Friction type self-resetting cast-in-place beam column joint

A self-reset, pouring beam-column technology, applied in building types, building components, building structures, etc., can solve problems such as high construction accuracy requirements, complex structural forms, affecting node performance, etc., and achieves short repair time, low difficulty, The effect of increasing the energy consumption of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to illustrate the present invention more clearly, below in conjunction with appendix Figure 1~4 The present invention is described in further detail.

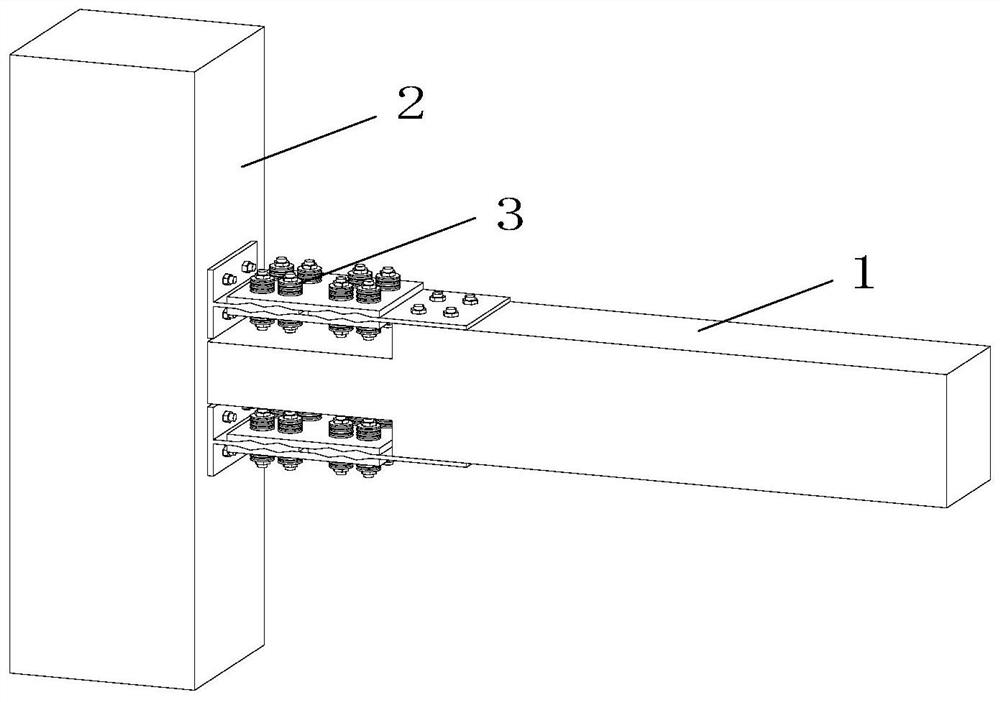

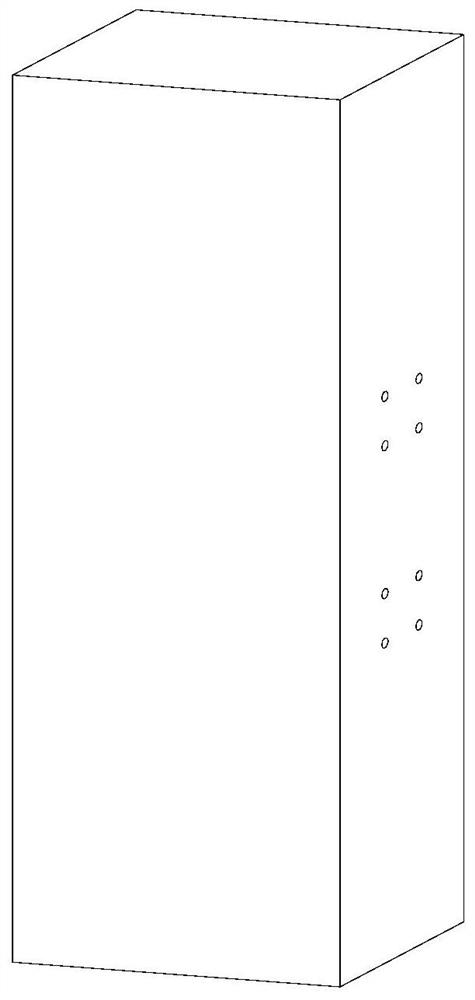

[0054] Such as Figure 1-4 As shown, a friction-type self-resetting cast-in-place beam-column node includes: a weakened reinforced concrete beam 1, a reinforced concrete column 2 and a self-resetting friction-type connector 3;

[0055] The weakened reinforced concrete beam 1 and the reinforced concrete column 2 are connected by cast-in-place, and the upper and lower two weakened areas 1-1 at the end of the weakened reinforced concrete beam 1 are connected by adding self-resetting friction connectors 3 .

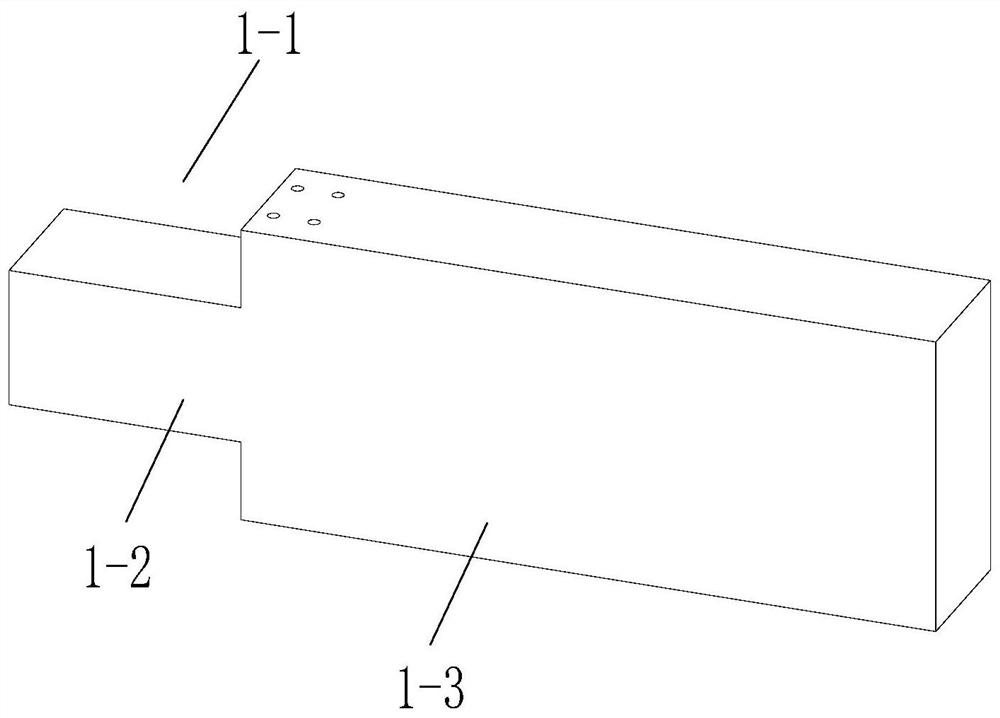

[0056] Such as figure 2 As shown, the weakened reinforced concrete beam 1 has two sections: a weakened section 1-2 and a non-weakened section 1-3.

[0057] Such as Figure 4 As shown, the self-resetting friction connector 3 includes: a T-shaped central plate 3-1, a straight central plate 3-2, an upper cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com