A self-cleaning method for the reflective surface of ultrasonic water meter based on condition monitoring

An ultrasonic and reflective surface technology, which is applied in the field of self-cleaning of the reflective surface of ultrasonic water meters based on state monitoring, can solve problems such as inaccurate measurement results, and achieve the effects of expanding the scope of use, ensuring measurement accuracy, and ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

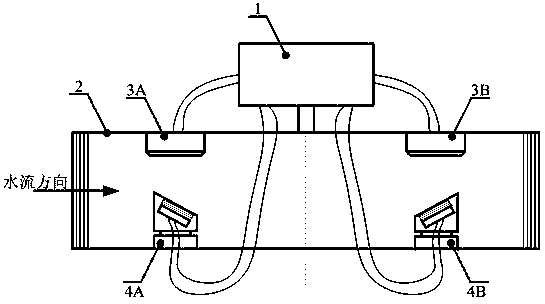

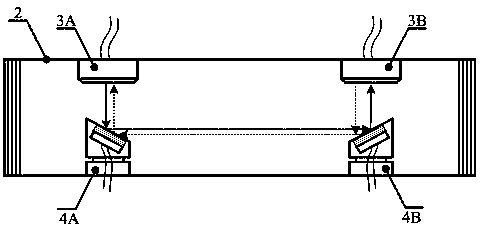

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

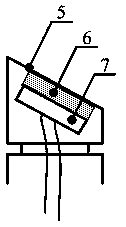

[0023] Such as figure 1 , image 3 As shown, the present invention respectively implants piezoelectric ceramic sheets 7 in the first reflective column 4A and the second reflective column 4B with the same structure installed symmetrically upstream and downstream inside the pipe section 2 of the ultrasonic water meter, and the water flow velocity in the pipe section 2 The ultrasonic beam signal strength monitored in real time with the piezoelectric ceramics is the trigger judgment condition. The trigger control circuit board 1 gives the respective piezoelectric ceramics 7 a sinusoidal excitation signal and drives the respective piezoelectric ceramics 7 to vibrate, thereby driving the reflection at the top of the respective reflection columns. The surfaces 5 vibrate and thus achieve self-cleaning of the respective reflective surface 5 .

[0024] Piezoele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com