Motor bearing random dynamic load testing device and testing method

A technology for testing motor bearings and loads, applied in mechanical bearing testing, measuring devices, force/torque/power measuring instruments, etc., can solve problems such as inaccurate testing of motor bearings, and achieve the effect of avoiding interference from environmental factors and human factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

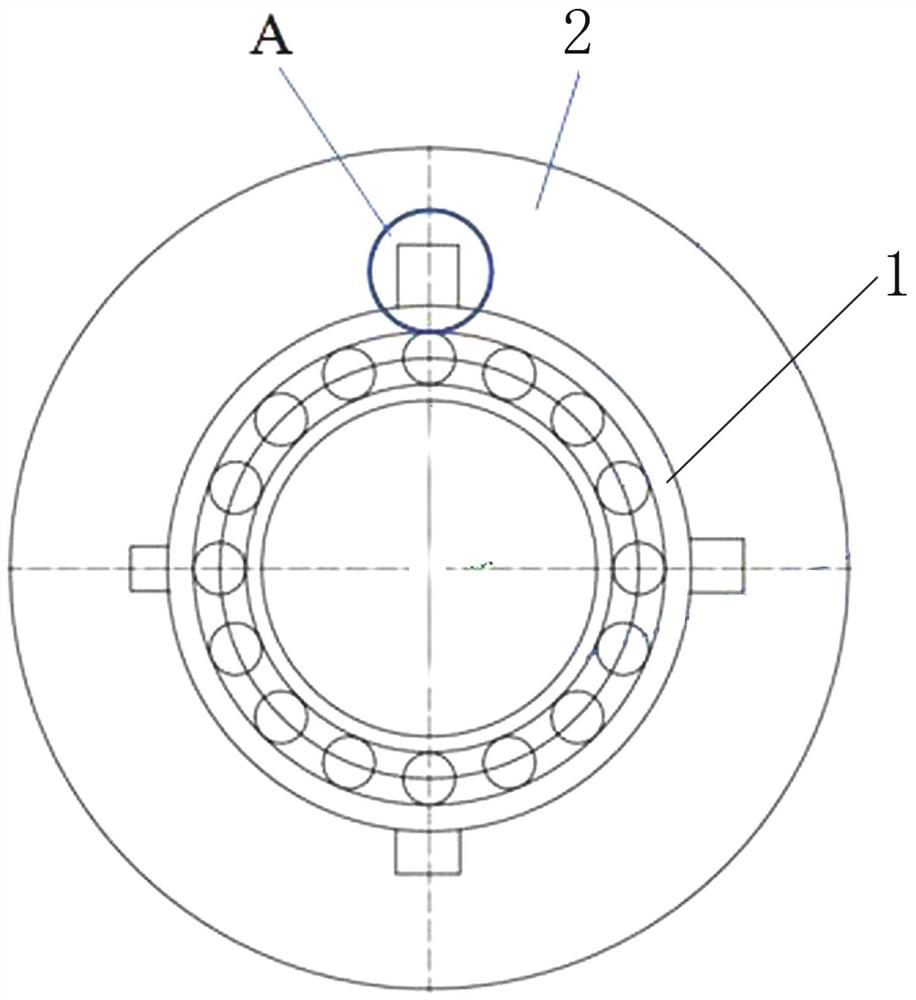

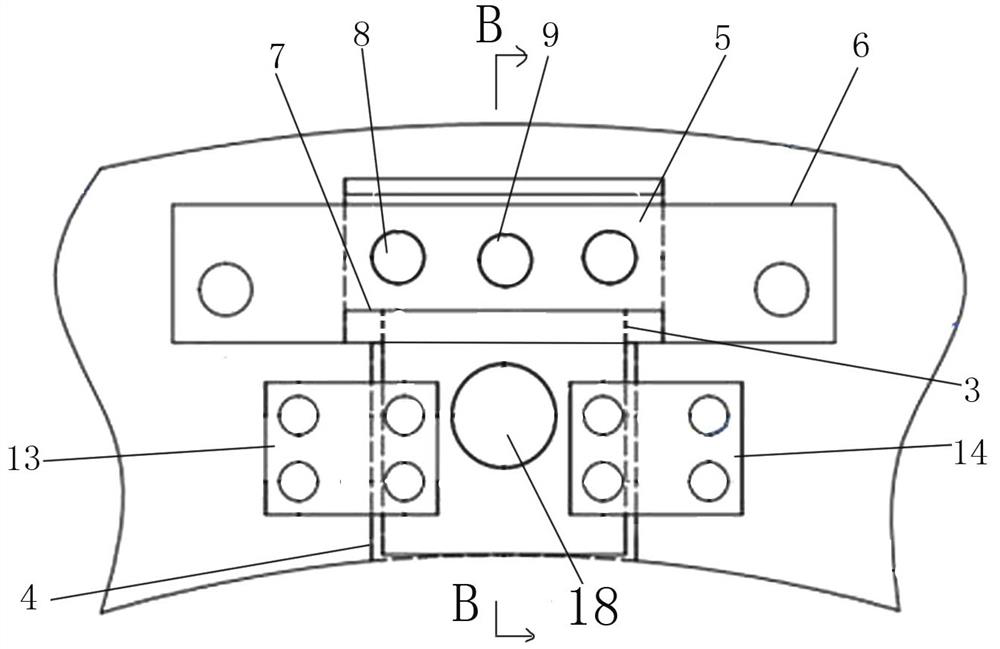

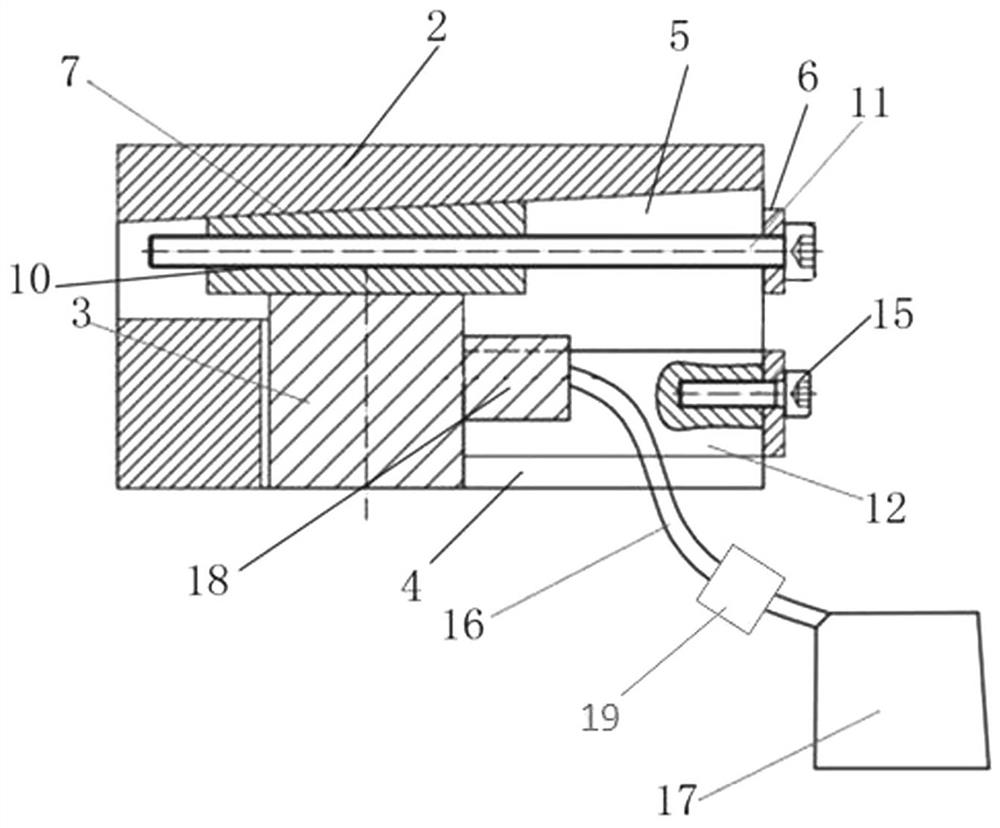

[0019] A random dynamic load testing device for a motor bearing, comprising a bearing bush 2 (well known to those skilled in the art, that the bearing bush 2 is fixed on the outer ring of the motor bearing 1 (this motor bearing is the motor bearing used for testing) have a certain thickness in the radial direction), data acquisition system, and the data acquisition system includes piezoelectric dynamometer 3 (known to those skilled in the art: the shape of piezoelectric dynamometer 3 is a hexagonal cylinder shape, and the bottom is At the detection end, at the same time, in order to facilitate the installation of data cables, one of the side walls of the hexagonal cylinder is provided with a cylindrical cable interface end 18) whose axial direction is perpendicular to the axial direction of the hexagonal cylinder, signal adjustment Instrument 19, dynamometer data cable 16 and supporting data collector 17, there are four rings arranged on the end face of the bearing bush 2 along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com