Forming processing method of PCB with ultra-long card groove

A molding processing and slotting technology, which is used in the processing of insulating substrates/layers, electrical components, and printed circuit manufacturing, etc., can solve the problems of slow efficiency, poor quality, and inability to produce ultra-long cardboards for manual beveling machines. Achieve the effect of improving efficiency, reducing production costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

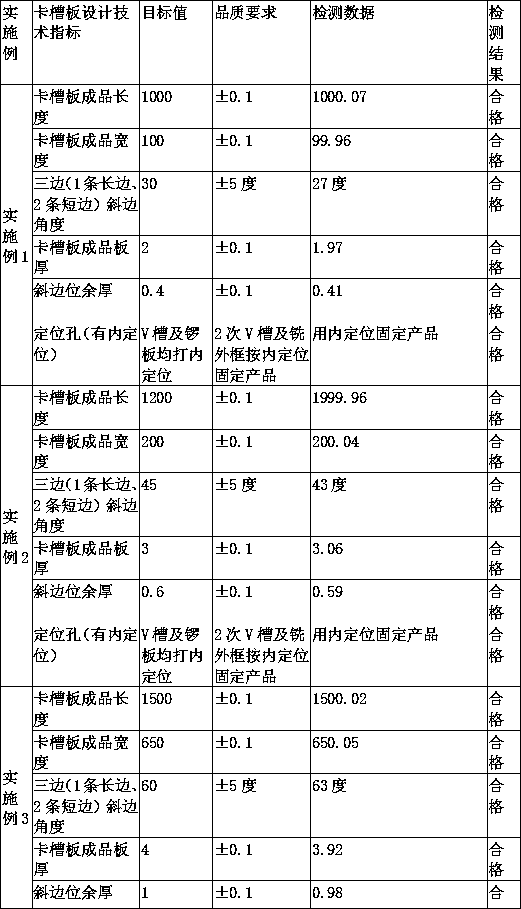

Examples

Embodiment Construction

[0030] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, and do not limit the protection scope of the present invention.

[0031] A method for forming and processing an ultra-long card slot PCB, characterized in that it comprises the following steps:

[0032] S1, V-CUT machine-CNC forming processing;

[0033] Choose a hanging PIN nail V-CUT machine that meets the hanging production length capacity and a V-CUT knife with the same angle as the beveled edge, design the remaining thickness of the V-CUT according to the remaining thickness after the beveled edge, and design it in the outer frame of the product information For the V-CUT hanging hole, use V-CUT machining to insert the three sides of the card slot firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com