Patents

Literature

39results about How to "Resolving inaccurate measurements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

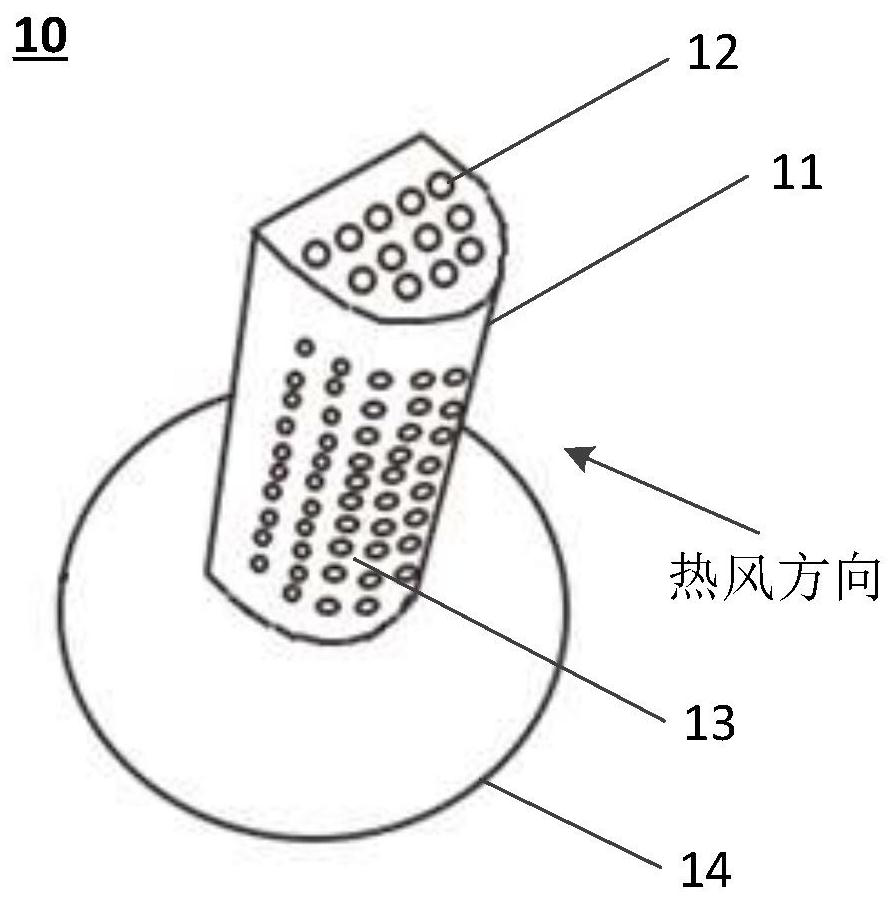

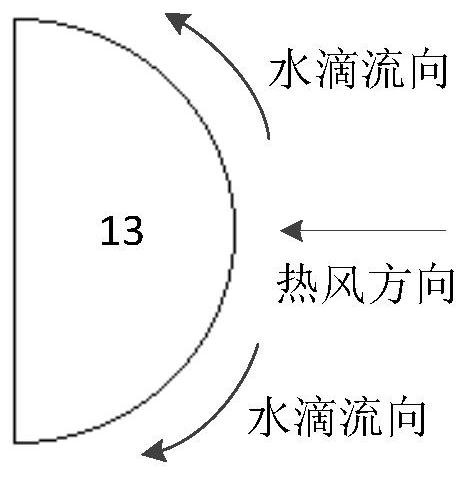

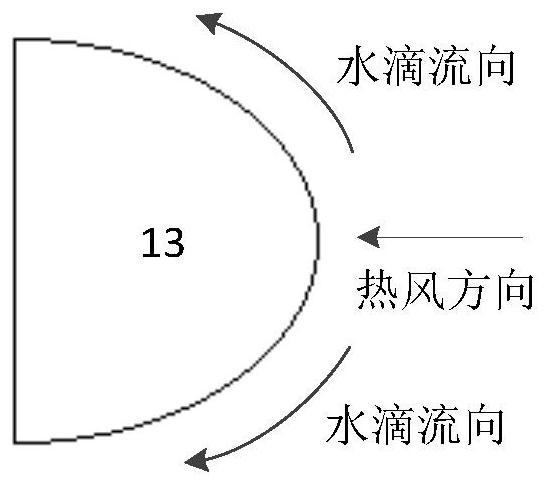

Microwave steaming and baking oven

PendingCN112754314ASimple structureImprove measurement accuracySteam cooking vesselsMicrowave heatingEngineeringMicrowave shielding

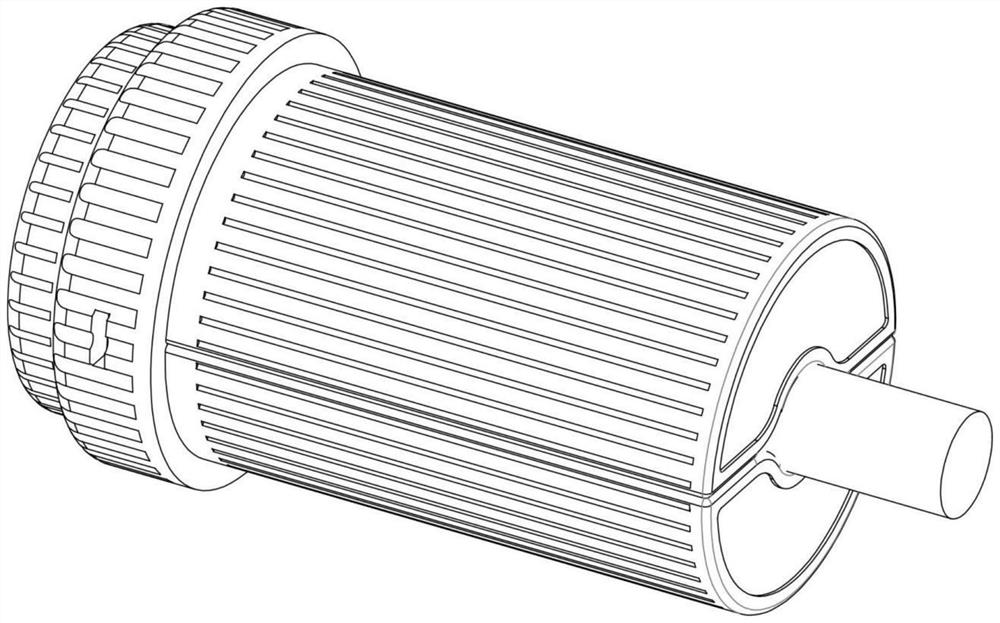

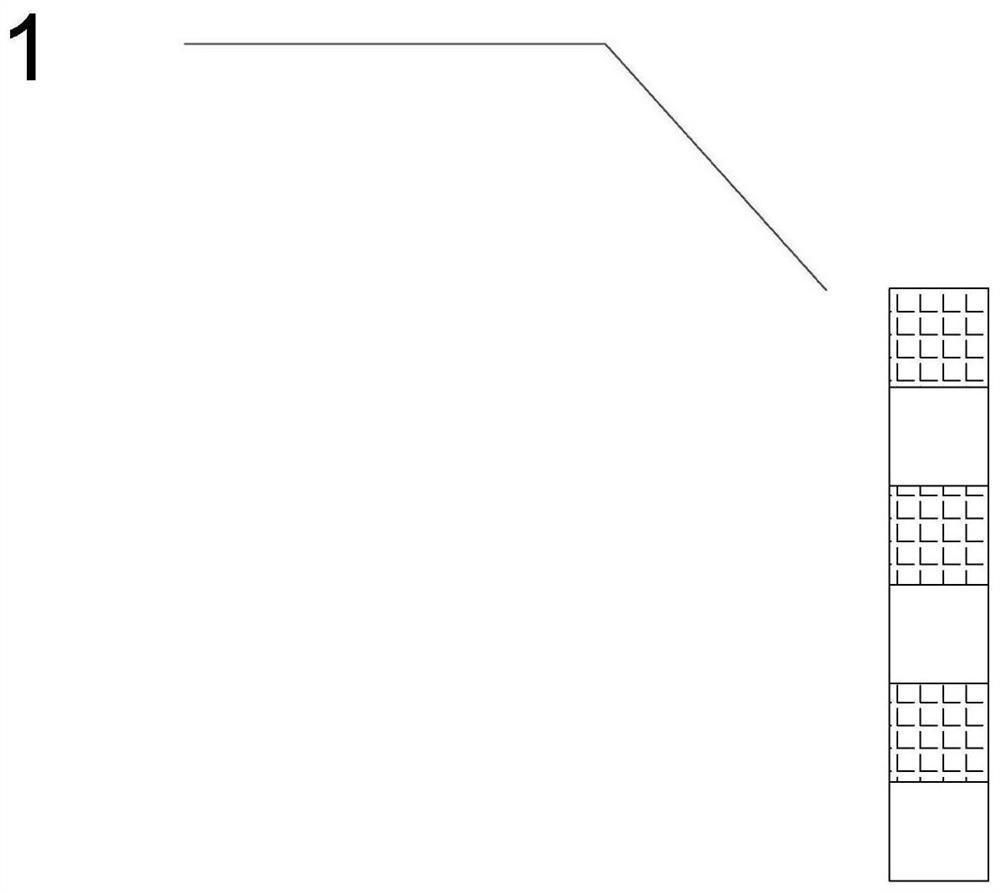

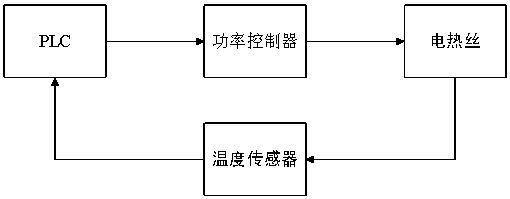

The invention provides a microwave steaming and baking oven. The steaming and baking oven comprises a box body, a microwave generating part, a heating device, a hot air fan, a temperature sensor sensor and a microwave shielding cover, wherein a cooking cavity is formed in a hollow part of the interior of the box body; the microwave generating part is configured to generate microwaves and conduct the microwaves into the cooking cavity to heat food to be heated; the heating device and the hot air fan are configured to enable heat generated by the heating device to form hot air and send the hot air into the cooking cavity; the temperature sensor sensor is configured to sense the temperature of the hot air; the sensor microwave shielding cover comprises a cover body, the cover body comprises a plurality of holes, the holes are configured to be capable of shielding microwaves from entering the sensor through the microwave shielding cover, the cover body is of a columnar structure, the side, facing hot air, of the cover body is provided with a non-planar structure, and the side, facing the hot air, of the cover body is provided with a plurality of holes along the hot air direction; the section area of the non-planar structure in a plane perpendicular to the hot air direction is gradually increased. According to the steaming and baking oven, packaging and microwave shielding of the temperature sensor are tighter, and measurement is more accurate.

Owner:YUNDING TECH (BEIJING) CO LTD

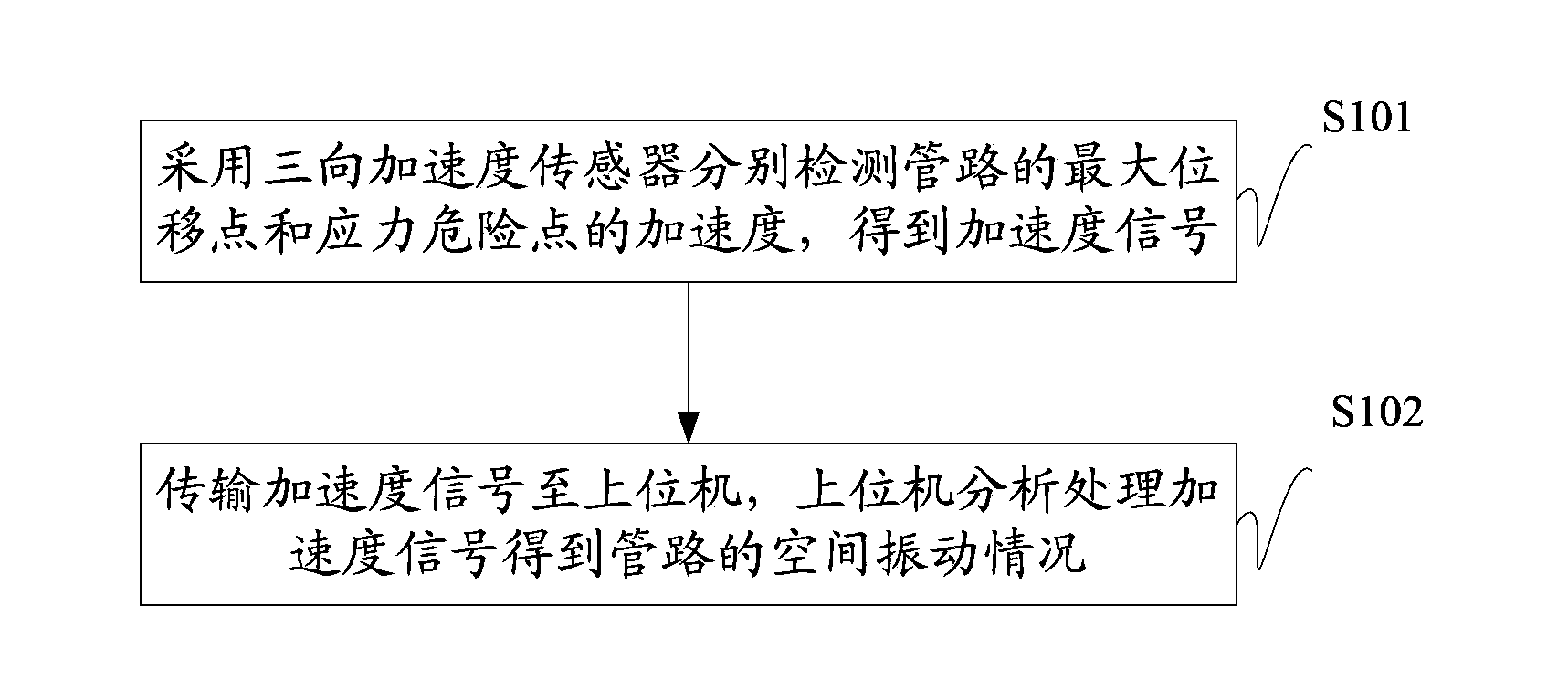

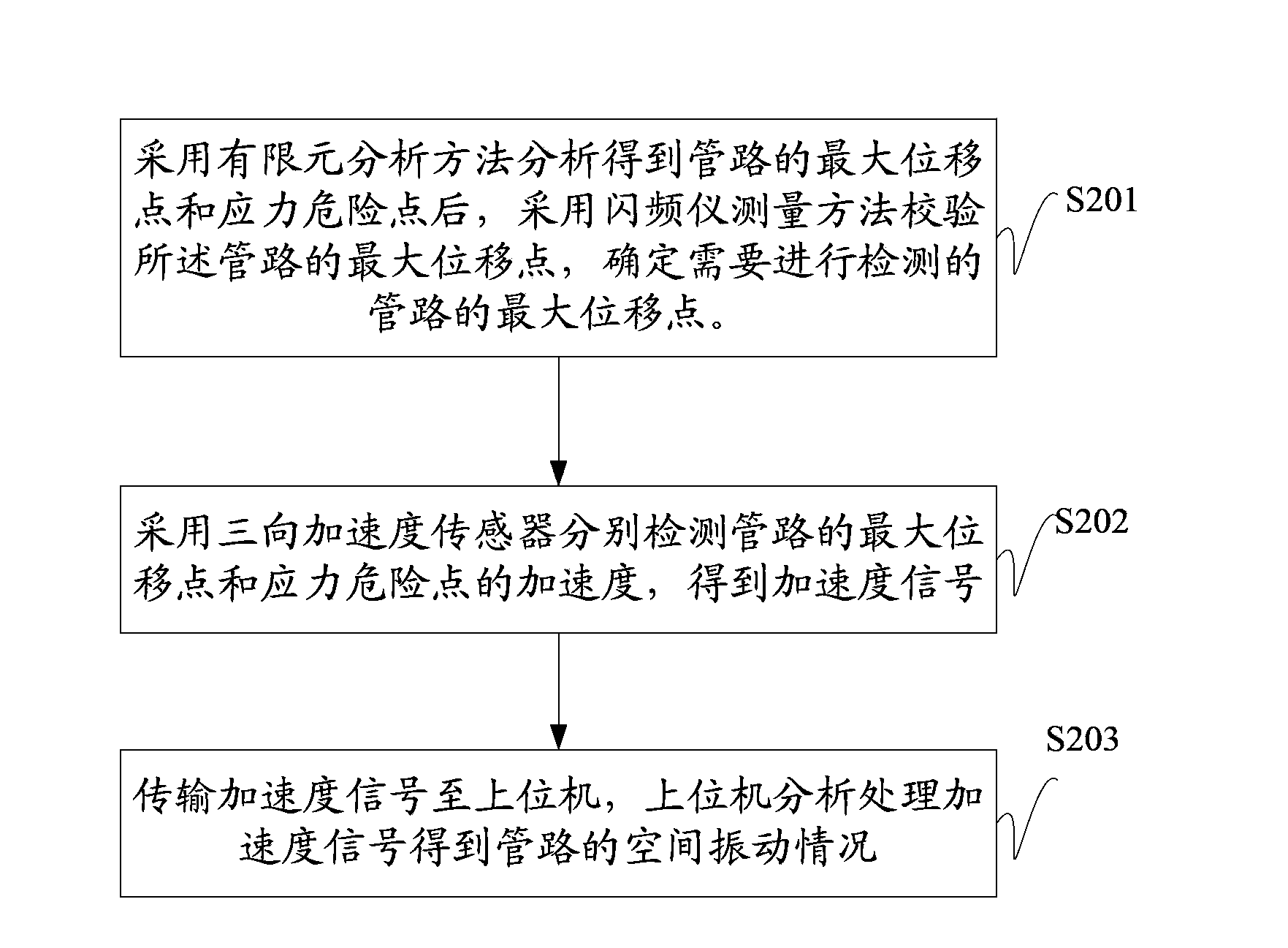

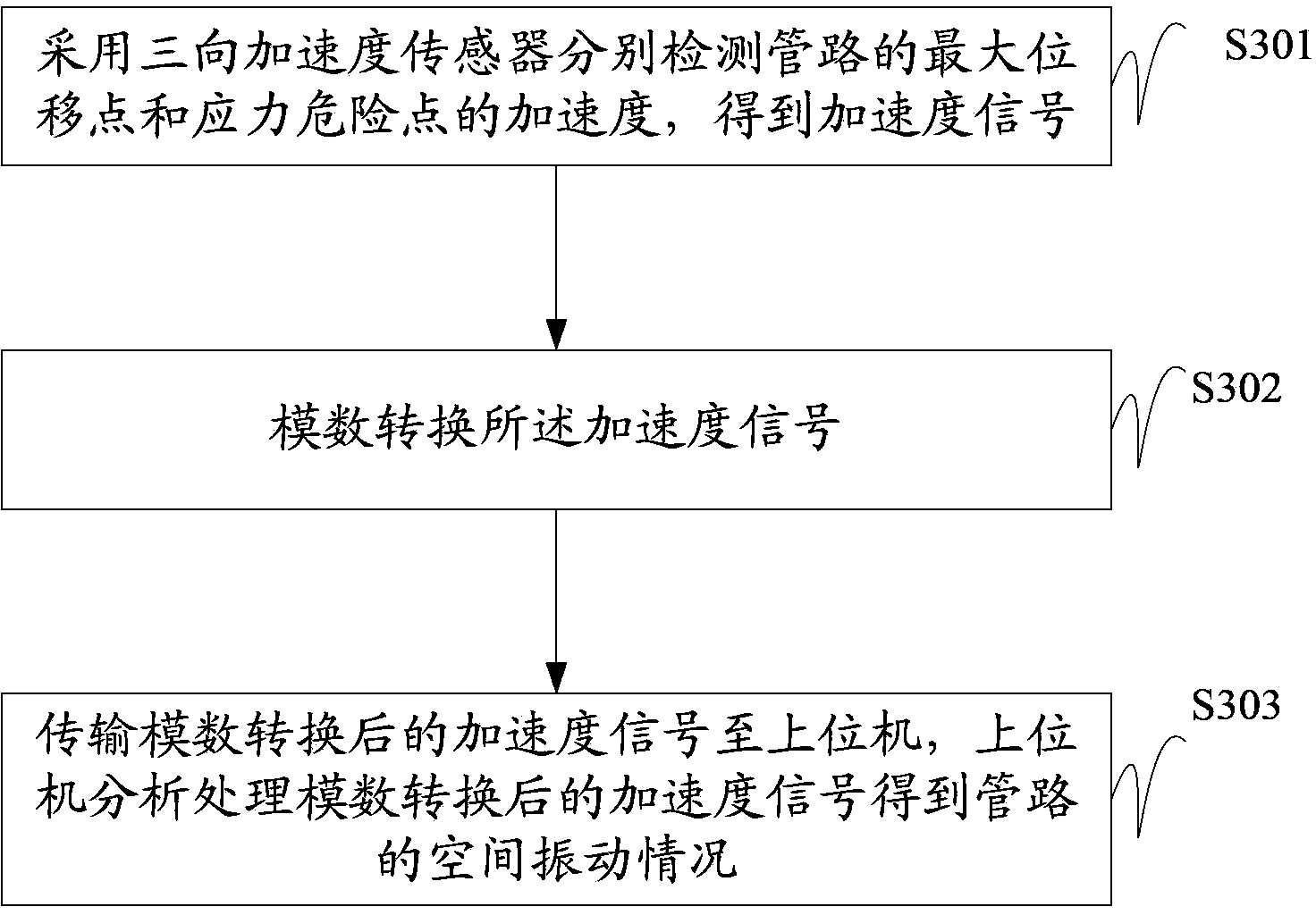

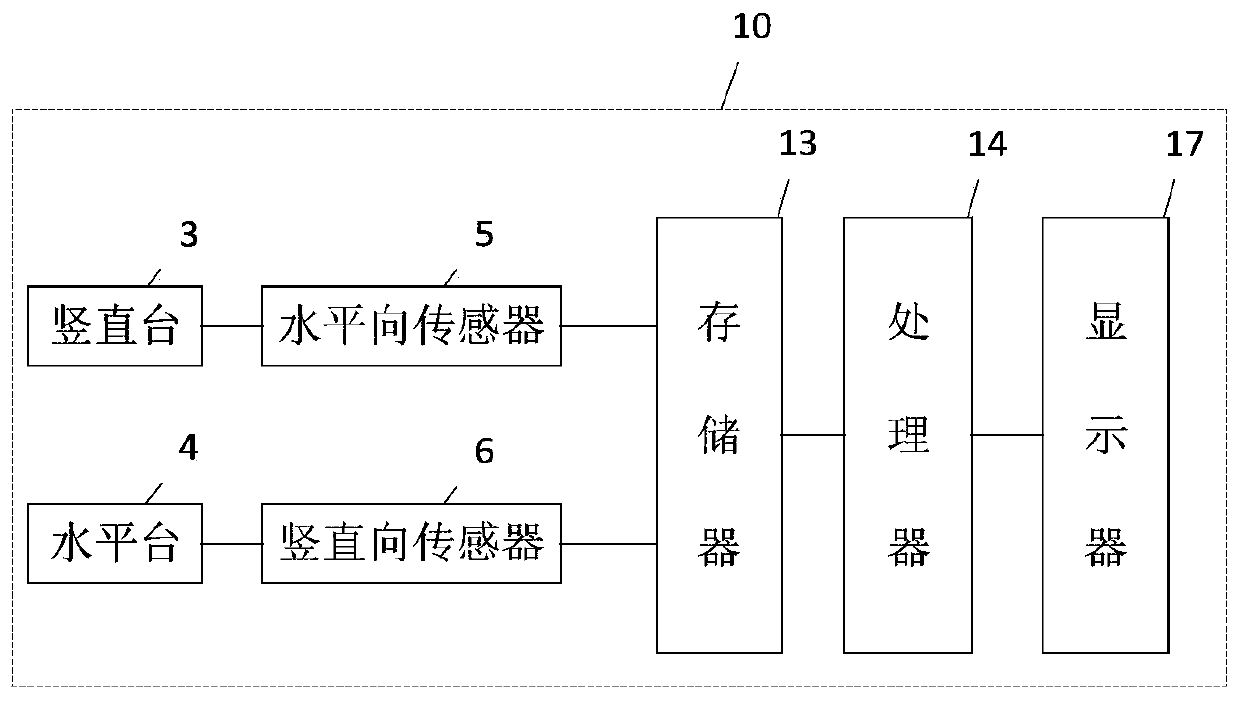

Pipeline test method and system

InactiveCN103822773AEfficient measurementRealize measurementMachine part testingSubsonic/sonic/ultrasonic wave measurementElement analysisClassical mechanics

The invention discloses a pipeline test method and system. At first, analysis is performed according to the finite element analysis method to obtain the maximum displacement point and the stress dangerous point of the pipeline, and then, accelerated speeds at the maximum displacement point and the stress dangerous point of the pipeline are detected separately with a three-directional acceleration sensor, measurement is effectively performed for the maximum displacement point and the stress dangerous point of the pipeline, the measurement result is accurate; and the three-directional acceleration sensor has the anti-interference and shielding performances, so the problem of inaccurate measurement result caused by external interferences can be solved; and the three-directional acceleration sensor can be arranged on a small-diameter pipeline, so the measurement of the small-diameter pipeline can be realized; the broken or short-circuit failure is not easy to occur, so the problem that the measurement cannot be performed due to the broken or short-circuit failure in the prior art can be solved.

Owner:GREE ELECTRIC APPLIANCES INC

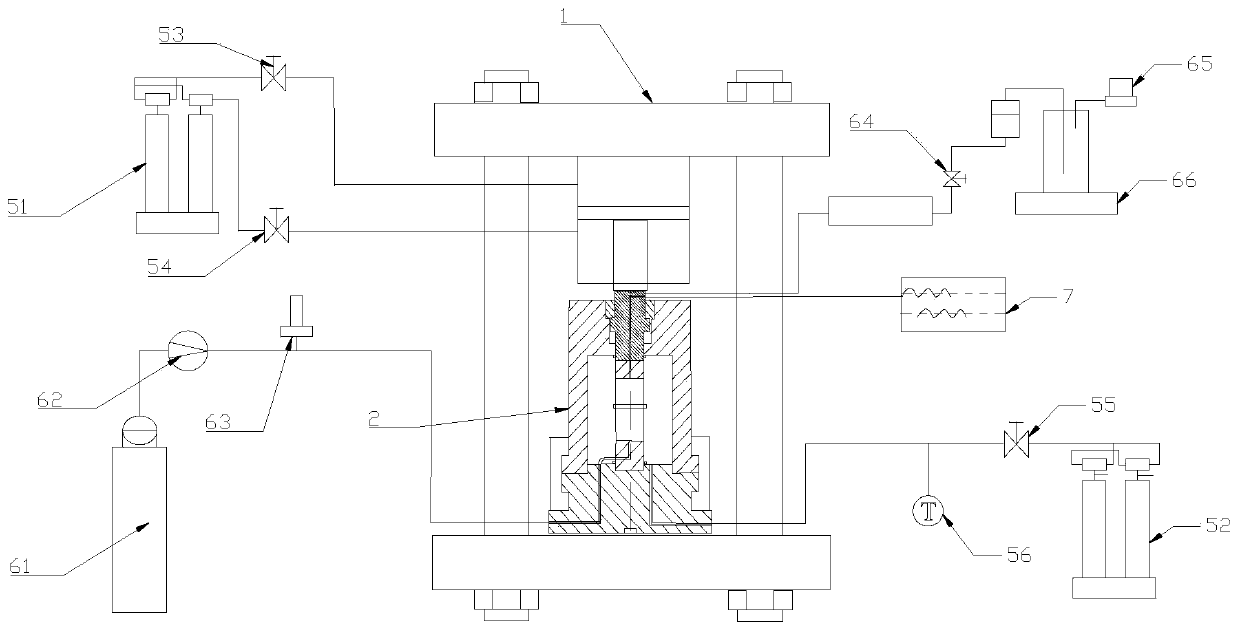

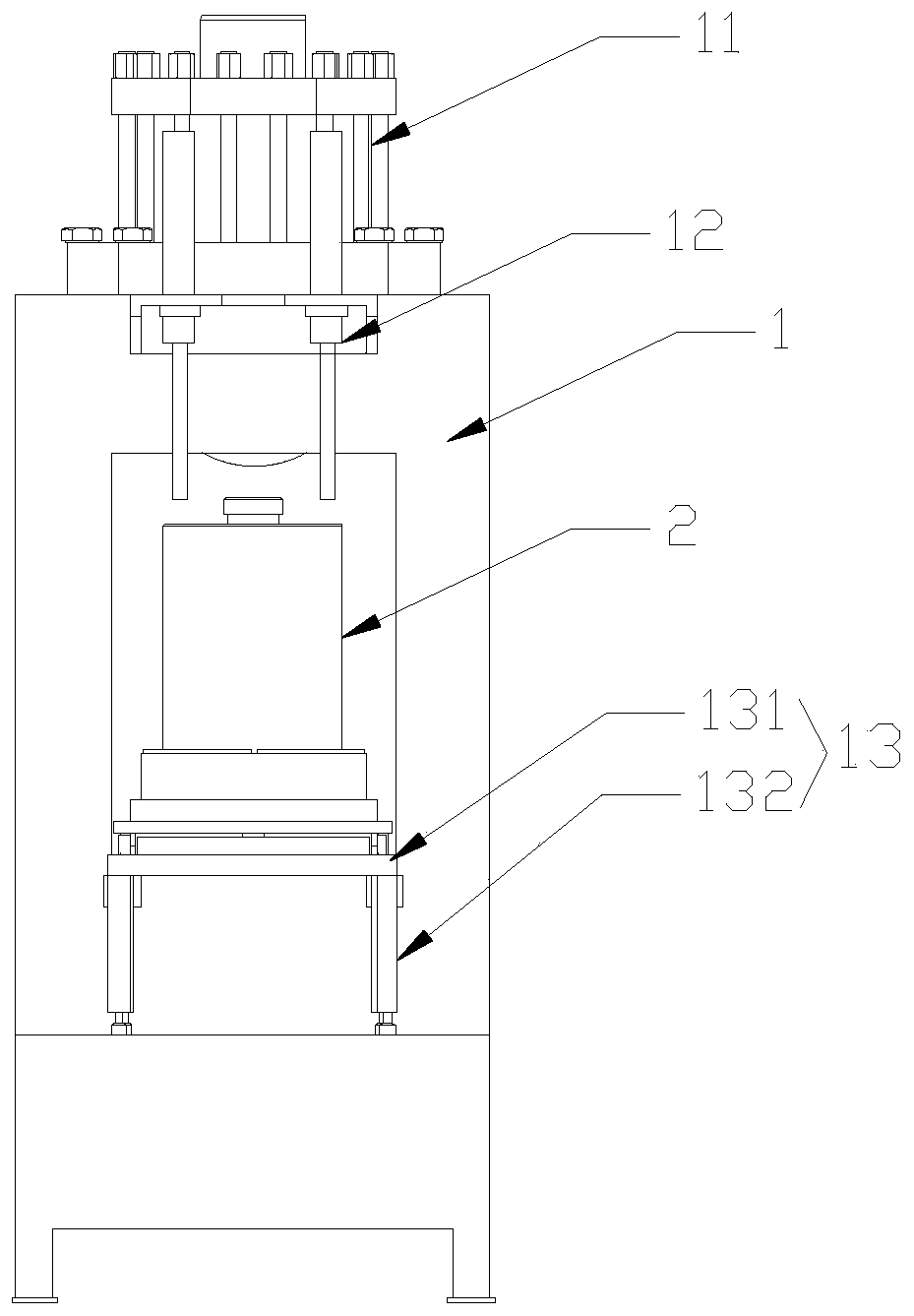

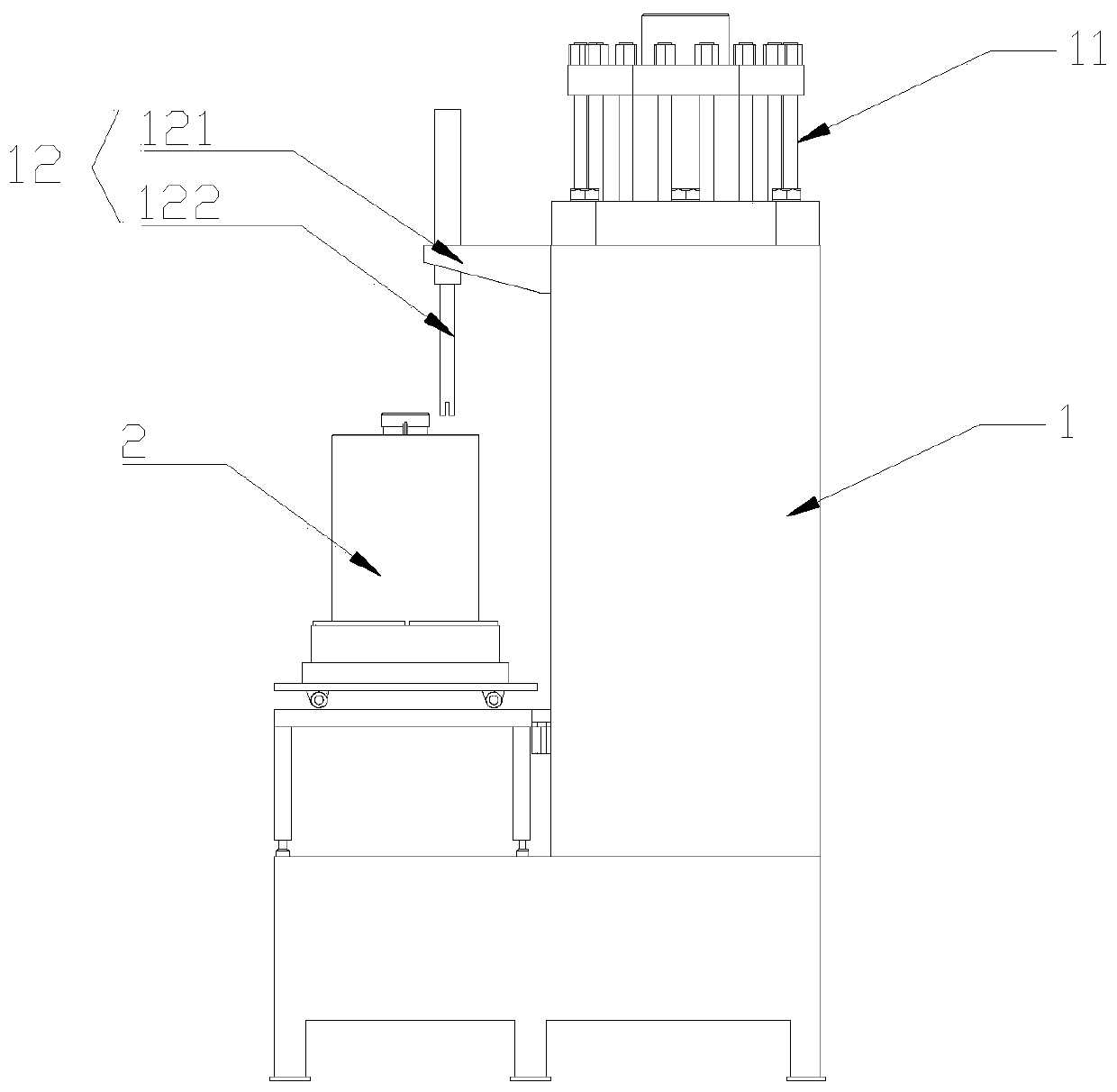

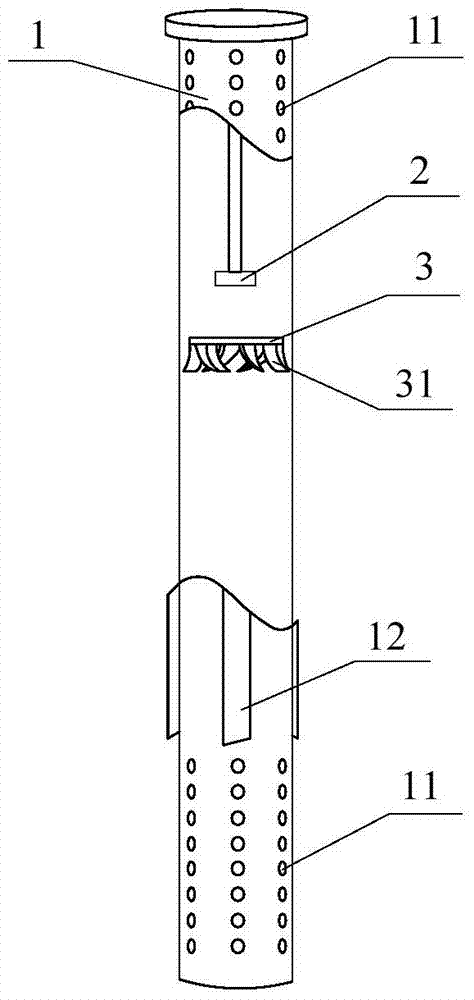

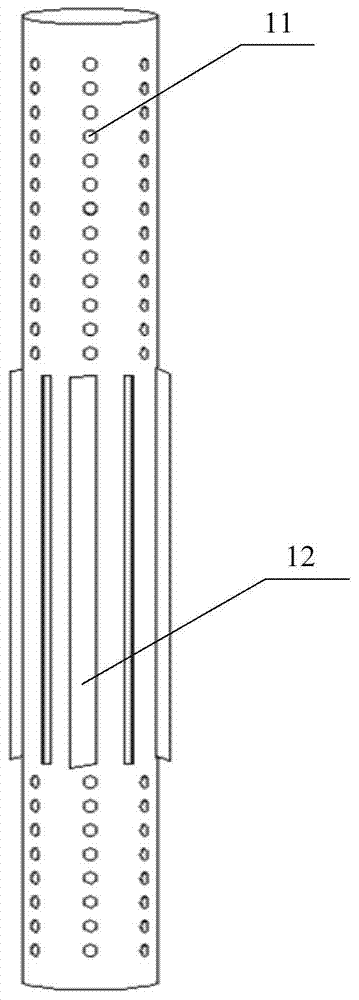

Triaxial experiment device for hydrate

InactiveCN110441153AComprehensive and more accurate detectionResolving inaccurate measurementsAnalysing solids using sonic/ultrasonic/infrasonic wavesFuel testingEngineeringExtensometer

The invention discloses a triaxial experiment device for a hydrate. The triaxial experiment device comprises a frame, a pressure chamber, an upper pressure assembly, a lower pressure assembly, a confining pressure assembly, a natural gas content detecting mechanism and a hydrate saturation measuring mechanism. The pressure chamber is installed in the frame and internally provided with a working chamber. The pressure chamber is provided with a confining pressure inlet-outlet, a gas inlet and a gas outlet. The upper pressure assembly and the lower pressure assembly are installed in the working chamber. The upper pressure assembly and / or the lower pressure assembly are connected with an axial extensometer. The confining pressure assembly is connected with the confining pressure inlet-outlet,and an object to be tested is provided with a radial extensometer. The natural gas content detecting mechanism respectively communicates with the gas inlet and the gas outlet. The hydrate saturation measuring mechanism communicates with the working mechanism. The triaxial experiment device measures displacement and deformation of the object to be tested by the axial extensometer and the radial extensometer, and detects content change and saturation of the natural gas in the object to be tested by the natural gas content detecting mechanism and the hydrate saturation measuring mechanism more comprehensively and accurately.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

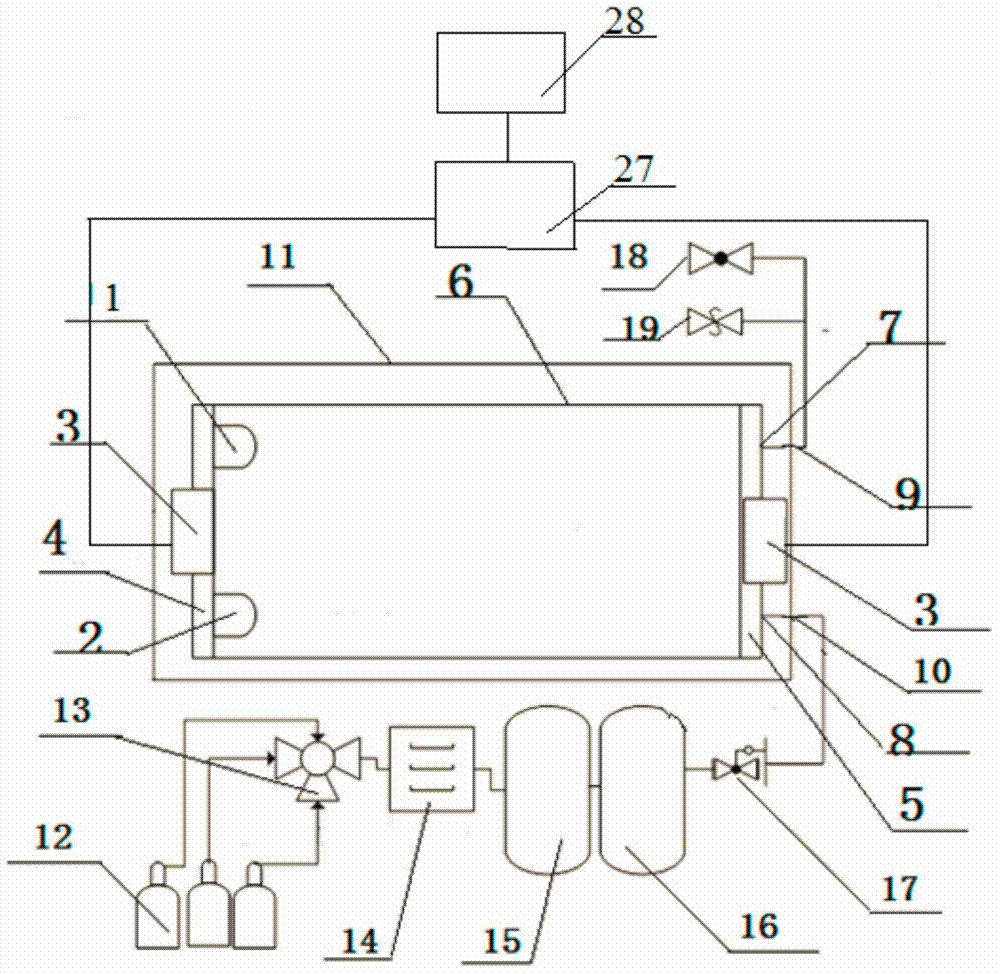

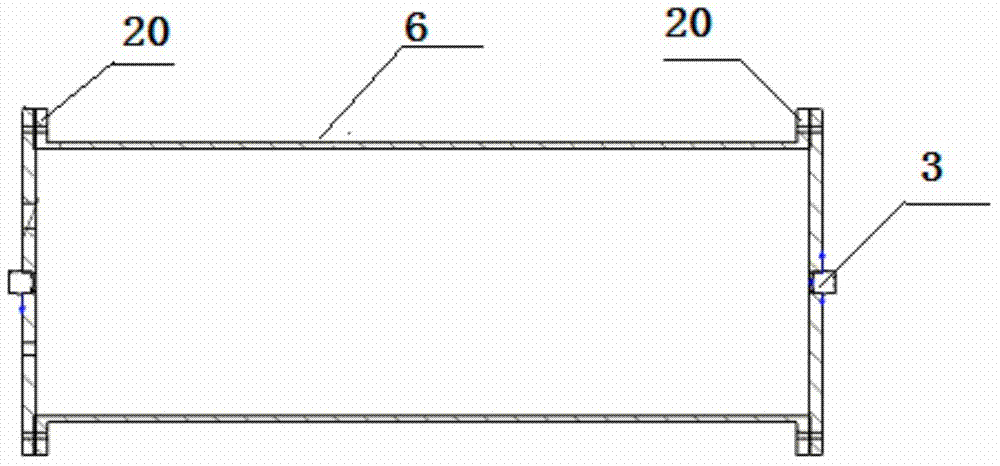

Multi-medium and temperature/pressure-adjustable ultrasonic propagation characteristic measuring device

ActiveCN103697998AAccurate measurementResolving inaccurate measurementsVelocity propogationSpeed of soundHigh pressure

The invention relates to a multi-medium and temperature / pressure-adjustable ultrasonic propagation characteristic measuring device. The influence from temperature, pressure and medium to ultrasonic propagation characteristics cannot be comprehensively considered by an existing ultrasonic propagation characteristic measuring device, and the measuring result is inaccurate. The multi-medium and temperature / pressure-adjustable ultrasonic propagation characteristic measuring device comprises a gas circuit switching device, a pressure adjusting device, a sound speed measuring device and a temperature adjusting device, wherein the gas circuit switching device is connected with one end of the pressure adjusting device, the other end of the pressure adjusting device is connected with the sound speed measuring device, and the sound speed measuring device is arranged in the temperature adjusting device. High-pressure gas can be input through the gas circuit switching device, enter into the sound speed measuring device through the pressure adjusting device and be used as the medium, and temperature adjusting can be carried out through the temperature adjusting device. The multi-medium and temperature / pressure-adjustable ultrasonic propagation characteristic measuring device disclosed by the invention has the advantages that the influence from the temperature, the pressure and the medium to the ultrasonic propagation characteristics can be comprehensively considered, and the measuring result is more accurate.

Owner:CHINA JILIANG UNIV

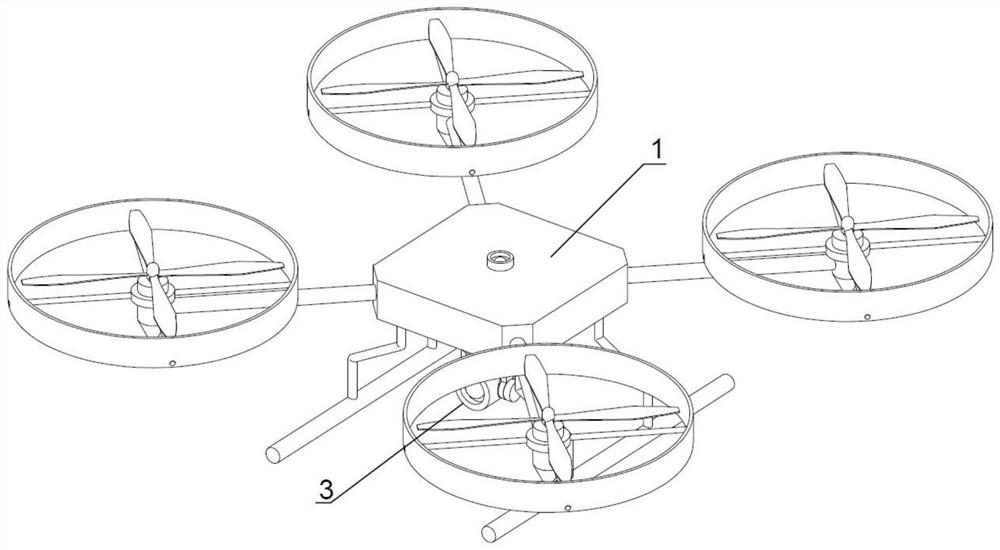

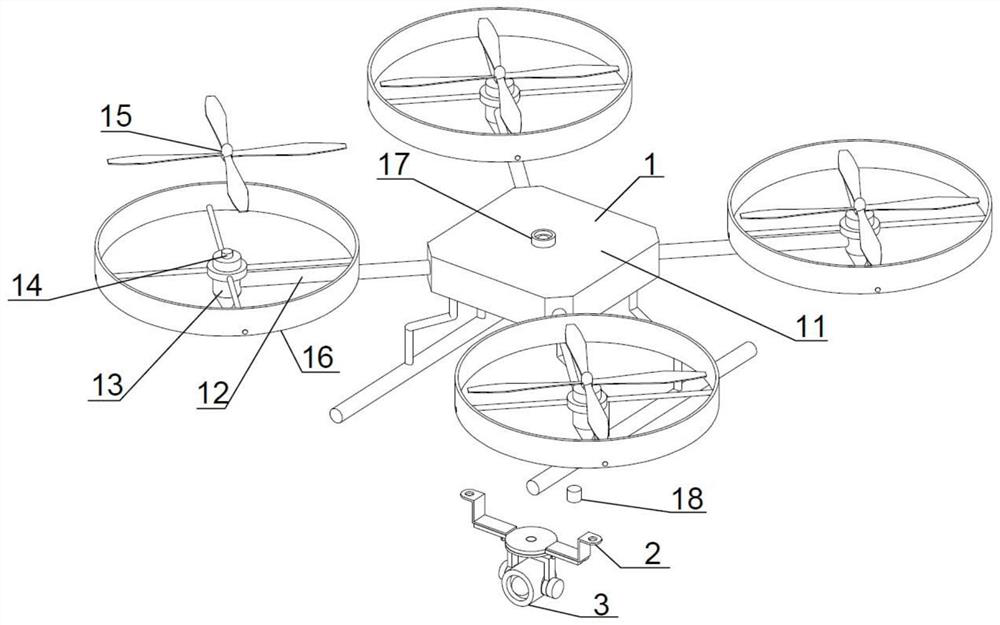

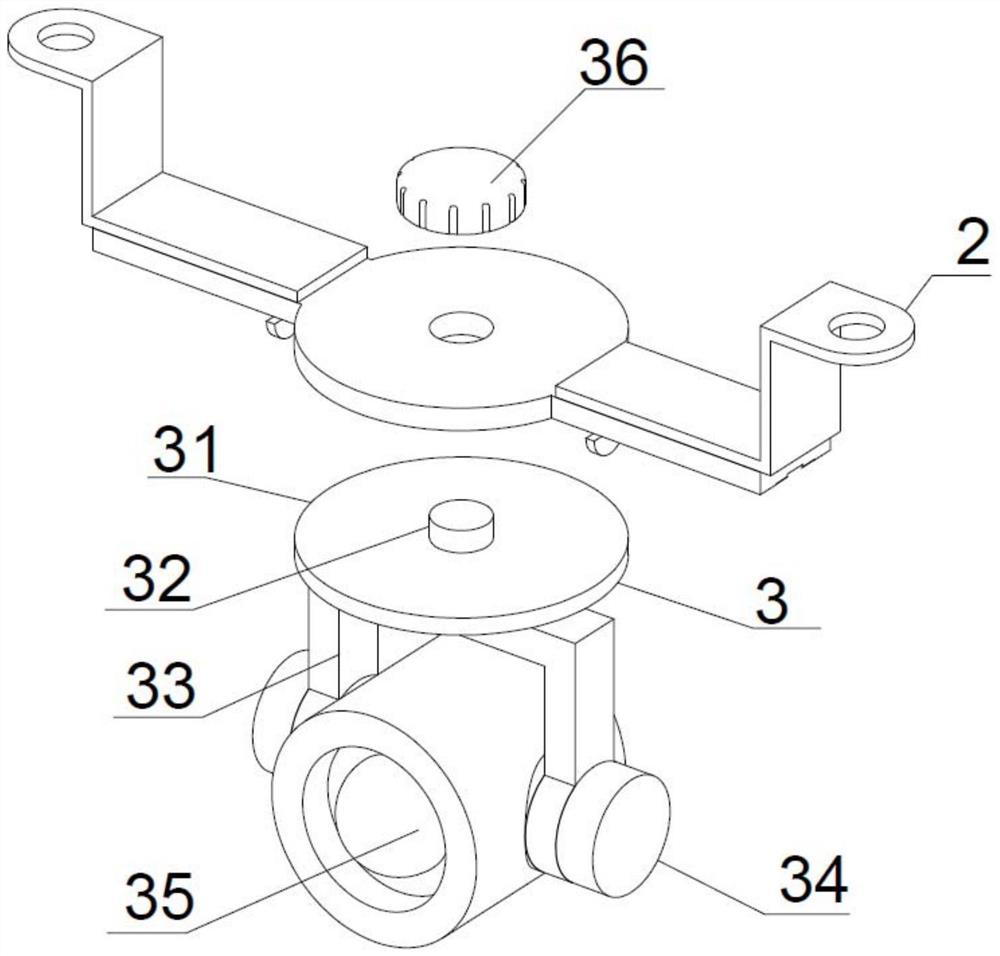

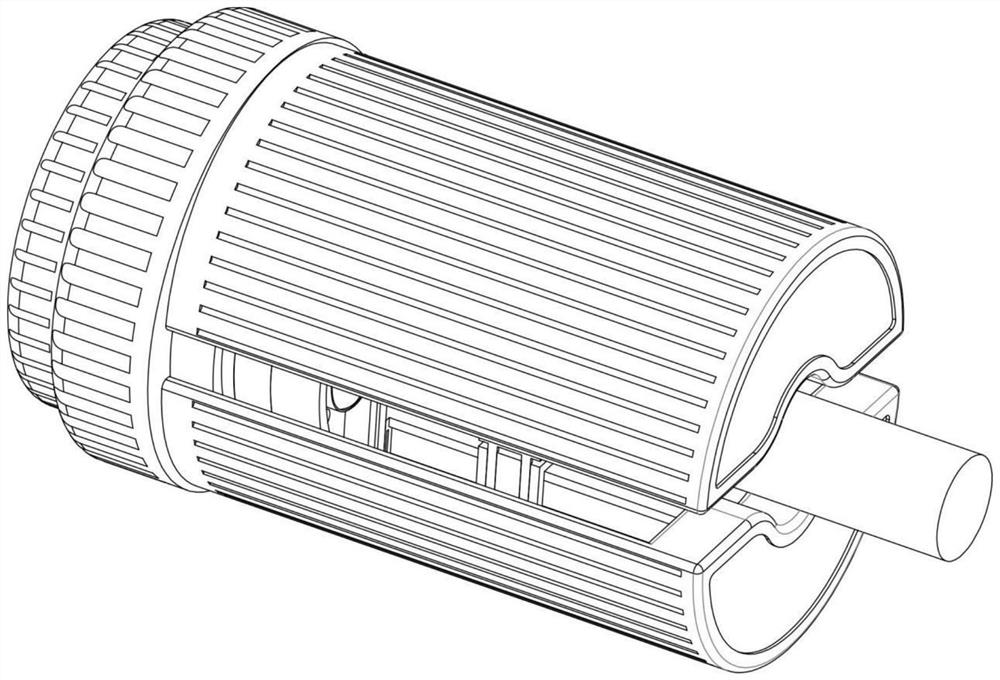

A measurement method and device for measuring the height of garden trees using drones

ActiveCN112097659BResolving inaccurate measurementsImprove adaptabilityUsing optical meansPicture interpretationFast measurementSimulation

The invention discloses a measuring device for measuring the height of trees in a garden by using an unmanned aerial vehicle. The present invention adopts an unmanned aerial vehicle measuring device with an image recognition algorithm added by an aerial camera and a recognizer. When in use, the recognition device and the internal program algorithm of the recognizer are used to quickly obtain the difference between the tree structure and the color of the external space. , after identification, the highest position in the image is obtained, and after being suspended at this position, the vertical height information of the tree is obtained by using the range finder combined with the information obtained by the height identification module inside the UAV, which effectively solves the existing problem. When measuring the height of trees, the measurement results are inaccurate by using tree shadow comparison, head-up auxiliary measurement and triangulation method, etc. The problem is that the structure is simple, the adaptability is high, and the measurement process is simple and fast.

Owner:GUANGDONG AIB POLYTECHNIC COLLEGE

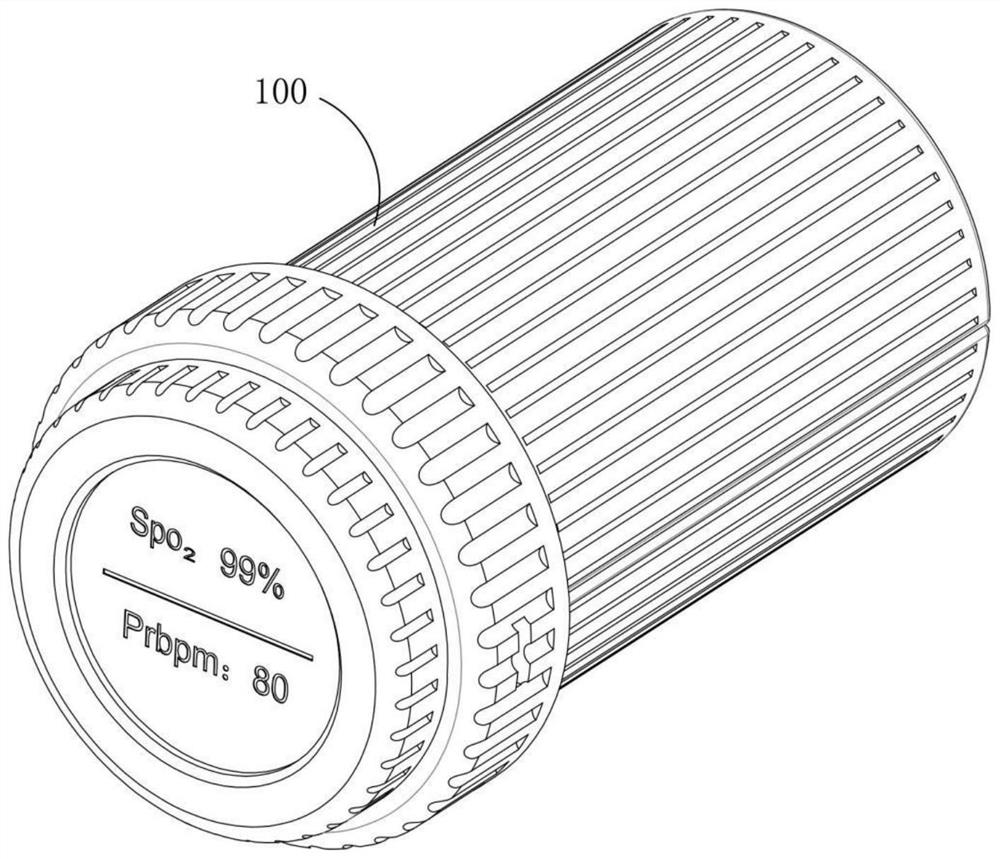

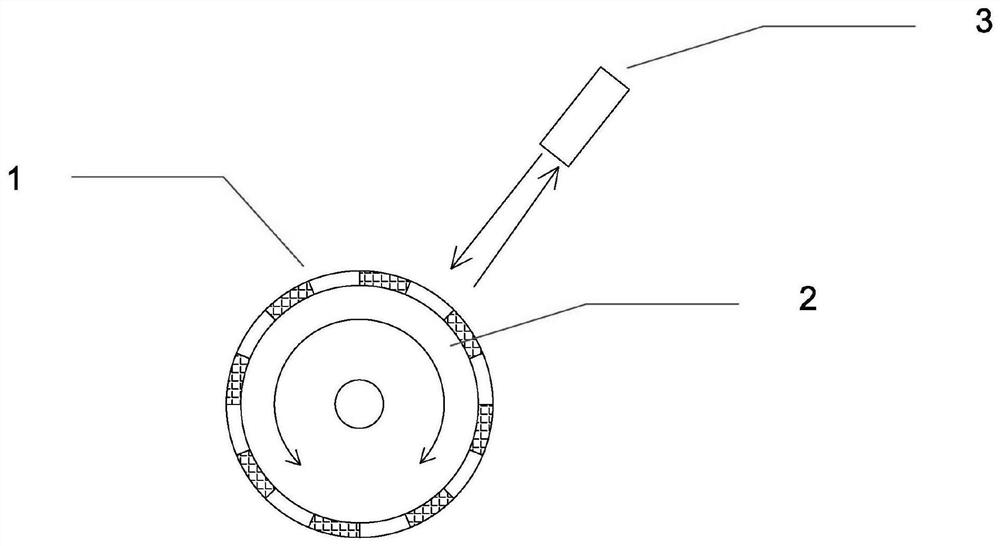

Surrounding scanning type longitudinal displacement multi-point sampling high-precision finger clamping oximeter

InactiveCN113616198ASolve the problem of finger clip oximeter fallingResolving inaccurate measurementsSurgerySensorsEngineeringSurgery

The invention discloses a surrounding scanning type longitudinal displacement multi-point sampling high-precision finger clamping oximeter. The oximeter comprises a finger clamping device and a multi-point sampling device; the finger clamping device is used for clamping a finger of a patient, and adjusting the size of an opening of a finger clamping area, used for clamping the finger of the patient, of the finger clamping device; the multi-point sampling device comprises a mounting frame, a rotating mechanism, a mounting mechanism, a first driving mechanism, a second driving mechanism, a distance sensor arranged on the mounting frame and a blood oxygen measuring element arranged on the mounting mechanism; the rotating mechanism is used for driving the mounting frame to rotate; the first driving mechanism is used for driving the blood oxygen measuring element to move close to the finger of the patient in the radial direction of a mounting sleeve; the second driving mechanism is used for driving the blood oxygen measuring element to move in the axial direction of the mounting sleeve; the distance sensor is used for sensing the length of the finger, stretching into two finger clamping plates, of the patient; and the blood oxygen measuring element is used for measuring blood oxygen of the finger of the patient.

Owner:深圳市亿米生命科技有限公司

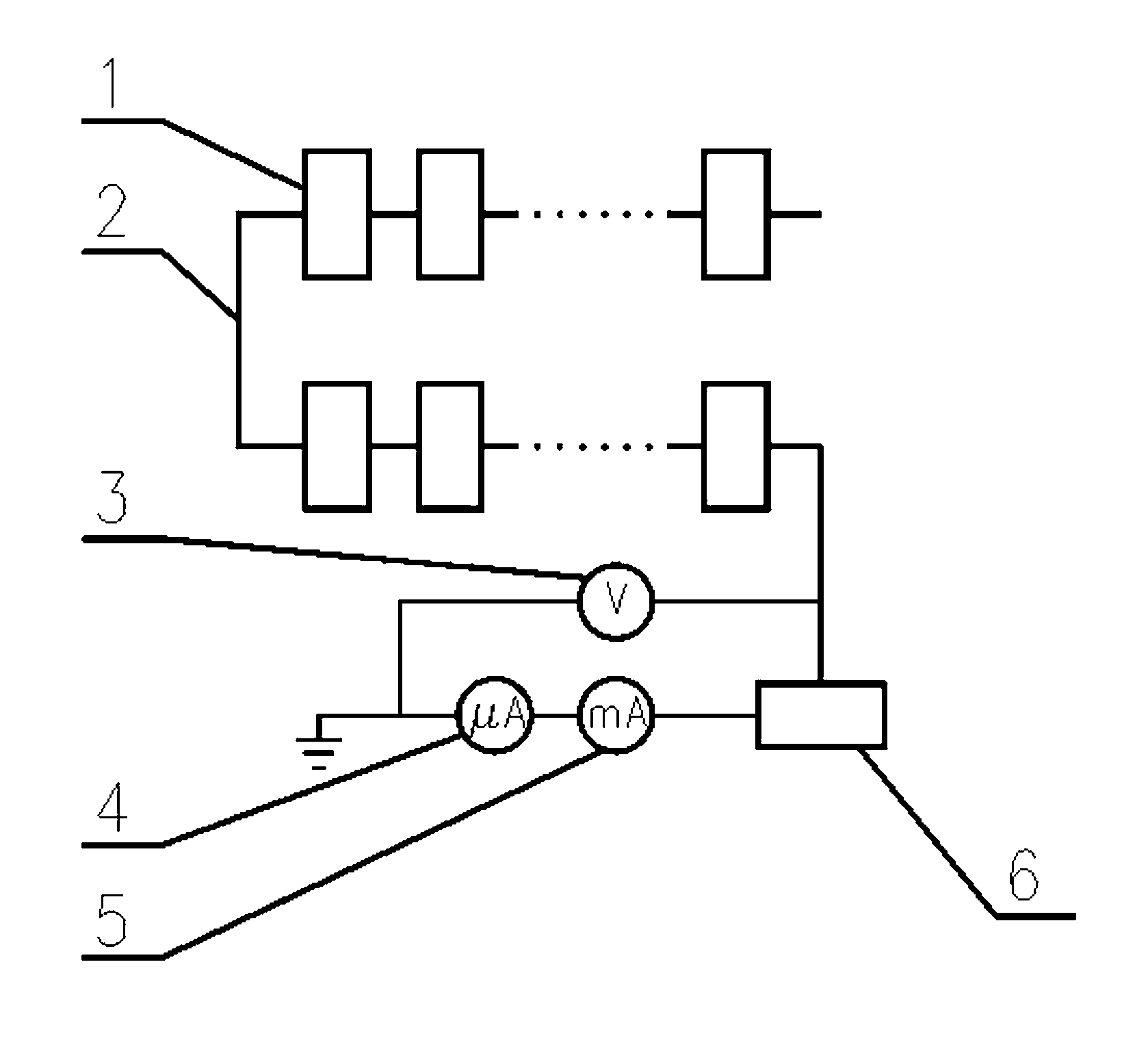

Aluminum electrolytic cell series ground insulation intensity measuring circuit

InactiveCN103105564AEffective assessmentResolving inaccurate measurementsTesting dielectric strengthINTERBUSDrain current

The invention relates to a measuring circuit, in particular to an aluminum electrolytic cell series ground insulation intensity measuring circuit which comprises an electrolytic cell and an interbus used for connecting the electrolytic cell. A voltage controlled power source is arranged between the electrolytic cell and the ground, a milliampere ampere meter is connected between the voltage controlled power source and the ground in series, a microampere ampere meter is connected between the milliampere ampere meter and the ground in series, and a voltmeter is connected between an adjustable end of the voltage controlled power source and the microampere ampere meter in parallel. The aluminum electrolytic cell series ground insulation intensity measuring circuit has the advantages that voltage is exerted between an electrolysis series and ground zero potential, detecting to voltage and a leakage current is conducted simultaneously, insulating intensity is calculated according to size and changing circumstances of ratio of the voltage and the leakage current, and accurate electrolytic series ground insulation intensity values are reached. The problem that measuring results are inaccurate caused by insufficient capacity of an insulating megger is solved effectively. The measuring circuit, in particular to an aluminum electrolytic cell series ground insulation intensity measuring circuit is close to actual circumstances after the electrolytic series is put in use, and therefore estimation to insulating intensity is effective.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

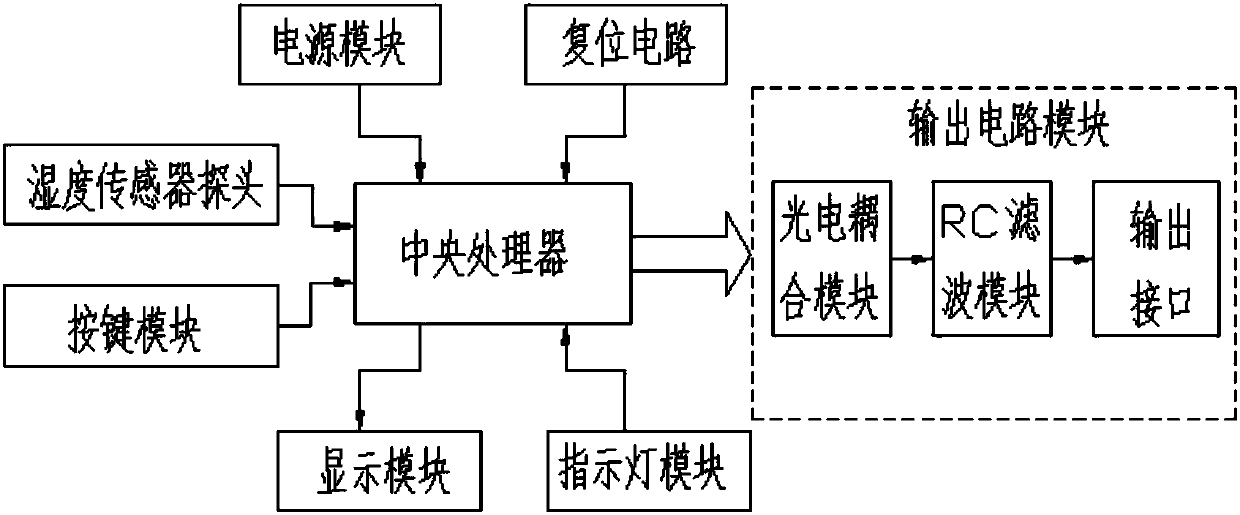

Humidity sensor for agriculture

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY

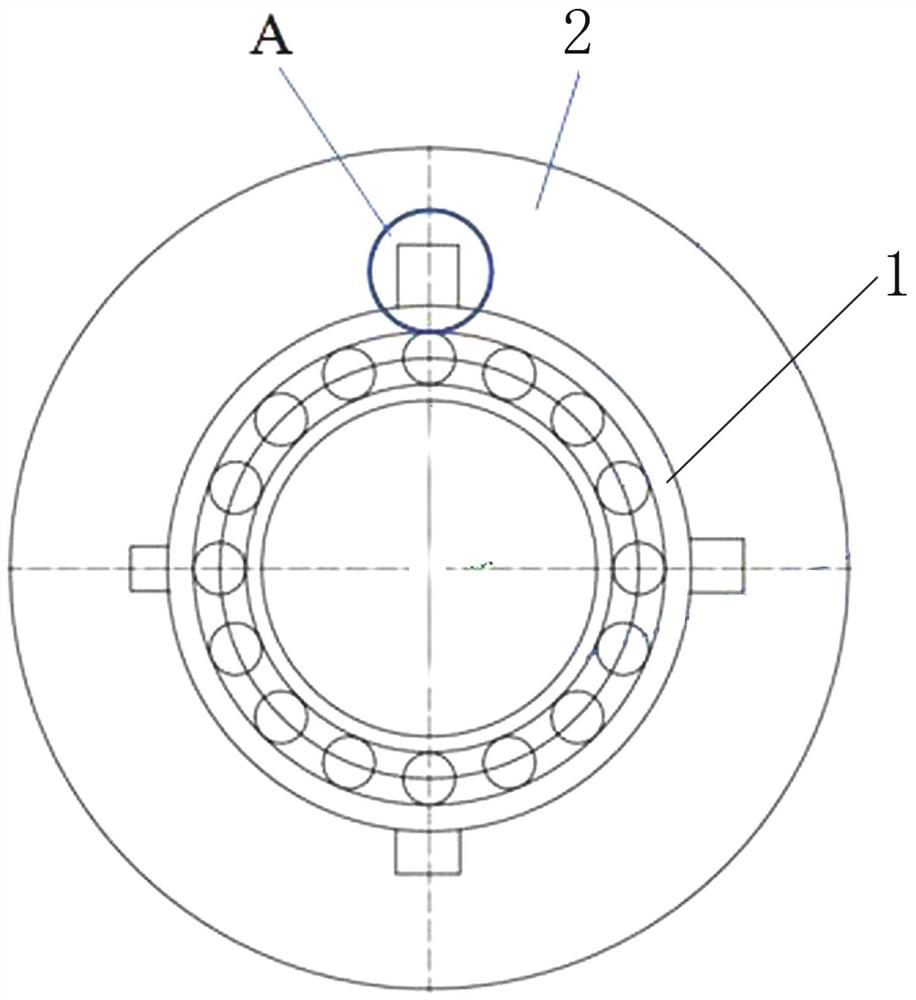

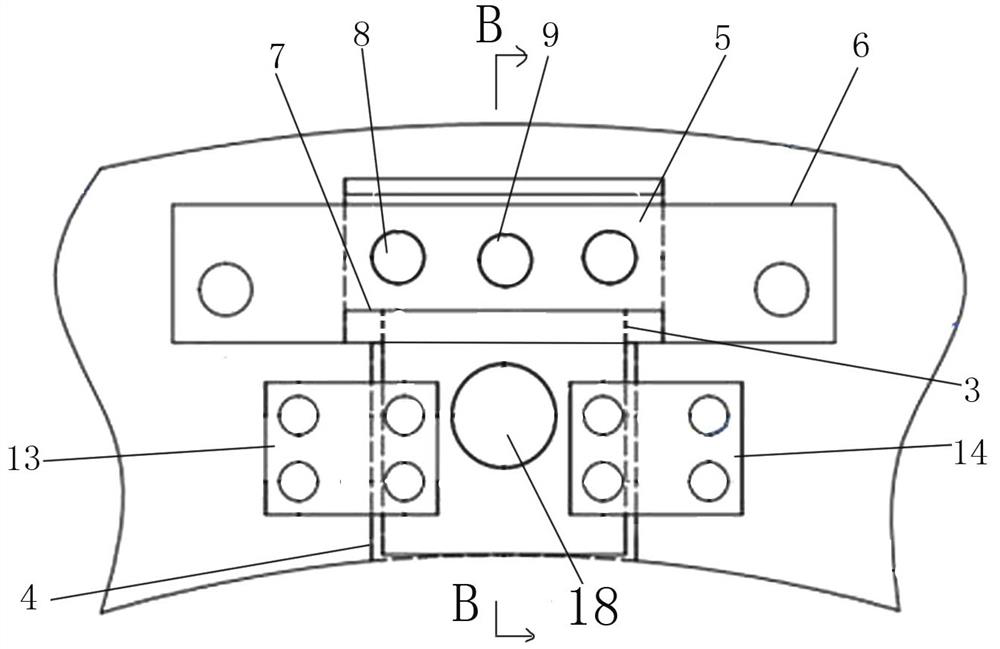

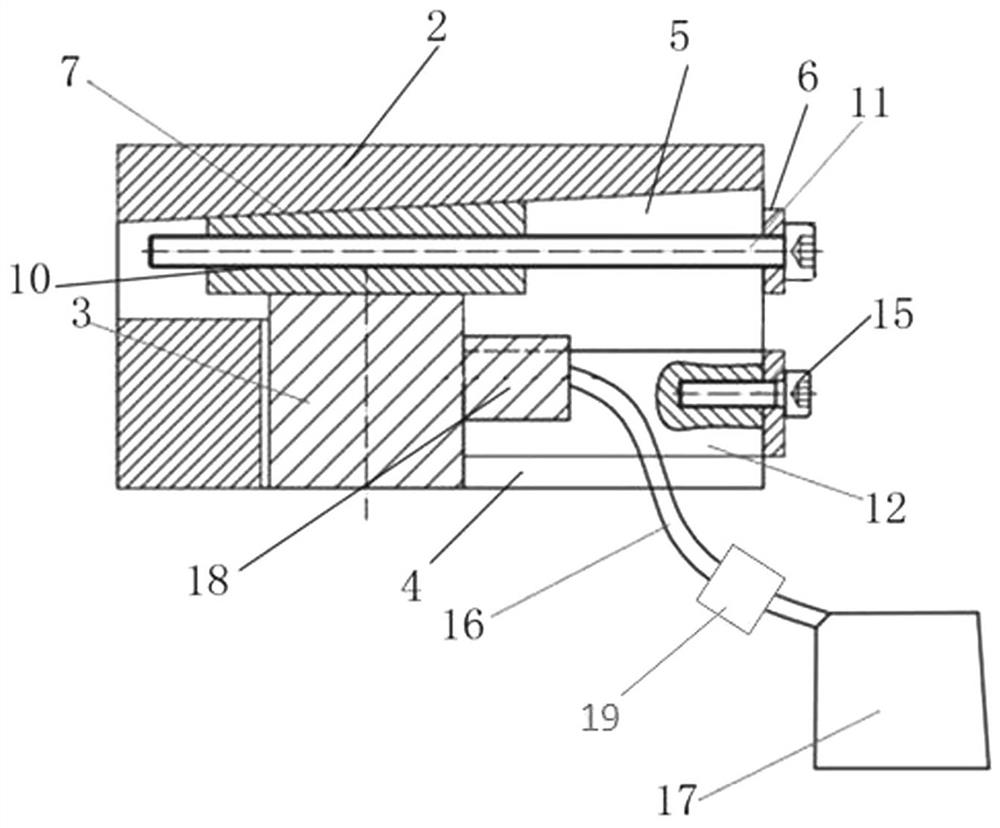

Motor bearing random dynamic load testing device and testing method

PendingCN114354190AResolving inaccurate measurementsAvoid situations where data cannot be detectedMachine bearings testingApparatus for force/torque/work measurementDynamic load testingElectric machine

The invention relates to a motor bearing, in particular to a motor bearing random dynamic load, and specifically relates to a motor bearing random dynamic load testing device and a testing method. In order to solve the problem that a random dynamic load test device and a test method of a motor bearing in the prior art are easy to cause inaccurate random dynamic load test of the motor bearing, the invention provides a novel random dynamic load test device of the motor bearing, which comprises a bearing bush provided with four positioning holes and an adjusting through hole, a dynamometer fixing assembly is arranged in each positioning hole; a dynamometer adjusting assembly is arranged in each adjusting through hole and comprises an adjusting block, the adjusting block is located between the upper end face of the piezoelectric dynamometer and the side wall of the upper portion of the adjusting through hole, and the face, making contact with the adjusting through hole, of the adjusting block is an inclined face. According to the testing device, the piezoelectric dynamometer can be in direct contact with the outer ring of the motor bearing, and the pretightening force can be adjusted through the inclined surface on the adjusting block, so that the testing result is more accurate.

Owner:CRRC YONGJI ELECTRIC CO LTD

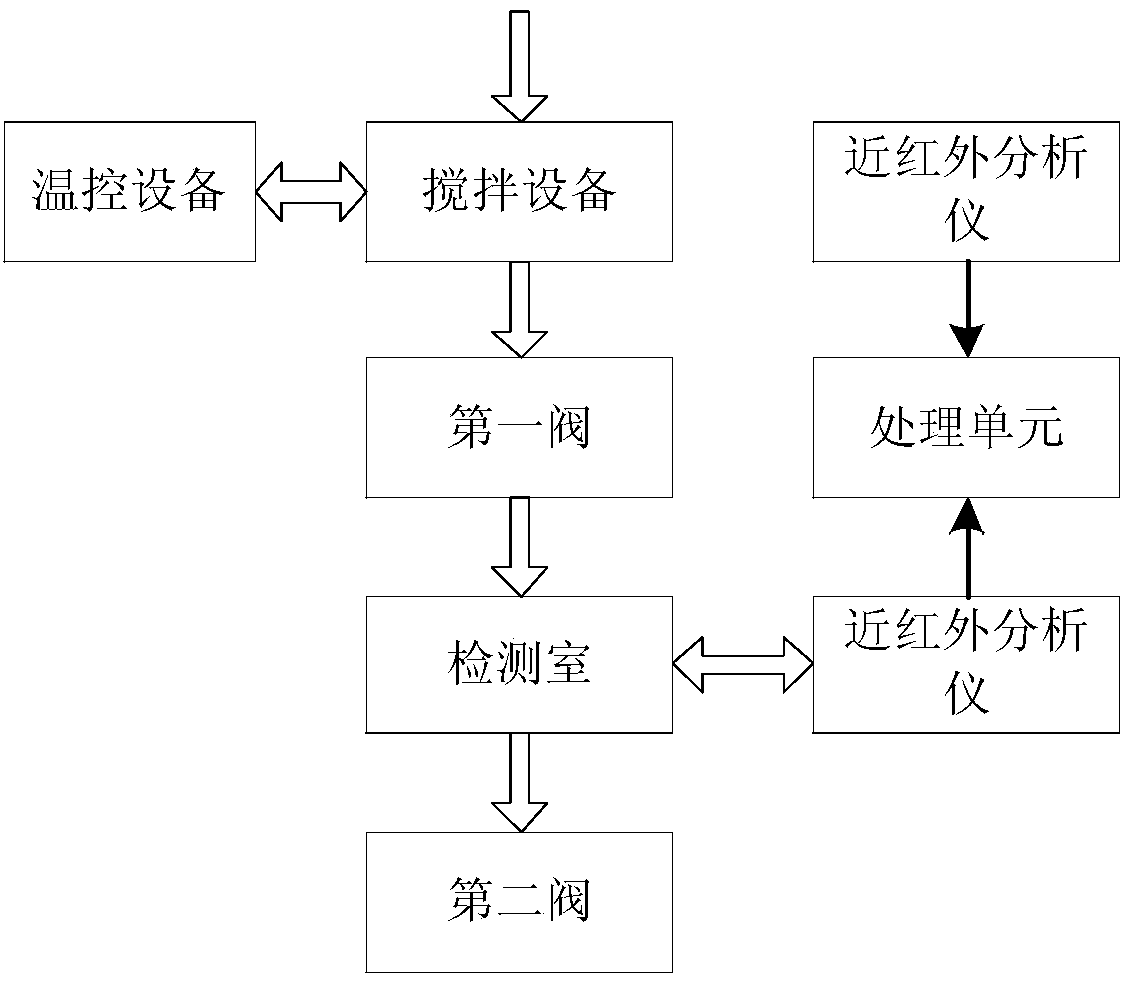

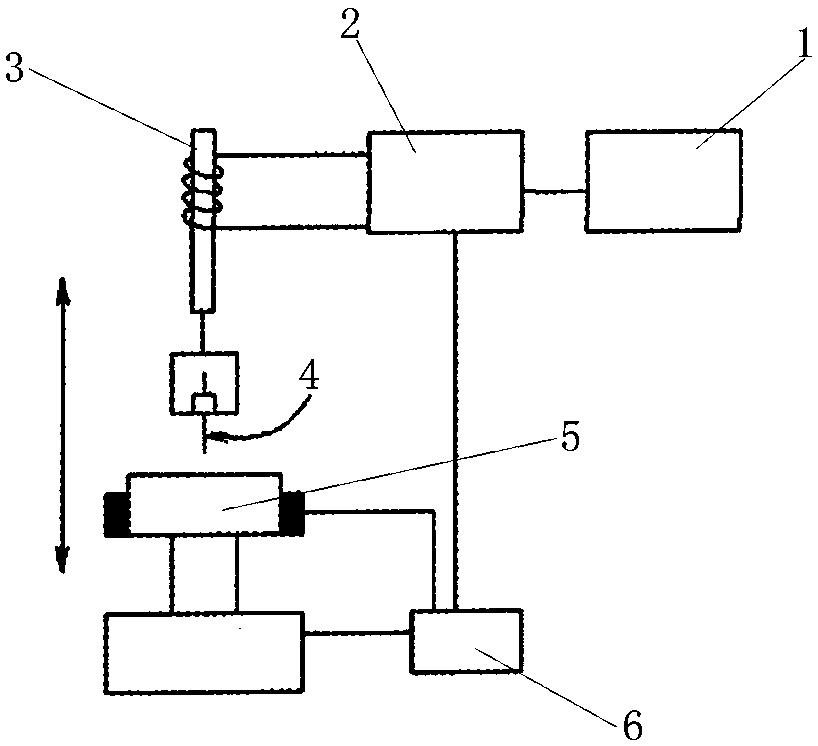

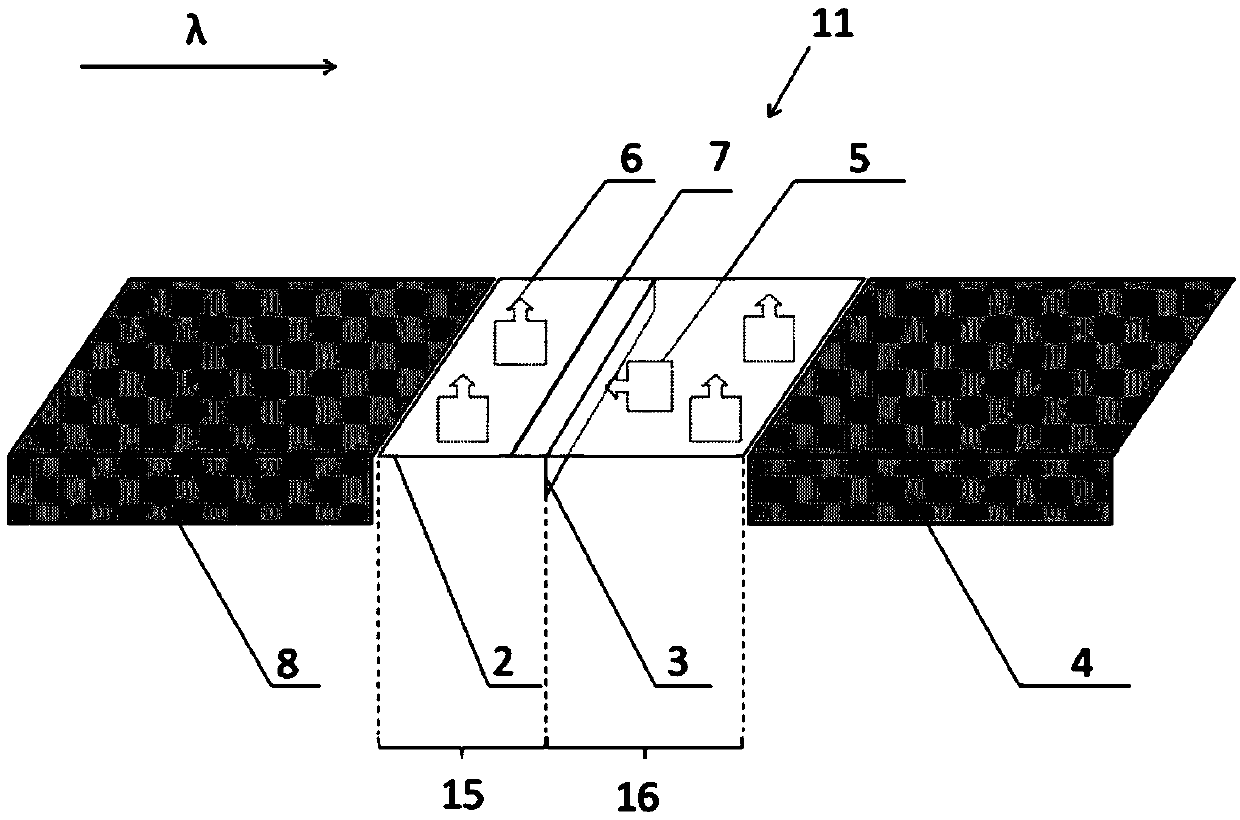

Near-infrared analysis system and method for solid material

PendingCN107831137ARange of moisture controlSolve the real problemPreparing sample for investigationMaterial analysis by optical meansTemperature controlSolid mass

The invention provides a near-infrared analysis system and method for a solid material. The near-infrared analysis system comprises a near-infrared analysis instrument, smashing equipment, temperaturecontrol equipment, stirring equipment, a first valve, a detection chamber and a second valve, wherein the smashing equipment is used for smashing the solid material, and conveying the solid materialto the stirring equipment; the temperature control equipment is used for temperature T in the smashing equipment to prevent moisture from condensing; the stirring equipment is used for mixing a powdery material conveyed by the smashing equipment; the first valve is arranged at the outlet of the stirring equipment; the detection chamber is used for containing the powdery material conveyed by the stirring equipment, and the near-infrared analysis instrument is used for detecting parameters of the powdery material in the detection chamber; the parameters comprise dry basis protein B1; the secondvalve is arranged at the outlet of the detection chamber. The near-infrared analysis system has the advantages of accurate detection and the like.

Owner:FOCUSED PHOTONICS +1

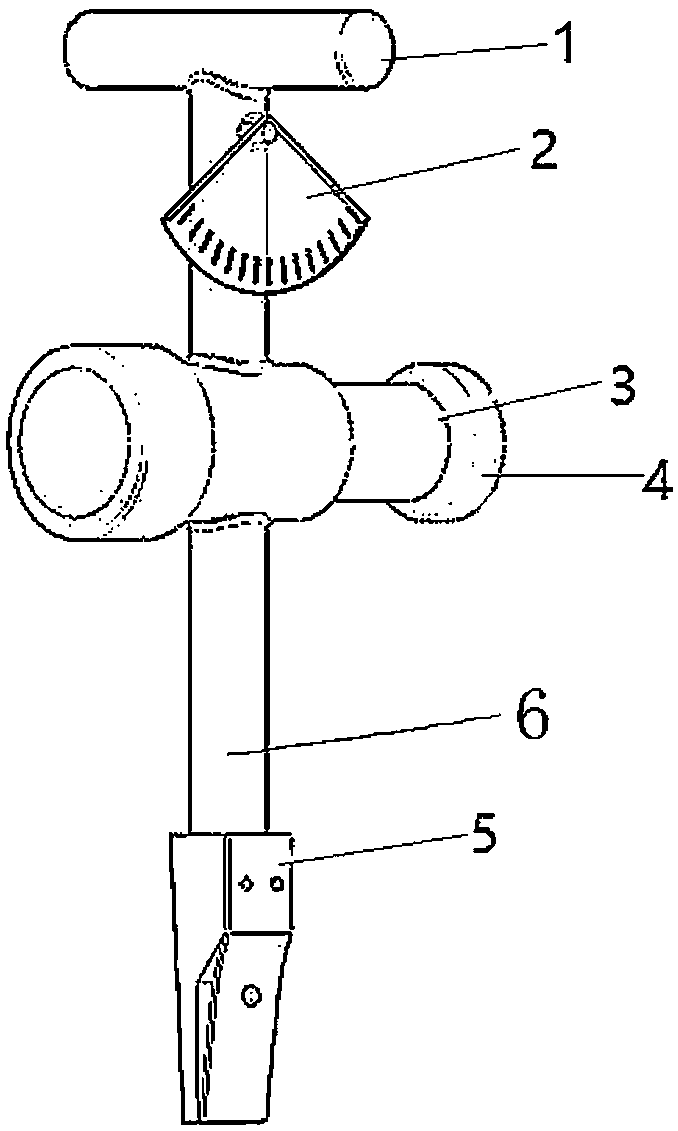

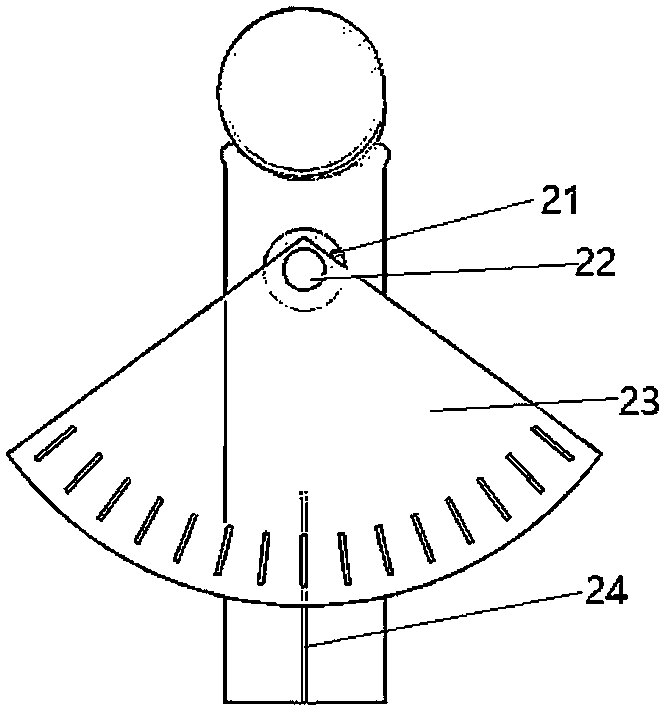

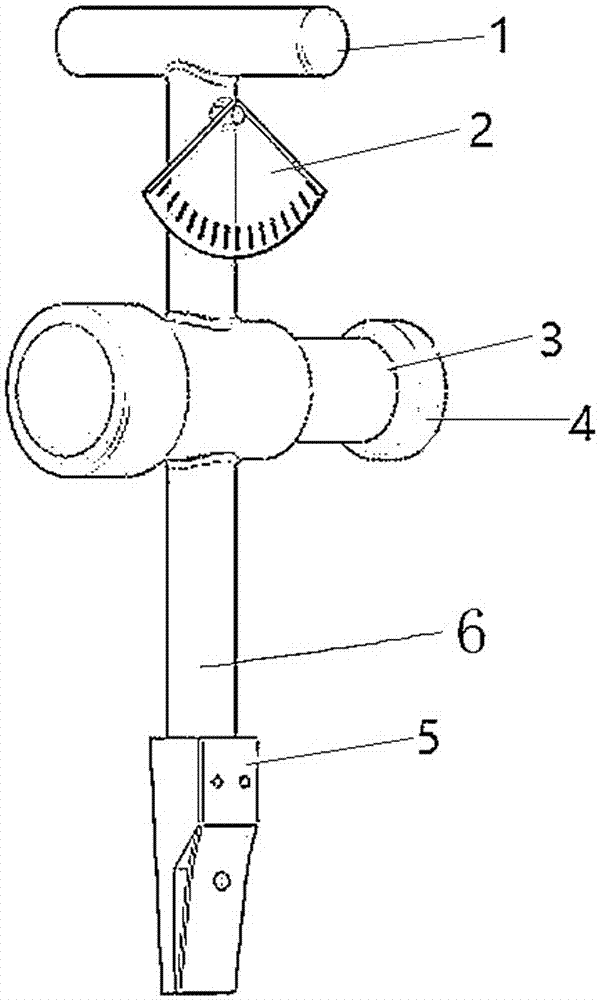

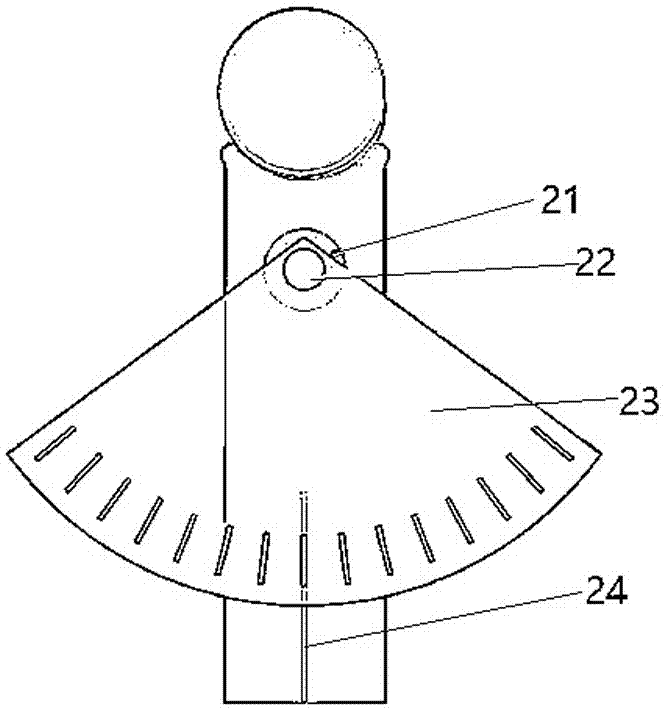

A sample clamping device for wettability experiment

The invention provides a test sample clamping device for a wettability experiment. The problem of an inaccurate measuring result caused by a relatively big error between a preset dipping angle and an actual dipping angle of a to-be-tested sample in the prior art is solved. The test sample clamping device for the wettability experiment comprises a hanging rod; a clamp for clamping the to-be-tested sample is arranged at the lower end of the hanging rod; a mark for cooperating with an angle disk to measure the dipping angle of the to-be-tested sample is arranged on the hanging rod; an angle control instrument for driving the hanging rod to swing to change the dipping angle of the to-be-tested angle is arranged on the hanging rod; the angle control instrument comprises a movable counter weight arranged on the hanging rod; and the moving direction of the counter weight is perpendicular to the swinging axis of the hanging rod. The clamping device is in a naturally droop state after clamping the test sample, the dipping angle is not changed and an inaccurate measuring result is not caused.

Owner:HENAN UNIV OF SCI & TECH

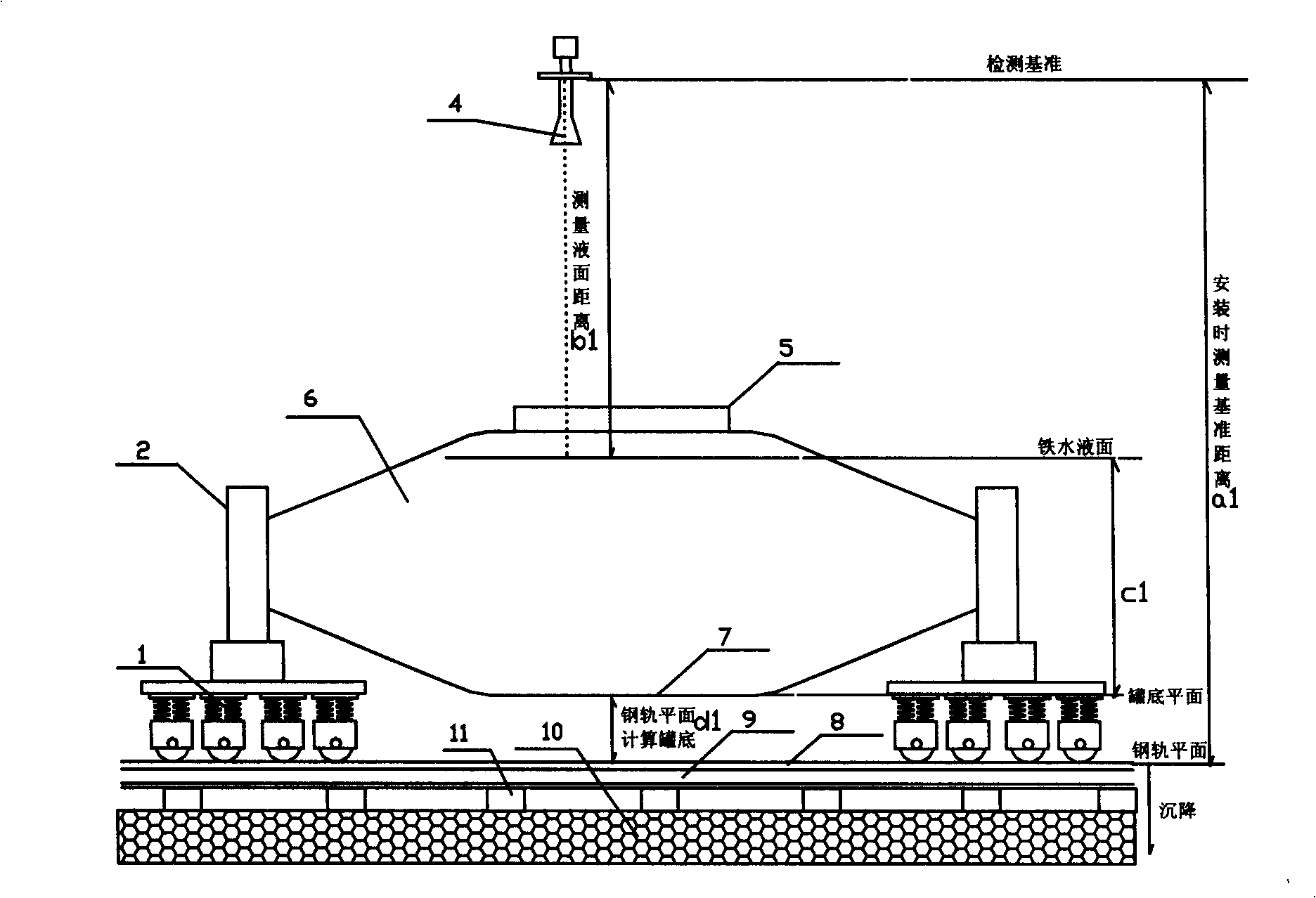

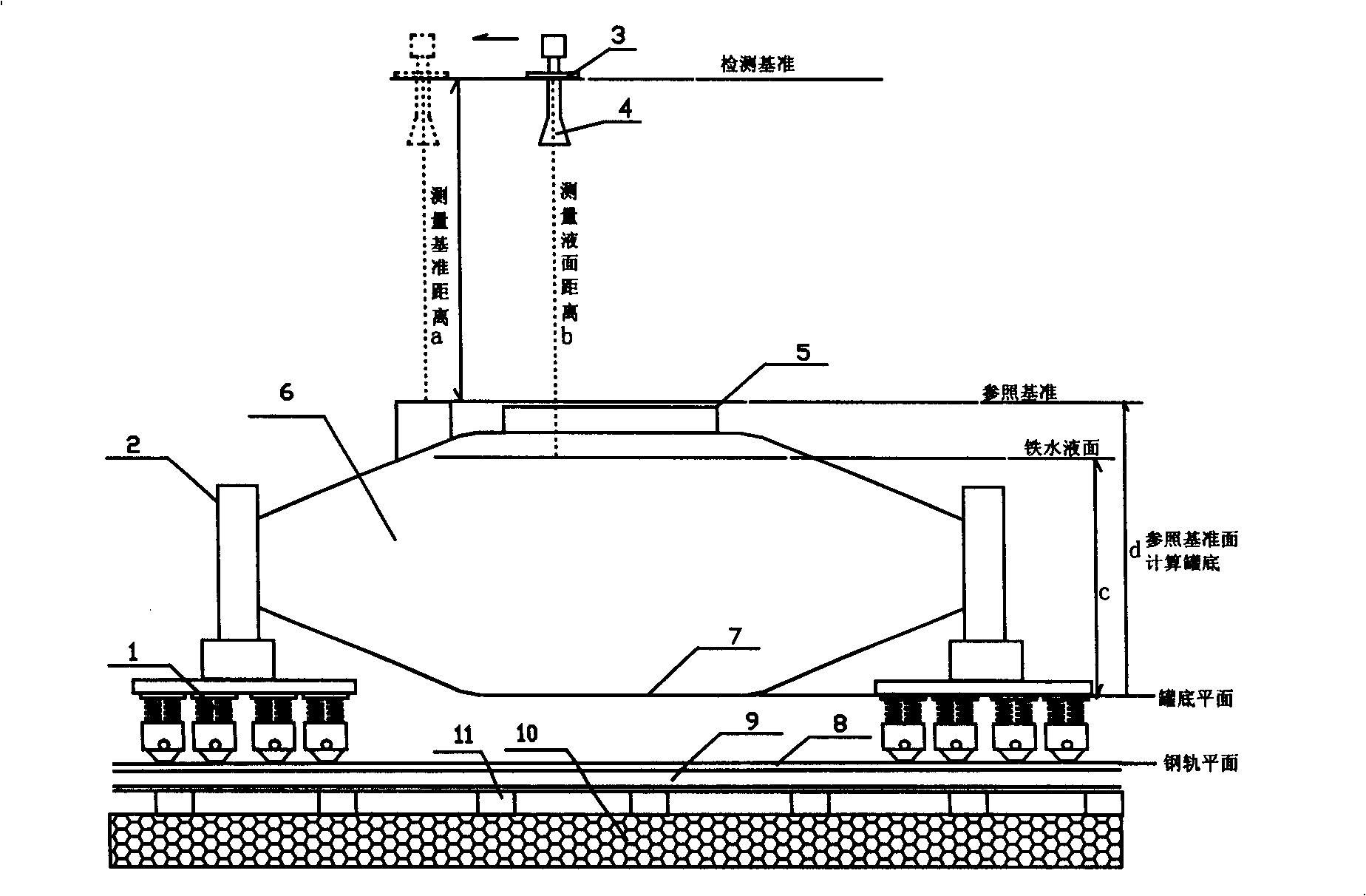

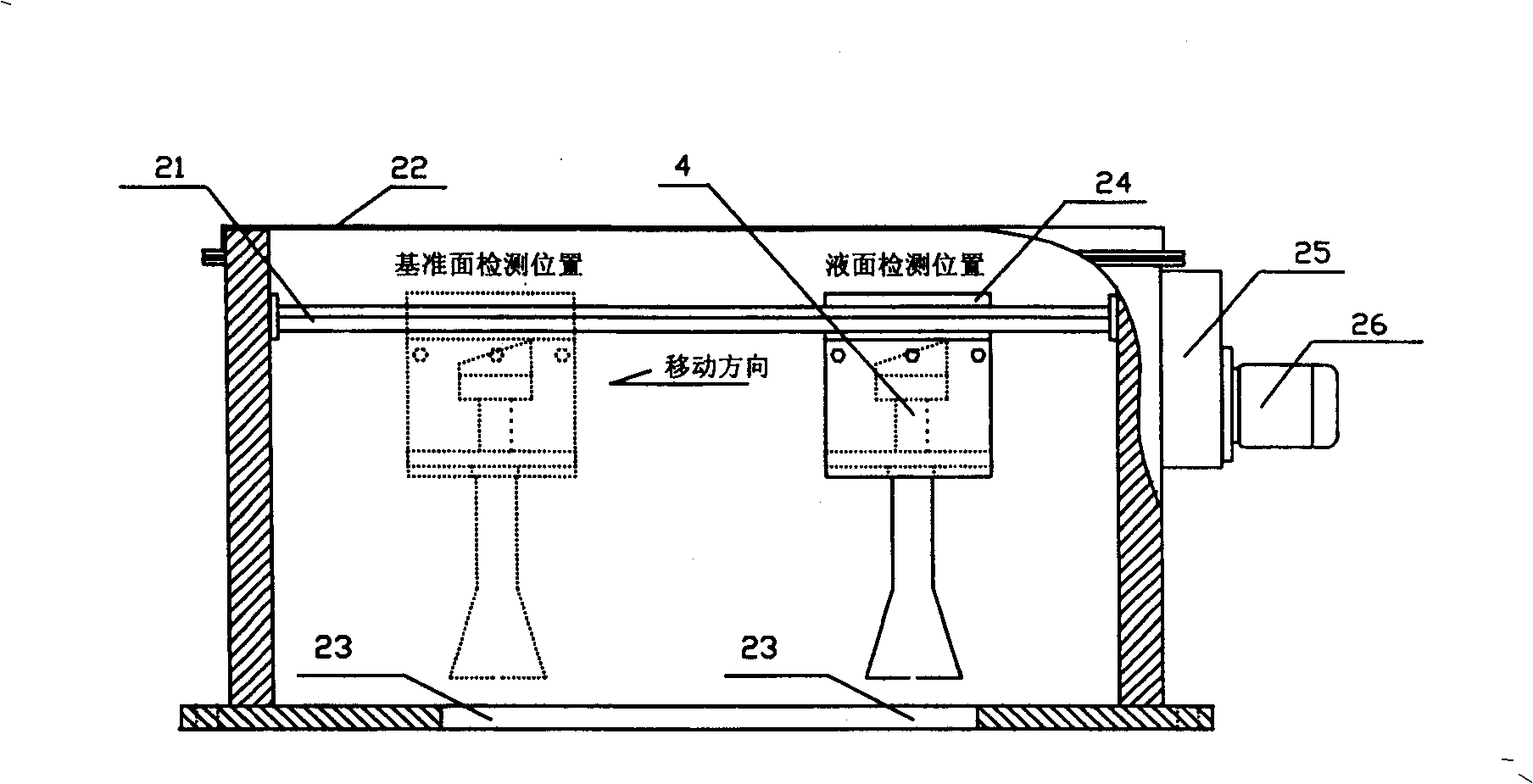

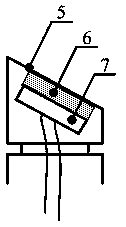

Torpedo tank car molten iron liquid surface measuring method and its device

InactiveCN100430698CAccurate measurementSimple structureMachines/enginesLevel indicatorsEngineeringOrbit

Owner:BAOSHAN IRON & STEEL CO LTD

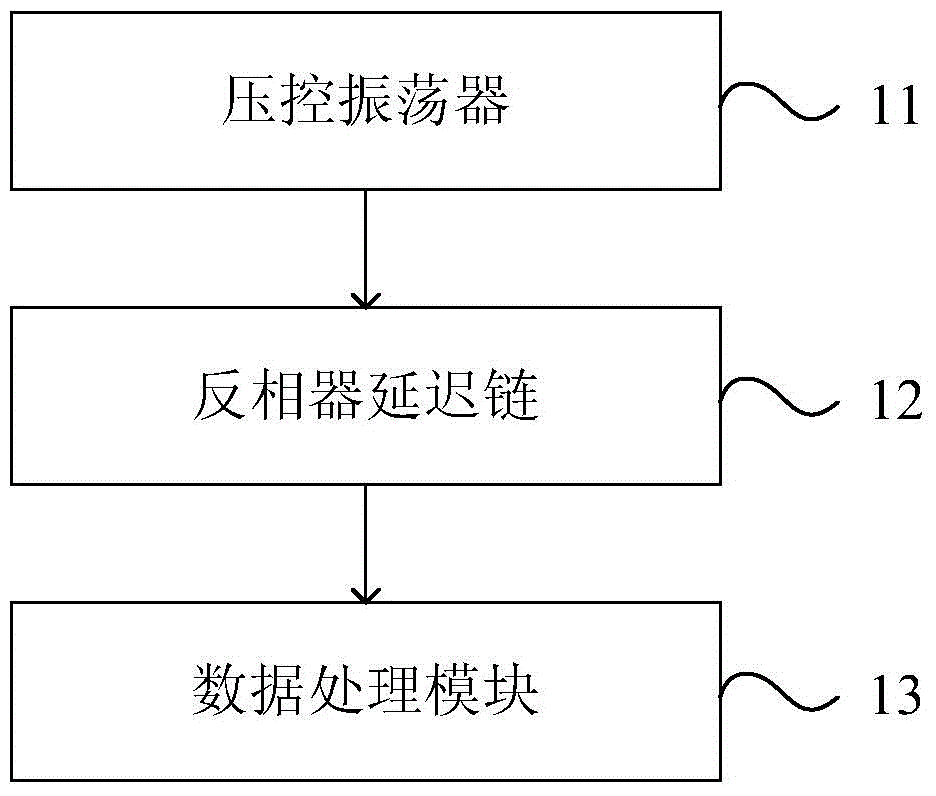

Device and method for measuring voltage drop of chip

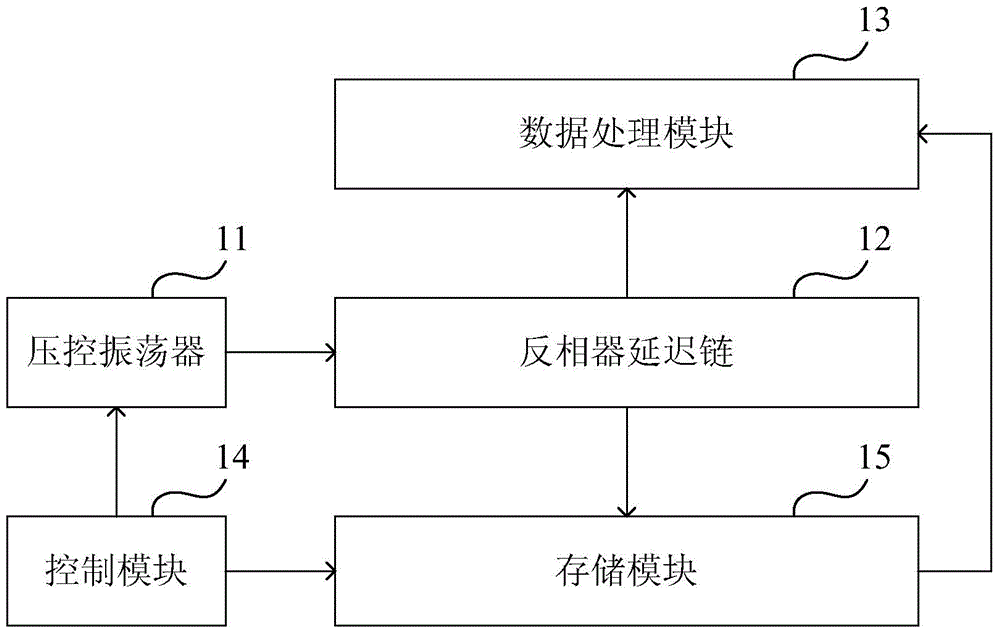

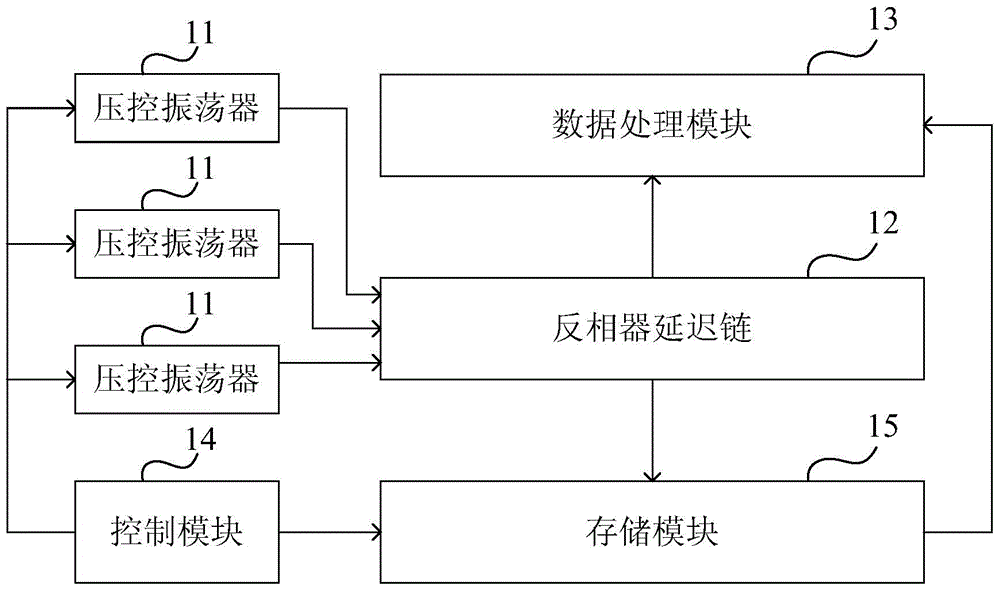

ActiveCN105988038AResolving inaccurate measurementsImprove accuracyCurrent/voltage measurementMeasurement deviceVoltage drop

The invention provides a device and method for measuring the voltage drop of a chip. The device provided by the invention comprises a voltage controlled oscillator arranged in a chip, an inverter delay chain, and a data processing module. The voltage controlled oscillator is used for generating a clock signal, when chip voltage drop is changed, and the frequency of the clock signal generated by the voltage controlled oscillator is changed with the change of the chip voltage drop. The inverter delay chain is connected to the voltage controlled oscillator and is used for measuring the frequencies of the clock signals generated by the voltage controlled oscillator when the chip is in different working states. The data processing module is connected to the inverter delay chain and is used for obtaining the change amount of the chip voltage drop according to the measured frequencies of the clock signals generated by the voltage controlled oscillator when the chip is in different working states. According to the device and the method, the problem of an inaccurate measurement result of the chip voltage drop caused by a condition that the time window of an inputted clock signal is uncertain in measuring the chip voltage drop in the prior art is solved.

Owner:LOONGSON TECH CORP

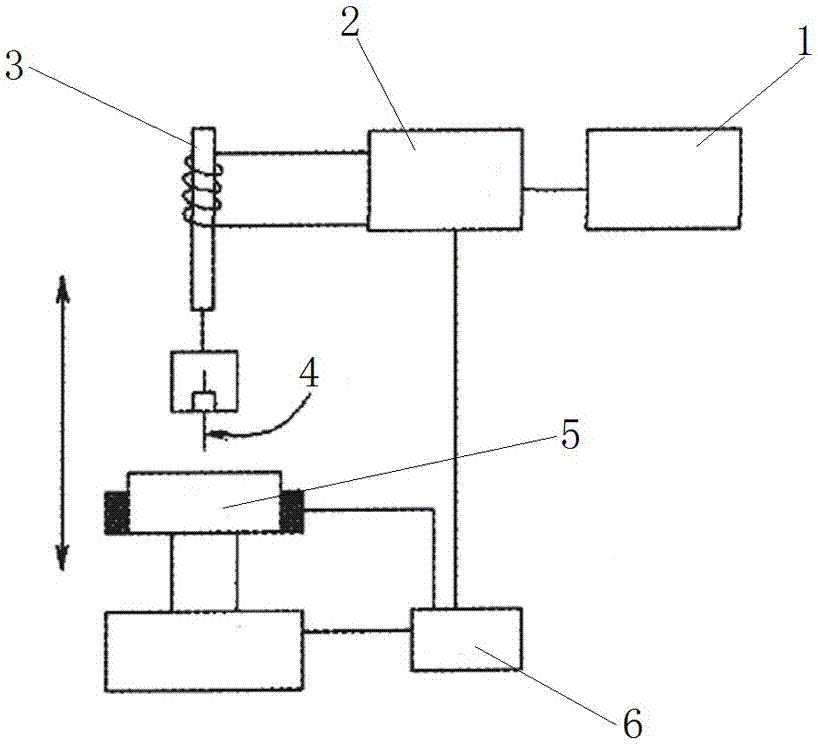

Test sample clamping device for wettability experiment

The invention provides a test sample clamping device for a wettability experiment. The problem of an inaccurate measuring result caused by a relatively big error between a preset dipping angle and an actual dipping angle of a to-be-tested sample in the prior art is solved. The test sample clamping device for the wettability experiment comprises a hanging rod; a clamp for clamping the to-be-tested sample is arranged at the lower end of the hanging rod; a mark for cooperating with an angle disk to measure the dipping angle of the to-be-tested sample is arranged on the hanging rod; an angle control instrument for driving the hanging rod to swing to change the dipping angle of the to-be-tested angle is arranged on the hanging rod; the angle control instrument comprises a movable counter weight arranged on the hanging rod; and the moving direction of the counter weight is perpendicular to the swinging axis of the hanging rod. The clamping device is in a naturally droop state after clamping the test sample, the dipping angle is not changed and an inaccurate measuring result is not caused.

Owner:HENAN UNIV OF SCI & TECH

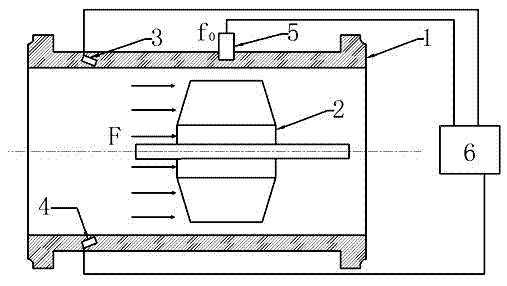

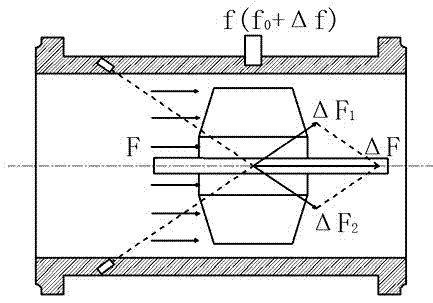

Meter coefficient self-correcting method of gas turbine flowmeter

InactiveCN102393236BHigh measurement accuracyResolving inaccurate measurementsTesting/calibration apparatusEngineeringMeasurement precision

The invention discloses a meter coefficient self-correcting method of a gas turbine flowmeter. An electromagnetic coil is embedded into a flowmeter shell, a fixed detection force is applied to equivalently simulate the axial impact force of fluid on turbine blades according to a set interval time, frequency variation corresponding to the detection force is calculated according to the frequency measured by a flow detector, and a new meter coefficient is calculated by using the relationship between flow and the frequency variation, thus calculating a flow measuring value according to the updated meter coefficient. The method solves the problem of inaccurate measurement results due to meter coefficient drifting caused by scaling, corrosion, abrasion, physical property change of fluid medium and the like. With the on-line self-diagnosis function, the method improves the measurement accuracy of the gas turbine flowmeter, avoids the inconvenience in detachment, calibration and the like of the flowmeter at regular intervals, prolongs the service life of the flowmeter, broadens the application area of the flowmeter and enables the flowmeter to be still normally available in a situation that cleanness of detected gas is lower.

Owner:ZHEJIANG UNIV

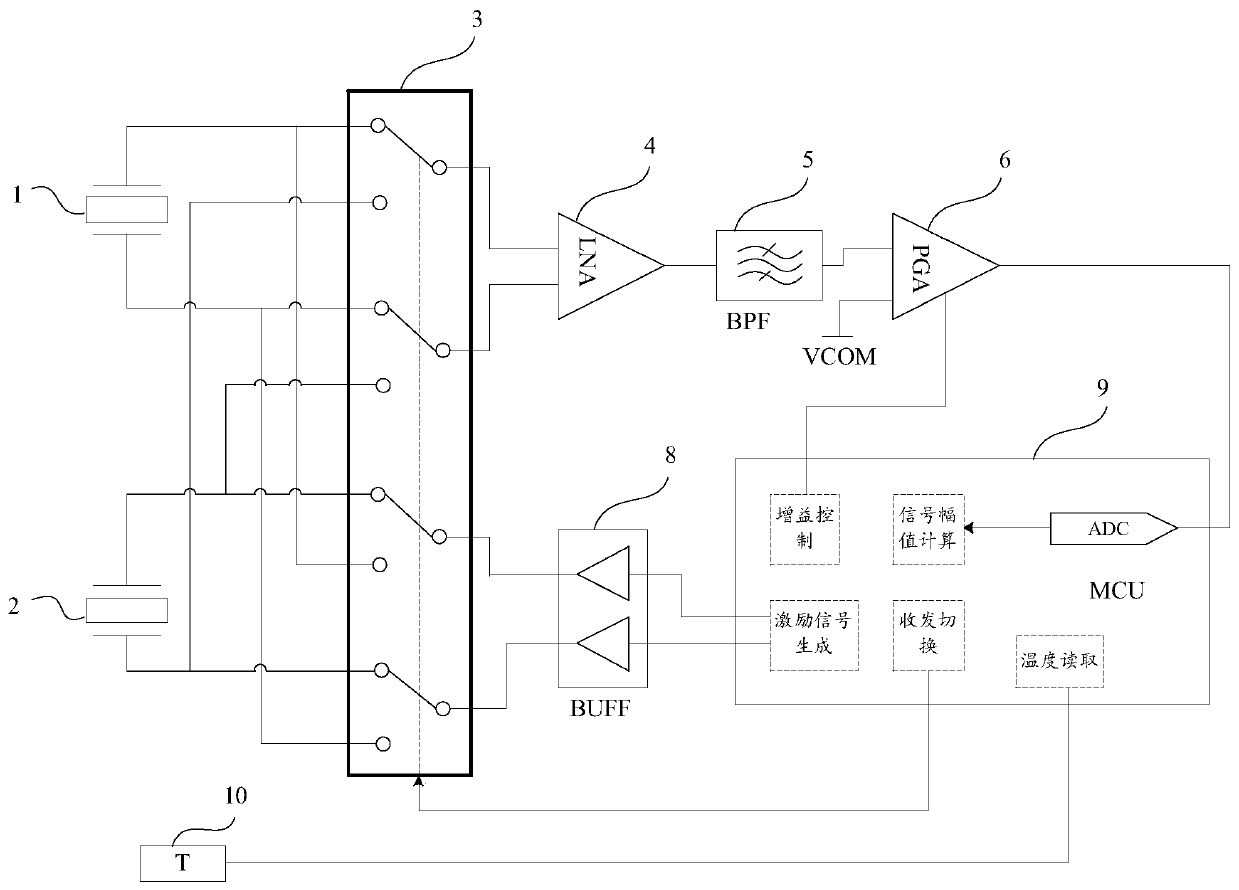

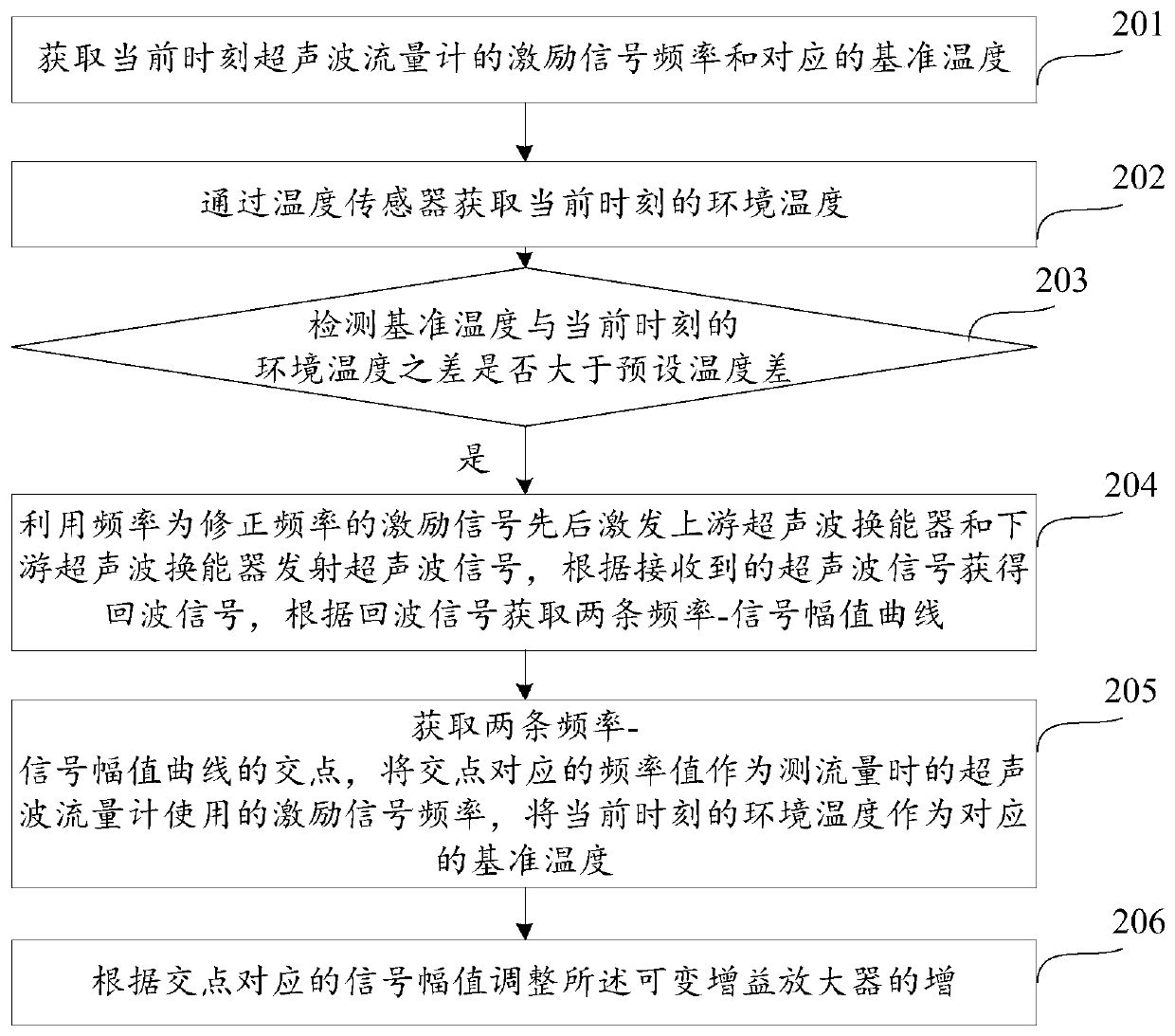

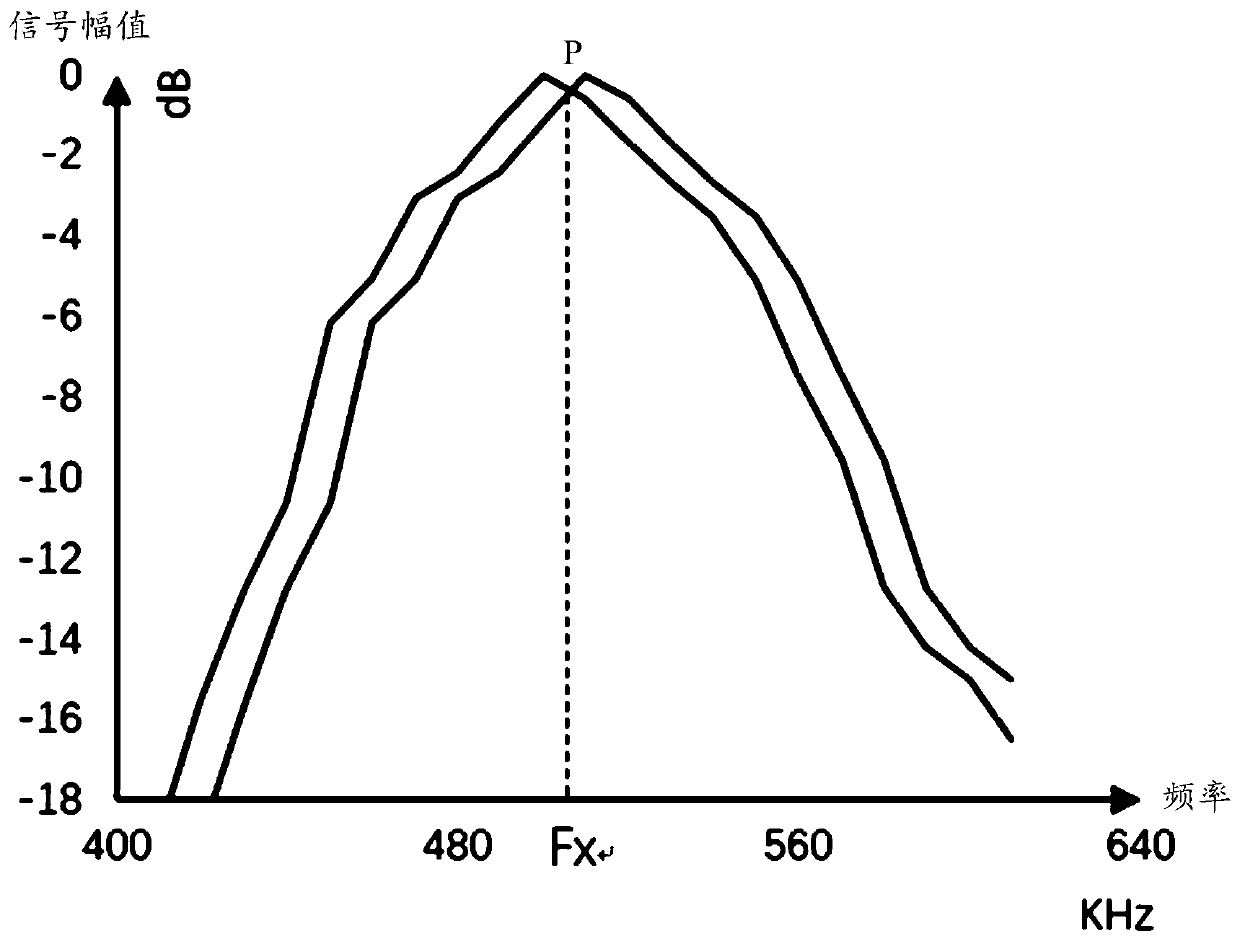

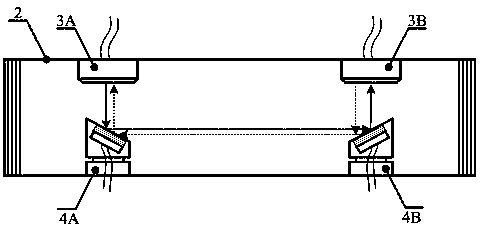

Correction Method of Ultrasonic Flowmeter with Frequency Drift Correction Function

ActiveCN110243421BResolving inaccurate measurementsHigh measurement accuracyVolume/mass flow measurementBandpass filteringLow noise

The invention discloses an ultrasonic flowmeter with a frequency drift correction function and a correction method thereof, and belongs to the field of ultrasonic flowmeters. The ultrasonic flowmeter comprises an upstream transducer, a downstream transducer, a signal change-over switch, a low noise amplifier, a bandpass filter, a variable gain amplifier, a microcontroller, a temperature sensor and an excitation signal buffer; the upstream transducer and the downstream transducer are separately connected with the signal change-over switch, and the signal change-over switch is separately connected with the low noise controller and the excitation signal buffer; the low noise amplifier is connected with the bandpass filter, the bandpass filter is connected with the variable gain amplifier, and the variable gain controller is connected with the microcontroller; the microcontroller is connected with the excitation signal buffer and the temperature sensor. The problem that the existing ultrasonic flowmeter is inaccurate in measurement result due to the resonant frequency drift of the transducers is solved; and the effects of improving the measurement accuracy of the time difference of the ultrasonic flowmeter and improving the measurement accuracy of the ultrasonic flowmeter are achieved.

Owner:智驰华芯(无锡)传感科技有限公司

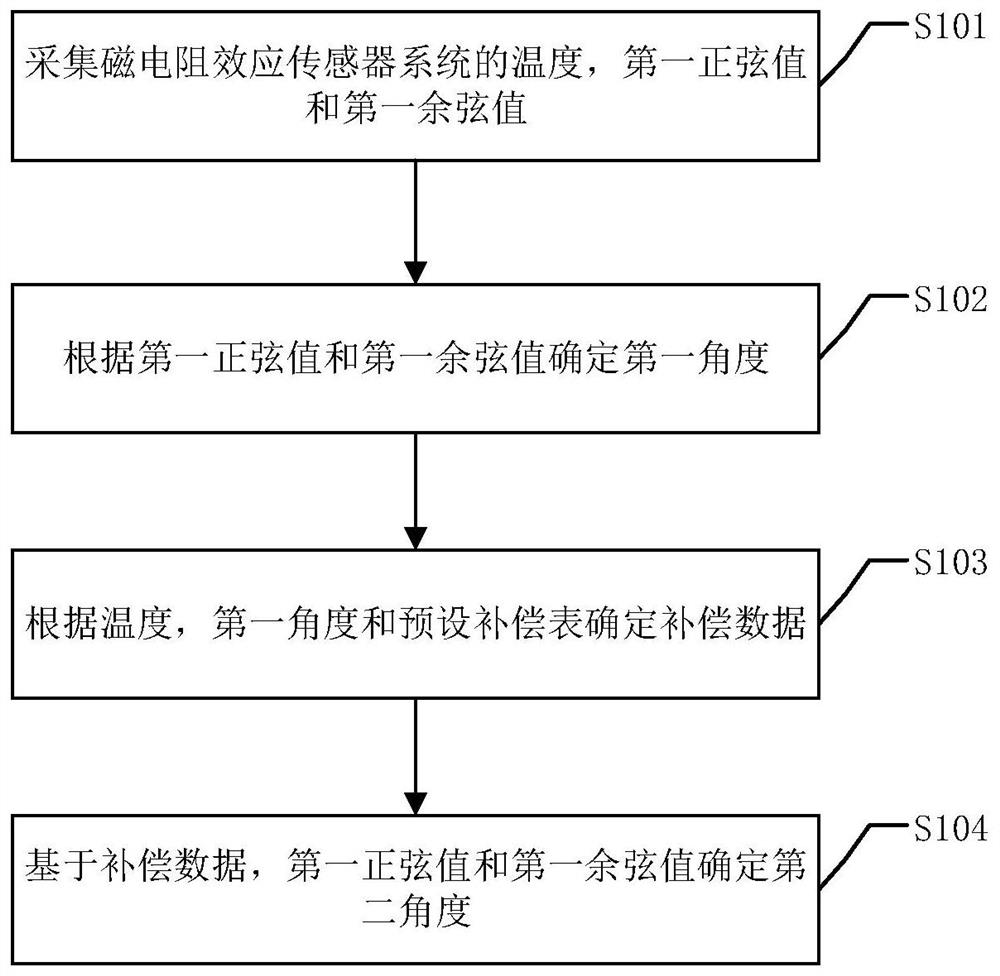

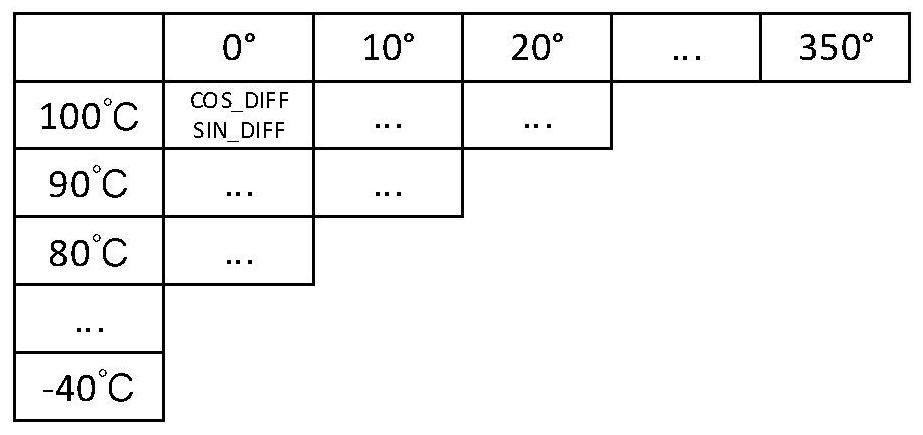

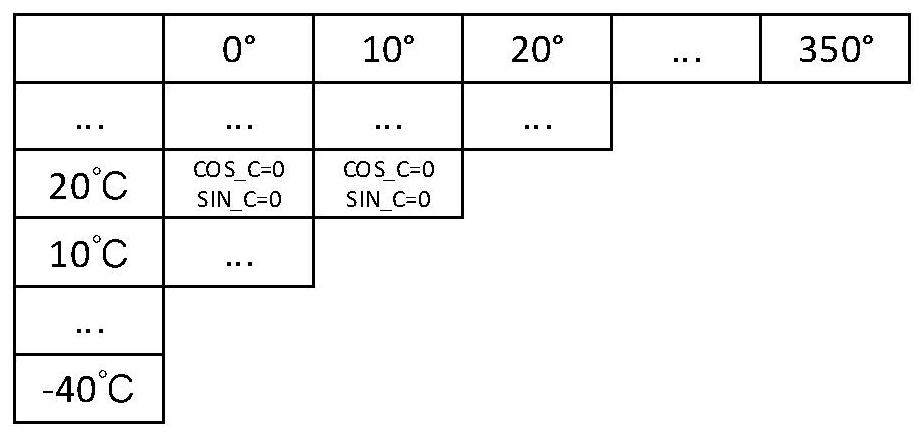

Sensor temperature compensation method, device and equipment and storage medium

ActiveCN112556569AResolving inaccurate measurementsUsing electrical meansMagnetoresistanceSensor system

The embodiment of the invention discloses a sensor temperature compensation method, device and equipment and a storage medium. The method comprises steps of firstly, collecting the temperature, a first sine value and a first cosine value of a magnetoresistance effect sensor system; determining a first angle according to the temperature, the first sine value and the first cosine value; determiningcompensation data according to the temperature, the first angle and a preset compensation table, the compensation table comprising a second sine value and a second cosine value corresponding to different preset angles of the magnetoresistance effect sensor system at each preset temperature and each preset temperature; and finally determining a second angle based on the compensation data, the firstsine value and the first cosine value. The problem that the measurement result of the angle sensor is inaccurate in the current technical scheme is solved, and the accuracy of the measurement resultis improved.

Owner:FATRI DIYAN BEIJING TECH CO LTD

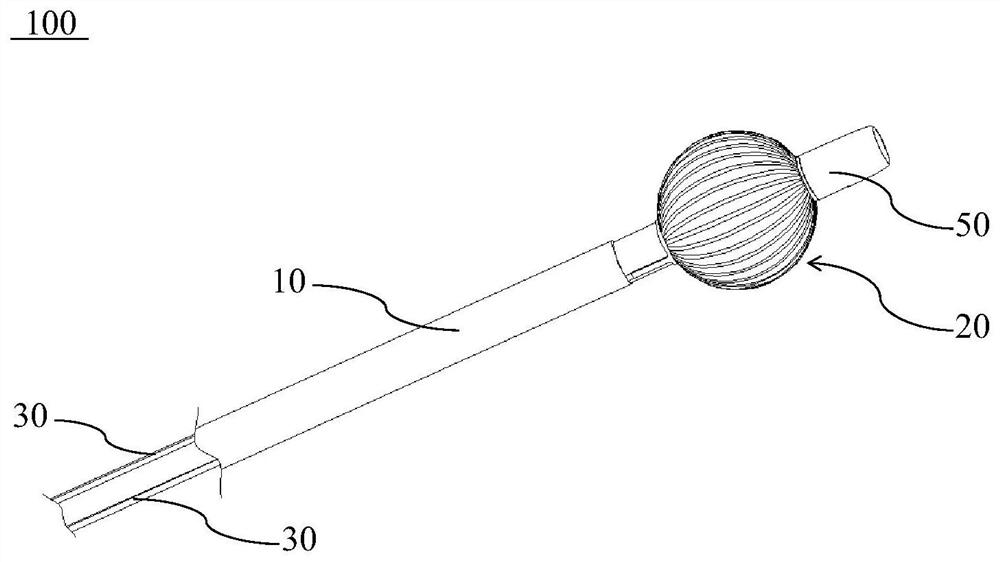

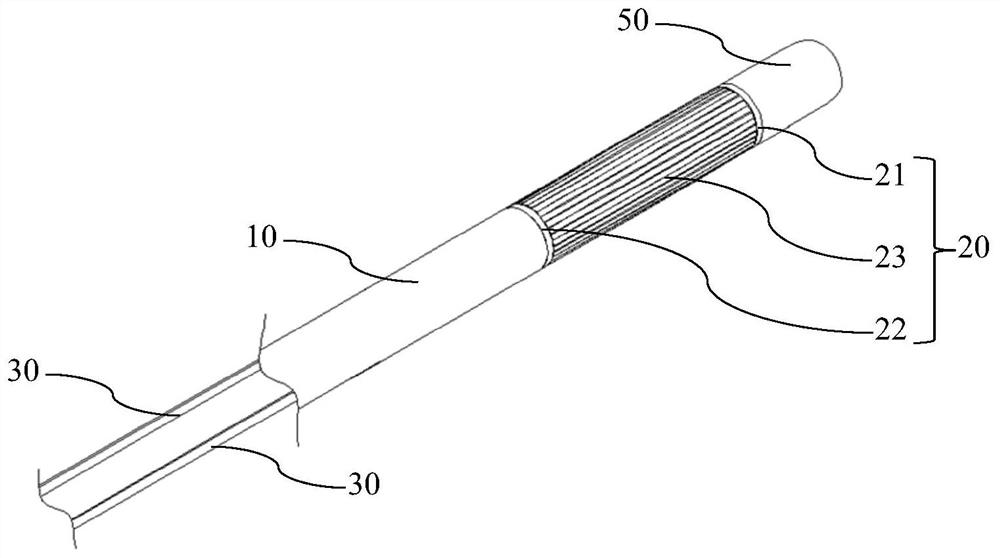

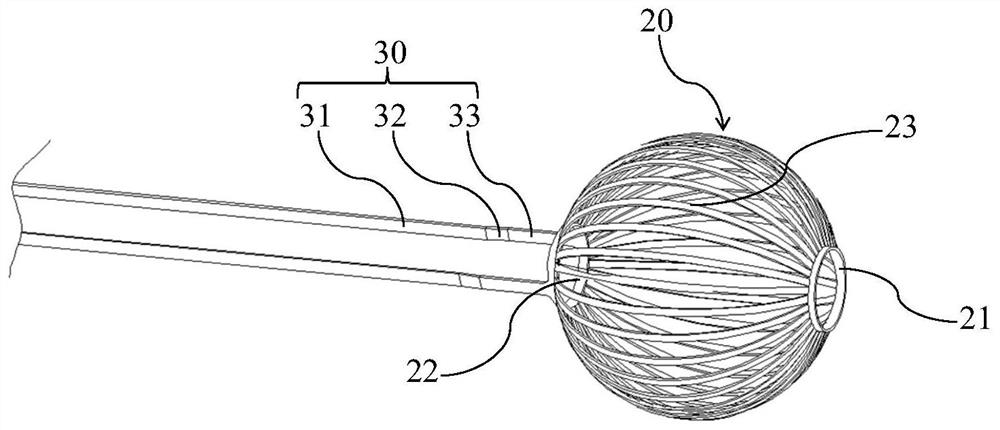

Measuring device, measuring system and measuring method

PendingCN114145765AResolving inaccurate measurementsIncrease success rateForeign body detectionEngineeringCatheter

The invention belongs to the technical field of medical instruments, and particularly relates to a measuring device, a measuring system and a measuring method. The measuring device comprises a catheter and a mapping piece, the catheter is of a hollow tubular structure, the mapping piece is arranged on one part of the outer surface of the far end of the catheter in a deformable and sleeving mode, and the mapping piece is in the shape of a regular sphere or in the shape close to the shape of the regular sphere during measurement and has developing performance. In the invention, as the mapping piece in the shape of the regular sphere is a circle with a constant size under any angle projection, the mapping piece is taken as a measurement basis, the measurement accuracy under equipment such as DSA can be ensured, a treatment instrument with a proper size and a corresponding specification can be accurately selected, and the success rate of an operation is improved. In addition, the boundary of the mapping piece of the regular sphere structure is clearer, rapid capture and accurate measurement are facilitated, the operation time is shortened, and the safety and reliability of the operation are improved.

Owner:LIFETECH SCIENTIFIC (SHENZHEN) CO LTD

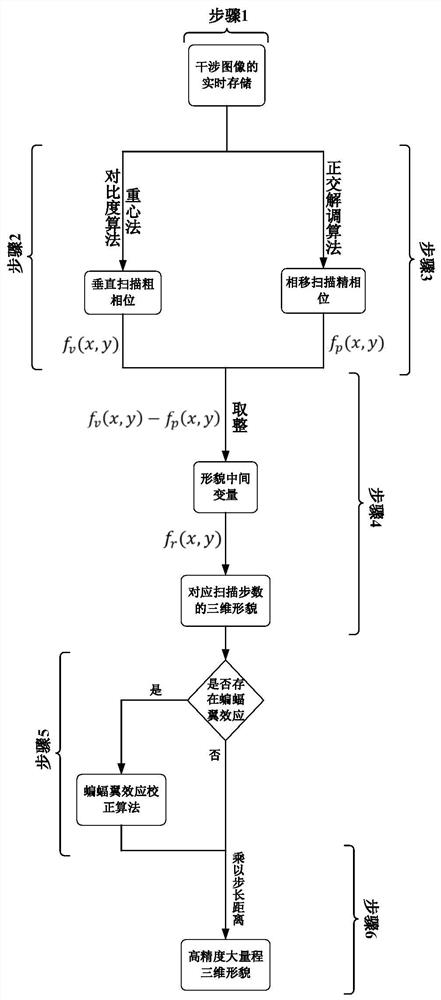

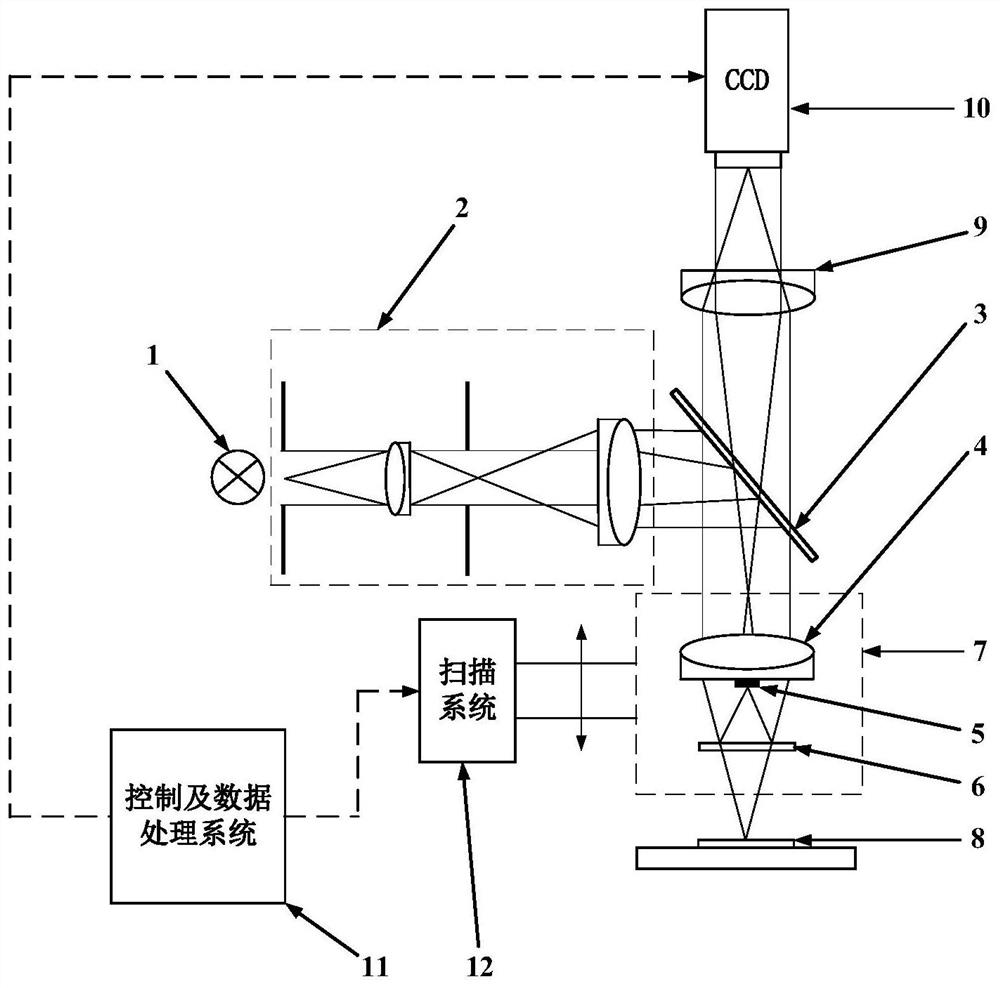

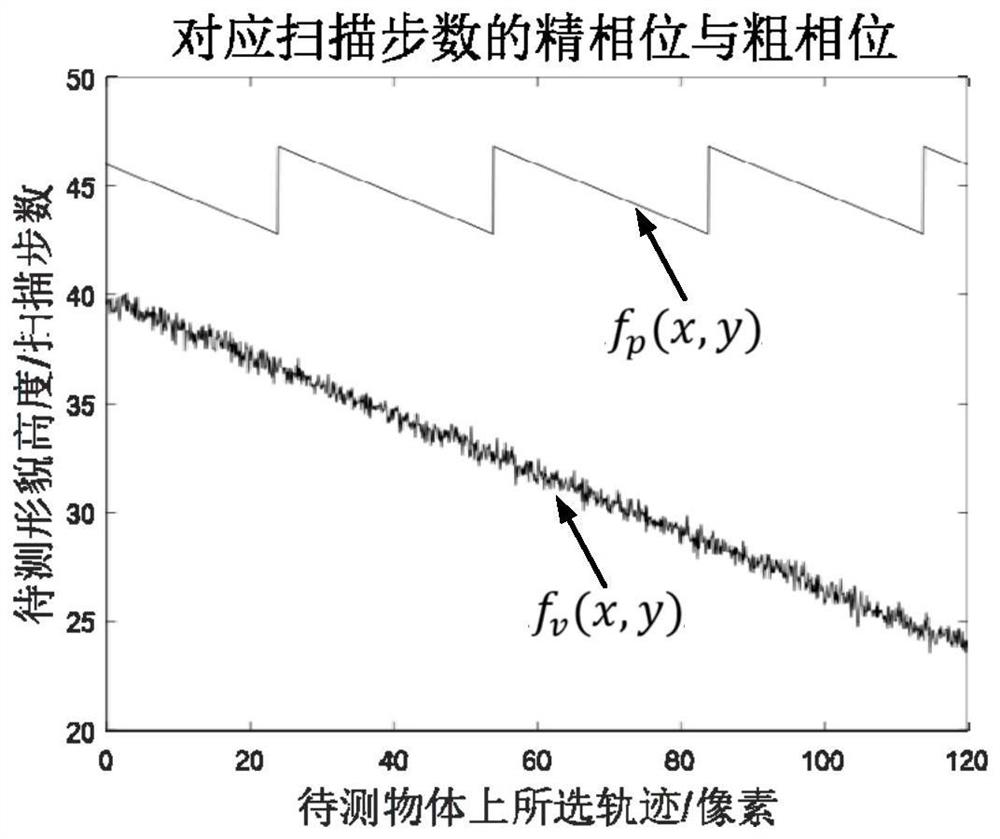

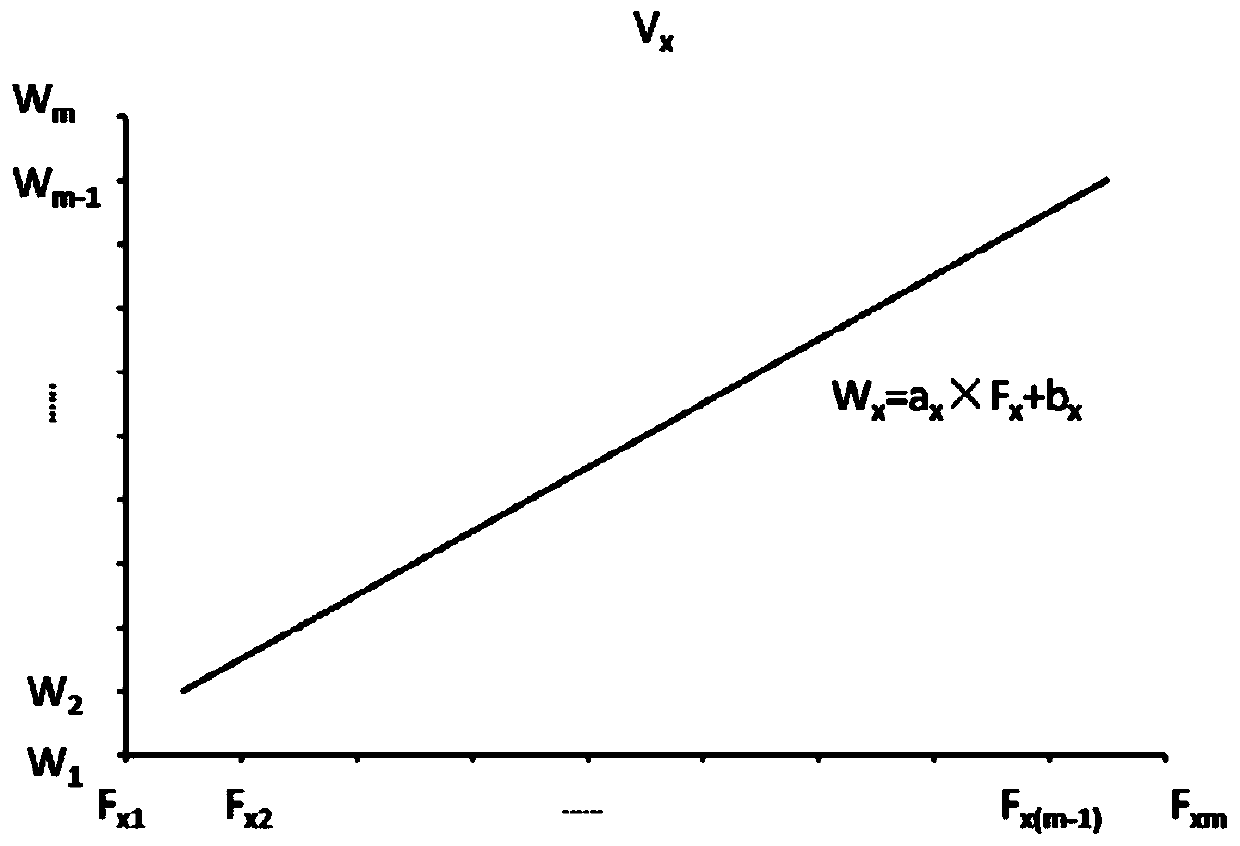

High-precision short-coherent light fast three-dimensional shape measurement algorithm

ActiveCN109751971BShort timeExact phase resultUsing optical means3D modellingFast measurementContrast level

The invention discloses a high-precision short coherent light three-dimensional morphology rapid measuring algorithm. The high-precision short coherent light three-dimensional morphology rapid measuring algorithm comprises the steps that firstly piezoelectric ceramics are driven to perform time sequence perpendicular scanning according to pi / 2 phase position stepping quantities within a certain scanning length, and an interference pattern is stored according to each corresponding stepping quantity; the interference patterns are calculated and processed and blended into the process of time sequence perpendicular scanning interference pattern storing to realize rapid measuring; the interference patterns are recorded complete while time sequence perpendicular scanning is carried out, contractratio solution of various pixel point phase shift scanning refined phase and the multiple interference patterns in airspace is completed. The contract ratio of the multiple interference patterns areprocessed to obtain a perpendicular scanning coarse phase; then, the phase shift scanning refined phase is fused with the perpendicular scanning coarse phase to obtain a three-dimensional morphology measuring result; and finally, batwing errors of a sample to be measure generated at edges of step morphology are judged and removed by adopting a two-dimension discrete difference algorithm to obtaina high-precision three-dimensional morphology measuring result. The high-precision short coherent light three-dimensional morphology rapid measuring algorithm is simple, the speed is high, the precision and confidence level is high, and environmental noise resistance capacity is high.

Owner:NANJING UNIV OF SCI & TECH

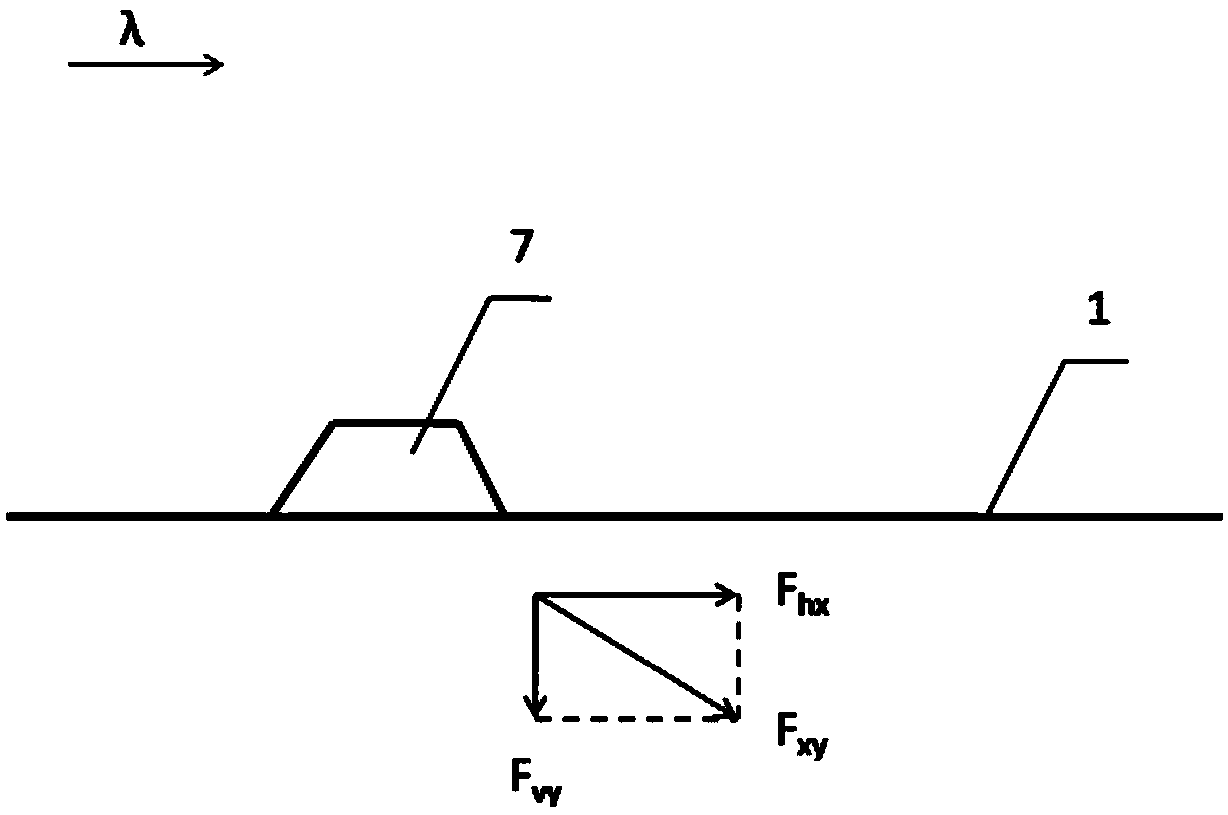

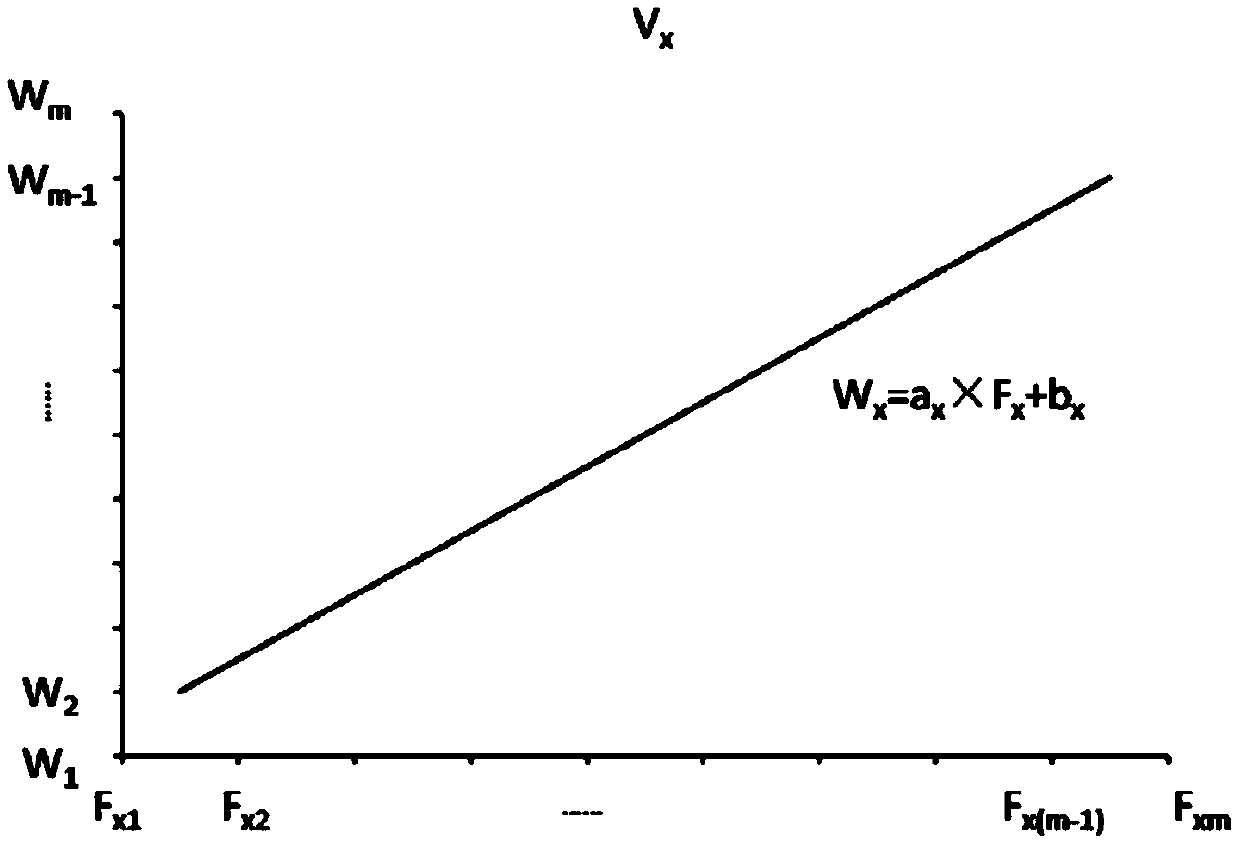

Method for measuring weight of dynamic vehicle and system for measuring weight of dynamic vehicle

ActiveCN106404140BResolving inaccurate measurementsWide measurement rangeSpecial purpose weighing apparatusClassical mechanicsLinear relationship

The invention provides a method for measuring the weight of a dynamic vehicle and a dynamic vehicle measuring system. The method comprises the following steps: constructing an equation set which includes a plurality of linear fitting equations which correspond to different vehicle velocities in a one by one manner; acquiring the average velocity of a certain vehicle when the vehicle passing a certain sloped distance and force generated in the horizontal direction and the vertical direction, and calculating a converged force; acquiring from a equation set a linear fitting equation which corresponds to the average velocity of the vehicle and is intended for representing the linear relationship between weight and the joint force, and calculating the weight of the vehicle based on the joint force. The system includes a slope bearing bench, a sensing support, a measuring apparatus, a memory and a processor. According to the invention, the method addresses the measuring inaccuracy caused by discontinuous contact between tires and the slope bearing bench when the vehicle runs at high velocity, and can cater to the requirements of accurate measurement of the vehicle.

Owner:上海筑邦测控科技有限公司

Interface gauge and interface measurement method

ActiveCN105203183BImprove accuracyImprove reliabilityMachines/enginesLevel indicatorsTransceiverBoundary element method

The invention provides an interface level meter and an interface level measuring method. The interface level meter is used for measuring the interface level of mixed liquid and comprises a conduit, an ultrasonic wave transceiver and a floater. The ultrasonic wave transceiver is fixedly arranged in the conduit, the floater is located in the conduit, the density of the floater is between the densities of two adjacent layers of media of the to-be-measured mixed liquid, an ultrasonic wave reflecting face is arranged on the side, close to the ultrasonic wave transceiver, of the floater, and the receiving-emitting end of the ultrasonic wave transceiver is towards the floater. According to the interface level meter in the technical scheme, ultrasonic waves emitted by the ultrasonic wave transceiver are returned through the floater located at the interface level position, returned energy is higher, and the position of the interface level can be more accurately reflected; in addition, the wave length of the ultrasonic waves is large, the ultrasonic waves can more easily bypass an interference object and are not prone to being disturbed by impurities in the mixed liquid, a false interface level can be avoided, and interface level measuring accuracy and interface level measuring reliability are improved.

Owner:PETROCHINA CO LTD

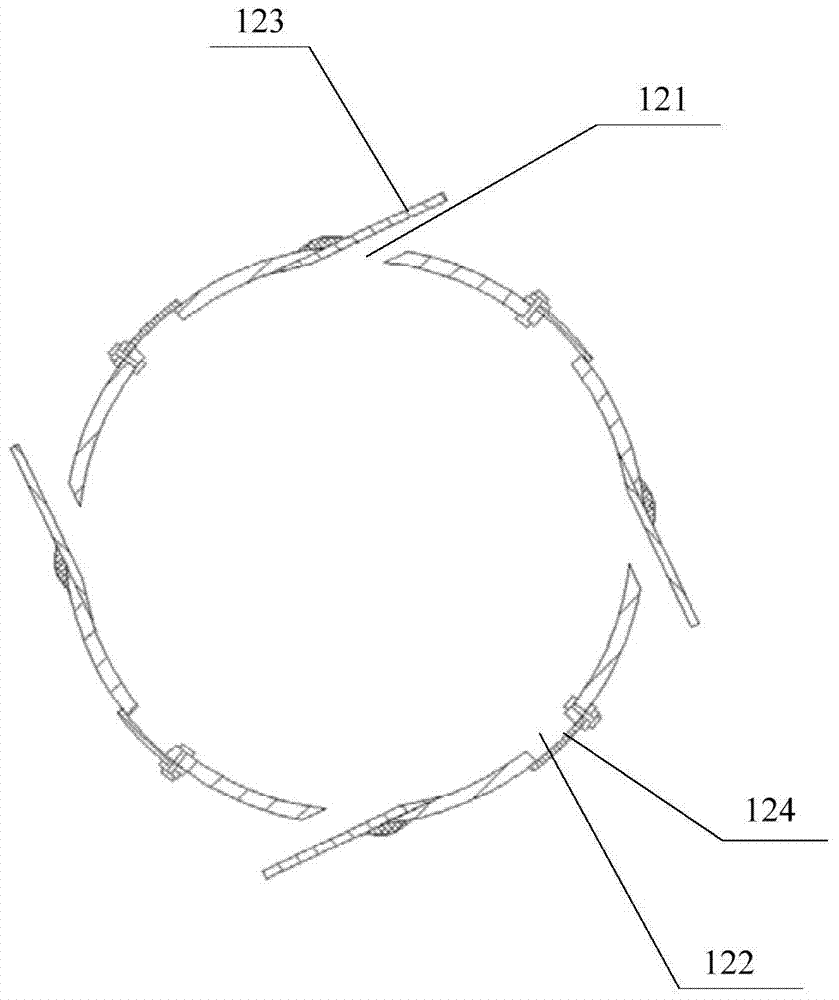

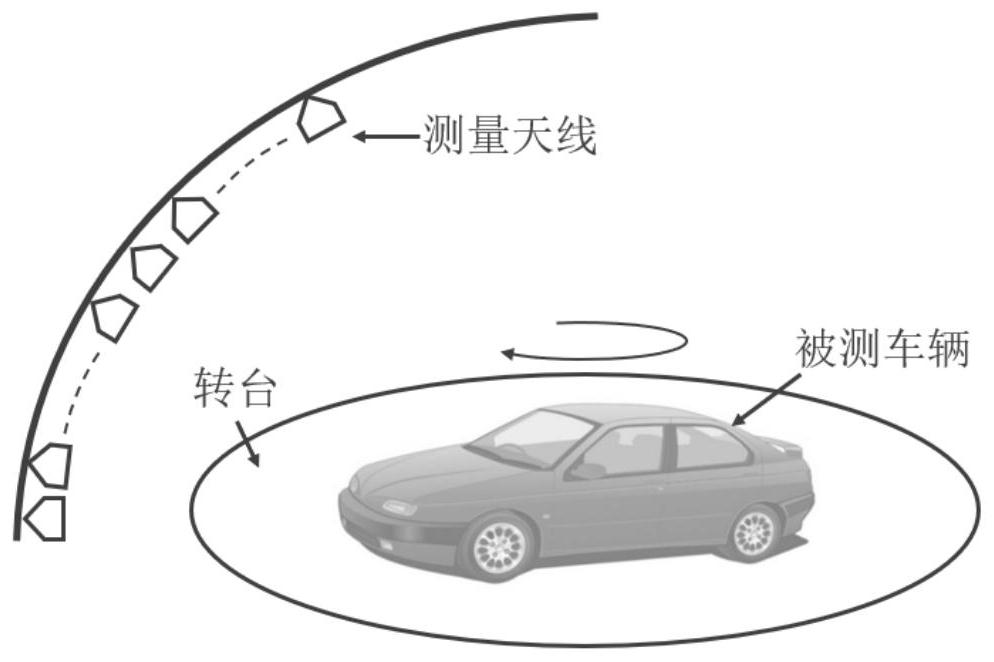

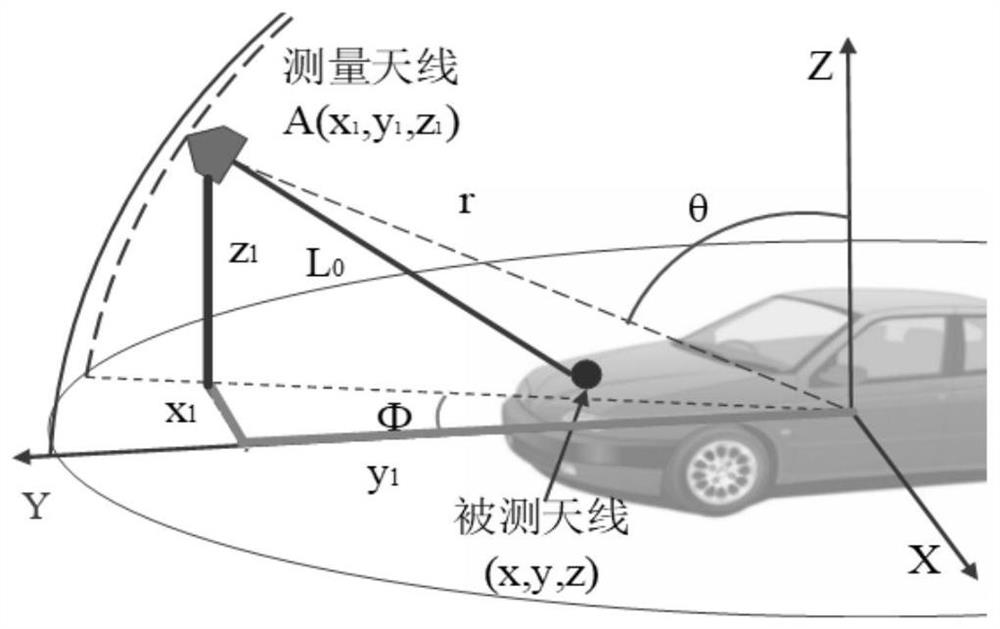

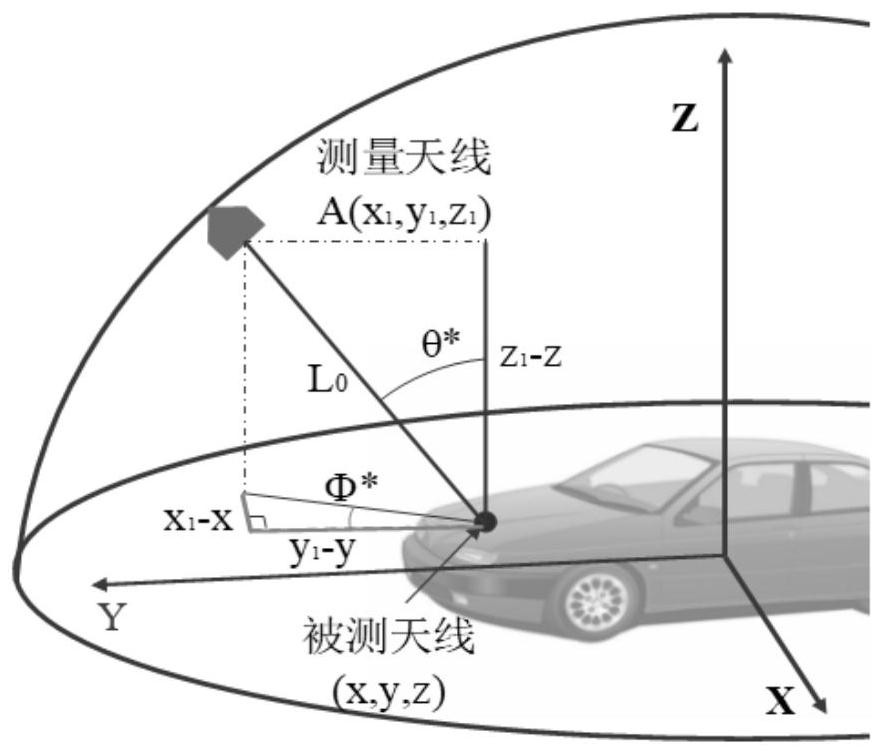

An Eccentricity Correction Method Applied to Automotive Antenna Performance Test

ActiveCN110703000BImplement testEasy to testElectromagentic field characteristicsAntenna radiation diagramsThree-dimensional spaceEngineering

The invention provides an eccentric correction method applied to the performance test of automobile antennas. Firstly, the spatial attenuation is corrected, and the distance between each measuring antenna and the measured antenna is calculated according to the position of the measured antenna, and the distance between each measuring antenna and the measured antenna is calculated according to the electromagnetic wave space attenuation formula and the measured The theoretical attenuation value when the antenna is located in the center of the test system is compared to obtain the spatial attenuation correction value, and then the spatial attenuation correction value is compensated and corrected for the electromagnetic field parameters obtained by each measurement antenna to obtain the measurement result when the antenna under test is located in the measurement center. Secondly, the angle of the measurement antenna is corrected. The measurement angle of the measurement antenna is relative to the measurement center. When the measured antenna deviates from the measurement center, the actual measurement result of the measurement antenna is the electromagnetic wave parameter at the angle of the measured antenna relative to the measurement antenna. Rather than relative to the center of the test system, it is necessary to calculate the angle value relative to each measurement antenna according to the position of the antenna under test as the actual measurement angle of each measurement antenna, and combine the corrected measurement parameters to obtain the antenna performance test in three-dimensional space result.

Owner:中汽研软件测评(天津)有限公司 +1

Speed-measuring light-reflecting device

PendingCN113533775AConsistent sizeConsistent intervalDevices using time traversedElectromagnetic wave reradiationMechanical engineeringOptics

Owner:ZHENJIANG MINGRUN INFORMATION TECH

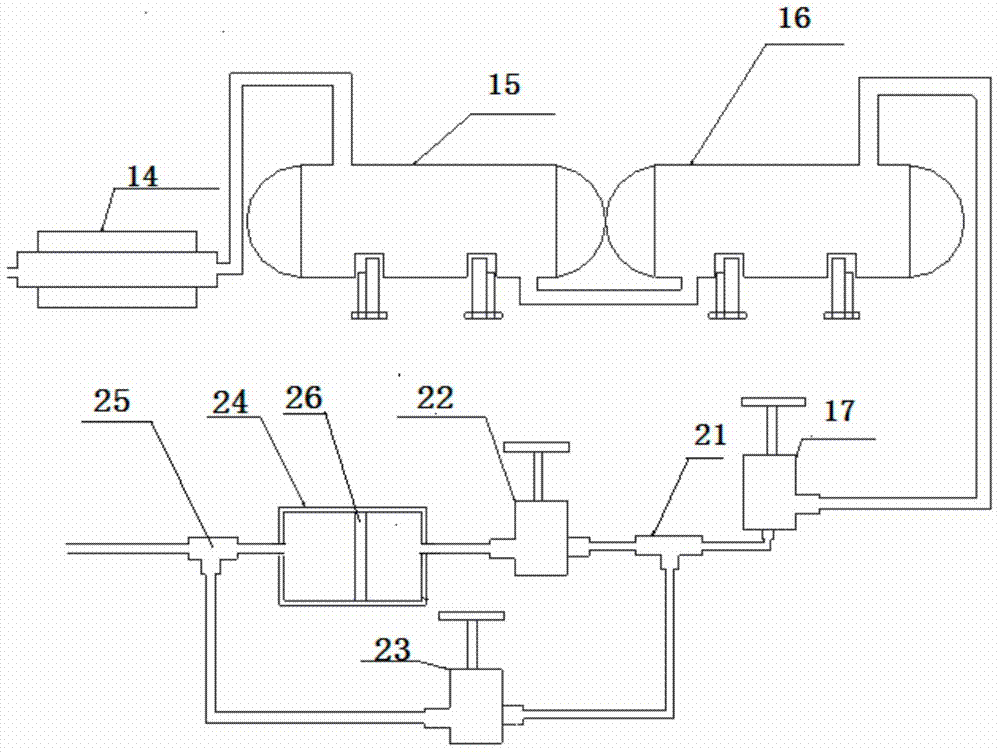

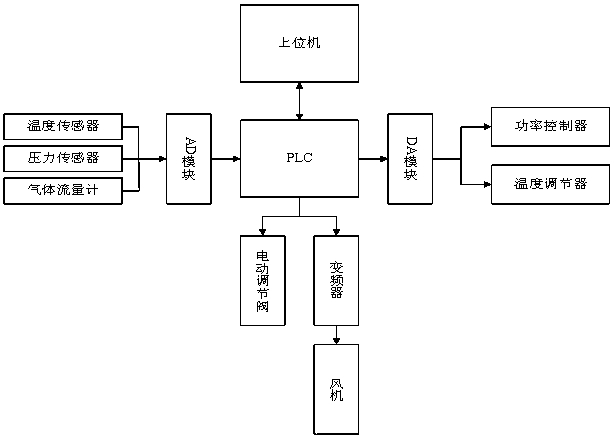

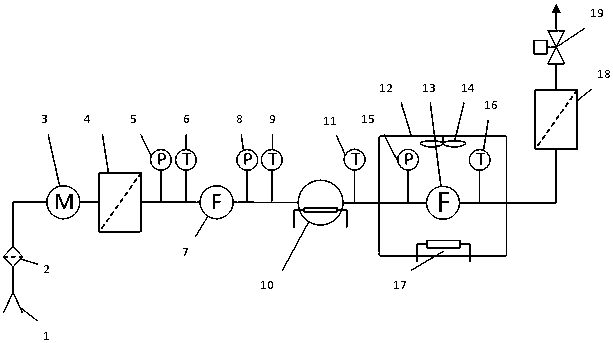

High temperature gas flow measurement standard device and its detection method

ActiveCN104807522BResolving inaccurate measurementsAccurate CalibrationTesting/calibration apparatusGas analysisPositive pressure

The invention relates to a high-temperature gas flow measurement standard device and a detection method thereof. The gas flow standard device of the existing standard meter method seldom considers that the temperature of the gas to be tested is not very high in the actual working place of the meter to be tested, and ignores the response of the gas flowmeter to gases of different temperatures, making the measurement results not very accurate. The present invention includes a flow regulating device, a temperature regulating device, and a flow detecting device. The flow detecting device is installed upstream of the temperature regulating device, the meter to be checked is installed downstream of the temperature regulating device, and the flow regulating device is installed in the overall device. Upstream, positive pressure is used to generate flow. The invention can consider the problem of the gas flowmeter being tested under normal temperature gas and used under high temperature gas, analyzes the working characteristics of the flowmeter at different gas temperatures, evaluates the characteristics of the flowmeter more comprehensively and objectively, and improves the accuracy of measurement results.

Owner:CHINA JILIANG UNIV

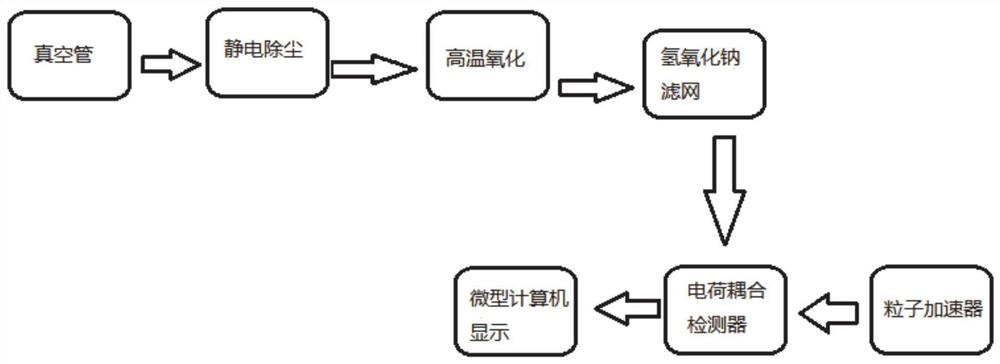

Air gas detection system and method based on low-temperature high-speed carbon atoms

PendingCN114152579AResolving inaccurate measurementsColor/spectral properties measurementsPhysicsAir cleaning

The invention belongs to the technical field of safety and discloses an air gas detection system and method based on low-temperature high-speed carbon atoms, the system comprises an underground working platform and a management terminal, the underground working platform comprises a gas purification module, a particle accelerator and a charge coupling detector, the gas purification module is used for purifying underground air to obtain a pure methane gas mixture, and the particle accelerator is used for accelerating carbon atoms, so that the accelerated carbon atoms and the pure methane gas mixture collide and are input into the charge coupling detector; the charge coupling detector is used for measuring the carbon atom content in the air by adopting a spectrum technology, converting the carbon atom content in the air into an electric signal and sending the electric signal to the management terminal, and the management terminal is used for converting the current signal into the corresponding gas content in the air, so that the gas content in the coal mine air can be monitored in real time.

Owner:SHANDONG DAQI COMM ELECTRONICS CO LTD

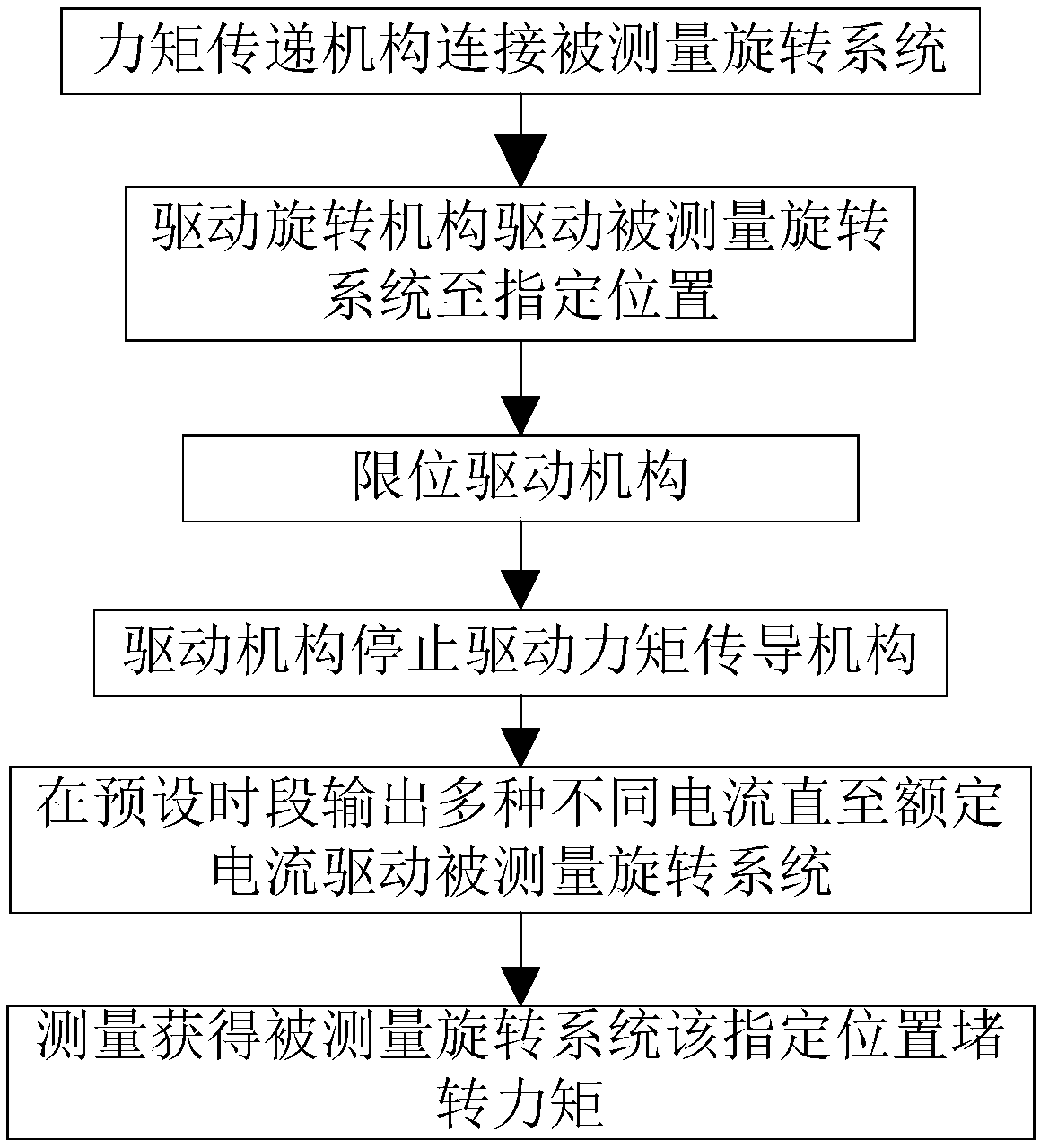

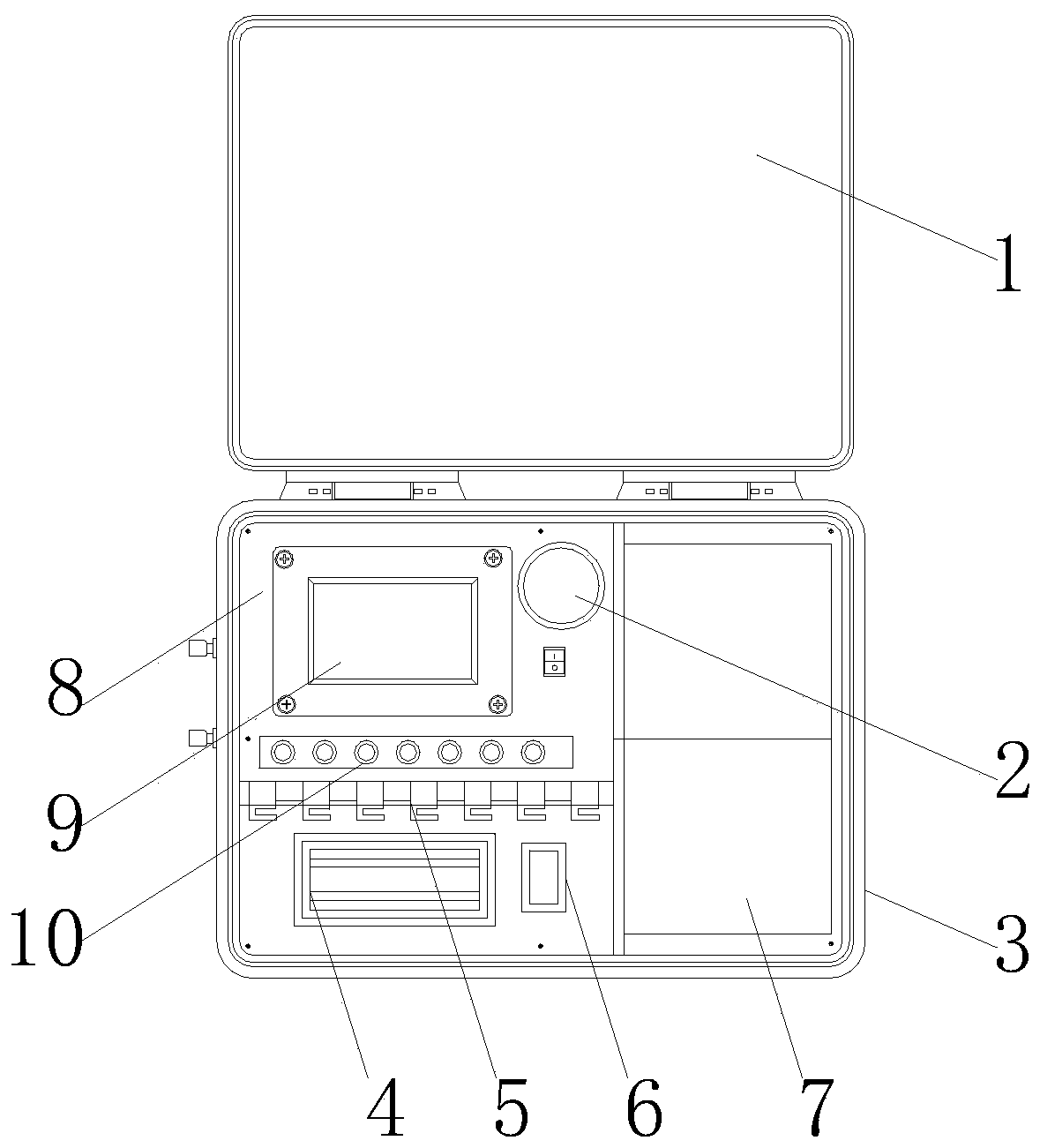

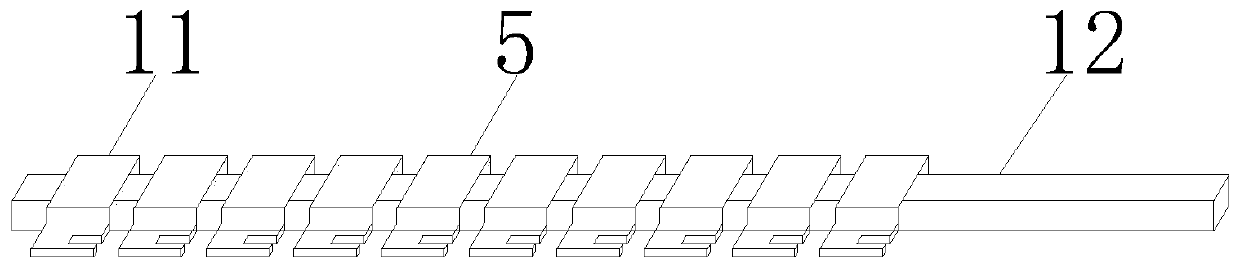

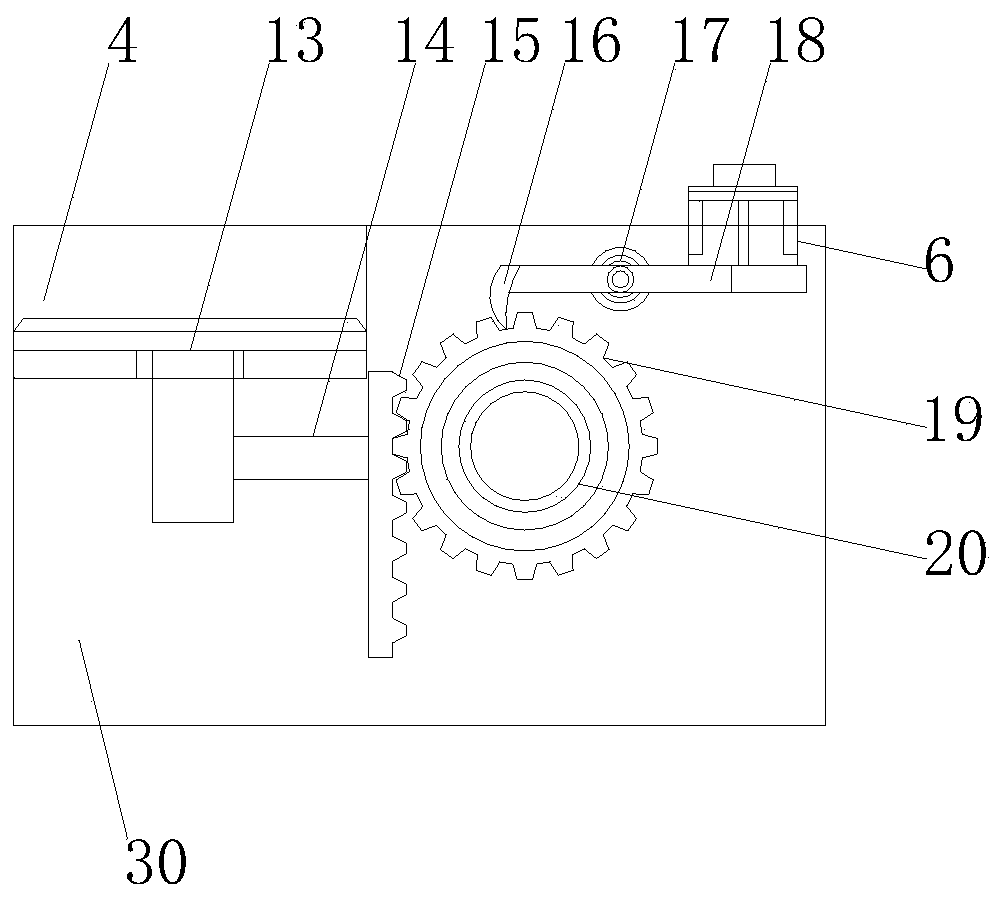

Rotating system stalling torque measuring device and measuring method thereof

InactiveCN109000840AGood repeat consistencyAccurate torque measurementApparatus for force/torque/work measurementTransfer mechanismControl theory

The invention discloses a rotating system stalling torque measuring device, comprising a driving mechanism, a torque transfer mechanism, a limiting mechanism and a torque measuring mechanism, whereinthe driving mechanism drives a measured rotating system to rotate to a specified location through the torque transfer mechanism; after the specified location is reached, the limiting mechanism limitsthe driving mechanism; after the specified location is reached, a plurality of different current values are output within a preset time period until the rated current value is output to drive the measured rotating system to rotate; and the measured rotating system transmits a stalling torque to the torque measuring mechanism through the torque transfer mechanism. The invention also provides a rotating system stalling torque measuring method. According to the measuring device and the measuring method disclosed by the invention, the problem of inaccurate measurement of the stalling torque of therotating system caused by the torque overshoot can be avoided, the accuracy of measuring the stalling torque of the rotating system can be improved, and the product stability of the rotating system can be further improved.

Owner:UNITED AUTOMOTIVE ELECTRONICS SYST

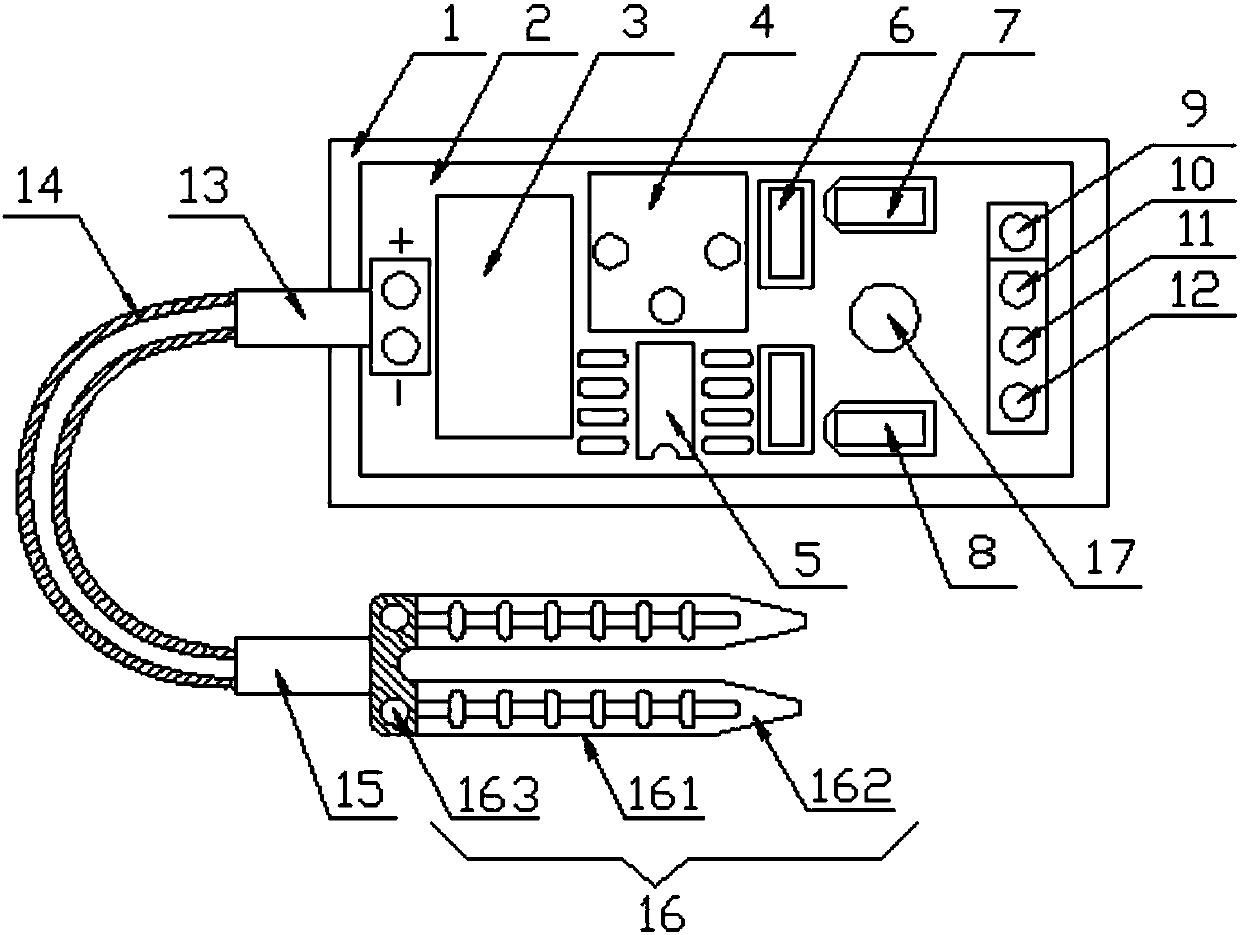

Mobile power supply state detection instrument

InactiveCN110794235AAchieve clampingResolving inaccurate measurementsPower supply testingMeasurement instrument housingTester deviceEngineering

Owner:ANHUI SANDI ELECTRONICS TECH CO LTD

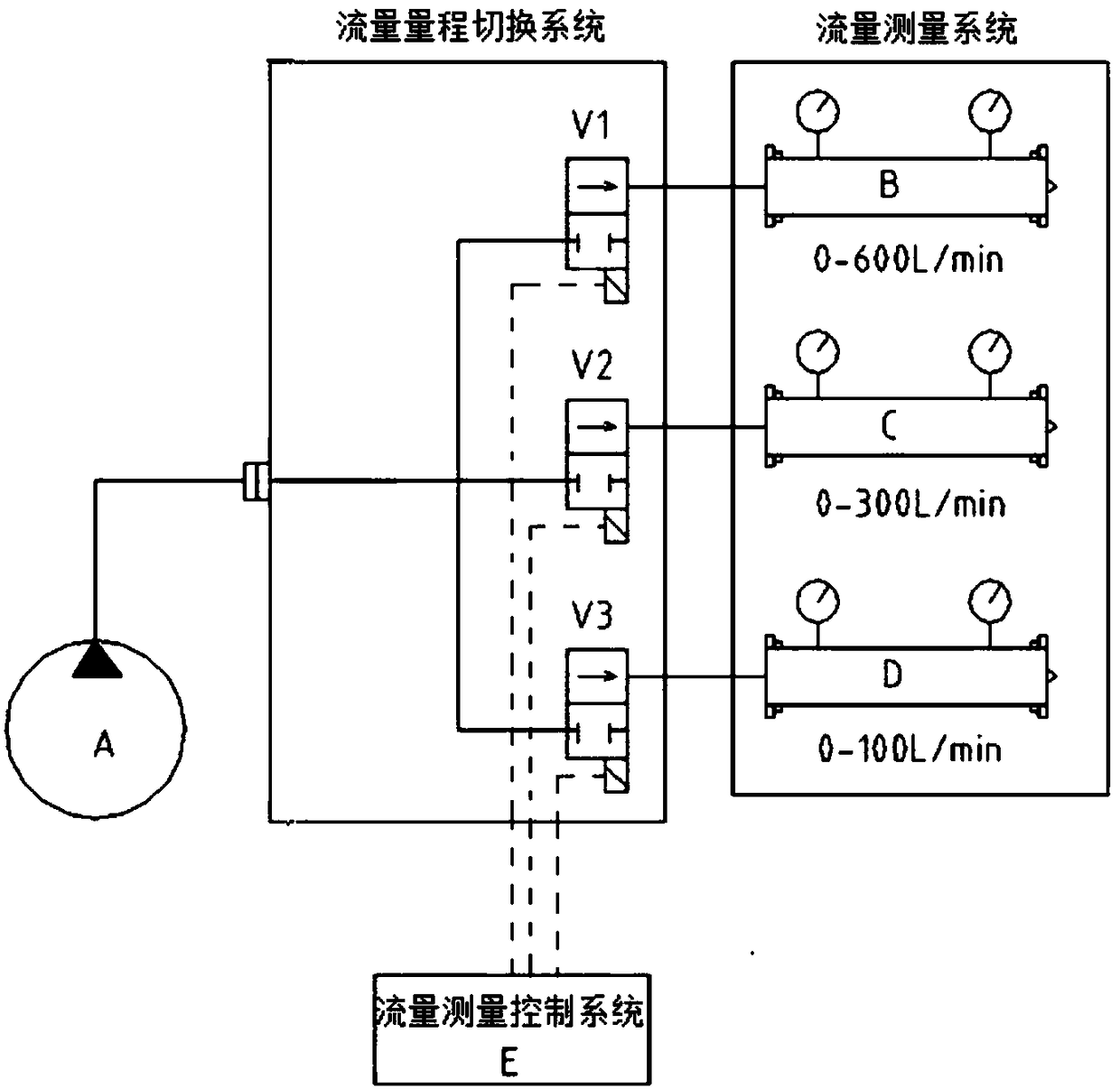

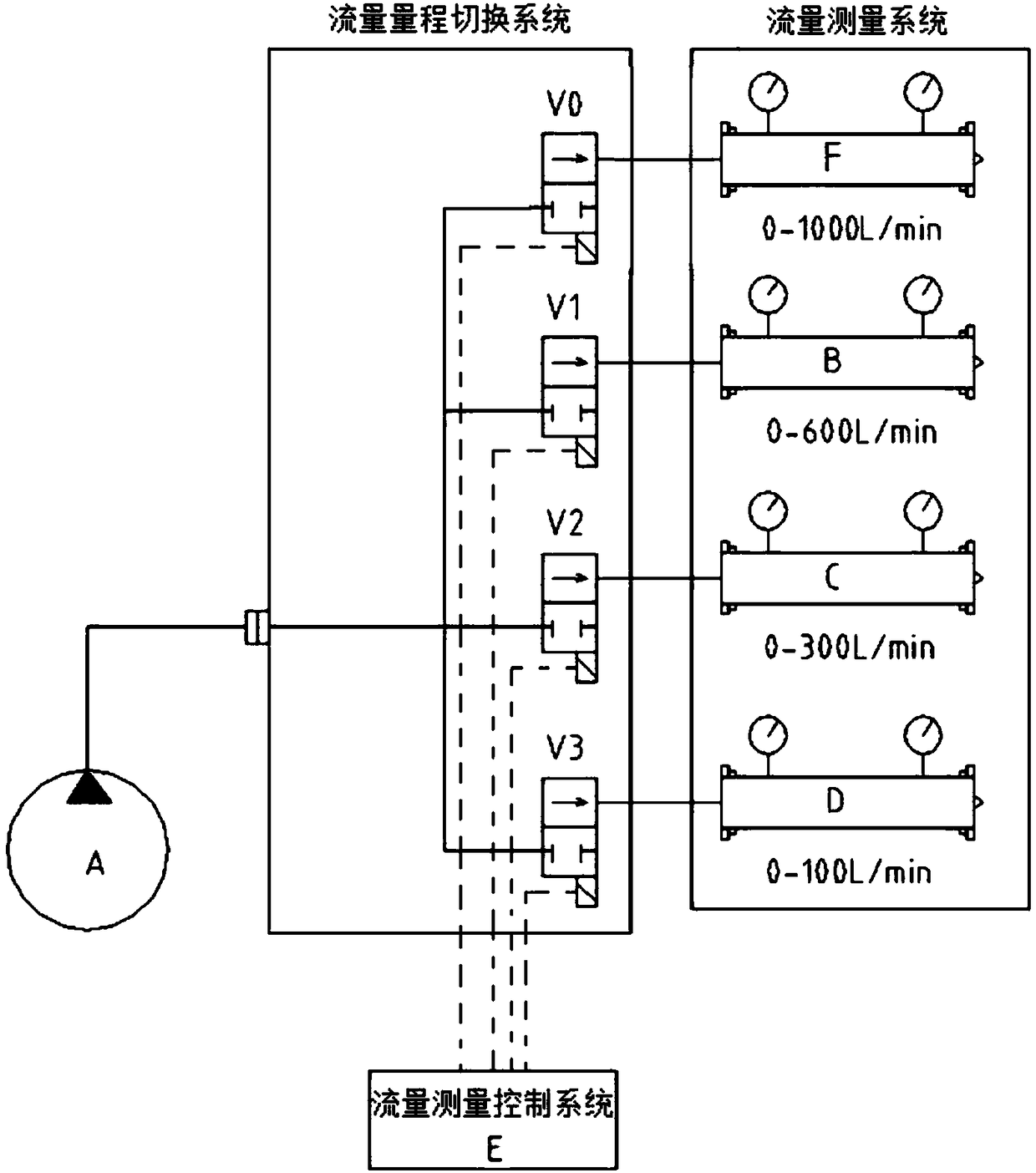

High-precision wide-range gas flow measuring device

InactiveCN108731755AImprove accuracyHigh degree of automationVolume flow measuring devicesControl systemControl line

The invention discloses a high-precision wide-range gas flow measuring device. The high-precision wide-range gas flow measuring device comprises at least two measuring branches, and one end of each measuring branch is short-circuited to be connected with an interface used for being connected with a to-be-measured gas source; a corresponding switch valve and a flow meter are sequentially arranged on each measuring branch from upstream to downstream. The device further comprises a measurement control system, wherein the measurement control system is in control connection with the switch valves through control lines and in sampling connection with the flow meters through sampling lines. The measuring branches are used, the number of the measuring branches can be increased according to needs,the measuring branches can be automatically selected during gas flow measurement through processing of the measurement control system, the automation degree is high, the problem of inaccurate measurement results caused by disassembly and assembly is solved, the flow measuring precision is improved, and the high-precision measuring range of the measuring device is expanded.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Method for measuring weight of dynamic vehicle and system for measuring weight of dynamic vehicle

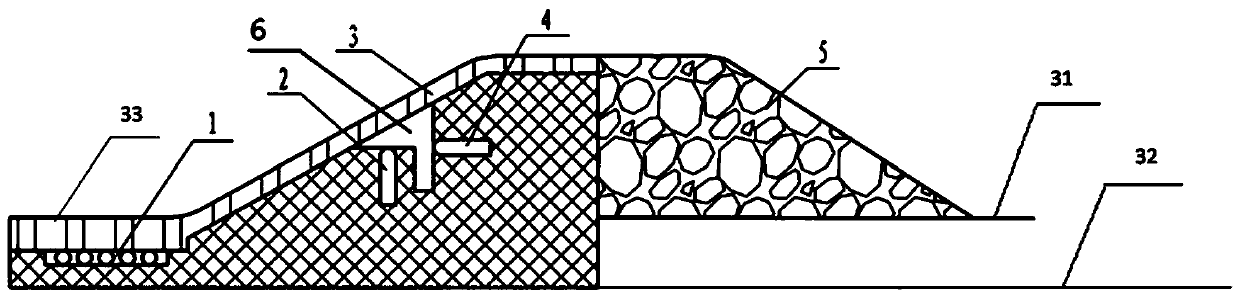

ActiveCN106289469BResolving inaccurate measurementsMeet the requirements of accurate weight measurementSpecial purpose weighing apparatusHorizontal forceLinear relationship

The invention provides a method for weight measuring of a dynamic vehicle and a dynamic vehicle weight measuring system. The method comprises the following steps of building an equation set including a number of linear fitting equations in a one-to-one corresponding to different vehicle speeds; obtaining the average vehicle speed of a vehicle and horizontal force and vertical force generated when the vehicle passes a certain section of horizontal distance, and calculating a resultant force; obtaining, from the equation set, a linear fitting equation corresponding to the average vehicle speed and for representing a linear relationship between the weight and the resultant force, and calculating the weight of the vehicle according to the resultant force. The system comprises roadbed, a weighing device, a memory and a processor. The method for weight measuring of the dynamic vehicle and the dynamic vehicle weight measuring system are advantageous in that, during weight measuring of the vehicle, the horizontal force generated due to horizontal impact of the vehicle is calculated, the problem that an inaccurate measuring result is caused by greater horizontal impact brought by a high-speed passing vehicle is solved, and the requirement for accurate weight measuring of the vehicle is satisfied.

Owner:上海筑邦测控科技有限公司

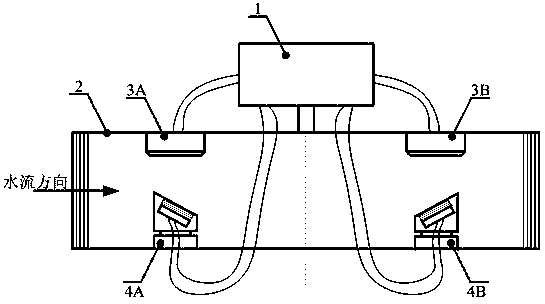

A self-cleaning method for the reflective surface of ultrasonic water meter based on condition monitoring

InactiveCN106595793BResolving inaccurate measurementsLow costVolume/mass flow measurementVolume meteringWater qualityCleaning methods

The invention discloses an ultrasonic water meter reflective surface self-cleaning method based on state monitoring. Piezoelectric ceramic sheets are implanted into a first reflective column and a second reflective column respectively. The first reflective column and the second reflective column, of the same structure, are symmetrically arranged at the upstream and downstream inside a pipe segment of an ultrasonic water meter. The speed of water current in the pipe segment and ultrasonic beam signals monitored by the piezoelectric ceramic sheets in real time are taken as trigger judgment conditions to trigger a control circuit board to provide sine excitation signals to the piezoelectric ceramic sheets and to drive the piezoelectric ceramic sheets to vibrate, so that reflective surfaces on tops of the respective reflective columns are driven to vibrate and clean by the reflective surfaces themselves. The method effectively solves a problem that a measurement result of the ultrasonic water meter is inaccurate because of limescale accumulating on the reflective surfaces. The ultrasonic water meter needs not to be dismounted from a pipe network, and the self-cleaning processing will not affect normal metering of water flows. The service life of the ultrasonic water meter is prolonged, and the ultrasonic water meter can still be utilized in a measuring occasion with bad water quality.

Owner:深圳齐环科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com