High-precision high-rigidity space camera filter switching mechanism

A filter switching and space camera technology, which is applied to the camera body, camera, optics, etc., can solve the problems of low position repeatability, difficult installation process, and affecting imaging quality, so as to improve rigidity and anti-vibration Good performance, the effect of improving position repeatability accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

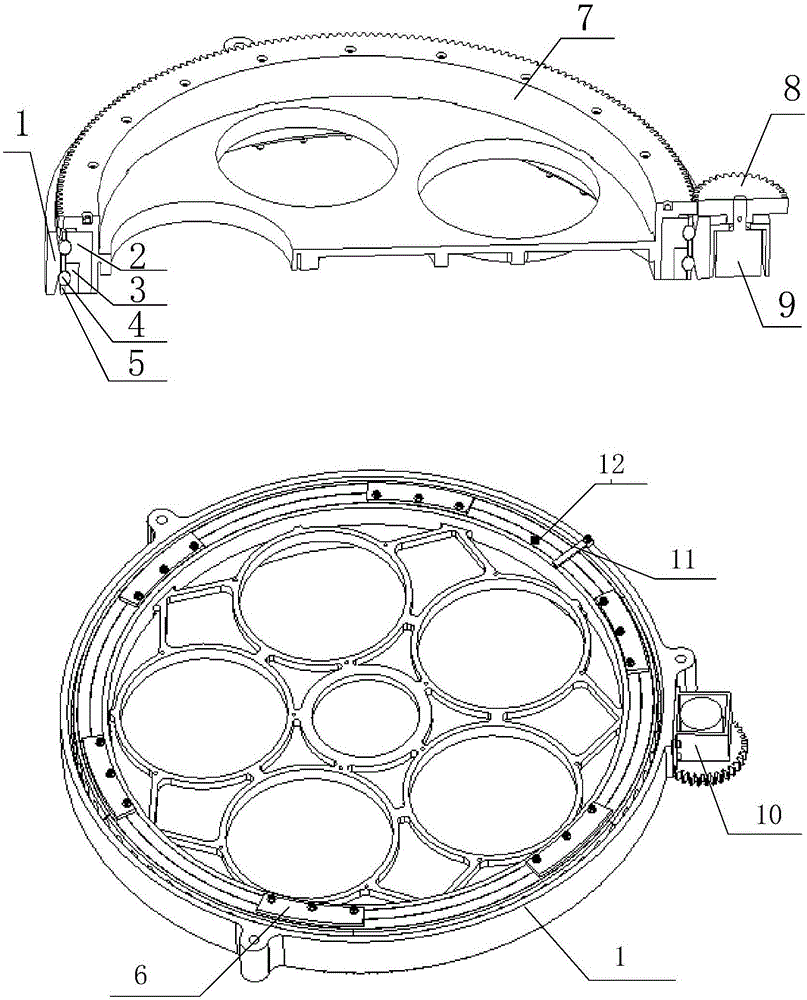

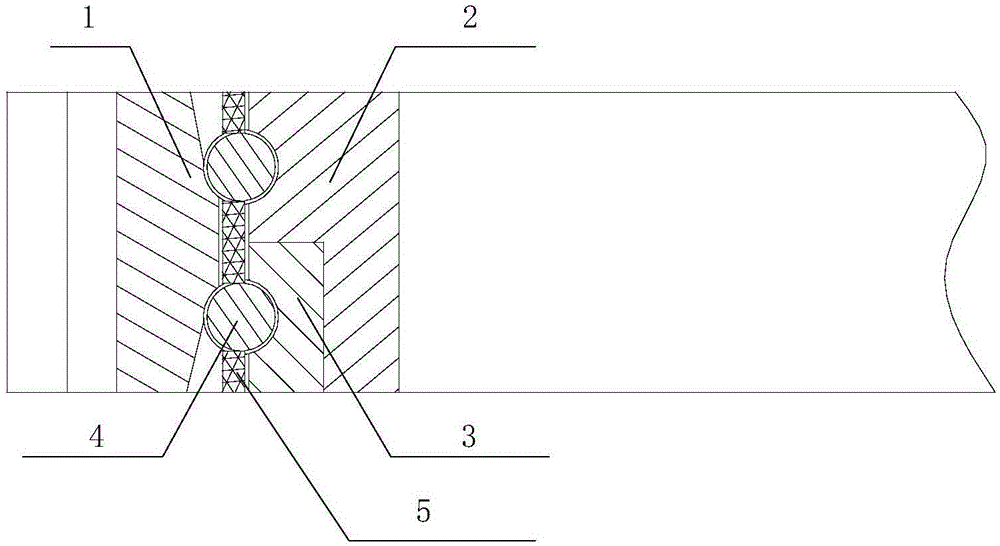

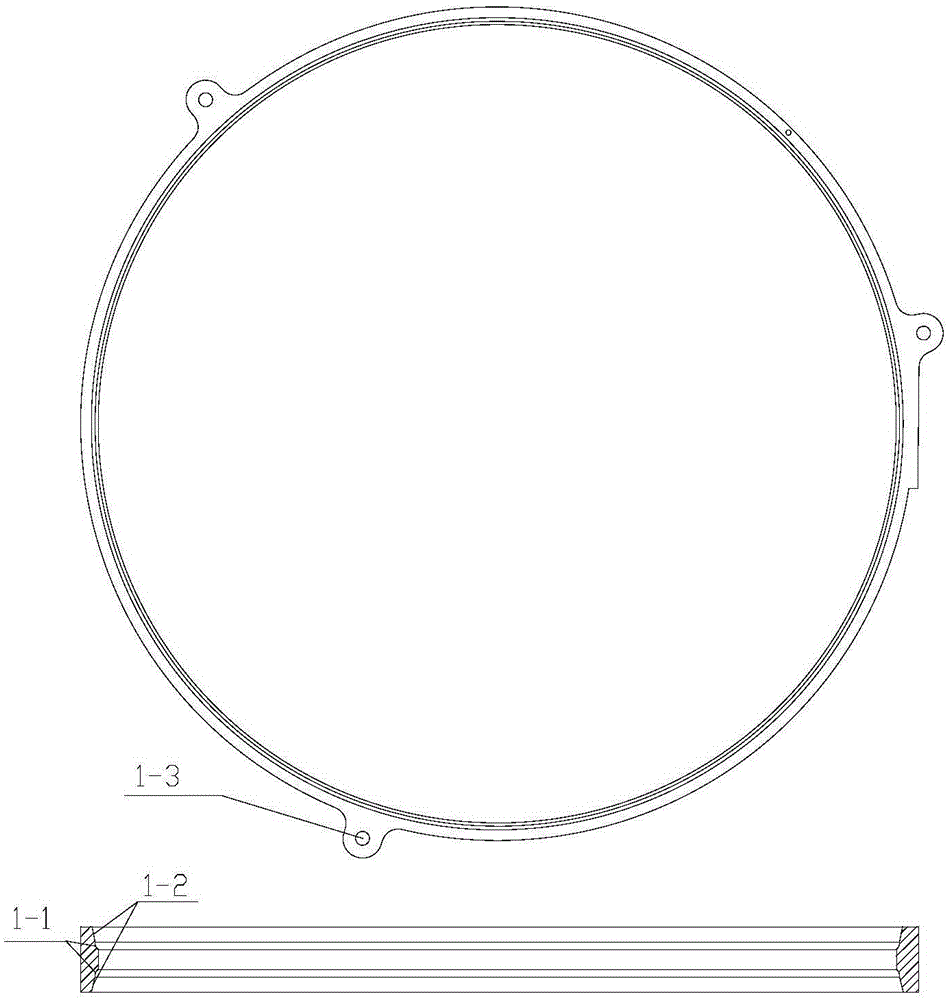

[0023] Such as figure 1 Shown is a schematic diagram of the composition of the high-precision and high-rigidity space camera filter switching mechanism of the present invention. As shown in the figure, it includes an integrated bearing, a gear pair, and a drive control part; the integrated bearing is external, the integrated bearing is outside, and the optical filter The mounting plate 7 is concentrically installed in the integrated bearing, and the drive control part is installed on the integrated bearing. The integrated bearing includes an integrated outer collar 1, an inner collar 2, an embedded ring 3, a ball 4, a ball cage 5 and a pressure block 6. This configuration integrates the switching mechanism with the external mounting interface and two bearings Design, reduce the number of structural parts and installation errors between structur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com