Meter coefficient self-correcting method of gas turbine flowmeter

A technology of instrument coefficient and gas turbine, applied in the field of self-calibration of gas turbine flowmeter, can solve the problems of many links, increase the length of the flowmeter, and high cost, and achieve the effect of expanding the scope of use, improving the measurement accuracy and prolonging the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

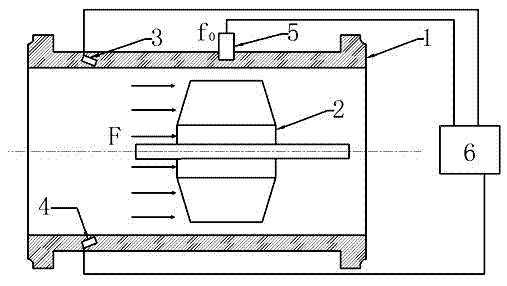

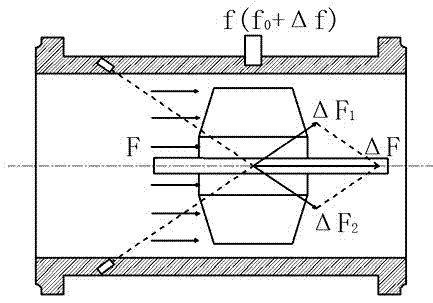

[0021] Such as figure 1 , figure 2 As shown, two electromagnetic coils 3 and 4 are implanted in the flowmeter casing 1, and a fixed detection force is applied according to the set interval time, which is equivalent to simulate the axial impact force of the fluid on the turbine blade. Calculate the frequency change corresponding to the detection force based on the obtained frequency, and then use the relationship between the flow rate and the frequency change to calculate a new meter coefficient, and obtain the flow measurement value according to the updated meter coefficient.

[0022] The key structure of the present invention includes a flowmeter casing 1 , a turbine 2 , an electromagnetic coil 3 and an electromagnetic coil 4 , a current detector 5 , and a signal processing and display unit 6 . Bearings and guide frames etc. have been omitted.

[0023] Such as fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com