Circulating single shaft dynamic load testing device with function of simulating tire load

A test device and tire load technology, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, can solve the problems of difficult to guarantee the accuracy of test results, inconsistent force conditions, and complicated test process, so as to achieve reliable preparation of measurement results , Accurate collection of deformation data, easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

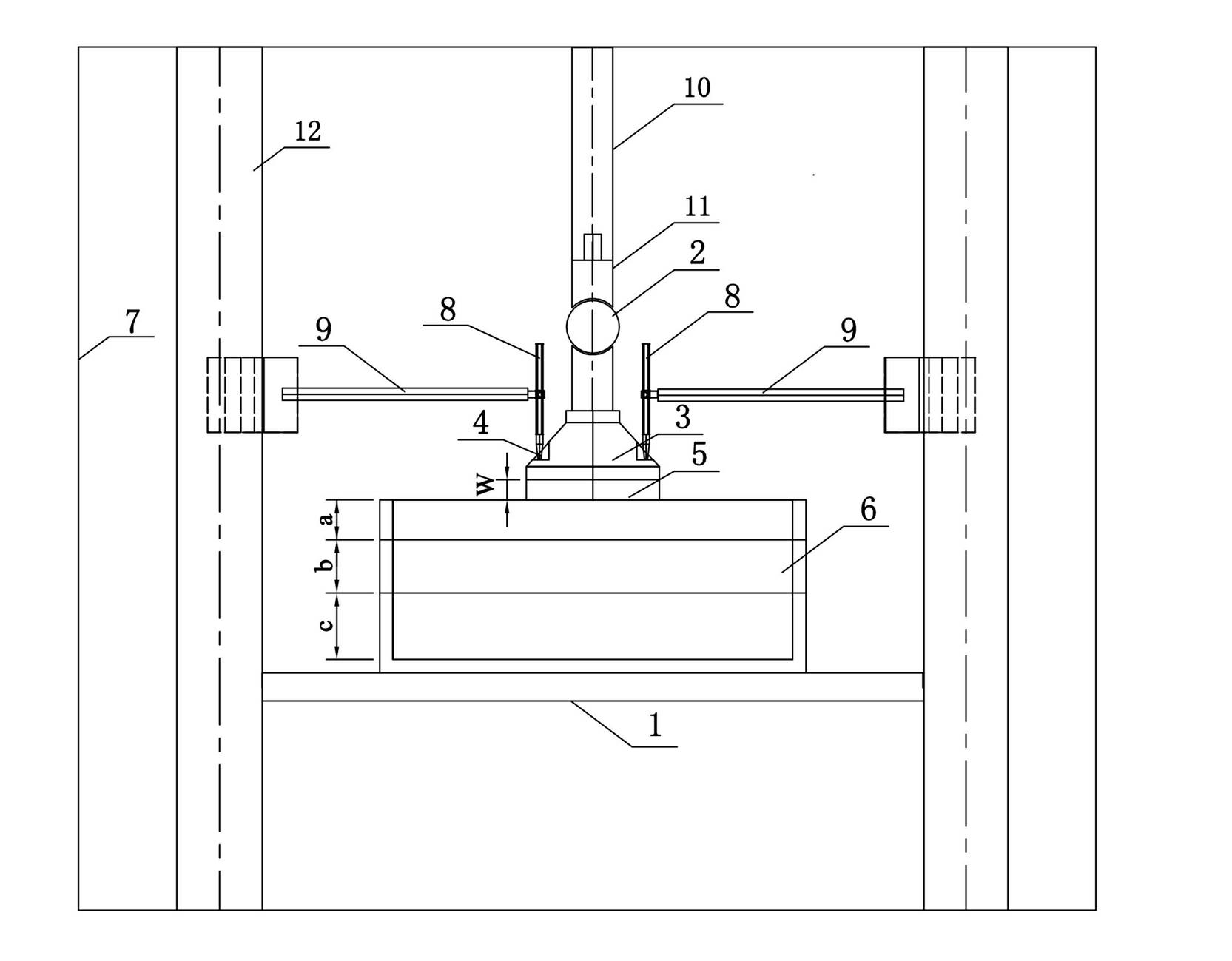

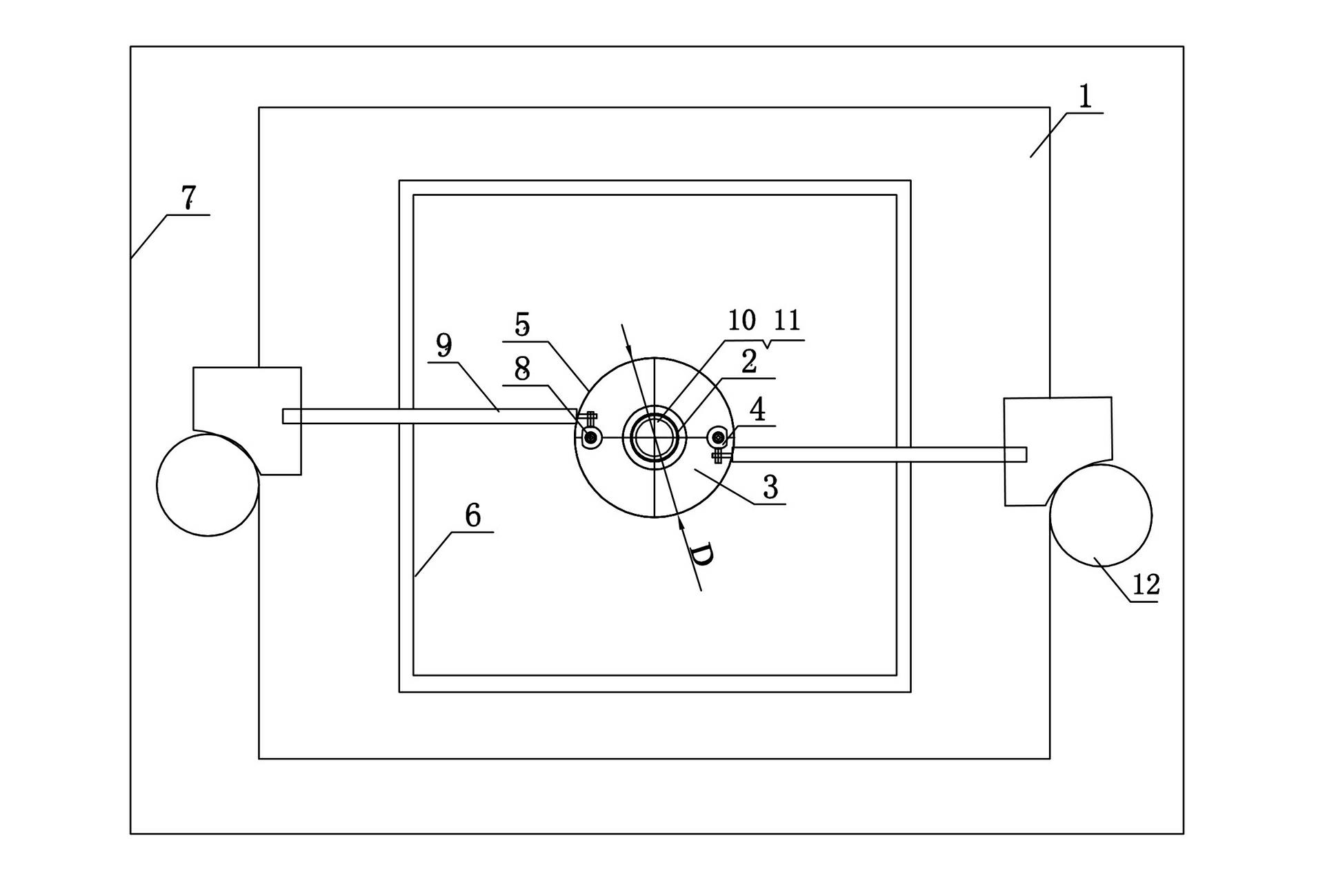

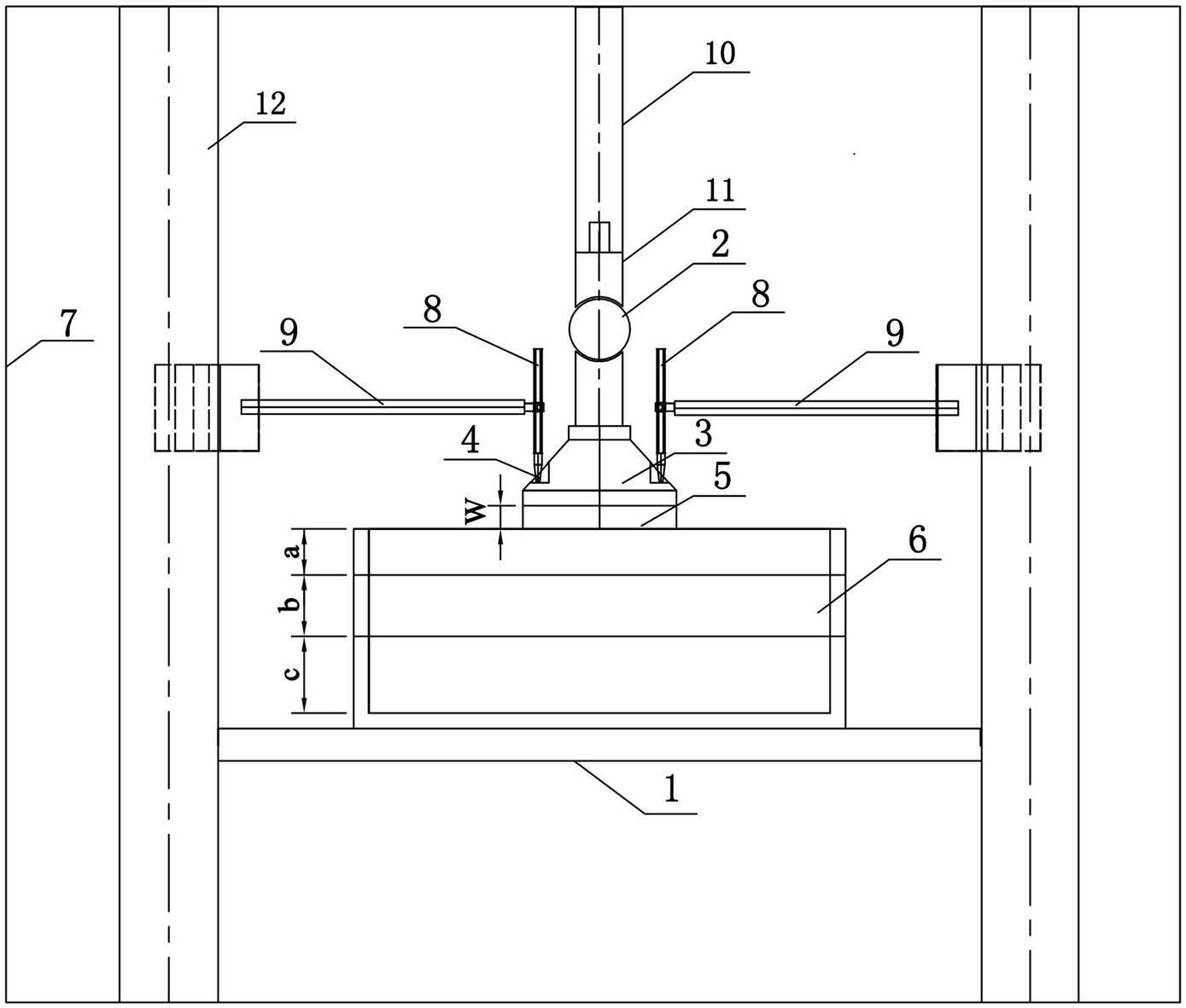

[0016] a kind of like figure 1 , figure 2 The cyclic uniaxial dynamic load test device of the present invention that can simulate the tire load is shown. The cyclic uniaxial dynamic load test device includes an environmental chamber 7, and a combined test mold 6 with variable thickness is placed inside the environmental chamber 7. A test loading device is correspondingly arranged above the test mold 6 . The test loading device includes a loading rod 10 connected to the testing machine, an indenter 3 and a displacement sensing device installed on the indenter 3 . A loading head 11 is provided at the end of the loading rod 10 , and the loading head 11 is threadedly connected with the main body of the loading rod 10 .

[0017] In this embodiment, the loading head 11 at the end of the loading rod 10 and the top of the indenter 3 are all provided with spherical crown grooves, and the loading head 11 passes through the spherical steel ball 2 placed between the aforementioned two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com