Converter transformer valve side bushing partial discharge detection system and method

A technology of partial discharge detection and commutation, which is applied in the direction of testing dielectric strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

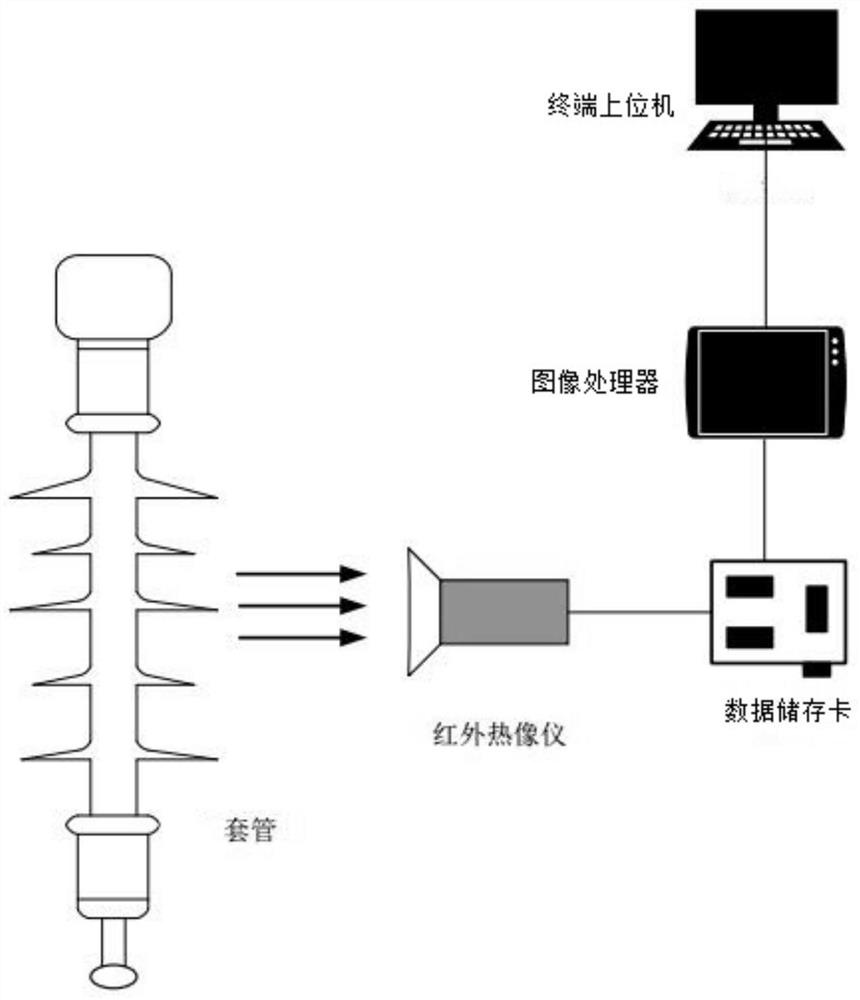

[0051] Such as figure 1 As shown, the present invention provides a partial discharge detection system for converting the valve side casing, including an image acquisition module, an image processor, and a terminal host computer;

[0052] The image acquisition module is used in a multi-angle acquisition of the thermal image map and performs real-time storage;

[0053] The image processor is configured to gray linear transformation of the multi-angle thermal image map and the median filtering process, expand the contrast, reduce environmental noise, and improve imaging quality.

[0054] The terminal upper machine is configured to fuse the multi-angle thermal image diagram of the image processor to form a full-scale sleeve surface temperature thermostat; based on the full-scale sleeve surface temperature hot pattern, calibration camera parameters And perform dimensional transformation, construct a three-dimensional cannula temperature model with the surface temperature information of...

Embodiment 2

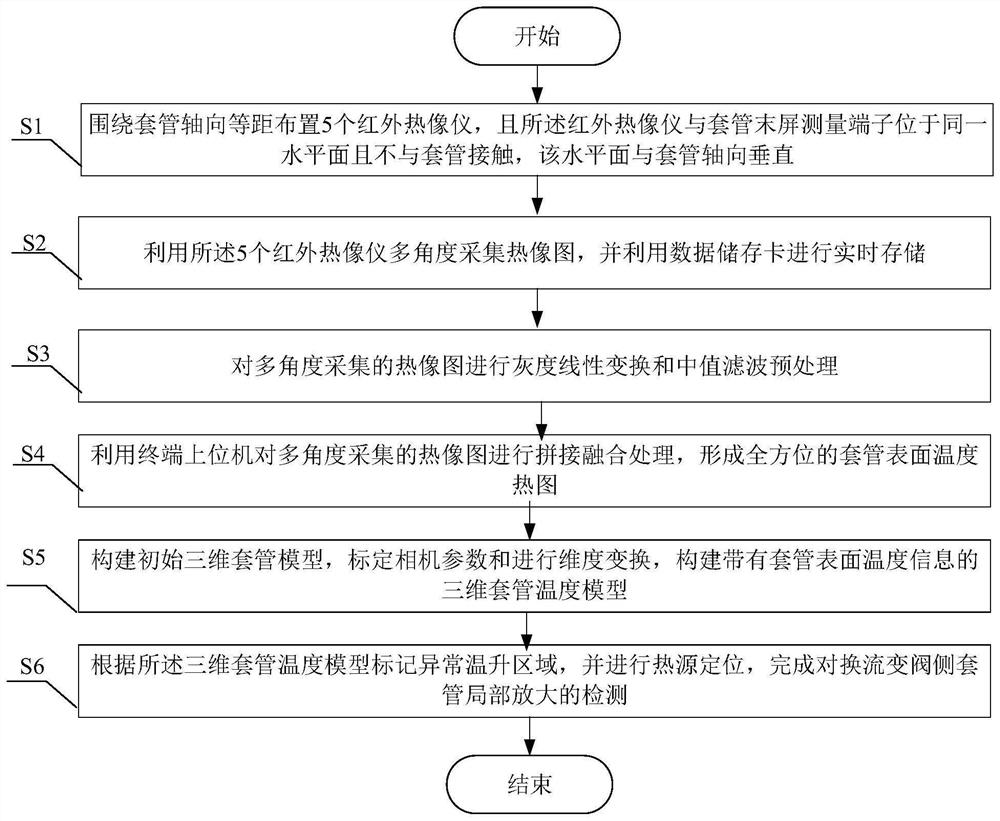

[0059] Such as image 3 As shown, the present invention provides the present invention also provides a partial discharge detection method for converting a variable valve side casing, which is as follows:

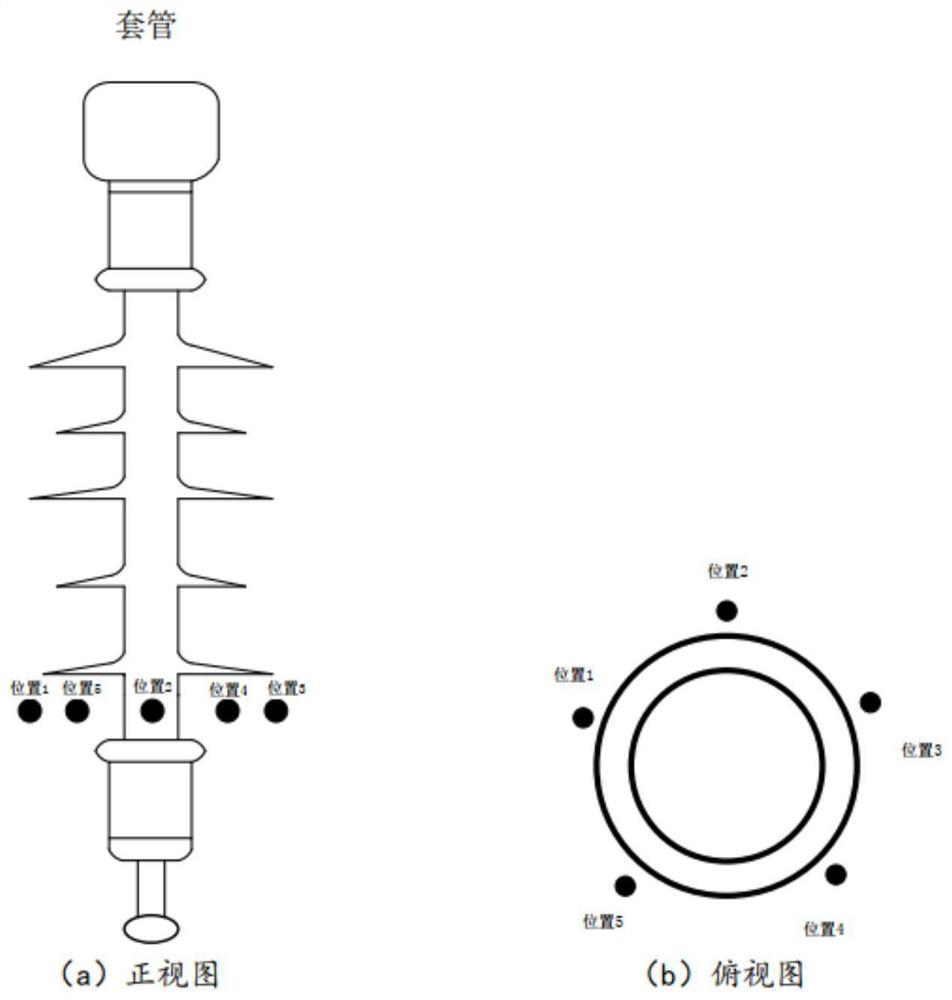

[0060] S1, a 5 infrared thermal imagery surrounding the sleeve is equipped, and the infrared thermal imager is located in the same horizontal plane and does not contact with the sleeve, the horizontal plane and the sleeve are axially perpendicular;

[0061] In this embodiment, 5 infrared thermal images are arranged around the sleeve axial orientation, and all infrared thermographs and sleeves measure the terminals at the same horizontal position and maintain a certain distance, and the plane is axially perpendicular to the casing. Real-time collection on the surface temperature of the running firing valve side sleeve.

[0062] S2, using the 5 infrared thermal imager multi-angle to collect the thermal image map, and use the data storage card to perform real-time storage;

[0063] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com