High temperature gas flow measurement standard device and its detection method

A standard device and flow measurement technology, which is applied in the field of high-temperature gas flow measurement standard device and its detection, can solve the problems affecting the measurement results of the flowmeter, the expansion of metal parts in the flowmeter, and the increase of sensor error, etc., to achieve comprehensive and accurate calibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

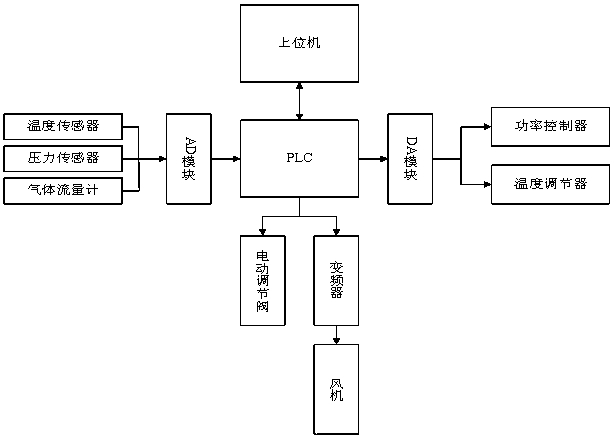

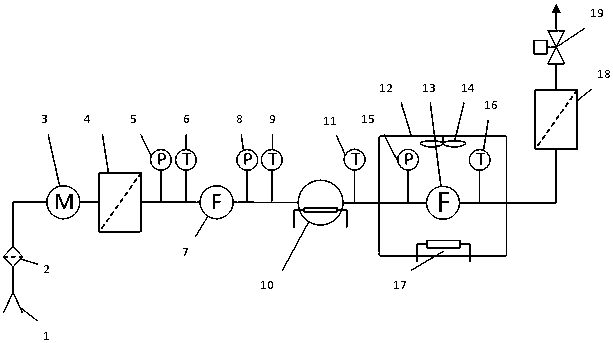

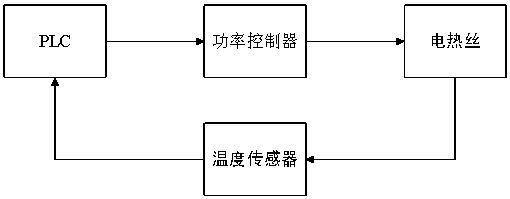

[0025] Such as figure 1 As shown, the control system of the present invention is composed of an upper computer part, a lower computer part, a data acquisition part and an actuator part. Described upper computer is PC, adopts LabVIEW software to write control program, can set temperature value, flow value in man-machine interaction interface, control device operation and stop, upper computer realizes the reception of data with lower computer through Ethernet protocol, According to the measured data, a verification report for the flowmeter to be tested can be generated. The lower computer part includes programmable controller PLC, AD module and DA module. The AD module converts the analog signals output by temperature sensors, pressure sensors, and flow meters into digital signals and transmits them to the programmable controller PLC to realize data collection. The DA...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com