Method for preparing furan or furfural compound from biomass cellulose

A cellulose and biomass technology, applied in chemical recycling, organic chemistry and other directions, can solve the problems of increasing process cost and difficult practical application, and achieve the effect of low cost, favorable for large-scale production and simple process conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

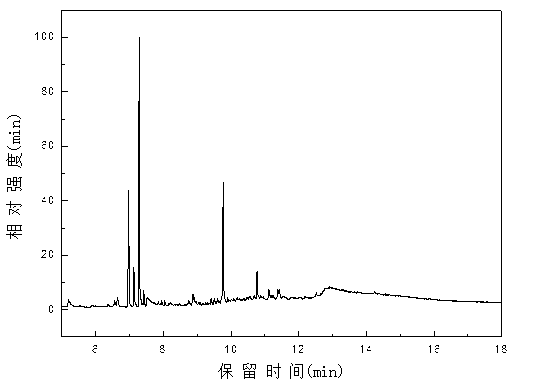

[0016] Using high-purity cellulose as raw material, take 10g (by dry weight) of the raw material and pour it into a 250ml liquefaction reactor, add 150ml of distilled water, and fill the reactor with N 2 Until the air in the reaction kettle is completely exhausted, heat up to 150°C while stirring, keep it for 60min, then stop the reaction, cool the reactor to room temperature rapidly, pour out the reaction mixture, separate the reaction mixture from solid to liquid, and analyze the obtained liquid phase The solution is extracted with ether, and the water-soluble product is obtained by separation. After removing the ether, the product 1 is obtained, and the yield can reach 14.8% (ratio to the dry weight of the raw material). The ether can be recovered and recycled; the obtained solid phase is extracted with tetrahydrofuran, filtered Get tetrahydrofuran solution, remove tetrahydrofuran to get product 2, the yield can reach 12.2% (to the raw material dry weight ratio), tetrahydrof...

Embodiment 2

[0018] Using high-purity cellulose as raw material, take 10g (by dry weight) of the raw material and pour it into a 250ml liquefaction reactor, add 150ml of distilled water, heat up to 180°C while stirring, keep it for 10min, then stop the reaction, and cool the reactor rapidly To room temperature, pour out the reaction mixture, carry out solid-liquid separation to the reaction mixture, extract the obtained liquid phase solution with ethyl acetate, separate and obtain the water-soluble phase product, remove the ethyl acetate to obtain the product 1, and the productive rate can reach 16.7% ( Ratio of raw material dry weight), ethyl acetate can be recovered and recycled; the obtained solid phase is extracted with dichloromethane, filtered to obtain a dichloromethane solution, and the product 2 is obtained after removing the dichloromethane, and the yield can reach 15.3% ( Compared with the dry weight of raw materials), dichloromethane can be recovered and recycled; product 1 is r...

Embodiment 3

[0020] Using high-purity cellulose as raw material, take 5g (by dry weight) of the raw material and pour it into a 250ml liquefaction reactor, add 150ml of distilled water, and fill the reactor with 2MPa N 2 , heated up to 260°C while stirring, then stopped the reaction, cooled the reactor rapidly to room temperature, poured out the reaction product, separated the reaction mixture from solid to liquid, extracted the obtained liquid phase solution with dichloromethane, separated to obtain water-soluble Phase product, product 1 is obtained by removing dichloromethane, and the yield can reach 15.9% (ratio to raw material dry weight), and dichloromethane can be recovered and recycled; the obtained solid phase is extracted with dichloromethane, filtered to obtain dichloromethane Methane solution, remove dichloromethane to obtain product 2, the yield can reach 22.9% (to the raw material dry weight ratio), dichloromethane can be recovered and recycled; product 1 is rich in 5-hydroxyme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com