A method for autonomous operation control of an excavating robot

A control method and robot technology, which can be applied to earth moving machines/shovels, program-controlled manipulators, manipulators, etc., can solve the problems of high physical and mental consumption, harsh working environment, high labor intensity, etc., and achieve high position repeatability. , The effect of good human-computer interaction and high degree of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

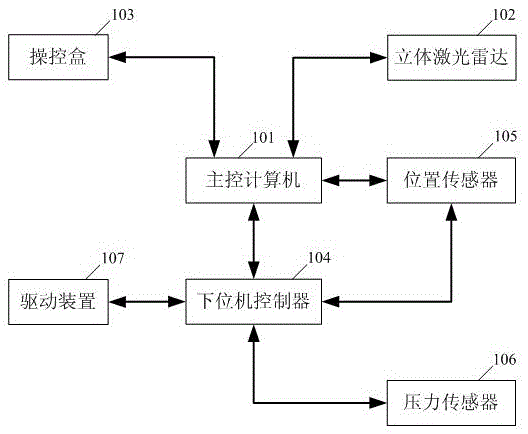

[0030] figure 1 It is a connection relationship block diagram between each component of the present invention, from figure 1 It can be seen from the figure that the excavating robot autonomous operation control system of the present invention includes a main control computer 101, a stereo laser radar 102, a control box 103, a lower computer controller 104, a position sensor 105, a pressure sensor 106 and a driving device 107. The main control computer 101 is connected with the stereo lidar 102 , the control box 103 , the position sensor 105 and the lower computer controller 104 , and the lower computer controller 104 is connected with the driving device 107 , the position sensor 105 and the pressure sensor 106 .

[0031] The main control computer 101 communicates with the control box 103 and the stereo laser radar 102 through Ethernet, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com