Magnetic steel inspection tool

A technology of checking tools and magnets, which is applied in the direction of measuring devices, instruments, and mechanical devices, etc., which can solve the problems of inability to install magnets, large gap between magnets and punching sheets, and scrapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

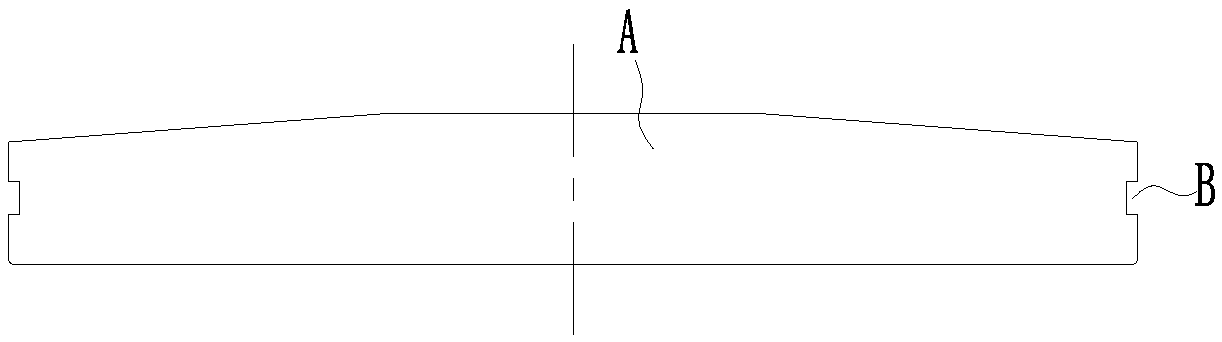

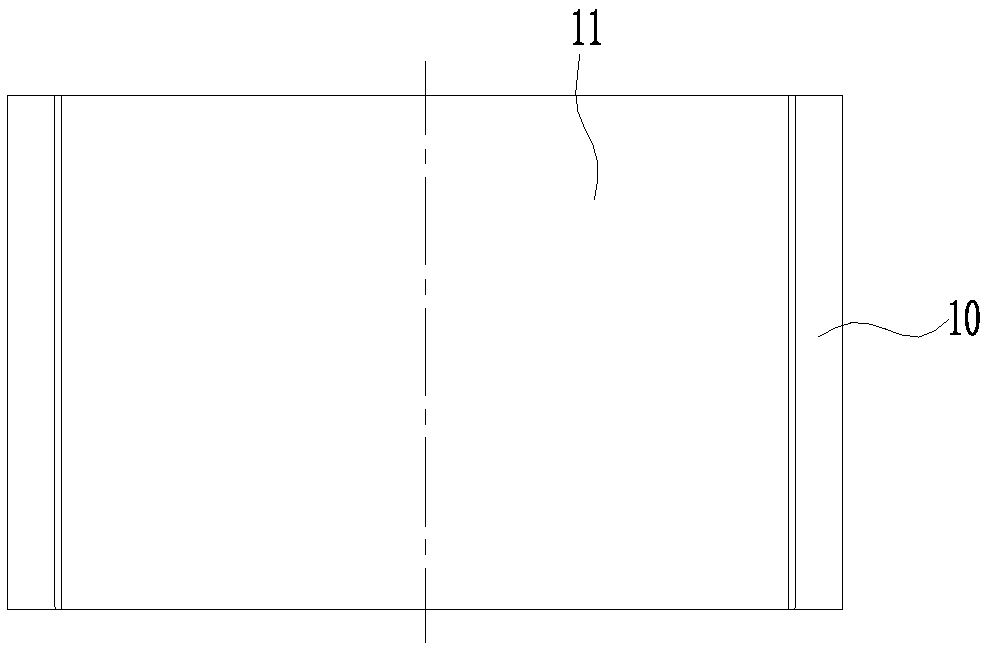

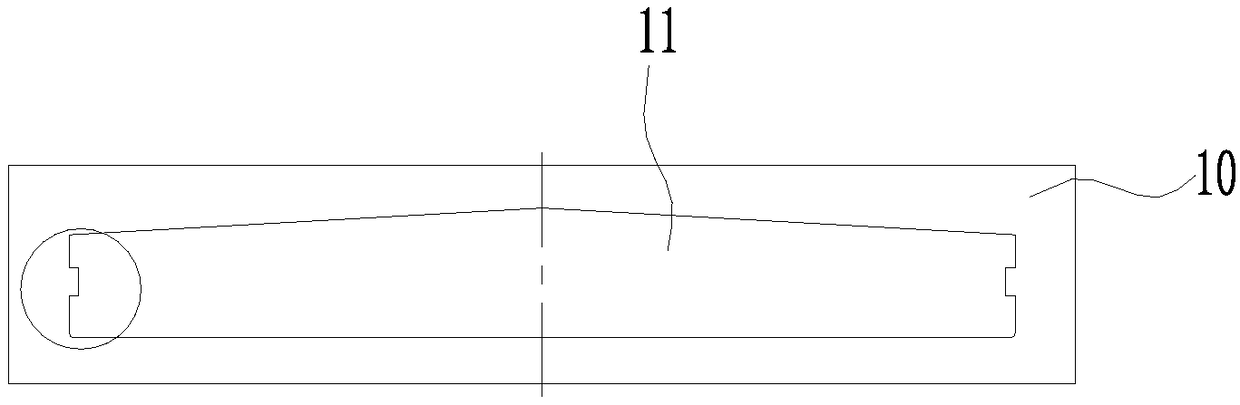

[0010] Such as figure 1 , figure 2 As shown, a magnetic steel inspection tool includes a body 10, and a through groove 11 is opened on the body 10, and the cross section of the groove 11 is the same as that of the stamping groove. By simulating the groove shape of the punching sheet, the groove 11 is processed by the wire cutting process. The magnet steel A to be inspected is used as the sub-block, and the inspection tool is used as the mother block. The magnet steel A to be inspected can pass through the groove on the body smoothly and If there is no obvious gap, the size of the magnetic steel A to be inspected is qualified. If the magnet steel A to be inspected cannot pass through the groove on the body smoothly, it means that the size of the magnet steel A to be inspected is too large and unqualified; if the magnet steel A to be inspected can pass through the groove on the body smoothly but the gap is too large, it means The size of the magnetic steel A to be inspected i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com