Torpedo tank car molten iron liquid surface measuring method and its device

A torpedo tank car and liquid level detection technology, which is applied in the direction of measuring devices, liquid level indicators, lubrication indicating devices, etc., can solve problems such as inaccurate measurement results, and achieve the effect of solving inaccurate measurement results, simple structure, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

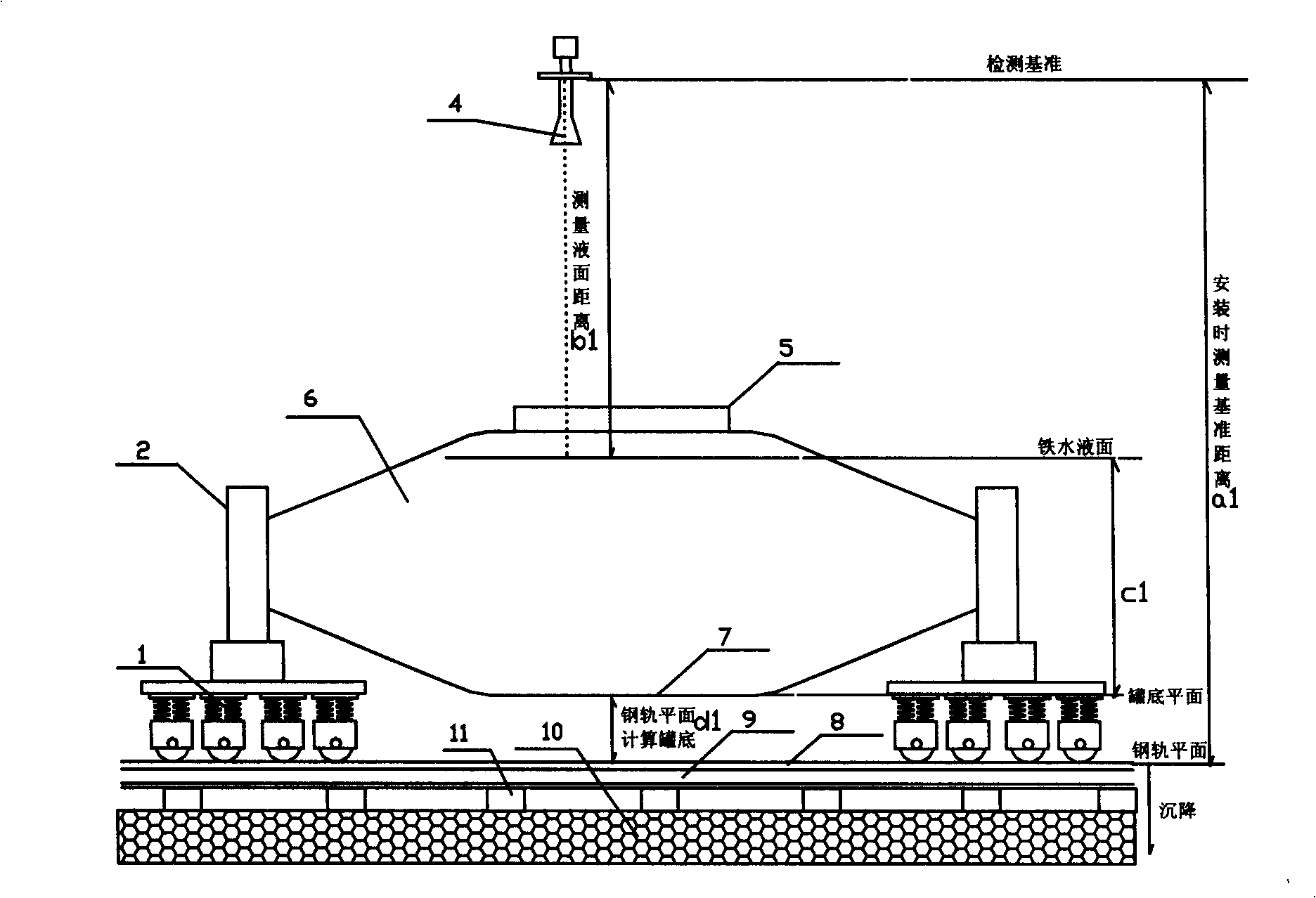

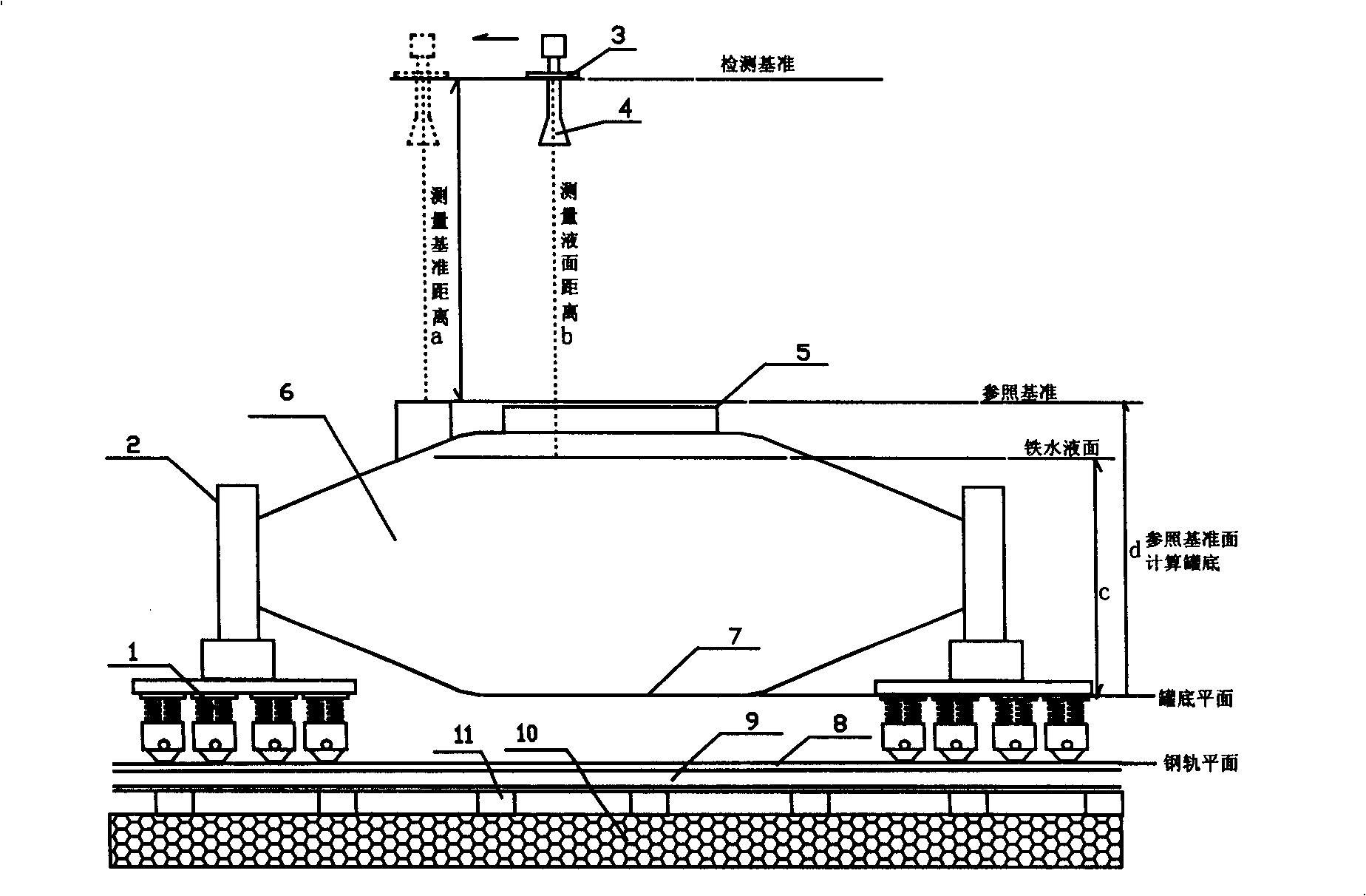

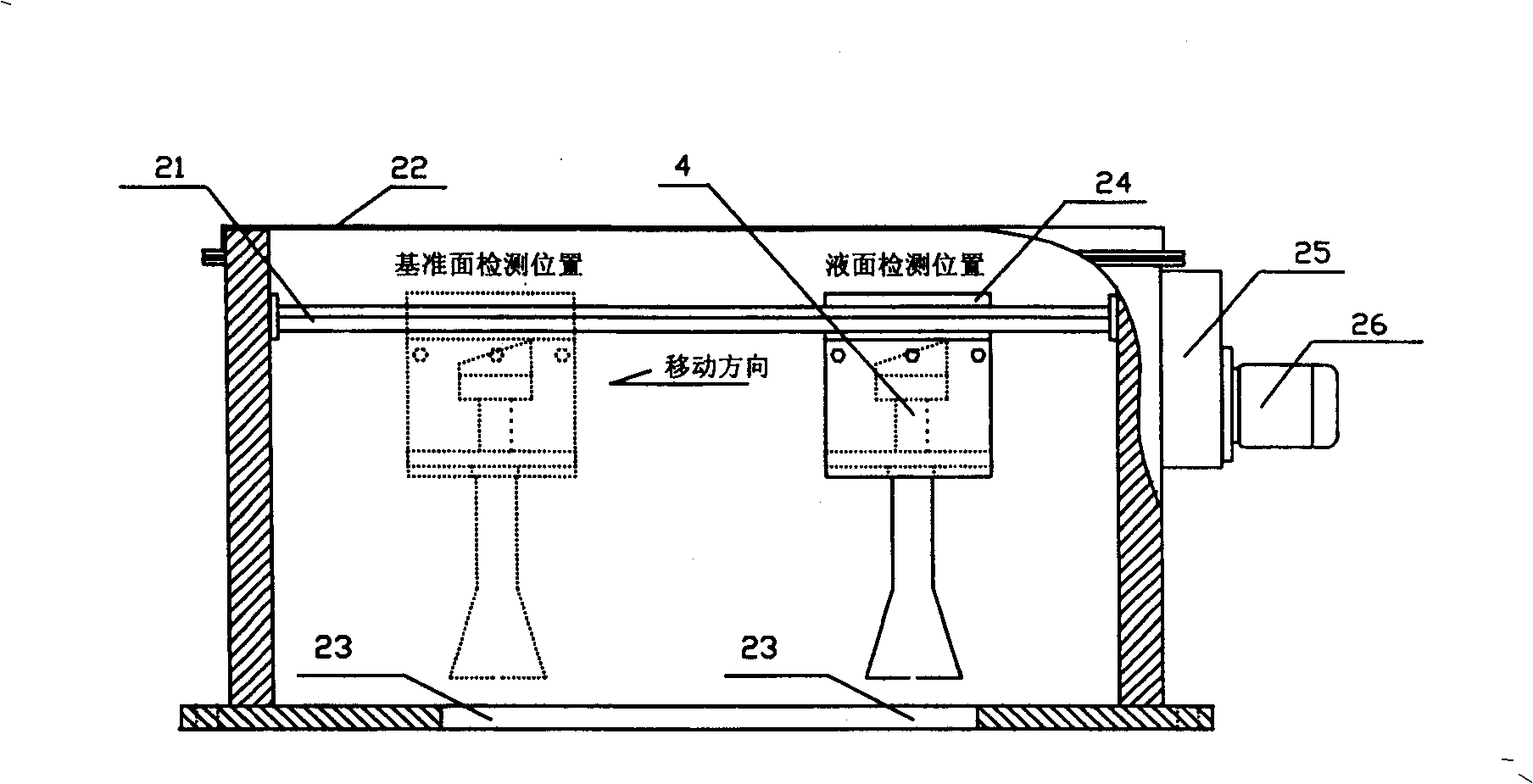

[0015] see image 3 , Figure 4 A torpedo tank car molten iron liquid level detection device, in which a tank reference plane is made on the upper surface of the molten iron tank body of the tank car, so that the height distance from the tank reference plane made by each molten iron tank to the bottom of the tank is consistent. A casing and an electric motor are housed above the blast furnace taphole torpedo tank car, and a moving track 21, a screw screw mandrel 34, a screw thread sleeve 33, a moving platform 24, and a sensor 4 are housed in the casing. The moving track 21 and the screw rod 34 are installed on the side plate 28 of the box body and are installed in parallel. The side plate 28 of the box body is installed on the bottom plate 27 of the box body. The bottom plate 27 is located at the bottom of the box body and can be used to fix the box body on the installation base On, the box body top is covered with cover plate 22. The mobile platform 24 is installed on the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com