Preparation method for modified graphene-loaded titanium dioxide composite photocatalyst

A technology of titanium dioxide and graphene, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as easy agglomeration, difficult dispersion, weak interaction, etc., to achieve difficult agglomeration, low cost, Meet the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

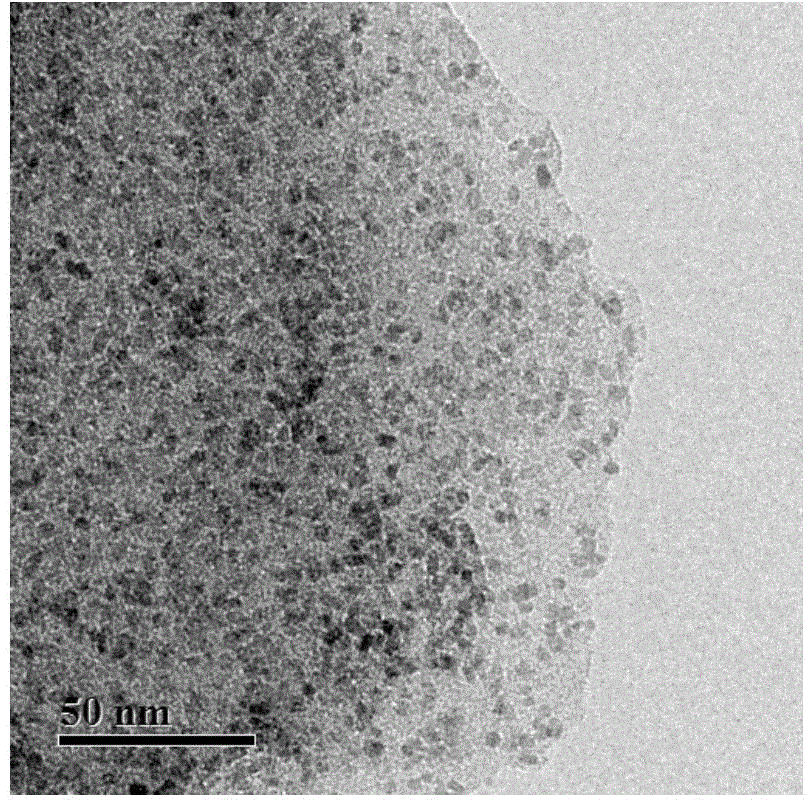

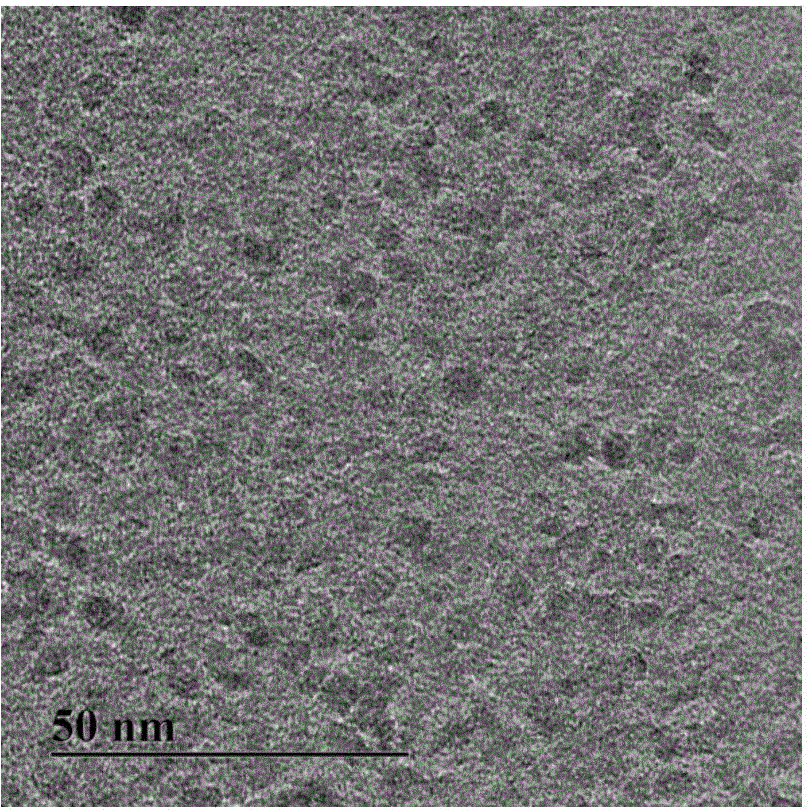

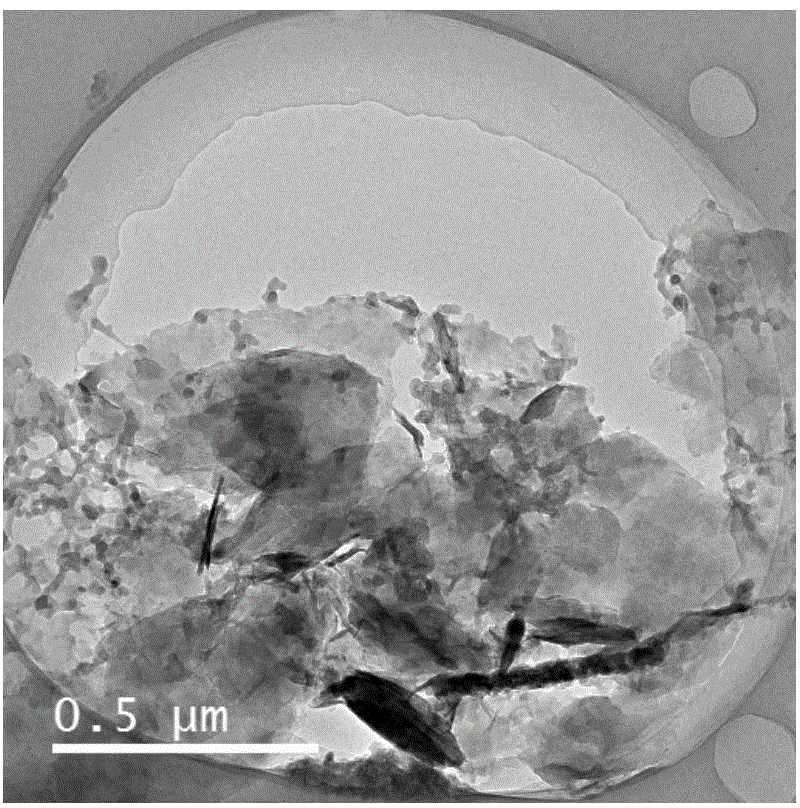

[0033] 6 mL of triethanolamine was added to 400 mL of graphene oxide suspension with a concentration of 5.5 mg / mL, and the reaction was stirred at 80° C. for 2 h. Centrifuge and wash until the eluent is neutral to obtain a graphene oxide suspension modified with triethanolamine. Dissolving 10g of titanyl sulfate in 500mL of sulfuric acid solution with a concentration of 0.3mol / L to obtain a titanyl cation solution, adding 240mL of triethanolamine-modified graphene oxide suspension to the above-mentioned titanyl cation solution, Ultrasonic assisted impregnation for 2 h and centrifugation to obtain a solid catalyst precursor. With 70mL of Na with a concentration of 0.1mol / L 2 CO 3 Solution After dispersing the catalyst precursor, it was transferred to a polytetrafluoroethylene-lined hydrothermal kettle, and placed in an oven at 80°C for hydrothermal reaction for 20 hours. The reaction mixture was centrifugally washed to neutrality, and the obtained solid was dried at 80°C and...

Embodiment 2

[0035]5 mL of triethanolamine was added to 400 mL of graphene oxide suspension with a concentration of 5.5 mg / mL, and the reaction was stirred at 120° C. for 2 h. Centrifuge and wash until the eluent is neutral to obtain a graphene oxide suspension modified with triethanolamine. Dissolving 10g of titanyl sulfate in 500mL of sulfuric acid solution with a concentration of 0.5mol / L to obtain a titanyl cation solution, adding 240mL of triethanolamine-modified graphene oxide suspension to the above-mentioned titanyl cation solution, Ultrasonic assisted impregnation for 3 h and centrifugation to obtain a solid catalyst precursor. With 70mL concentration of 0.3mol / L Na 2 CO 3 Solution The catalyst precursor was dispersed and transferred to a polytetrafluoroethylene-lined hydrothermal kettle, and placed in a 70°C oven for hydrothermal reaction for 25 hours. The reaction mixture was centrifugally washed to neutrality, and the obtained solid was dried at 80°C and transferred to a muf...

Embodiment 3

[0037] 3 mL of triethanolamine was added to 400 mL of graphene oxide suspension with a concentration of 5.5 mg / mL, and the reaction was stirred at 60° C. for 3 h. Centrifuge and wash until the eluent is neutral to obtain a graphene oxide suspension modified with triethanolamine. Dissolving 10g of titanyl sulfate in 500mL of sulfuric acid solution with a concentration of 0.1mol / L to obtain a titanyl cation solution, adding 240mL of triethanolamine-modified graphene oxide suspension to the above-mentioned titanyl cation solution, Ultrasonic assisted impregnation for 1 h and centrifugation to obtain a solid catalyst precursor. With 70mL concentration of 0.5mol / L Na 2 CO 3 Solution After dispersing the catalyst precursor, it was transferred to a polytetrafluoroethylene-lined hydrothermal kettle, and placed in a 100°C oven for hydrothermal reaction for 15 hours. The reaction mixture was centrifugally washed to neutrality, and the obtained solid was dried at 80°C and transferred ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com