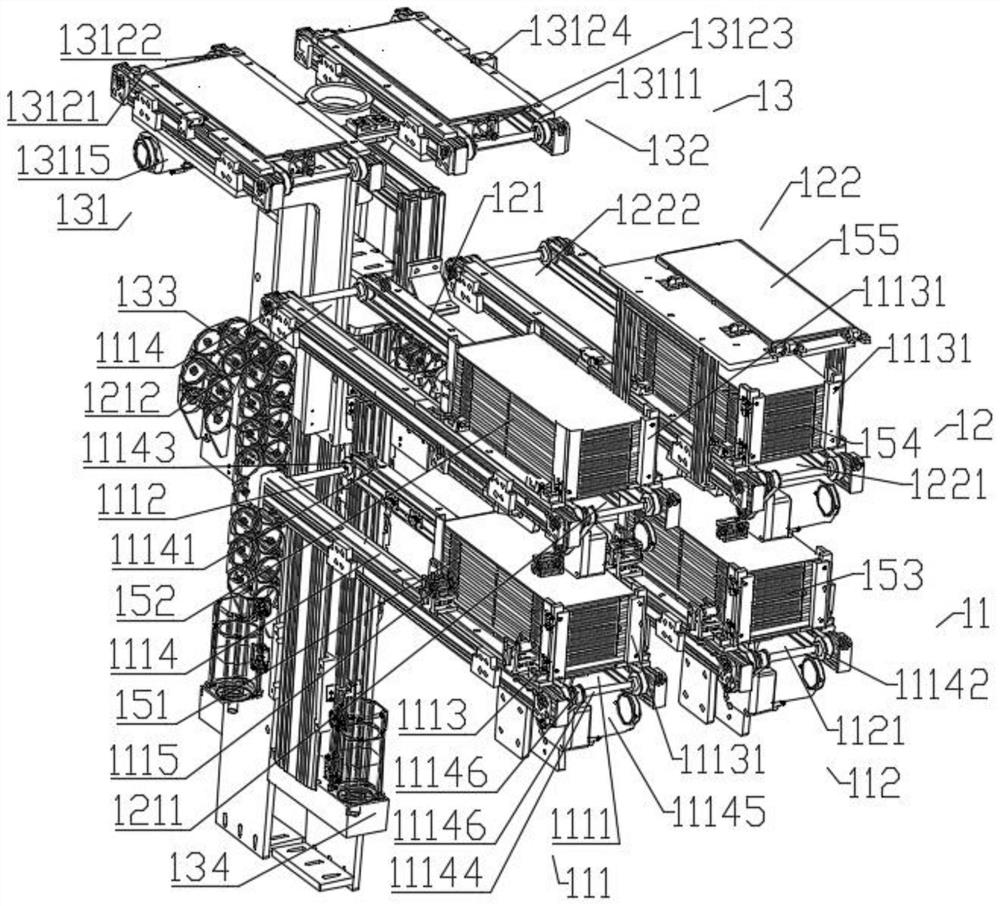

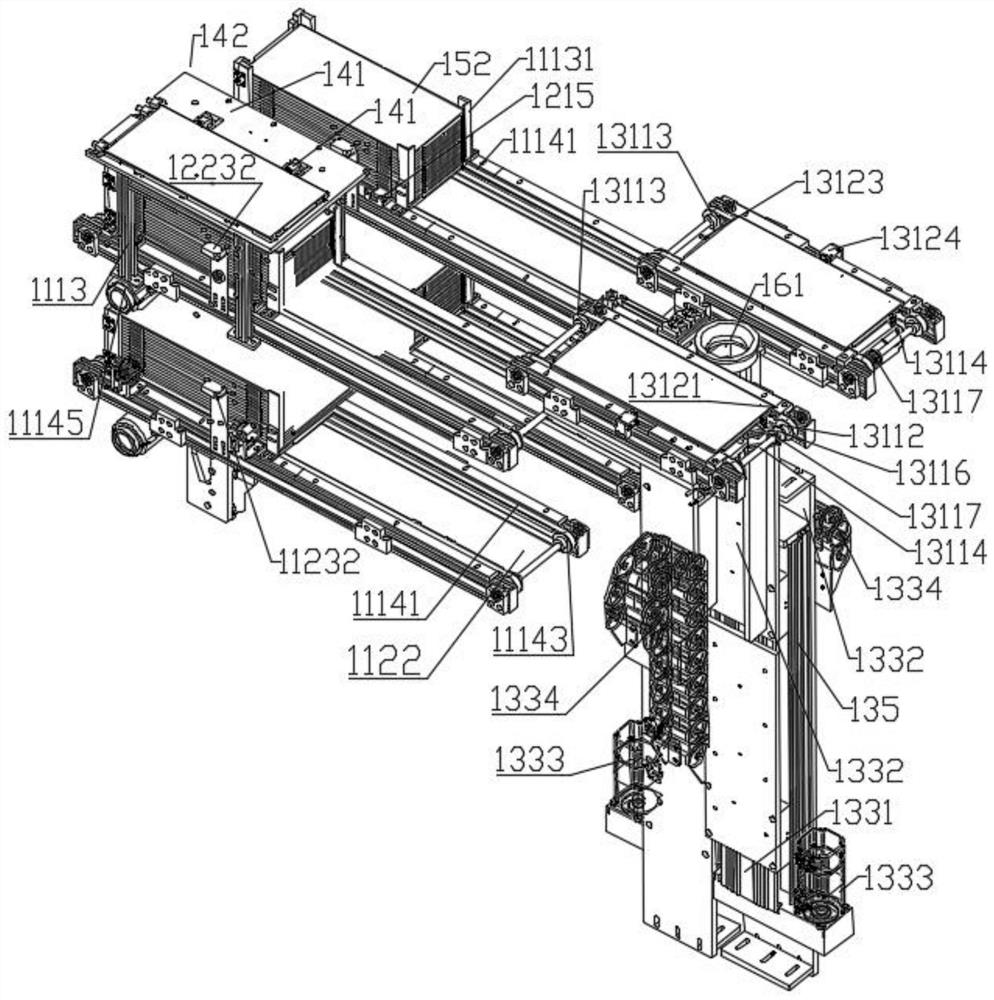

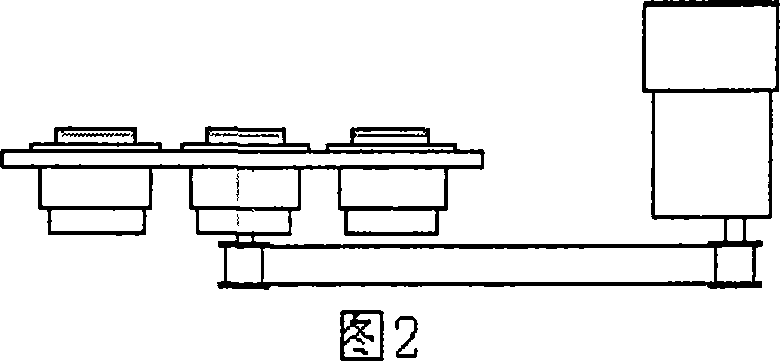

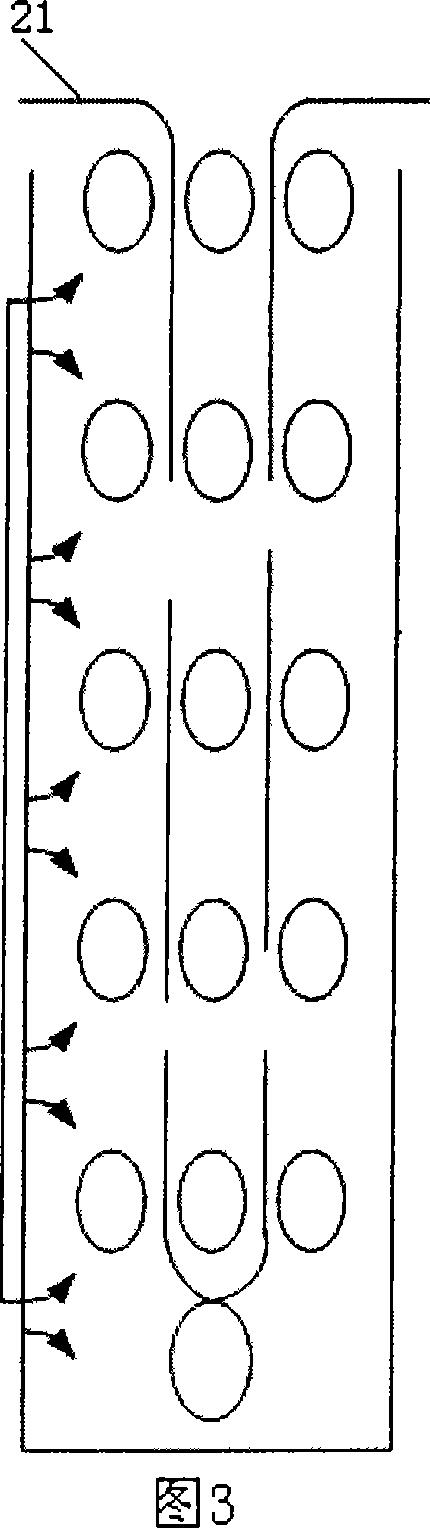

Automatic feeding and discharge system applicable to function testing equipment

ActiveCN108974825AOptimize walking pathIncrease production capacityControl devices for conveyorsStacking articlesTesting equipmentSmall footprint

The invention discloses an automatic feeding and discharge system applicable to function testing equipment. The automatic feeding and discharge system comprises a first conveying mechanism unit, a second conveying mechanism unit and a third conveying mechanism unit, wherein the first conveying mechanism unit moves along a first direction; the second conveying mechanism unit moves along the first direction; the first conveying mechanism unit and the second conveying mechanism unit are sequentially arranged along a second direction; the third conveying mechanism unit moves along the second direction, and when the third conveying mechanism unit moves to a first position, the third conveying mechanism unit is in butt joint with a first butt joint end; when the third conveying mechanism unit moves to a second position, the third conveying mechanism unit is in butt joint with a second butt joint end. The automatic feeding and discharge system is small in floor space, high in space utilization rate, capable of achieving feeding and discharge without shutdown, capable of achieving an around-the-clock working mode, capable of avoiding interference with a mechanical arm, capable of optimizing the traveling path of the mechanical arm and capable of greatly increasing the productivity and output of the function testing equipment.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

Positioning method of electric control object stage

InactiveCN103206974AImprove smoothnessNot easy to rolloverMeasurement apparatus componentsElectric machineryElectric control

The invention relates to a positioning method of an electric control object stage. The positioning method of the electric control object stage mainly solves the problem that an object stage in the prior art cannot position an object accurately. The positioning method includes the following steps: a) hard supporting columns and soft supporting columns on a supporting frame of the object stage are fixed on a base station; b) eccentric pins are fixed on the base station; c) an object to be carried is placed on the supporting frame and clamped between the eccentric pins; d) a motor below the soft supporting columns is adjusted to rotate, threaded structures of the soft supporting columns move up and down along the base station, and upper end points of the soft supporting columns cling to the object to be carried; e) motors below the eccentric pins are controlled to rotate so as to enable the object to be carried to move horizontally relative to the base station; f) a motor below the hard supporting columns is adjusted to rotate so as to enable the object to be carried to move vertically relative to the base station; and g) motors below other eccentric pins are adjusted so as to enable the pins and plungers to fix objects to be carried on the object stage. The positioning method of the electric control object stage solves the problem of inaccuracy well and can be applied to positioning operation of object stages for accurate operation.

Owner:KUN SHAN POWER STENCIL

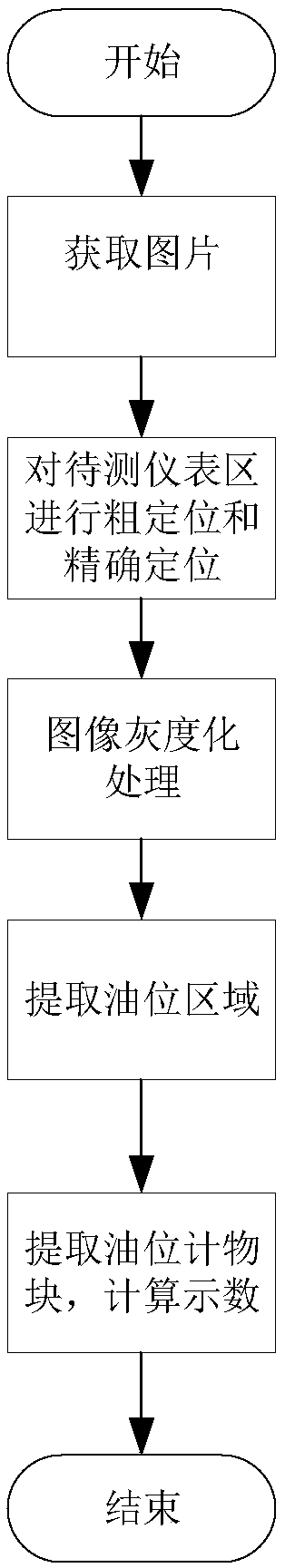

A transformer oil level gauge identification method based on a patrol inspection robot

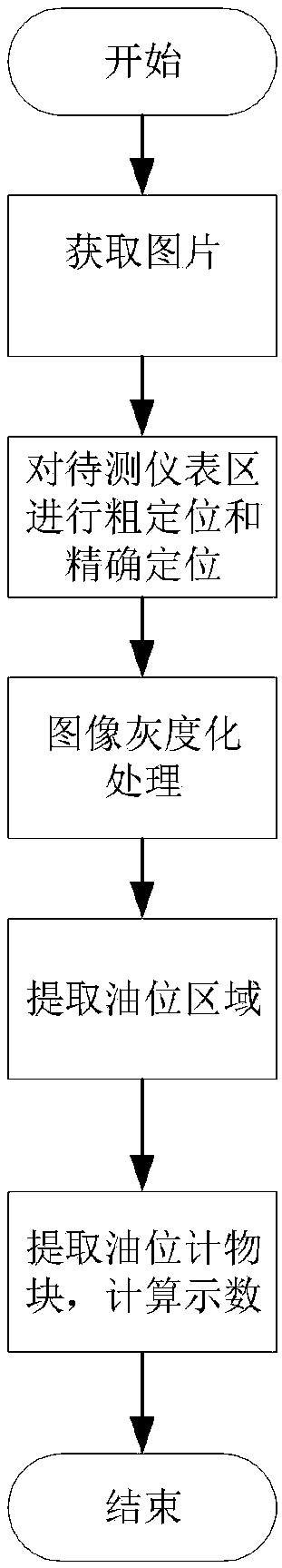

InactiveCN109389165AReduce false positivesHigh position repeatabilityCharacter and pattern recognitionImage feed-backEngineeringContour segmentation

The invention discloses a transformer oil level gauge identification method based on a patrol inspection robot. The detection process fuses the positioning information of the patrol inspection robot.The processing flow is as follows: (1) the patrol inspection robot goes to the patrol inspection point, locates the instrument and takes pictures; (2) roughly positioning and accurately positioning the target instrument area to be detected, and screening the target candidate area to obtain the oil level gauge image; (3) performing grayscale treatment on the image; (4) The oil level region is extracted according to the obvious difference between the oil level region and the background region when the color of the oil level region and the background region are not used and converted into the gray scale; 5) according to that difference in shape and brightness, the oil level gauge block is extracted by using the contour segmentation, and the numerical value is calculated from the upper and lower boundaries of the oil level gauge area and the position of the block; The invention utilizes machine learning, and can detect and identify the transformer oil level gauge under various illuminationand attitude changes.

Owner:NANJING UNIV OF SCI & TECH

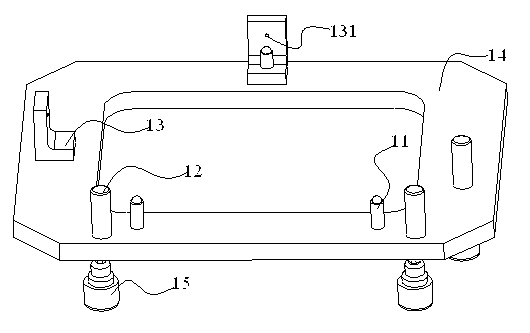

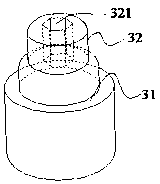

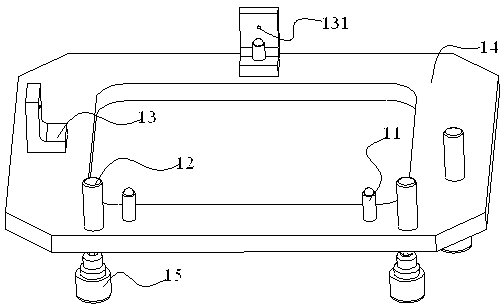

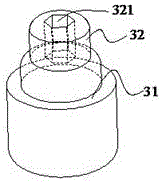

Electric control object stage

InactiveCN103206973AImprove smoothnessNot easy to moveMeasurement apparatus componentsEngineeringBase station

The invention relates to an electric control object stage which mainly solves the problem that an object stage in the prior art cannot position an object accurately. The position electrically controllable object stage comprises a base station, supporting columns, eccentric pins and motors, wherein the supporting columns and the eccentric pins are fixed on the base station, the heights of the eccentric pins and plungers are higher than those of the supporting columns in the direction perpendicular to the base station, and a plane is formed by peaks of supporting positions of the supporting columns. An object to be carried is placed at the supporting positions of the supporting columns, the edge of the object to be carried is in contact with the eccentric pins, at least one plunger is located at the position opposite to the eccentric pins, the lower ends of the eccentric pins are provided with rotating mechanisms matched with the motors, and the motors are fixed below the eccentric pins and the supporting columns. The electric control object stage solves the problem of inaccuracy well and can be applied to industrial production of object stages for accurate operation.

Owner:KUN SHAN POWER STENCIL

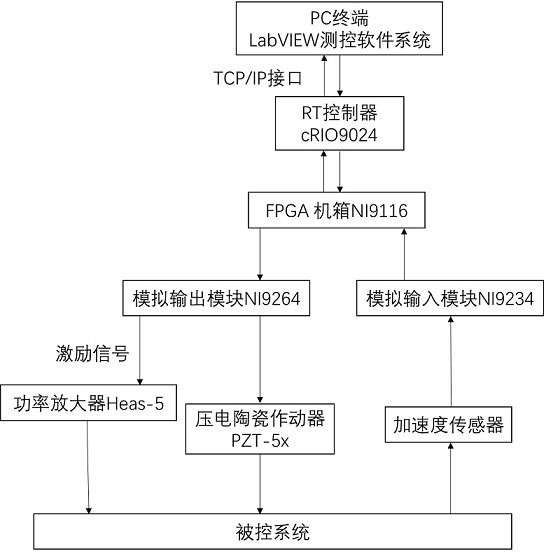

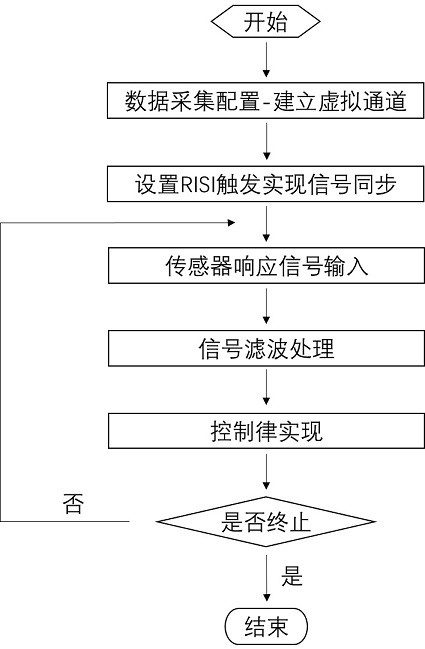

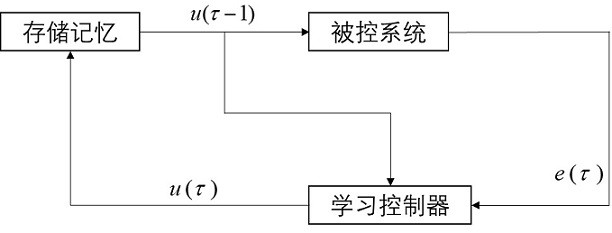

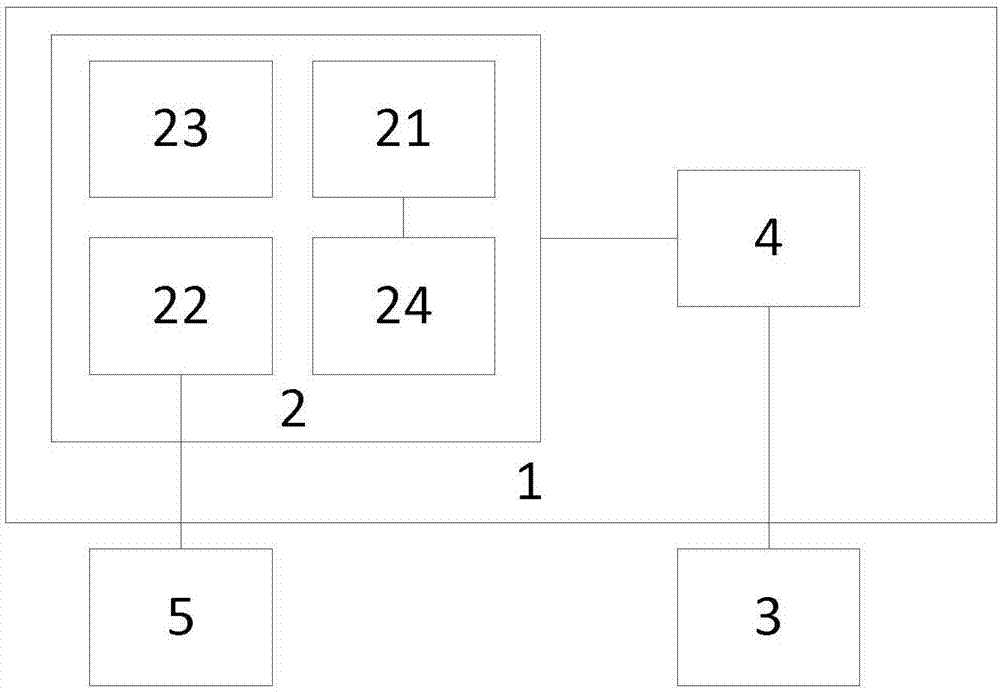

CompactRIO-based real-time active vibration reduction system and vibration reduction method

InactiveCN112415899AImprove tracking performanceHigh position repeatabilityMechanical oscillations controlNon-rotating vibration suppressionControl signalData acquisition

The invention provides a CompactRIO-based real-time active vibration reduction system and vibration reduction method. The active vibration reduction system comprises a data acquisition module, a dataprocessing module, a control signal output module and an actuation vibration suppression module; the data acquisition module is used for acquiring an original vibration signal of a controlled system;the data processing module is used for obtaining a control component through operation of a control algorithm according to the original vibration signal; the control signal output module is used for converting the control component into an analog signal and outputting the analog signal; and the actuation vibration suppression module is used for suppressing vibration of the passive system accordingto the control analog signal. According to the software and hardware platform design scheme based on the simplified iterative learning control strategy, a complete tracking task in a limited intervalcan be realized according to the iterative learning control strategy, and non-ideal control signals are corrected by trying to control the system according to the deviation between output signals andtarget signals, so that the tracking performance of the system is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

A liquid level instrument identification method based on a patrol inspection robot

InactiveCN109359646ASolve the problem of number recognitionHigh position repeatabilityCharacter and pattern recognitionData setGauge block

The invention discloses a liquid level instrument identification method based on a patrol inspection robot, which includes training an Adaboost classifier by utilizing instrument image data set, and selecting an image centered by the instrument as a template image for each patrol inspection point; obtaining the pictures of the instruments to be detected at the designated patrol points, combining the adaboost classifier and template images for rough positioning and accurate positioning, and screening out the dial area; extracting the oil level region from the dial region according to the colordifference between the oil level region and the background region; according to the difference in shape and brightness, extracting the oil level gauge block from the oil level area, and calculating the liquid level gauge representation number according to the upper and lower boundaries of the oil level gauge area and the position of the block. The invention utilizes machine learning, and can detect and identify the liquid level meter representation number under various illumination and attitude changes.

Owner:NANJING UNIV OF SCI & TECH

Stage with motorized control position

InactiveCN103206977BImprove smoothnessNot easy to rolloverMeasurement apparatus componentsElectric machineEngineering

The invention relates to a position electrically controllable object stage which mainly solves the problem that an object stage in the prior art cannot position an object accurately. The position electrically controllable object stage comprises a base station, supporting columns, plungers, eccentric pins and motors, wherein the supporting columns, the plungers and the eccentric pins are fixed on the base station, the heights of the eccentric pins and the plungers are higher than those of the supporting columns in the direction perpendicular to the base station, and a plane is formed by peaks of supporting positions of the supporting columns. An object to be carried is placed at the supporting positions of the supporting columns, the edge of the object to be carried is contacted with the eccentric pins and the plungers, at least one plunger is located at the position opposite to the eccentric pins, the lower ends of the eccentric pins are provided with rotating mechanisms matched with the motors, and the motors are fixed below the eccentric pins. The position electrically controllable object stage solves the problem of inaccuracy well and can be applied to industrial production of object stages for accurate operation.

Owner:KUN SHAN POWER STENCIL

An automatic loading and unloading system suitable for functional testing equipment

ActiveCN108974825BOptimize walking pathIncrease production capacityControl devices for conveyorsStacking articlesFunctional testingRobotic arm

The invention discloses an automatic loading and unloading system suitable for functional testing equipment, comprising: a first conveying mechanism group, a second conveying mechanism group and a third conveying mechanism group; the first conveying mechanism group moves along the first direction; the second conveying mechanism group The mechanism group moves along the first direction; the first conveying mechanism group and the second conveying mechanism are arranged in sequence along the second direction; the third conveying mechanism group moves along the second direction, when the third conveying mechanism group moves to the first position, The third conveying mechanism group docks with the first docking end; when the third conveying mechanism group moves to the second position, the third conveying mechanism group docks with the second docking end. The invention occupies a small area and has a high space utilization rate; it does not need to stop loading and unloading, and can realize a 24-hour uninterrupted working mode; it does not interfere with the mechanical arm, and optimizes the walking path of the mechanical arm; it greatly improves the productivity and performance of the functional testing equipment. output.

Owner:UNIVERSAL SCIENTIFIC INDUSTRIAL (SHANGHAI) CO LTD

Motorized stage positioning method

The invention relates to an electric objective table positioning method, which mainly solves the problem that the objective table in the prior art can not be precisely positioned. The electric objective table positioning method comprises the following steps of a) fixing shores of the objective table onto a base station, and connecting the lower ends of the shores with the rotation mechanism of a motor; b) fixing eccentric pins onto the base station, and connecting the lower ends of the eccentric pins with the rotation mechanism of the motor; c) regulating the motor below the shores to rotate, enabling the upper end points of the shores to be positioned on one horizontal plane, putting a carried objective onto a support frame, and clamping the carried objective between the eccentric pins and plunger pistons; d) controlling the motor below the eccentric pins on one side of the carried objective to rotate, and enabling the carried objective to horizontally move relative to the base station; e) regulating the motor below the shores to rotate to enable the carried objective to vertically move relative to the base station; and f) regulating the motor below other eccentric pins to fix the carried objective on the objective table by the eccentric pins and the plunger pistons. According to the technical scheme, the problem is better solved, and the electric objective table positioning method can be used for the positioning operation of the objective table for the precise operation.

Owner:KUN SHAN POWER STENCIL

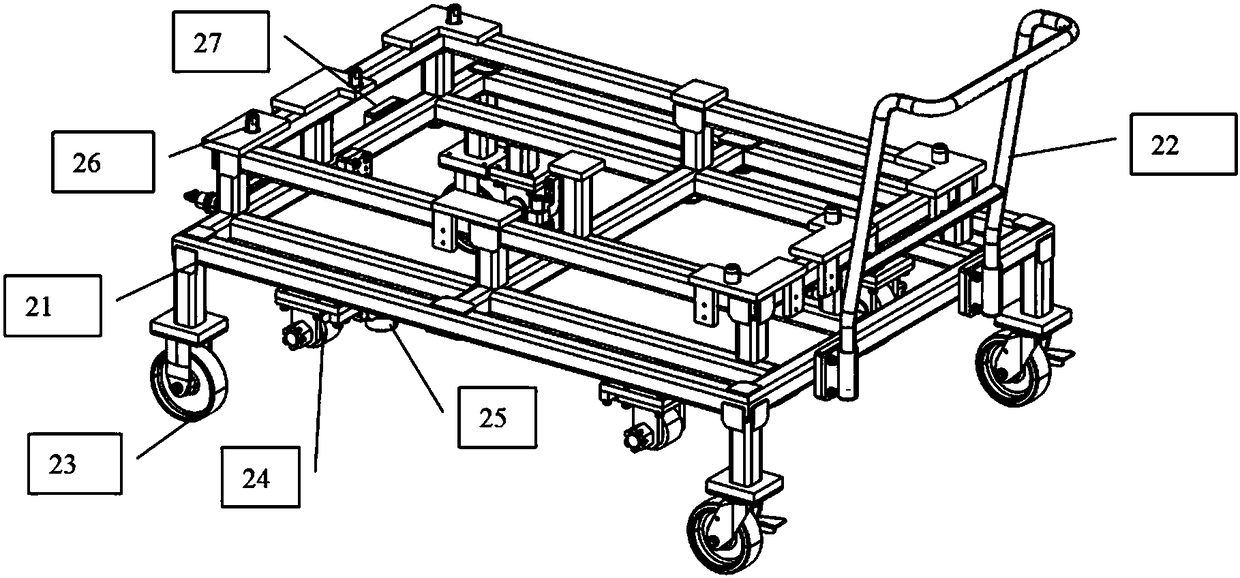

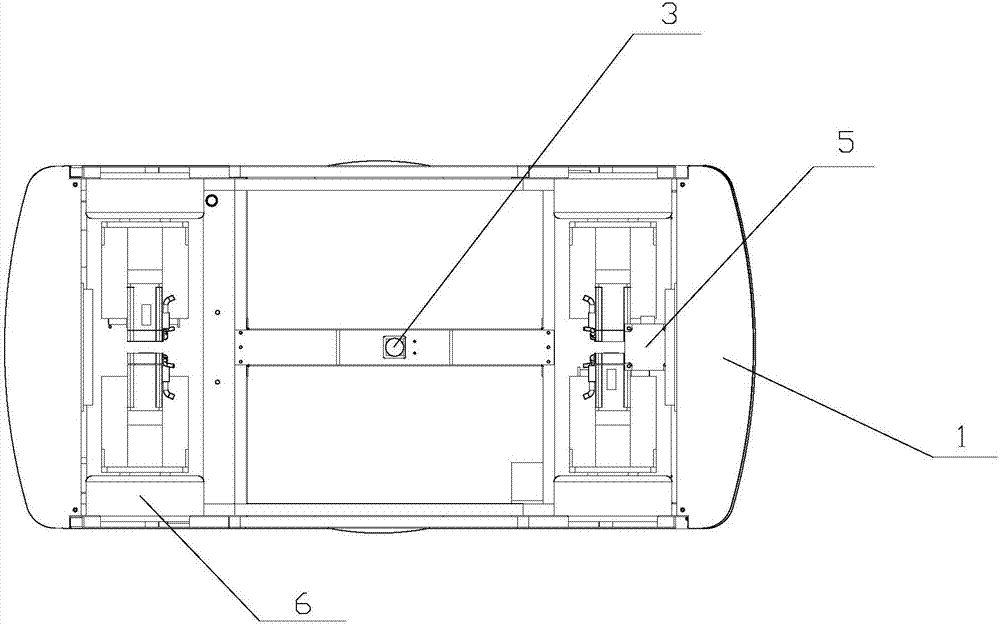

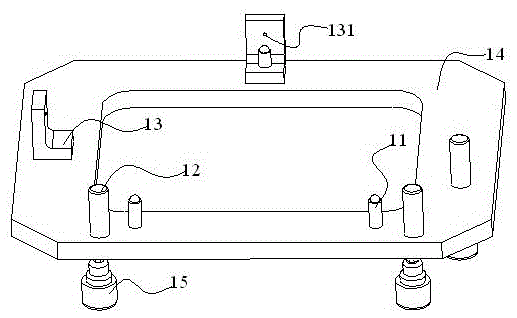

AGV station arrival positioning device and method thereof

InactiveCN107885199AHigh position repeatabilitySolve big problems with real-world applicationsPosition/course control in two dimensionsVehiclesEngineeringManipulator

The invention discloses an accurately-positioned AGV station arrival positioning device, which is made by adopting the above technical scheme. The device has the advantages that the AGV positioning repeatability precision can be improved within + / -1 mm from normal + / -5 mm finally, and the AGV carrying a manipulator for production operation becomes a reality. Through the technology, the AGV plus vision plus a robot plus a scheduling system plus precise positioning is a robot which can replace a human completely. The AGV has the brain (the scheduling system), the eyes (the vision), the feet (theAGV body) and the hand (the manipulator) and can do fine work, and thus, the AGV can be applicable to various situations, and major problems in practical applications of the robot can be solved.

Owner:上海艾崇机器人有限公司

Power meter detection method based on fusion of inspection robot positioning information

ActiveCN109360289BReduce false positivesHigh position repeatabilityChecking time patrolsCharacter and pattern recognitionPhase correlationRobot position

Owner:NANJING UNIV OF SCI & TECH

Motorized stage

The invention relates to an electric objective table, which mainly solves the problem that the objective table can not be precisely positioned in the prior art. The objective table capable of electrically controlling the position comprises a base station, shores, plunger pistons, eccentric pins and a motor, wherein the shores, the plunger pistons and the eccentric pins are fixedly arranged on the base station; in the direction vertical to the base station, the height of the eccentric pins and the plunger pistons is more than the height of the shores; a plane is formed by the vertexes of the supporting positions of the shores; a carried objective is arranged on the supporting positions of the shores; the edge of the carried objective is contacted with the eccentric pins and the plunger pistons; at least one plunger piston is positioned on the relative position of the eccentric pin; and the lower ends of the eccentric pins and the shores are provided with a rotation mechanism cooperated with the motor. According to the technical scheme that the motor position is fixed below the eccentric pins and the shores, the problem is better solved, and the electric objective table can be used for the industrial production of the objective table for the precise operation.

Owner:KUN SHAN POWER STENCIL

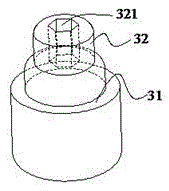

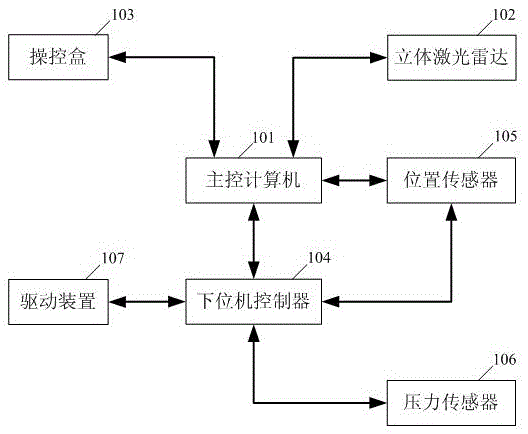

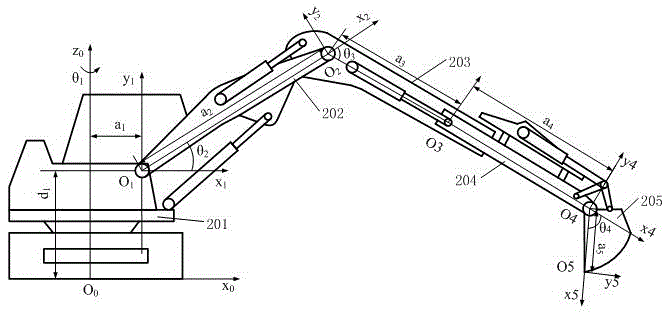

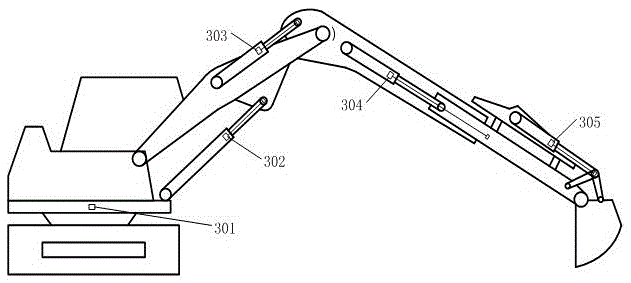

A method for autonomous operation control of an excavating robot

ActiveCN104476548BHigh degree of intelligenceHigh position repeatabilityProgramme-controlled manipulatorSoil-shifting machines/dredgersRadarControl system

The invention provides an excavating robot autonomous working control system and method. In the excavating robot autonomous working control system, a master control computer is connected with a three-dimensional laser radar, a control case, a position sensor and a lower computer controller; the lower computer controller is connected with a driving device, the position sensor and a pressure sensor. The excavating robot autonomous working control system and method can achieve unmanned autonomous excavation of an excavator and accordingly meet the requirements on excavation under severe environment inappropriate to human involvement. The excavating robot autonomous working control system is high in automation degree, good in man-machine interactivity, stable in operation and high in position repetition precision.

Owner:中国兵器装备集团自动化研究所有限公司

Embedded door machine motor

An embedded door machine motor relates to the technical field of elevator door machine motors. The embedded door machine motor comprises a motor shell, a rotating shaft, a rotor, a stator, a belt pulley and a radiating device, wherein the rotating shaft is installed inside the motor shell, the right end face of the motor shell is uniformly provided with four mounting holes, the rotor is sleeved on the rotating shaft, the stator is arranged on the outer side of the rotor, the belt pulley is installed at one end of the rotating shaft, and the radiating device is installed on one side of the rotating shaft and inside the motor shell. The embedded door machine motor further comprises a coded disc, Hall sensors and a microprocessor, wherein the coded disc is sleeved on the rotating shaft, four Hall sensors are uniformly arranged at the positions corresponding to the coded disc, and the microprocessor is arranged inside the motor shell and connected with the four Hall sensors. The embedded door machine motor disclosed by the invention can precisely control and measure rotating speed and displacement and is accurate in control, wider in application range, simplified in installation step and longer in service life.

Owner:南通赛福利机电科技有限公司

Digital colour enlarge printer with linear motion image processer

InactiveCN101067715AImprove image qualityIncrease flushing speedPhotographic printingCamera lensLinear motion

The invention relates to a digital color printer, concretely a digital color printer with a straight-line motion image processor, comprising: machine frame, image processor installed on the machine frame and developing tank installed on one side of the machine frame, and it is characterized in that: the image processor comprises a bottom plate, the bottom plate is equipped with two slide rails, the slide rails are fixed with slide plates, and the slide plates are equipped with lens. And the invention improves the original turnplate mode of mechanically locating optical device into straight-line motion electronic locating mode, thus improving locating repeating accuracy, and reducing the volume to not more than 2 / 5 of that of the original system; converts the traditional three-point spatial locating into two-point assembly debugging so as to extremely shorten the debugging time and largely improving imaging quality and developing rate.

Owner:武汉华工赛百数据系统有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com