Dynamic load testing method for compound planetary gear transmission mechanism with wet-type gear shifting element

A compound planetary gear and transmission mechanism technology, applied in the testing of mechanical components, machine/structural component testing, measuring devices, etc., can solve the complex dynamic load characteristics, difficult to be directly applied, and unable to reach the interior of the compound planetary gear transmission mechanism Component dynamic load test objectives and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

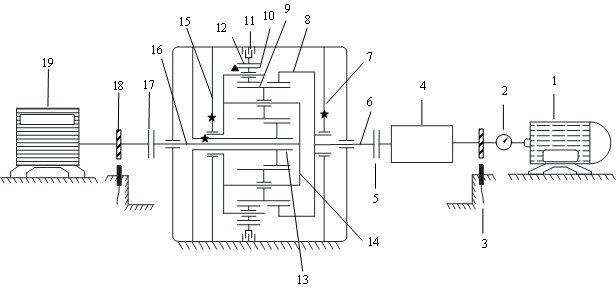

[0036] Such as figure 1 As shown, in this embodiment, a dynamic load test is performed on a compound planetary gear transmission mechanism with a double ring gear. The test device includes a motor 1, a torque meter 2, a speedometer 3, a gearbox 4, a coupling 5, and a belt connected in sequence. Compound planetary gear transmission mechanism 6-16 of double ring gear, shaft coupling 17, speedometer 18 and dynamometer 19. Among them, the compound planetary gear transmission mechanism with double ring gear includes input shaft 6, ring gear 8 and its fixed support 7, long planetary gear 9, short planetary gear 10, wet shifting element 11, ring gear 12, sun gear 13 , the planet carrier 14 and its fixed support 15 , and the output shaft 16 . Among them, the small ring gear 8 is connected with the input shaft 6, the planet carrier 14 is connected with the output shaft 16, the long planetary gear 9 meshes with the ring gear 8, the sun gear 13, and the short planetary gear 10 at the sa...

Embodiment 2

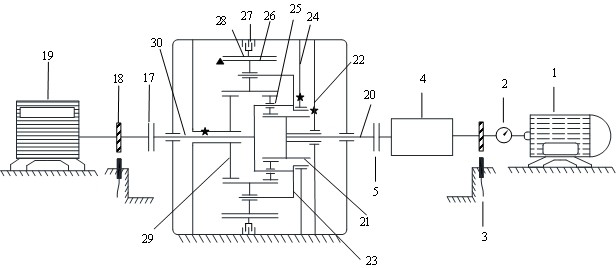

[0039] Such as figure 2 As shown, in this embodiment, a dynamic load test is carried out on a compound planetary gear transmission mechanism with double sun gears. The test device includes a motor 1, a torsion meter 2, a speedometer 3, a gearbox 4, a coupling 5, and a belt connected in sequence. Compound planetary gear transmission mechanism 20-30 of double sun gear, shaft coupling 17, speedometer 18 and dynamometer 19. The compound planetary gear transmission mechanism with sun gear in this embodiment includes input shaft 20, sun gear 21 and its fixed support 22, planet carrier 23 and its fixed support 24, short planetary gear 25, long planetary gear 26, wet type Blocking element 27, ring gear 28, sun gear 29 and output shaft 30. Wherein, the sun gear 21 is connected with the input shaft 20, the planet carrier 23 is connected with the output shaft 30, the long planetary gear 26 meshes with the ring gear 28, the short planet 25, and the sun gear 29 at the same time, and the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com