Automatic clamping device for testing dynamic balance of flexible flywheel

An automatic clamping, flexible flywheel technology, applied in static/dynamic balance testing, measuring devices, machine/structural component testing, etc. and other problems, to achieve the effect of improving the dynamic balance test accuracy, protecting the runout tolerance, and avoiding large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with accompanying drawing.

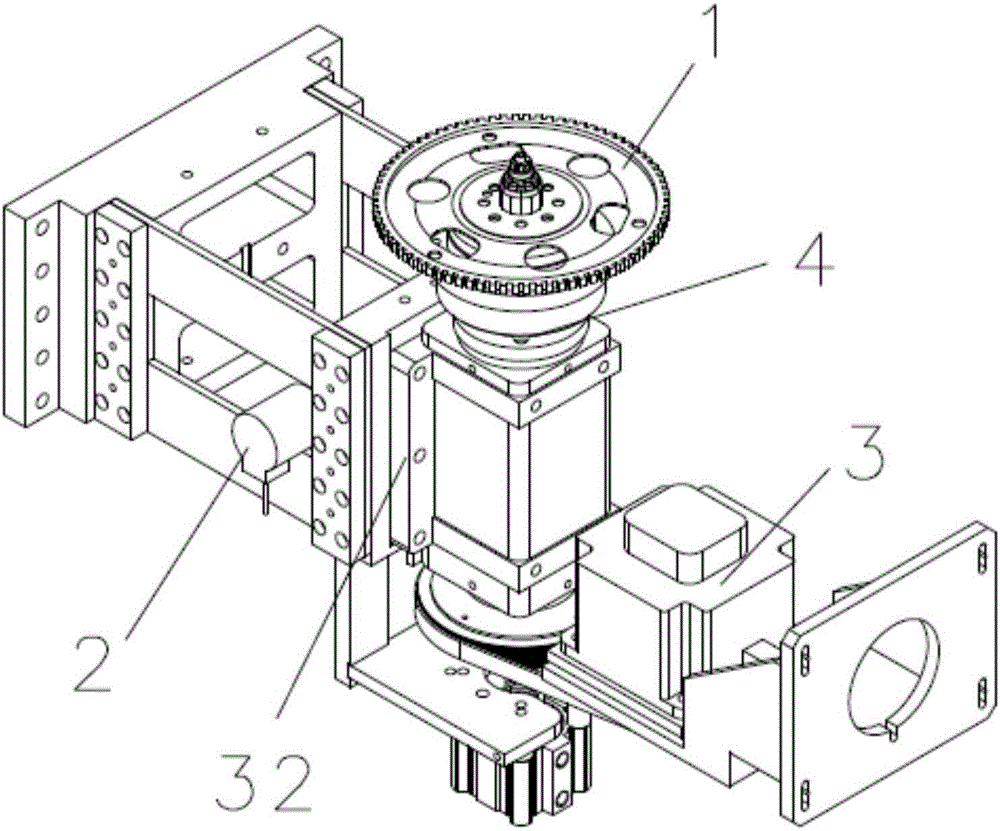

[0033] Such as figure 1 As shown, the universal hard support balance testing machine of the present invention comprises a vibrating body 32, an automatic clamping device 4 and a driving part 3, and the automatic clamping device 4 is fixedly installed on the vibrating body 32 of the general hard supporting balancing testing machine, and the flexible flywheel 1 is installed on the top of the automatic clamping device 4 and is automatically clamped by the automatic clamping device 4. The automatic clamping device 4 is connected to the driving part 3, and the rotating shaft in the automatic clamping device 4 is driven to speed up by the driving part 3 to perform a dynamic balance test.

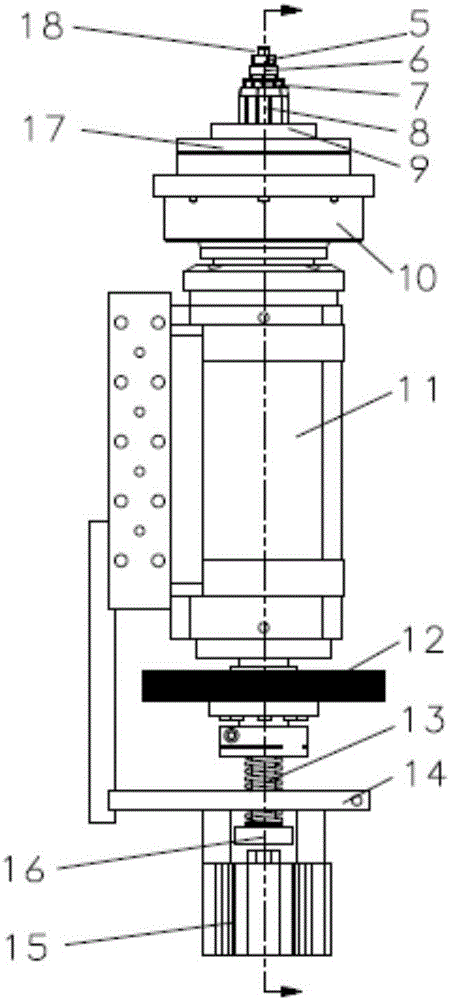

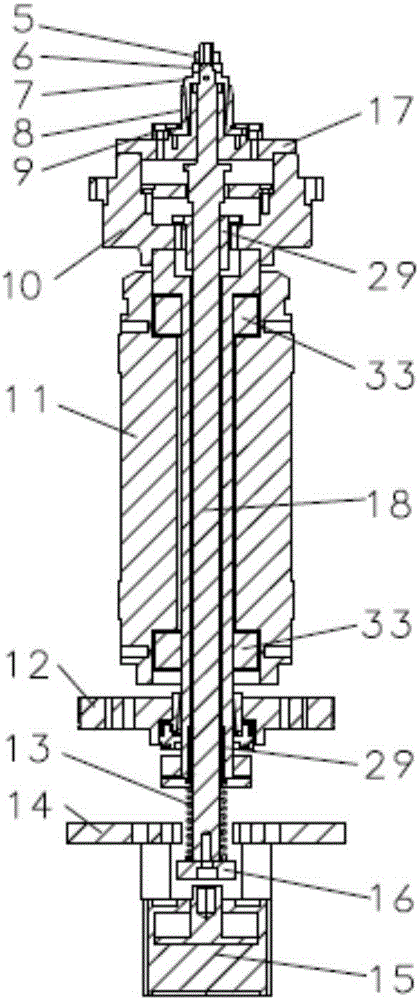

[0034] Such as Figure 2-4 As shown, the automatic clamping device 4 includes a rotating main shaft seat 11, a pull rod 18 and a rotating main shaft 10, the rotating main shaft seat 11 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com