Crankshaft dynamic balance testing and calibration method

A calibration method and crankshaft technology, applied in the static/dynamic balance test, measuring device, machine/structural component test, etc., can solve the problems of crankshaft bump damage, troublesome operation, inability to use dynamic balance detection, etc., to avoid bumping The effect of injury, easy operation and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

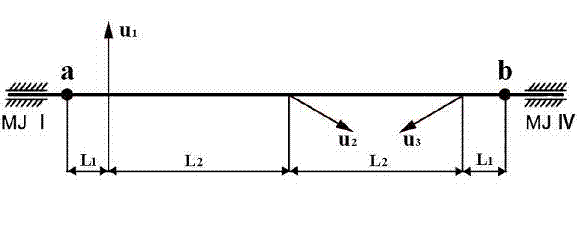

[0016] Taking the three-cylinder V6 crankshaft as an example, the crankshaft dynamic balance detection and calibration method is described in detail. The specific implementation steps are as follows:

[0017] The first step is to carry out the unbalance conversion calculation first, decompose the unbalance on the three crank pins of the V6 crankshaft to the main journals at both ends, and calculate the unbalance of the crankshaft on the main journals at both ends. The unbalance quantity includes two physical quantities of unbalance mass and angle. The unbalanced angle is the included angle formed by the unbalanced direction on the circumference of the crankshaft and the line connecting the center of the first crank pin and the center of the main journal.

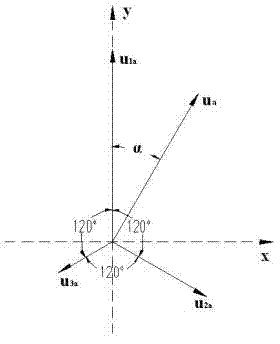

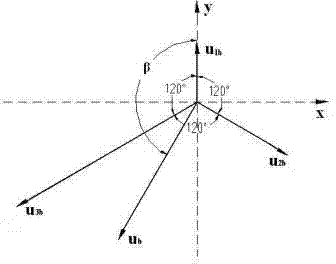

[0018] figure 1 It is a schematic diagram of distribution of crank pin unbalance in the present invention. figure 2 It is a combined schematic diagram of unbalanced quantities on plane a of the present invention. image ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com