Dynamic load test bed for shaft coupler

A technology of couplings and test benches, which is applied in the testing of machine gears/transmission mechanisms, etc., can solve problems such as high cost and affecting the normal operation of couplings, and achieve the effect of reducing test costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

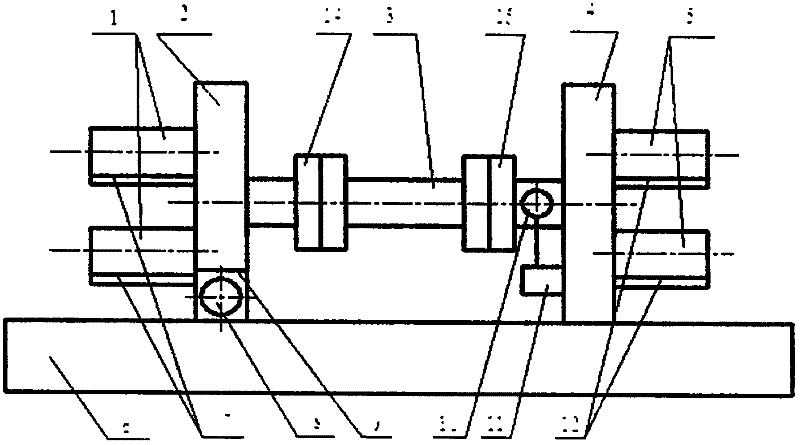

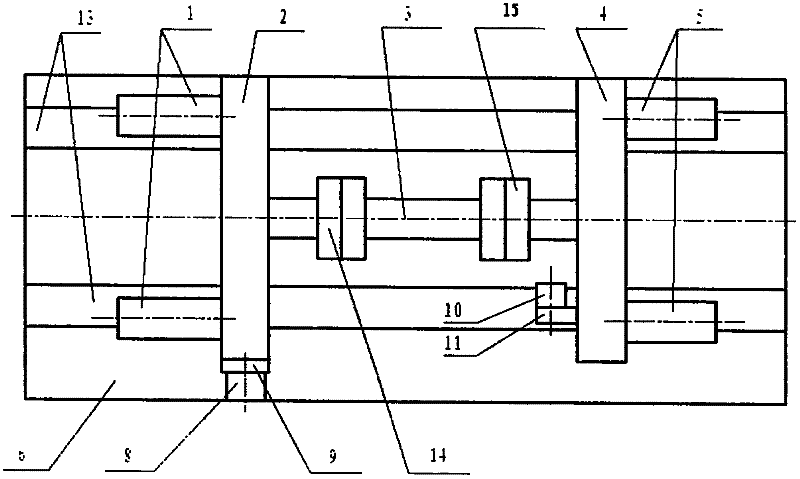

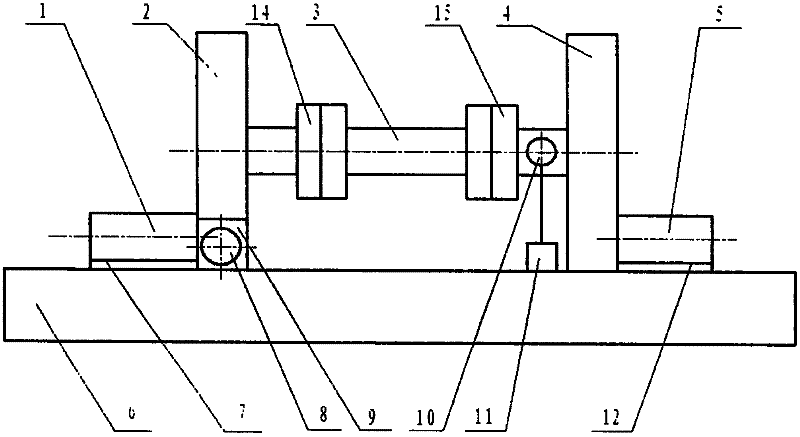

[0012] Further describe the technical scheme of the present invention below in conjunction with accompanying drawing: Figure 1~4 , The coupling dynamic load test bench includes, load motor 1, output reducer 2, tested coupling 3, input reducer 4, motor 5, equipment base 6, pressure sensor 7, travel motor 8, travel mechanism 9, The rotational speed sensor 10, the rotational speed sensor mounting bracket 11, the pressure sensor 12, the moving auxiliary slide rail 13, the output flange 14, and the input flange 15.

[0013] The output reducer 2 is connected to the equipment base 6 through the running mechanism 9, the output end of the output reducer 2 is mechanically connected to the load motor 1, and the input reducer 4 is connected to the equipment base 6 Mechanically connected, the input end of the input reducer 4 is mechanically connected to the motor 5 , and the traveling mechanism 9 is mechanically connected to the traveling motor 8 .

[0014] The input end of the output re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com