Triaxial experiment device for hydrate

A triaxial experiment, hydrate technology, applied in material inspection products, using sonic/ultrasonic/infrasonic waves to analyze solids, and using stable tension/pressure to test the strength of materials, etc., can solve problems such as inaccurate measurement results and achieve detection. full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

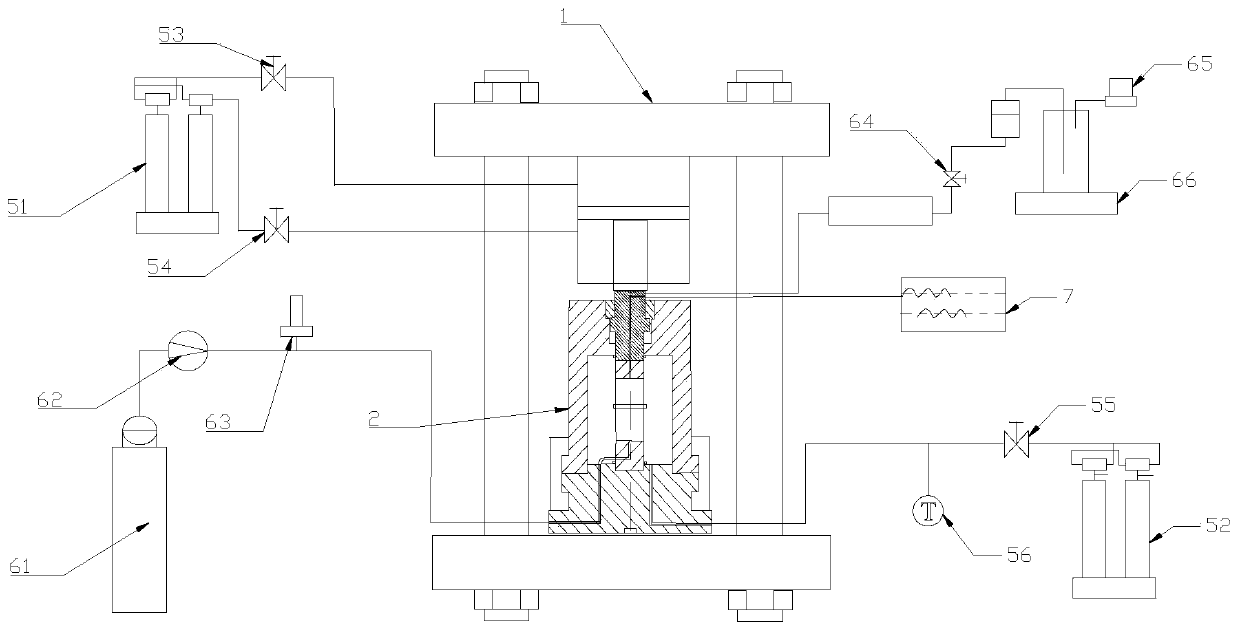

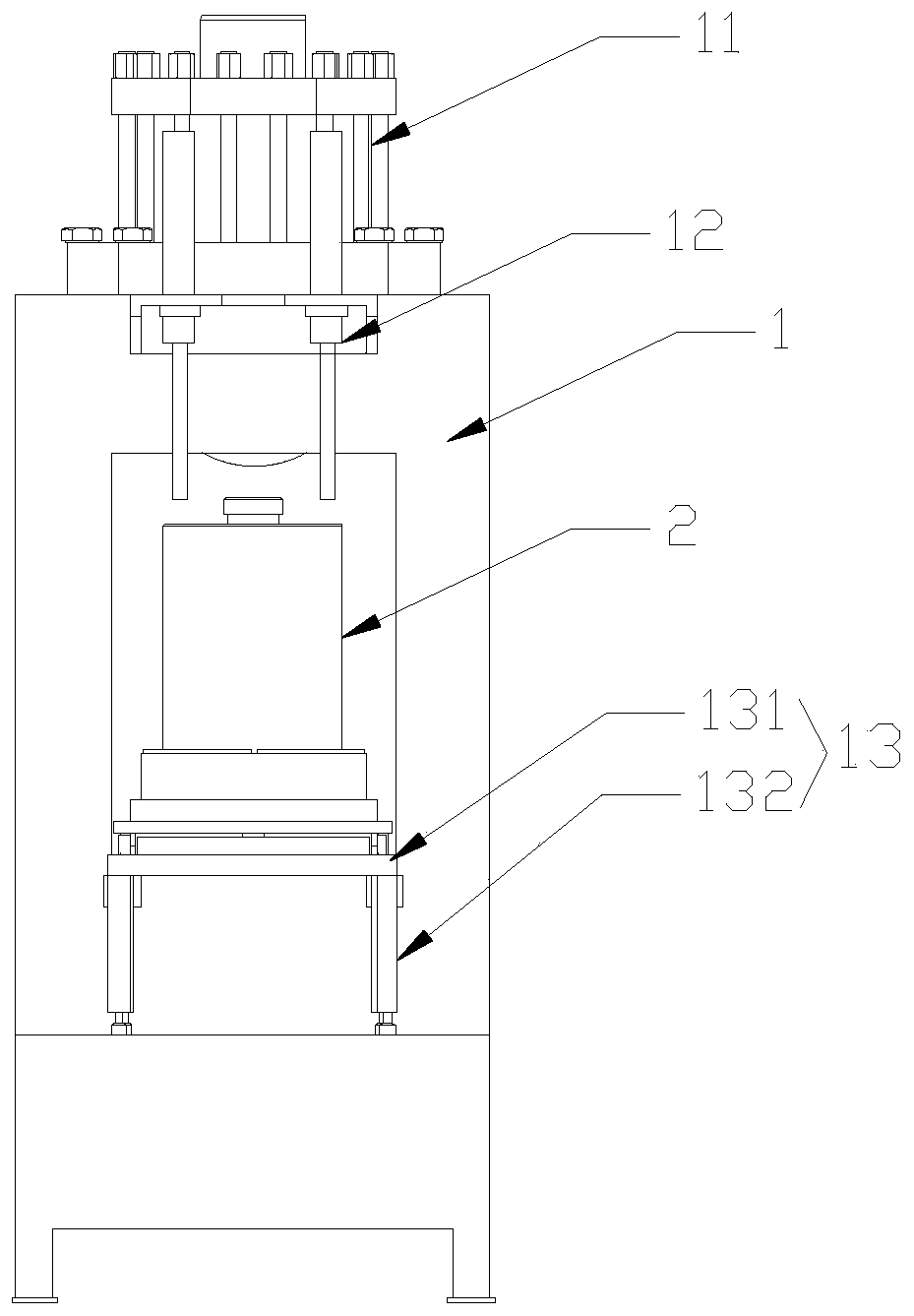

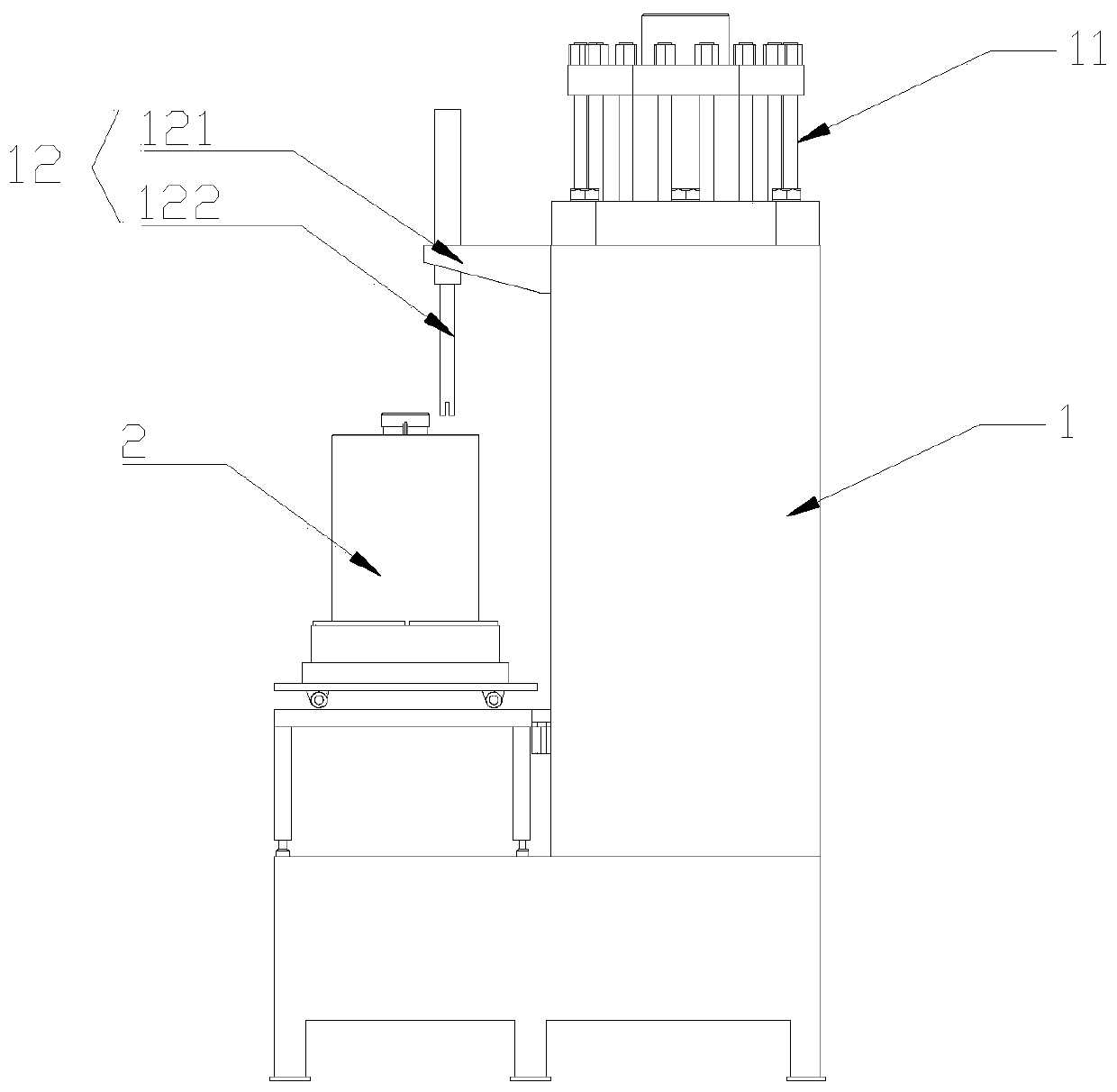

[0043] combined with figure 1 As shown, this embodiment provides a hydrate triaxial experimental equipment, including a frame 1, a pressure chamber 2, an upper pressure component 3, a lower pressure component 4, a confining pressure component 5, a natural gas content detection mechanism 6 and a hydrate saturation Concrete structures such as degree measuring mechanism 7.

[0044] The frame 1 of this embodiment can be regarded as a square-shaped frame structure with a certain preset height as a whole, and there is a space for accommodating the above-mentioned pressure chamber 2 inside. The motor 11 of lower motion.

[0045] The pressure chamber 2 of this embodiment is installed in the upper space of the frame 1, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com