A heat treatment method for precipitation hardened blade steel

A heat treatment method, precipitation hardening technology, applied in the field of thermal processing of turbine blades, can solve problems such as large deformation, achieve small deformation, qualified size, and solve the effect of large deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

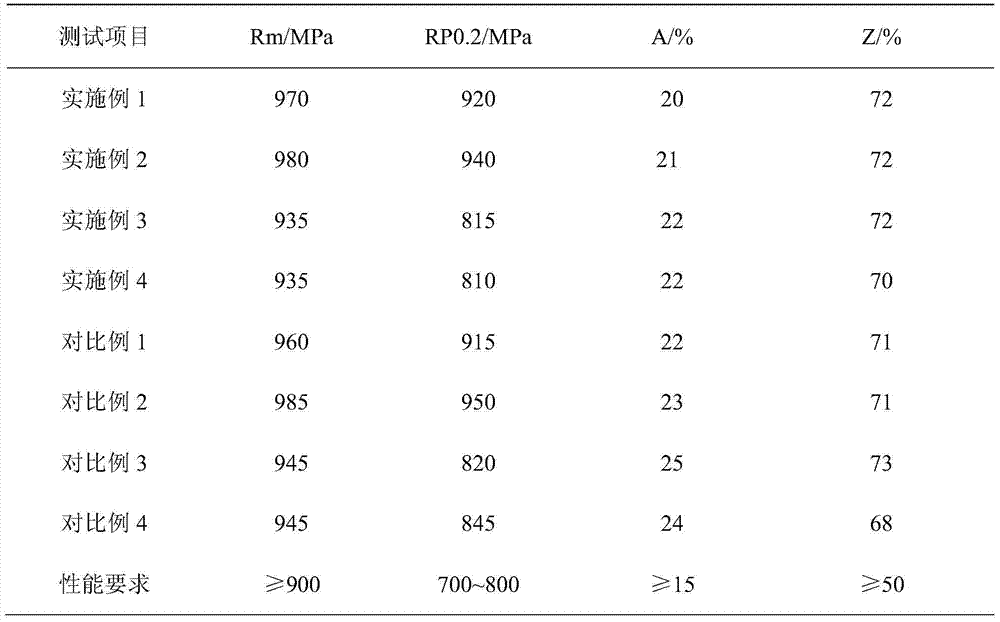

Examples

Embodiment 1

[0014] Put 600 pieces of precipitation-hardened blade steel with the composition of 0Cr17Ni4Cu4Nb into the furnace, raise the temperature to 850°C for medium temperature heating, and keep it warm for 2 hours. Air cooling out of the furnace to produce forgings.

Embodiment 2

[0016] The composition is 0Cr17Ni4Cu4Nb 500 pieces of precipitation hardened blade steel are loaded into the furnace, the temperature is raised to 800°C for medium temperature heating, and kept for 3 hours, and after being released from the furnace, thermal correction is carried out on the corresponding mold, aging treatment is carried out at 500°C, and kept for 5 hours, Air cooling out of the furnace to produce forgings.

Embodiment 3

[0018] Put 600 pieces of X4CrNiCuMo14-5 precipitation hardened blade steel into the furnace, raise the temperature to 900°C for medium temperature heating, and keep it warm for 2 hours. After 4 hours, it was taken out of the furnace and air-cooled to obtain a forging.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com