Near-infrared analysis system and method for solid material

An analysis system and solid material technology, which is applied in the field of near-infrared analysis system of object materials, can solve the problems of water loss, inability to reflect the moisture value of materials, and decrease in the accuracy of near-infrared detection results, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

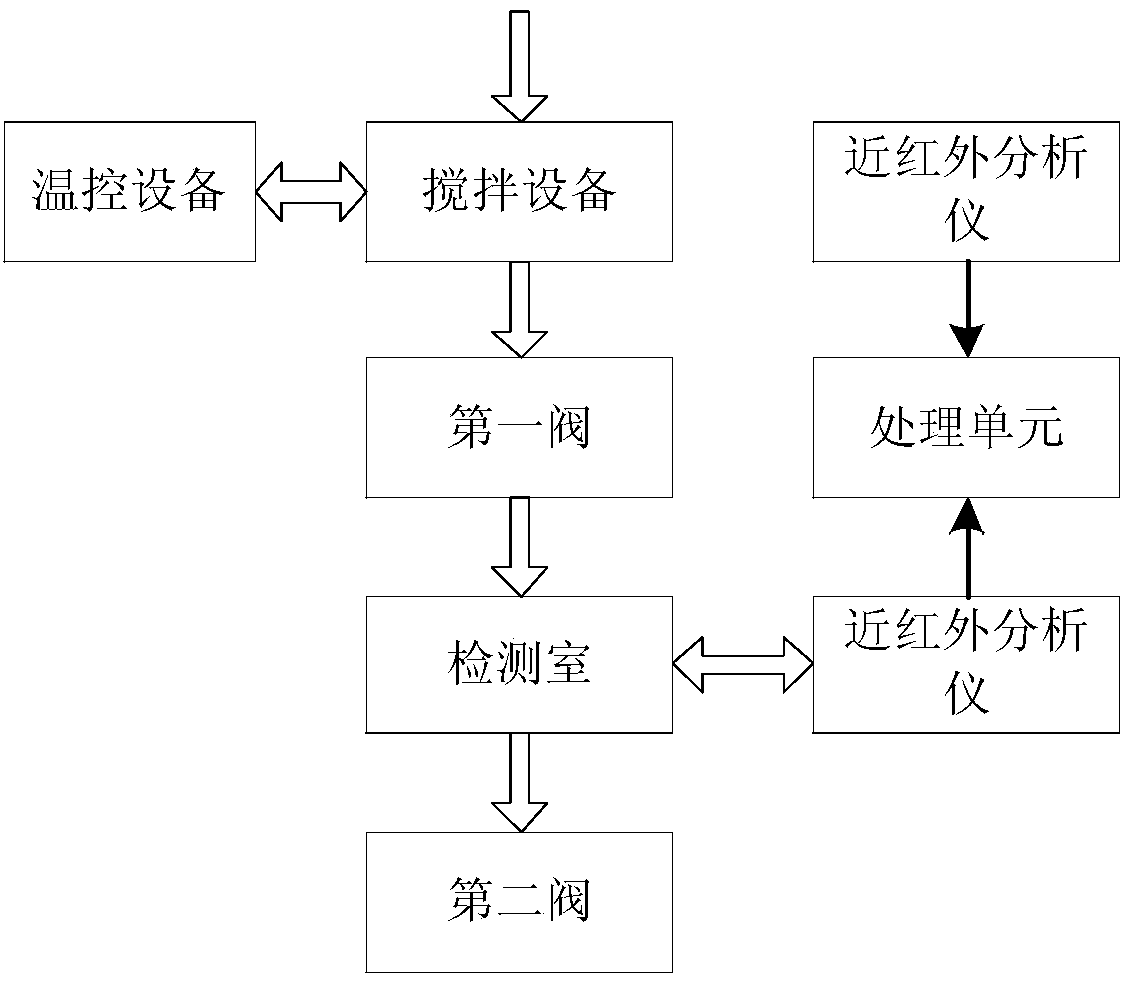

[0028] figure 1 The structure diagram of the near-infrared analysis system for solid materials in an embodiment of the present invention is schematically given, such as figure 1 As shown, the near-infrared analysis system includes:

[0029] Near-infrared analyzer; near-infrared analyzer is an existing technology in this field, and will not be repeated here;

[0030] Crushing equipment, such as a mechanical pulverizer, which is used to pulverize the solid materials and transport them to the mixing equipment;

[0031] Temperature control equipment, such as a water cooling device using circulating water, the temperature control equipment is used to set the temperature T in the crushing device, such as 35°C≤T≤45°C, so as to prevent condensation of moisture generated during the crushing process;

[0032] Stirring equipment, which is used to mix the powdery materials delivered by the crushing equipment;

[0033] A first valve, the first valve is arranged at the outlet of the mixing device; ...

Embodiment 2

[0052] An application example of the near-infrared analysis system according to Embodiment 1 of the present invention in soybean detection.

[0053] In this application example, the clean gas provided by the gas has been degreasing and dewatering in advance, and the gas pressure is 0.5MPa; the crushing equipment, mixing equipment, and detection chamber are connected through pipelines, and the on-off is controlled by valves; temperature control equipment Specifically: an attached shell is made on the outer wall of the crushing device, circulating water is passed through the shell, and the temperature of the circulating water is adjusted to control the temperature in the crushing device between 35°C and 45°C to prevent condensation water in the crushing device; Near infrared analyzer to obtain moisture content A 1 Dry protein B 1 ; A separately configured moisture detector directly obtains the moisture content of the uncomminuted soybeans A 2 , No pretreatment is required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com