Dynamic testing and analysis system of motor

A dynamic test and analysis system technology, applied in the direction of motor generator testing, measuring devices, instruments, etc., can solve problems affecting products to be installed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

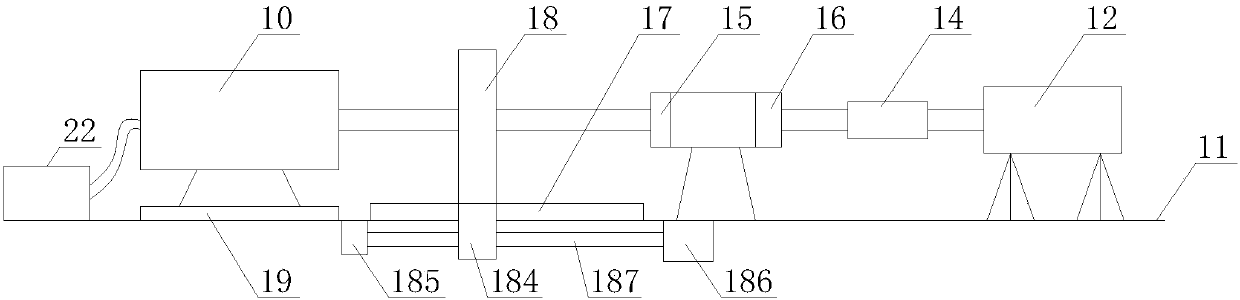

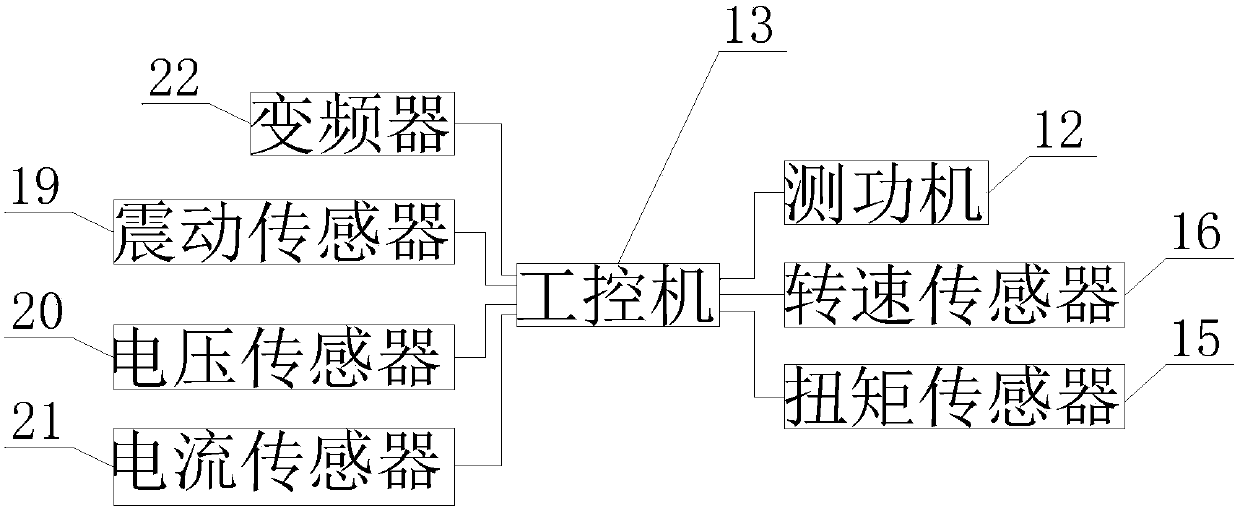

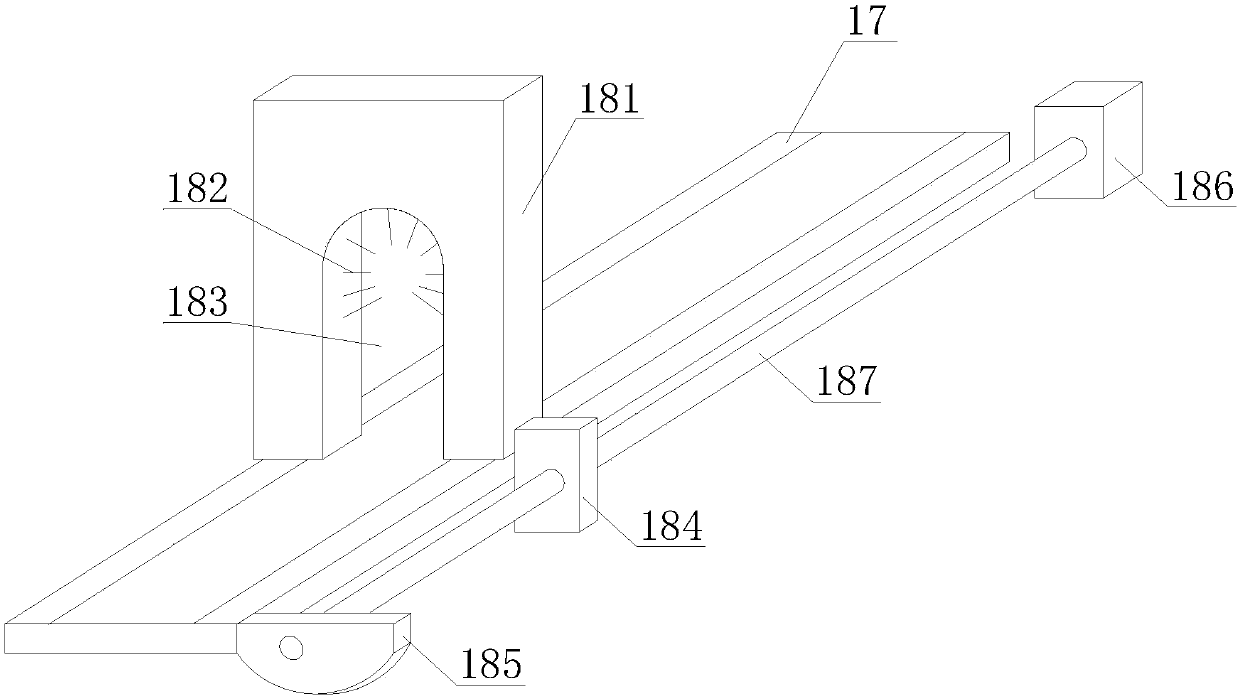

[0024] Motor dynamic test analysis system, such as Figure 1-6 As shown, it includes a motor to be tested 10 and a workbench 11. The motor to be tested 10 is installed on the workbench 11, and an industrial computer 13 is also included. A dynamometer 12 is also fixed on the workbench 11. The motor to be tested 10 and the dynamometer 12 is connected with a coupling 14, the coupling 14 enables the force of the motor 10 to be tested to be stably transmitted to the dynamometer 12, and a torque sensor 15 and a speed sensor are connected between the coupling 14 and the motor 10 to be tested 16. The torque sensor 15 is used to detect the torque value of the motor 10 to be tested, and the rotational speed sensor 16 is used to detect the rotational speed value of the motor 10 to be tested. Both the torque sensor 15 and the rotational speed sensor 16 are connected to the industrial computer 13, and the workbench 11 is also fixed Track 17 is arranged, and track 17 is double track, makes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com