High-precision wide-range gas flow measuring device

A technology of gas flow and measuring devices, which is applied in the direction of volume flow measuring devices, measuring devices, liquid/fluid solid measurement, etc., can solve problems such as inaccurate measurement results, achieve inaccurate measurement results, improve accuracy, and avoid disassembly The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

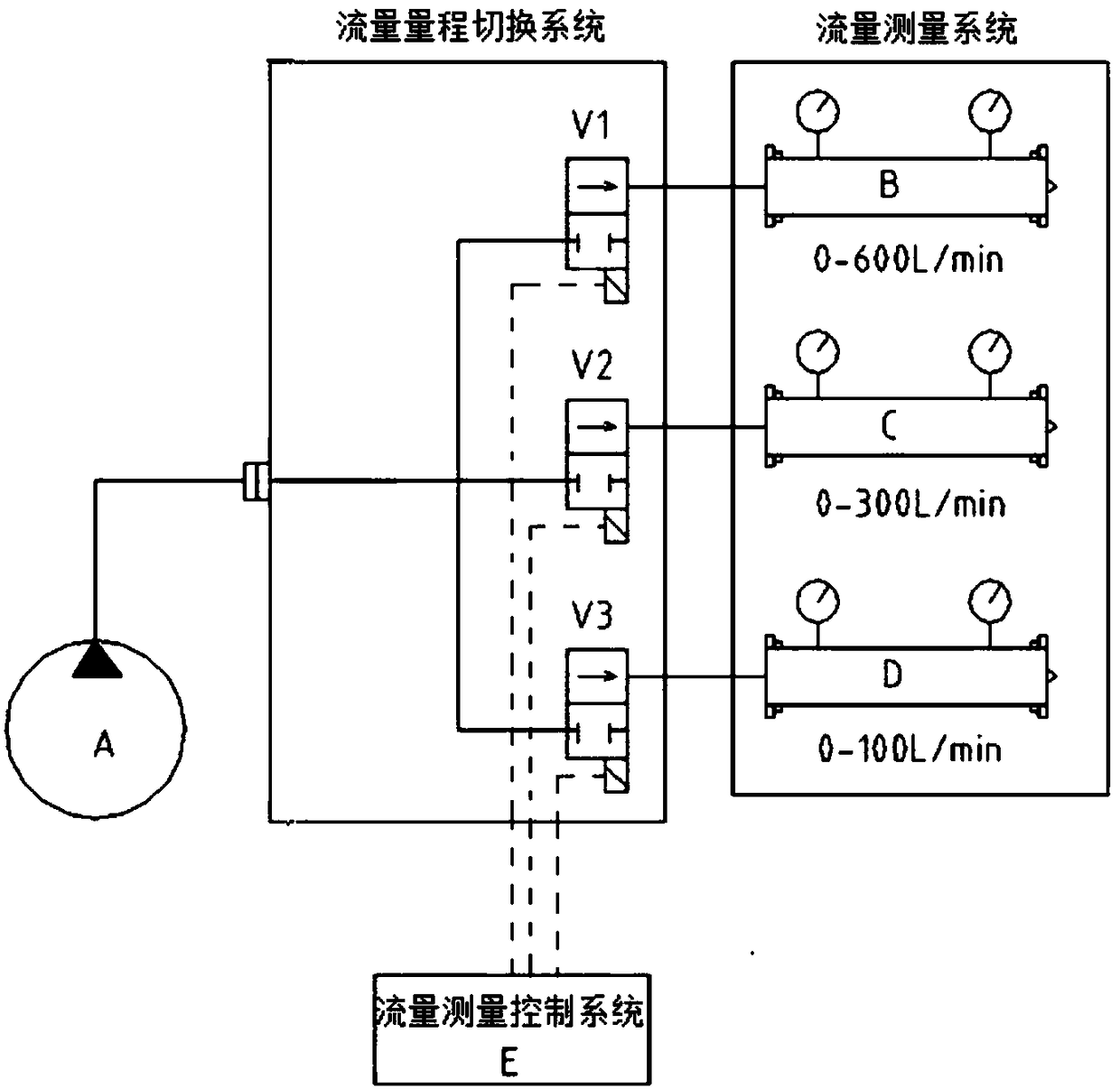

[0021] Such as figure 2 As shown, the gas measured by the high-precision wide-range gas flow measurement device of this embodiment comes from the air compressor A of the measured gas source, the flow measurement control system E is a controller with computing power, and the measurement range switching system includes V1, V2, V3 has three solenoid valves, and the flow measurement system is composed of three flowmeters B, C, and D. The solenoid valves V1, V2, and V3 correspond to the three flowmeters B, C, and D respectively to form a measurement branch. The above solenoid valve controls the conduction and disconnection of the measurement branch.

[0022] The flowmeters are arranged continuously according to the high-precision interval gradient. For example, the flowmeter B in this embodiment has a range of 0-600L / min, and a high-precision measurement interval of 200L / min-300L / min; the flowmeter C has a range of 0-300L / min, the high-precision measurement range is 100L / min-200L...

Embodiment 2

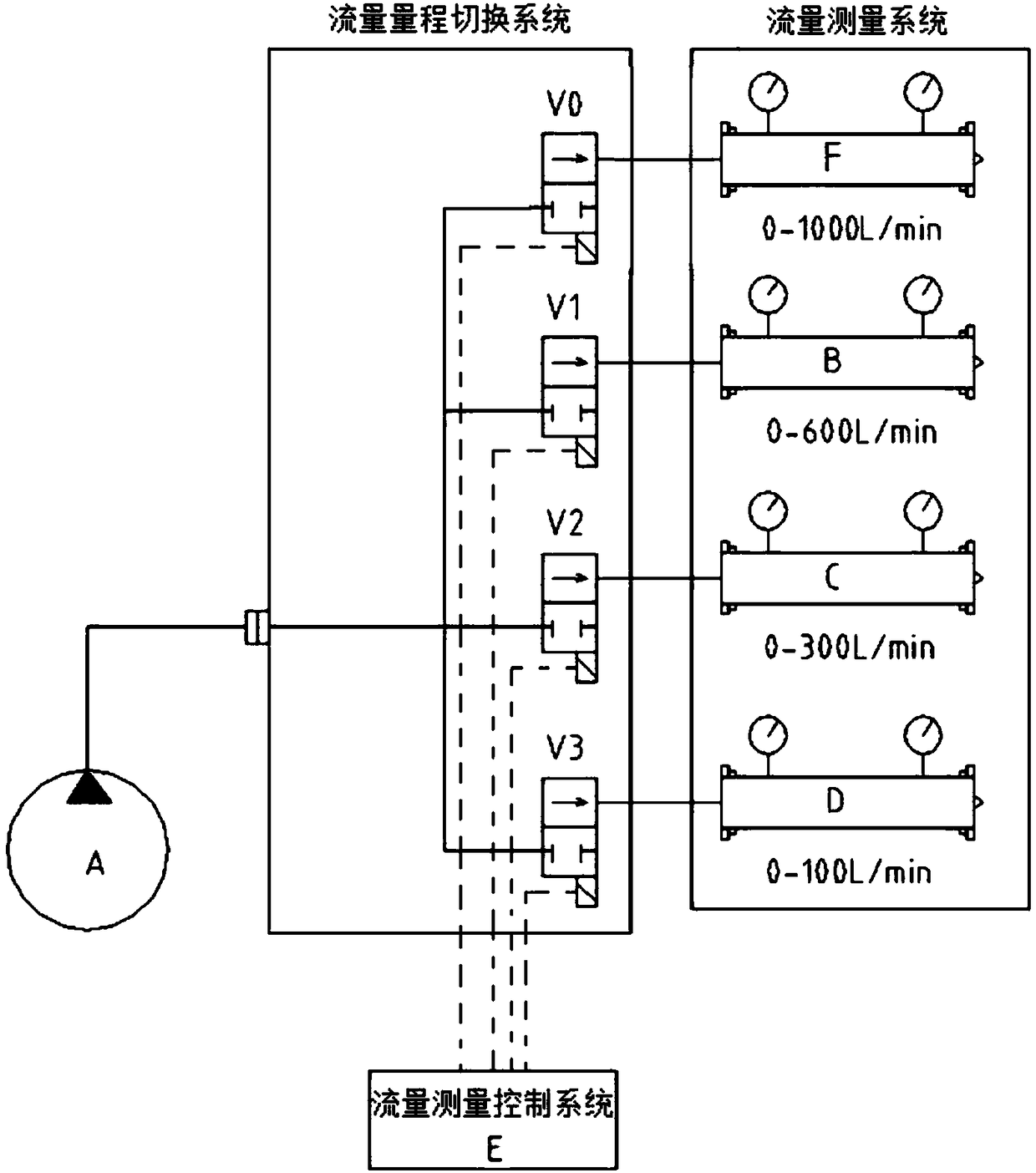

[0027] Such as image 3 As shown, the only difference from Embodiment 1 is that the system also includes a rough flow measurement branch, one end of the flow rough measurement branch is connected to the short-connected ends of the measurement branches, and the flow rough measurement branch is provided by From upstream to downstream, there are coarse measuring solenoid valve V0 and a rough measuring flowmeter F with a large range. Before the measurement, open the rough measurement solenoid valve and close the rest of the solenoid valves. The high-precision wide-range gas flow measurement device collects the gas generated by the gas source, first transmits it to the rough measurement branch, and performs preliminary measurement by the rough measurement flowmeter F. The measured value is transmitted to the flow measurement control system through the sampling line. The flow measurement control system compares the measured value with the high-precision intervals of all measuring br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com