Method for manufacturing end socket of voltage stabilizer for nuclear power

A manufacturing method and a technology of a voltage stabilizer, which are applied in the field of pressure vessels, can solve the problems of long manufacturing cycle, difficult to achieve high head shape, size and quality, and high manufacturing cost, and achieve the advantages of shortened manufacturing cycle, qualified size and reduced cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

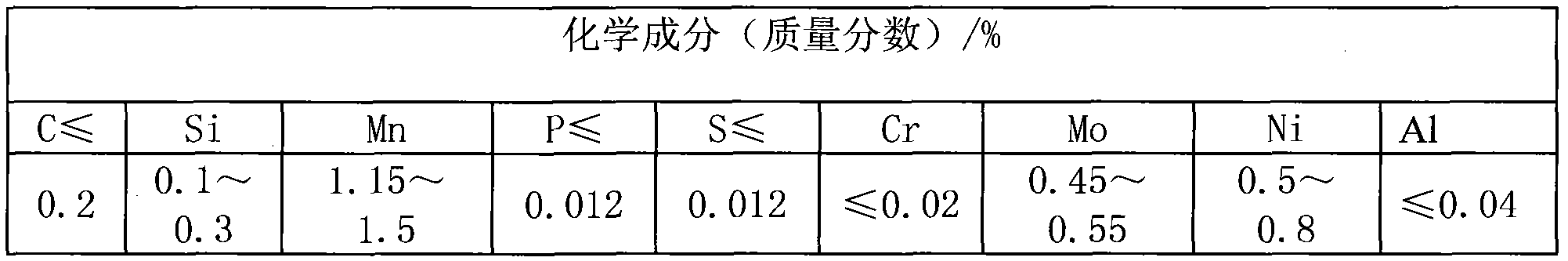

[0015] 16MND5 low-alloy steel is the main pressure material for nuclear power equipment. It is used for pressure vessel shells and components of primary equipment with excellent performance. The following table shows the chemical composition of 16MND5 low-alloy steel.

[0016] Table 1: Chemical Composition of 16MND5 Low Alloy Steel

[0017]

[0018] Due to the complex chemical composition of 16MND5 low-alloy steel, in the process of using 16MND5 low-alloy steel plate to manufacture the head of a voltage stabilizer for nuclear power, in order to ensure that the head has good mechanical properties and precise dimensions, the following steps must be implemented :

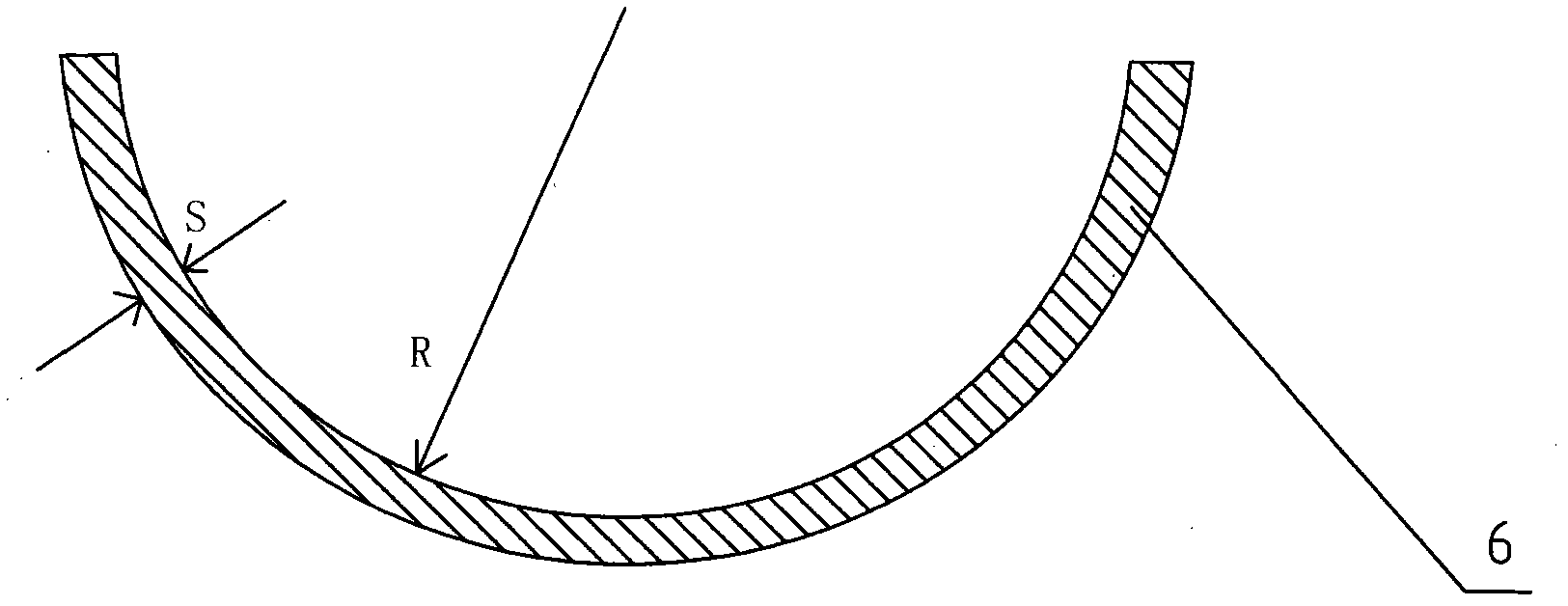

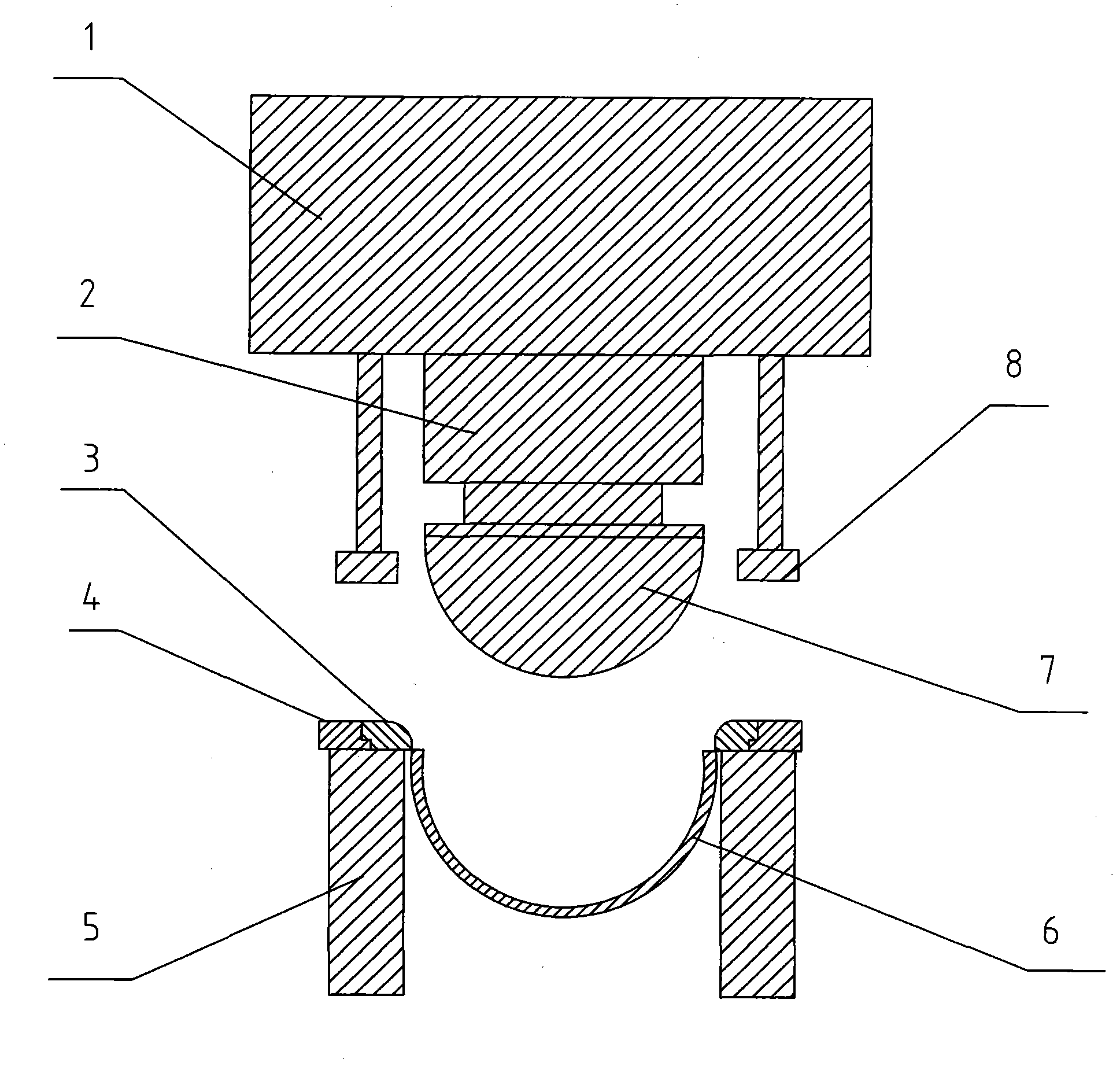

[0019] a. Accurately design and manufacture the hemispherical upper mold and circular lower mold of the molding mold according to the molding size of the head. According to the design drawings and technical requirements of the head, design calculations and based on rich manufacturing experience and a large number o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com