Method for extracting peanut polysaccharide from cold pressed peanut cake

A technology of cold-pressing peanut meal and peanut meal, which is applied in the field of extracting peanut polysaccharides, can solve the problem of low purity of peanut meal polysaccharides, and achieve the effects of small structural damage, mild conditions, and improved purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, prepare peanut polysaccharide from cold-pressed peanut meal

[0038] (1) Take cold-pressed peanut meal powder, add distilled water, and prepare a peanut meal suspension with a mass concentration of 8% to dissolve it, so as to fully combine with protease;

[0039] (2) Add Neutrase neutral protease (purchased from Beijing Suolaibao Technology Co., Ltd.) to the above solution, the enzyme dosage is 5200U / g cold-pressed peanut meal, and enzymatically react in a constant temperature water bath shaker at 45°C for 150min;

[0040] (3) Take it out after the enzymatic hydrolysis reaction, put it in a constant temperature water bath at 90°C for 10 minutes to inactivate neutral protease, and centrifuge at 4500r / min for 20 minutes to obtain a precipitate, which is the peanut meal residue from which protein has been removed;

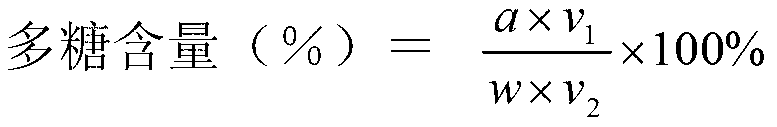

[0041] (4) Extract polysaccharides from the obtained peanut meal residue by hot water extraction, the extraction temperature is 90°C, the extract...

Embodiment 2

[0045] Embodiment 2, the method for preparing peanut polysaccharide from cold-pressed peanut meal

[0046] (1) Take cold-pressed peanut meal powder, add distilled water, and prepare a peanut meal solution with a concentration of 8% to dissolve it, so as to fully combine with protease;

[0047] (2) Add Flavorzyme neutral protease (purchased from Beijing Suolaibao Technology Co., Ltd.) to the above solution, the enzyme dosage is 5200U / g cold-pressed peanut meal, and enzymatically react in a constant temperature water bath shaker at 45°C for 150min;

[0048] (3) Take it out after the reaction is over, put it in a constant temperature water bath at 90°C for 10 minutes to inactivate neutral protease, and centrifuge at 4500r / min for 20 minutes to obtain a precipitate, which is the peanut meal residue from which protein has been removed;

[0049] (4) Extract polysaccharides from the peanut meal residue obtained above by hot water extraction, the extraction temperature is 80°C, the ex...

Embodiment 3

[0053] Embodiment 3, the method for preparing peanut polysaccharide from cold-pressed peanut meal

[0054] (1) Take cold-pressed peanut meal powder, add distilled water, and prepare a peanut meal solution with a concentration of 8% to dissolve it, so as to fully combine with protease;

[0055] (2) Add Protamex neutral protease (purchased from Beijing Suolaibao Technology Co., Ltd.) to the above solution, the enzyme dosage is 2600U / g cold-pressed peanut meal, and react in a constant temperature water bath shaker at 45°C for 150min;

[0056] (3) Take it out after the reaction is over, put it in a constant temperature water bath at 90°C for 10 minutes to inactivate neutral protease, and centrifuge at 4500r / min for 20 minutes to obtain a precipitate, which is the peanut meal residue from which protein has been removed;

[0057] (4) Extract polysaccharides from the peanut meal residue obtained above by hot water extraction, the extraction temperature is 50°C, the extraction time is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com