An automatic continuous flow electroplating device and method for the inner wall of a pipe fitting

A technology of electroplating equipment and pipe fittings, which is applied in the direction of electrolysis components, electrolysis process, cells, etc., can solve problems such as difficult solution in the pipe, chamber pressure, initial velocity range, decreased precision, cumbersome process, etc., to prevent metal impurities from entering the plating solution, solve Coordination problems, the effect of preventing contamination of the plating solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

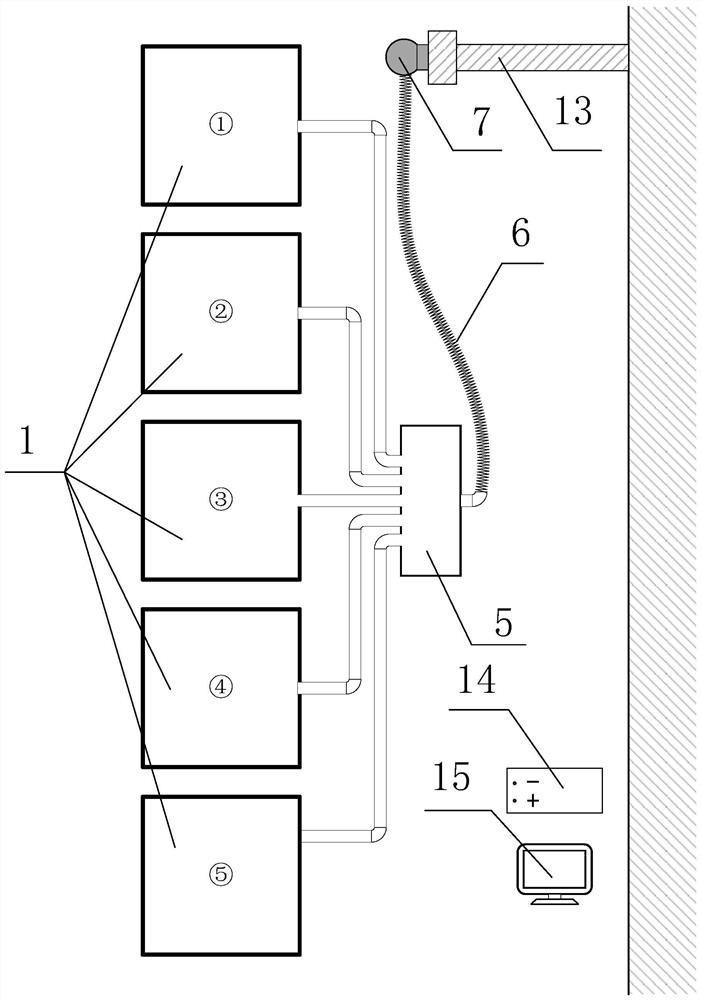

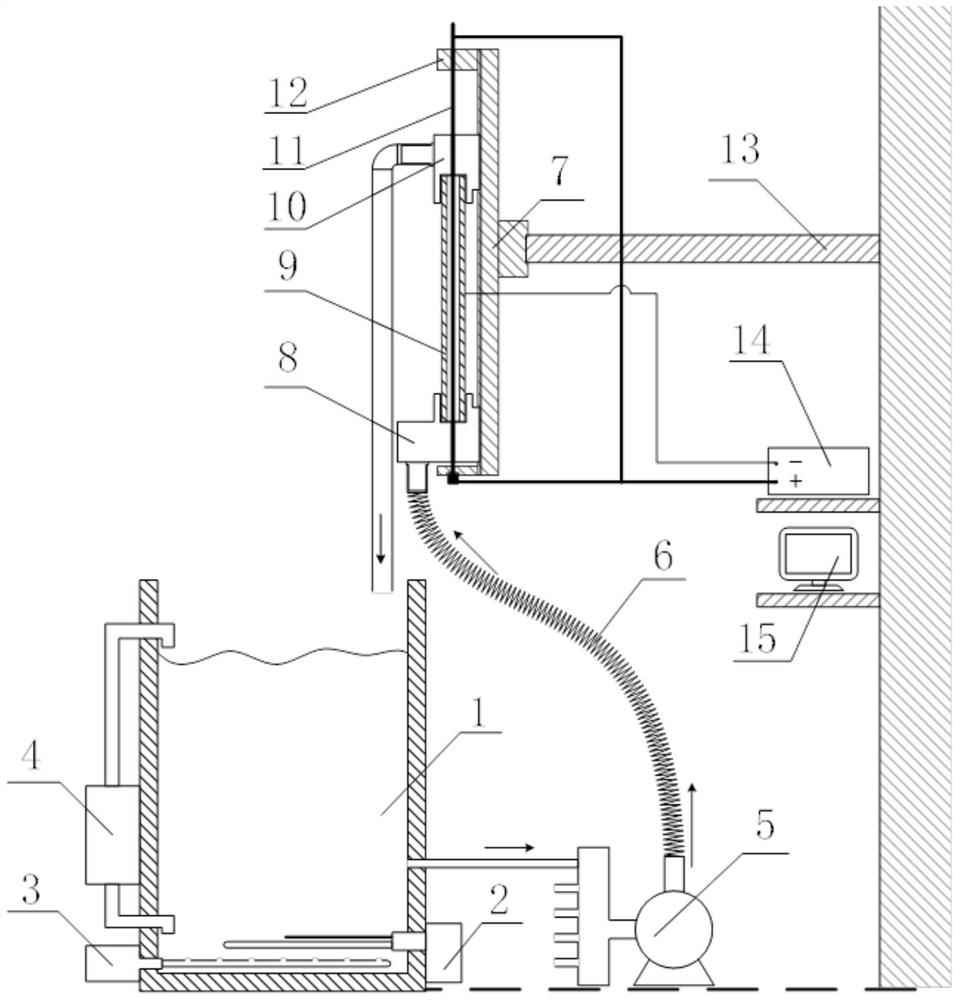

[0040] Adopt the present invention to prepare hexavalent chromium coating by flow plating in pipe fittings with an aspect ratio of about 78, such as figure 1 As shown, the plating solution tank 1 should include three plating tanks: pure water tank ①, activation tank ②, and chrome plating tank ③. The specific implementation process is as follows:

[0041] (1) To formulate the experimental parameters, the inner surface area of the large aspect ratio pipe fittings used in the experiment is about 1dm 2 , the current density of hexavalent chromium plating is 25A / dm 2 , the corresponding current is 25A, the electroplating time is 120min; the washing time is 2min, the activation time is 1min, and the solution flow rate is 5L / min.

[0042] (2) Turn on the heater 2, the air stirrer 3 and the filter 4 of the chrome plating tank through the display controller to make the plating solution reach 50°C and maintain it. At the same time, the pipe fittings undergo pre-treatment processes ...

Embodiment 2

[0050] Adopt the multi-layer coating system of flow plating nickel+trivalent chromium in pipe fittings with length-to-diameter ratio of the present invention being about 78, such as figure 1 As shown, the plating solution tank 1 should include five plating tanks including pure water tank ①, nickel plating activation tank ②, nickel plating tank ③, chrome plating activation tank ④ and chrome plating tank ⑤. The specific implementation process is as follows:

[0051] (1) To formulate the experimental parameters, the inner surface area of the large aspect ratio pipe fittings used in the experiment is about 1dm 2 , the current densities of nickel plating and chromium plating are 2A / dm respectively 2 、25A / dm 2 , the corresponding currents are 2A and 25A respectively, the electroplating time is 20min and 60min respectively; the washing time is 2min, the activation time is 1min, and the solution flow rate is 5L / min.

[0052] (2) Turn on the heater 2, the air stirrer 3 and the fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com