Peeling method of layered material and high-quality peeling material obtained by peeling

A layered material and delamination technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve problems affecting graphene performance, original structure damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

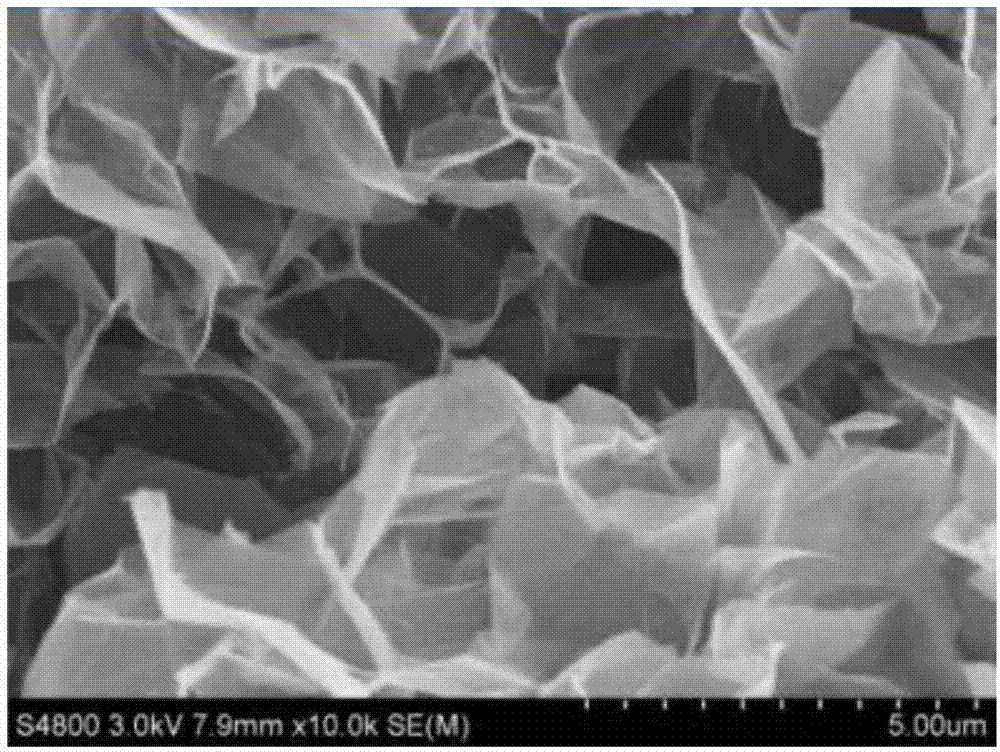

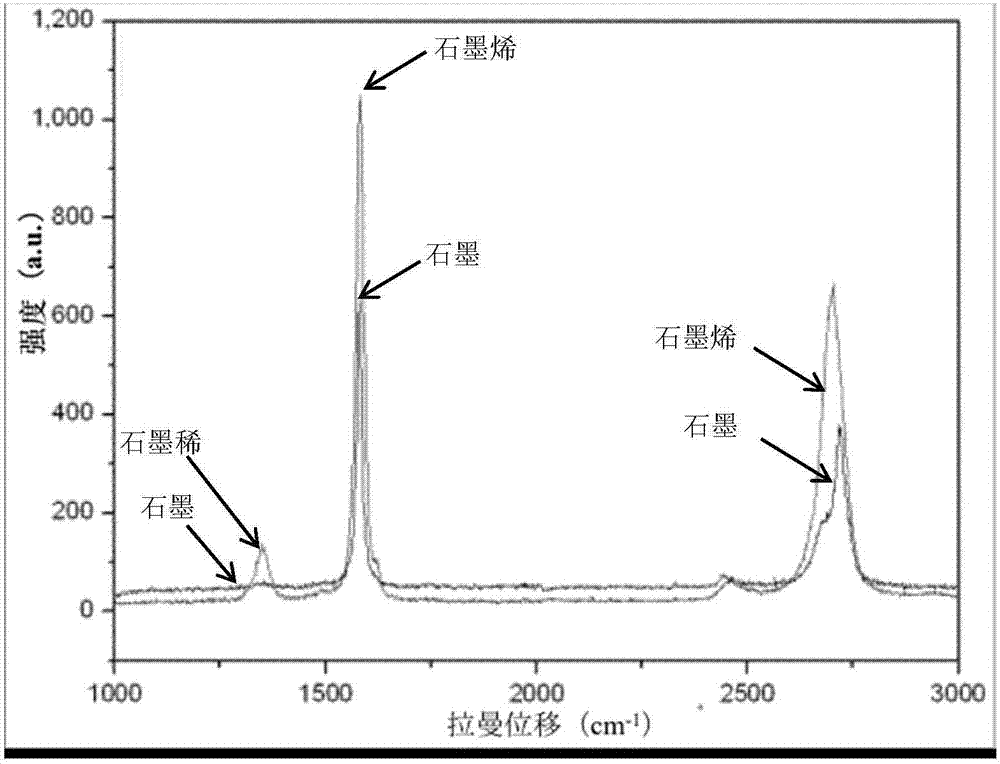

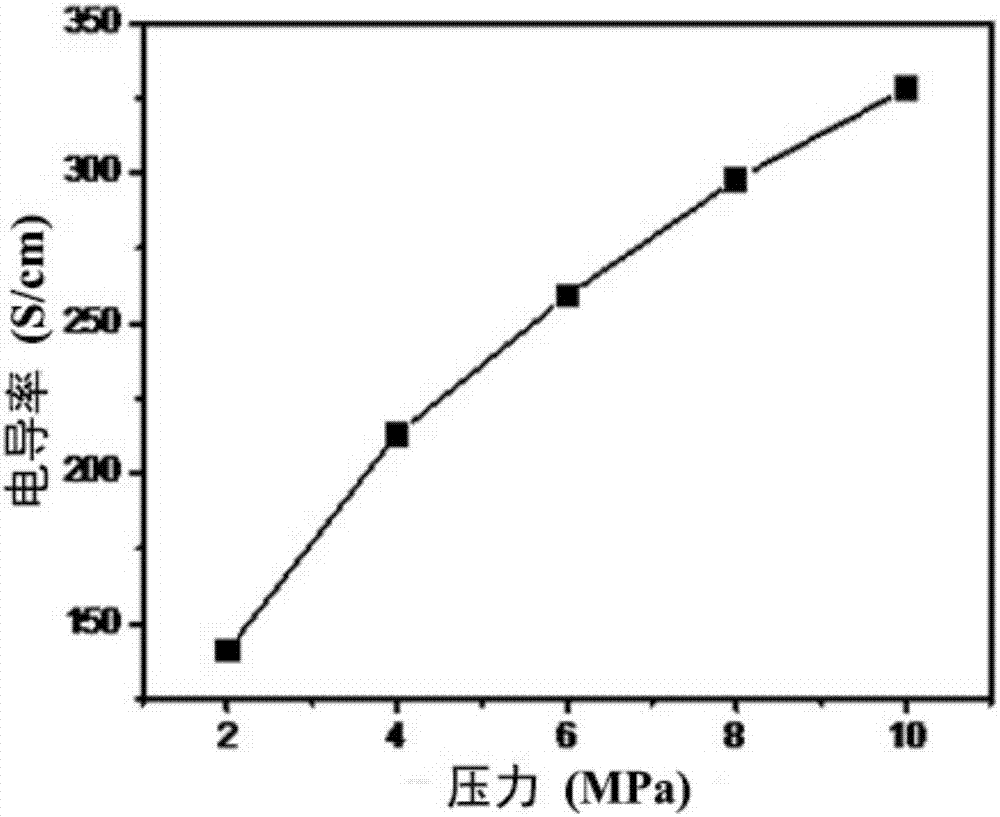

[0073] (1) Taking natural flake graphite (13 μm in particle size) as starting raw material, by natural flake graphite: ammoniacal liquor (mass ratio)=1:250 ratio, in natural flake graphite, add intercalant ammoniacal liquor, mechanical stirring mixes 4h, Realize the infiltration of natural flake graphite, intercalation of ammonia water to the surface and interlayer of natural flake graphite;

[0074] (2) slowly drip activator hydrogen peroxide (mass fraction is 50%) in the mixed liquor that step (1) obtains, the add-on of hydrogen peroxide is 20 times of the natural flake graphite quality of step (1), and simultaneously with 300r / Stirring at a speed of min, the activator hydrogen peroxide reacts with the intercalation agent ammonia water to generate airflow and peel off the sheets of natural graphite flakes;

[0075] (3) after completion of the reaction, add distilled water to the solution obtained in step (2) (wherein, the mass ratio of distilled water and the natural flake ...

Embodiment 2

[0084] (1) take natural flake graphite (30 μ m in particle diameter) as starting raw material, by natural flake graphite: the ratio of chlorosulfonic acid (mass ratio)=1:150, add intercalation agent chlorosulfonic acid in natural flake graphite, mechanical Stir and mix for 8 hours to realize the infiltration of natural flake graphite, and the intercalation of chlorosulfonic acid to the surface and interlayer of natural flake graphite;

[0085] (2) slowly drip activator hydrogen peroxide (mass fraction is 50%) in the mixed solution that step (1) obtains, the add-on of hydrogen peroxide is 40 times of the natural flake graphite quality of step (1), and simultaneously with 500r / Stirring at a speed of min, the activator hydrogen peroxide reacts with the intercalation agent chlorosulfonic acid to generate a strong air flow, which makes the sheets of natural graphite flakes peel off;

[0086] (3) After the reaction is completed, add distilled water (wherein, the mass ratio of disti...

Embodiment 3

[0092] (1) Take expanded graphite worms as starting raw material, press expanded graphite worms: the ratio of chlorosulfonic acid (mass ratio)=1:50, add intercalation agent chlorosulfonic acid in expanded graphite worms, mechanical stirring mixes 1h, realizes Infiltration of expanded graphite worms, intercalation of chlorosulfonic acid to the surface and interlayer of expanded graphite worms;

[0093] (2) slowly add activator sodium nitrite in the mixed solution that step (1) obtains, the add-on of sodium nitrite is 85 times of the expanded graphite worm quality of step (1), and simultaneously stirs rapidly with 400r / min speed , the activator sodium nitrite reacts with the intercalation agent chlorosulfonic acid to generate airflow, which makes the sheets of expanded graphite worms peel off;

[0094] (3) After the reaction is completed, add distilled water (wherein, the mass ratio of distilled water to the expanded graphite worms of step (1) is 200:1) to the solution obtained ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com