Lever used in leveraged adjustable load dynamic test bench

A lever-type, test-bed technology, which is used in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problem that ordinary levers cannot meet the test needs of test-beds, etc., and achieves easy realization of automated assembly lines, low cost and land occupation. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

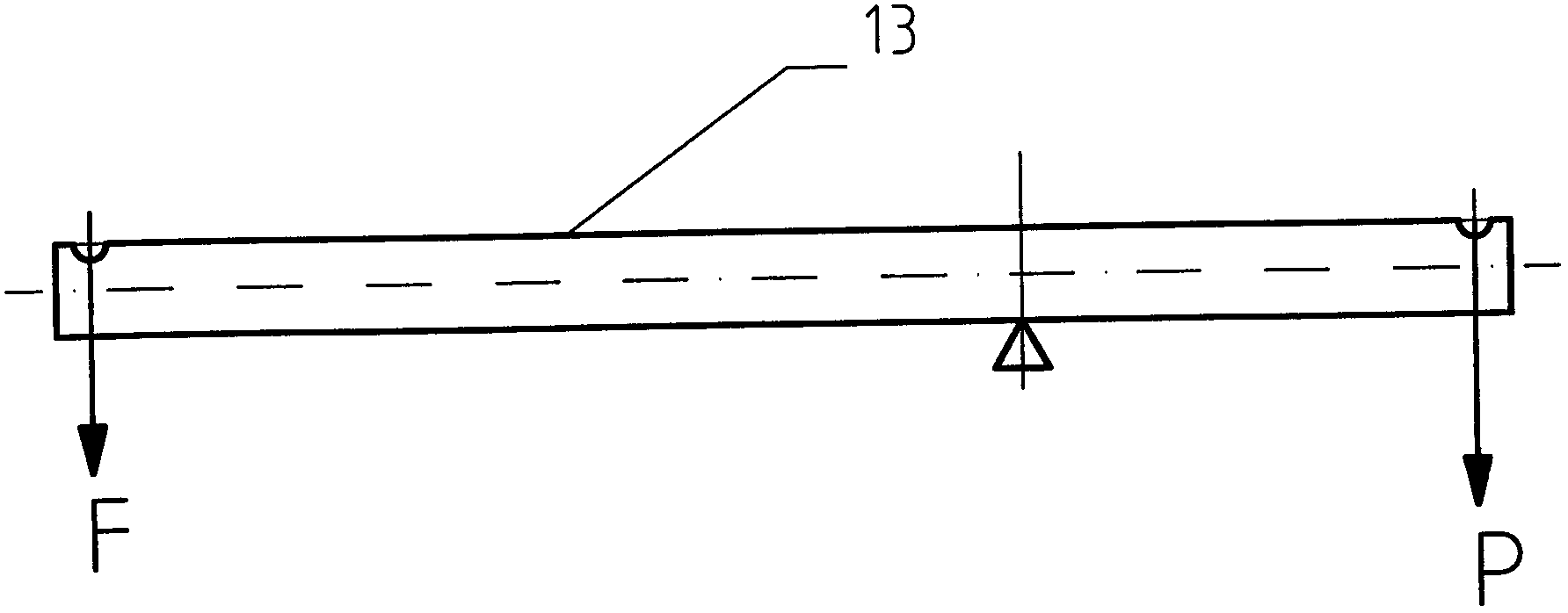

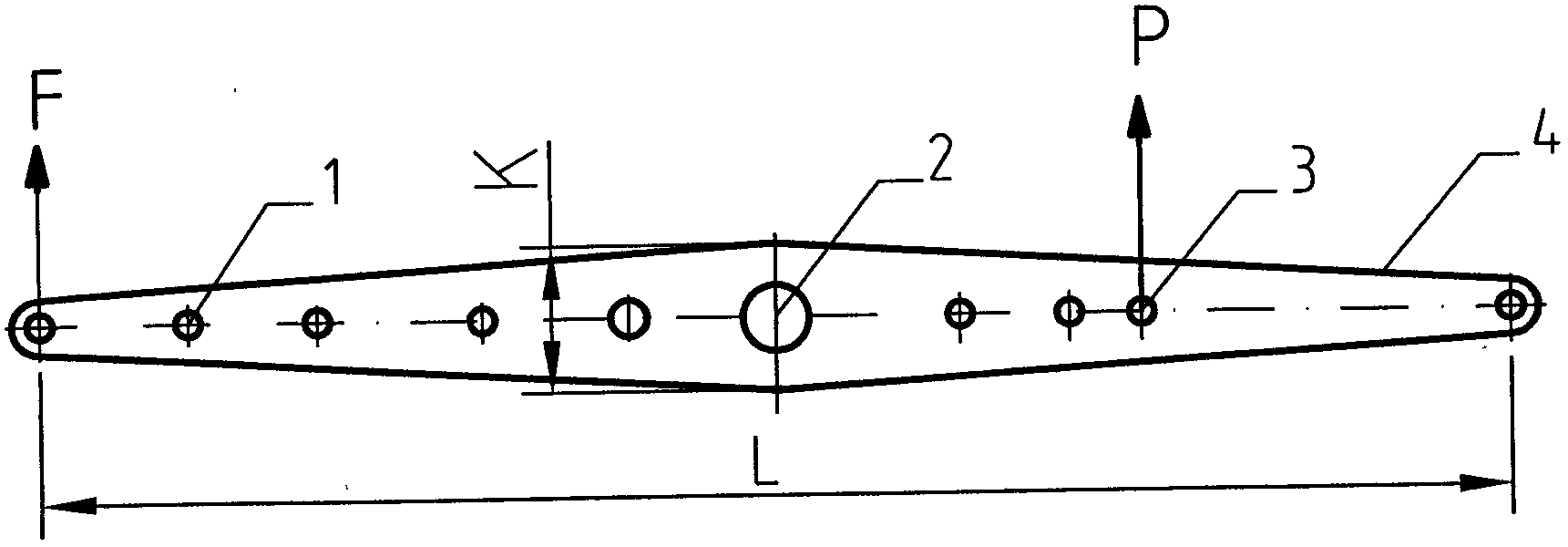

[0033] A lever used on a lever-type adjustable load dynamic load test bench, such as figure 2 , 3 Shown, on lever 4 force arm side, have force arm side mounting hole 1, force arm side mounting hole 1 can be one, or two, or three, or more (present embodiment force arm side mounting hole 1 is Five), the mounting holes 1 on the arm side can be arranged in any position on the arm side in sequence;

[0034] On the lever 4 heavy arm side, there are heavy arm side mounting holes 3, and the heavy arm side mounting holes 3 can be one, or two, or three, or more (the present embodiment heavy arm side mounting holes 3 are four ), the mounting holes 3 on the boom side can be arranged in sequence at any position on the boom side;

[0035] There is a lever support point hole 2 between the lever 4 arm side and the lever 4 heavy arm side;

[0036] The material of the lever 4 is a material whose strength is greater than or equal to the strength of steel, which can be steel;

[0037] The le...

Embodiment 2

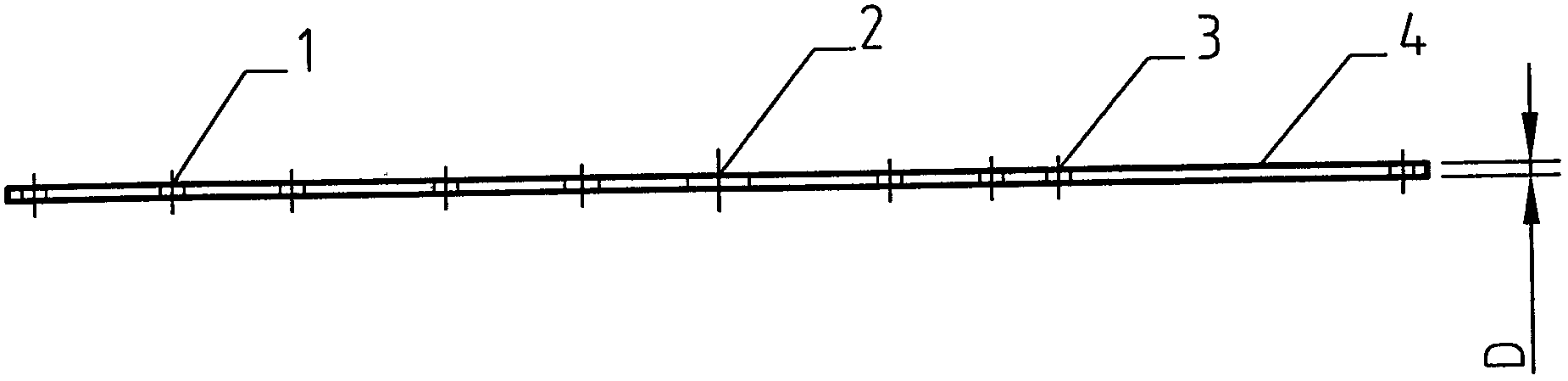

[0059] A kind of lever used on the lever-type adjustable load dynamic load test bench, its structure is basically the same as that of embodiment 1, the only difference is as follows Figure 4 As shown, there is a horizontal rail groove 5 on the arm side of the lever 4, and the mounting hole 1 on the arm side is opened in the horizontal rail groove 5, and the fixed shaft installed in the mounting hole 1 on the arm side can Exit downward and move along the horizontal track groove 5 to the other arm side mounting hole 1 for fixation.

Embodiment 3

[0061] A kind of lever used on the lever-type adjustable load dynamic load test bench, its structure is basically the same as that of embodiment 1, the only difference is as follows Figure 5 As shown, there is a horizontal rail groove 5 on the heavy arm side of the lever 4, and the mounting hole 3 on the heavy arm side is opened in the horizontal rail groove 5, and the fixed shaft installed in the mounting hole 3 on the heavy arm side can be moved from the The lower exit moves along the horizontal track groove 5 and is fixed in the mounting hole 3 on the other boom side.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com