Metal flange plastic lining layer machining process

A processing technology and plastic lining technology, which is applied in the field of metal flange plastic lining plastic layer processing technology, can solve the problems of multi-flange plastic lining layer allowance, affecting production and processing, etc., and achieves qualified size, easy operation and simple process method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

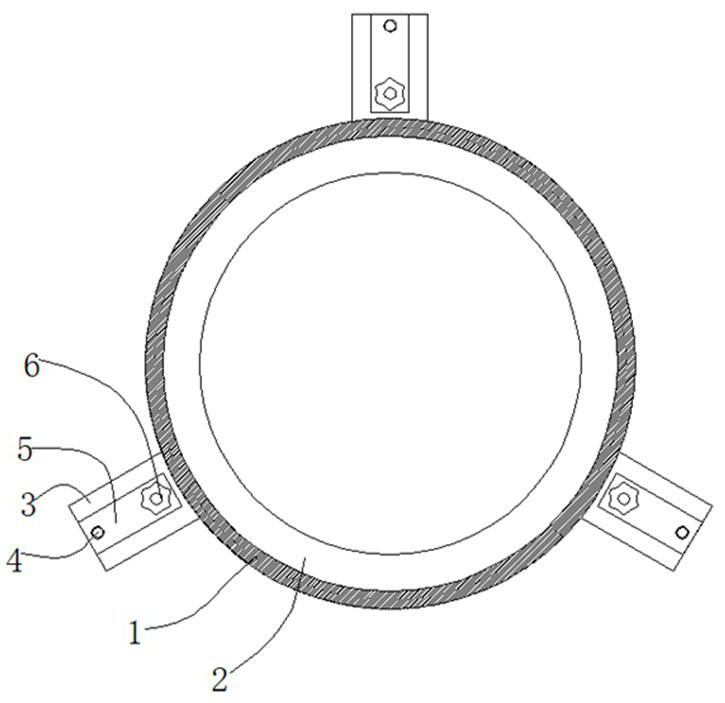

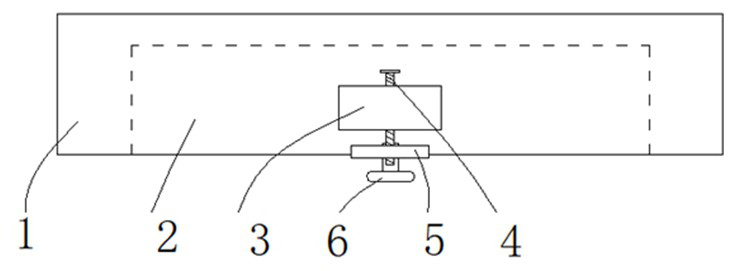

[0023] Please refer to figure 1 , figure 2 ,in, figure 1 A schematic structural view of the fixed mold of the metal flange plastic lining processing technology provided by the present invention; figure 2 for figure 1 The schematic diagram of the side view structure is shown. A metal flange lining plastic layer processing technology, comprising the following steps:

[0024] Step 1: Place the plastic-lined flange naturally until the plastic-lined layer cools down;

[0025] Step 2: Use a saber saw to cut off the redundant lining plastic corners after the flange surface is demoulded;

[0026] Step 3: Then put the fixed mold on the plastic-lined flange, and clamp and fix the fixed mold and the plastic-lined flange;

[0027] Step 4: Then use the engraving machine to cut along the fixed mold. After the cutting is completed, remove the fixed mold;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com