A masterbatch cutting and packaging device

A granulation and masterbatch technology, applied in packaging, packaging machines, transportation and packaging, etc., can solve the problems of spending more time, wasting packaging resources, resource waste, etc., to save raw materials and production costs, improve production efficiency, Improve the effect of cutting force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical solution, purpose and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

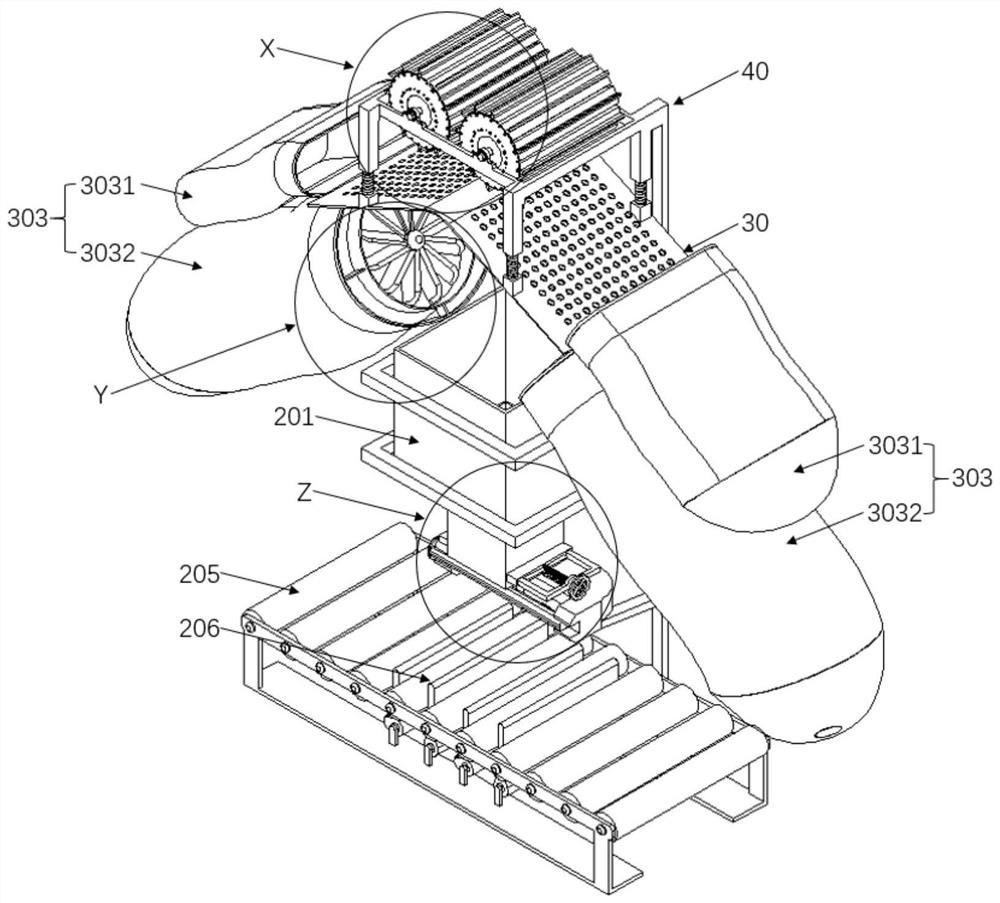

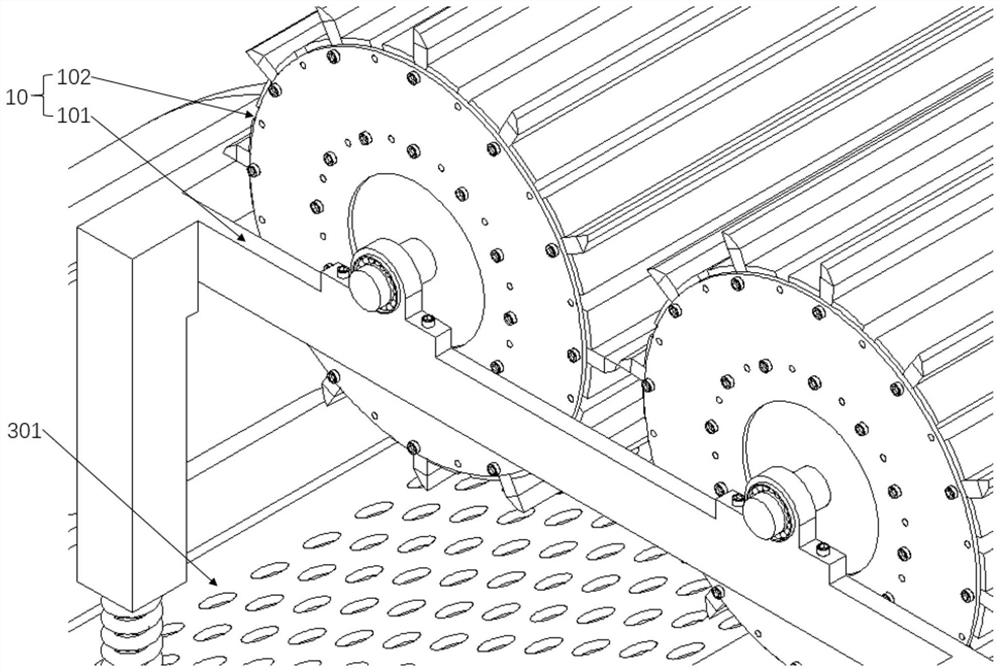

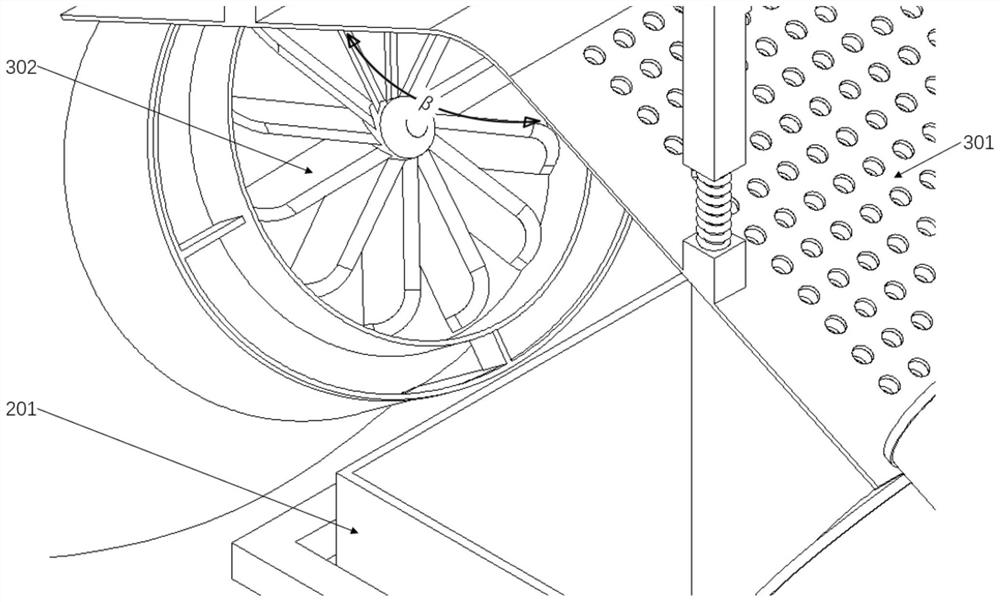

[0039] Such as Figure 1 to Figure 10As shown, a master batch cutting and packing device includes a cutting mechanism 10 and a packing mechanism 20. The cutting mechanism 10 includes a knife holder 101, and two hobs 102 with the same height and the same outer diameter are arranged side by side on the knife holder 101. , the outermost blades of the two hobs 102 are connected, and when the extruded strip of plastic masterbatch passes through it, it will be continuously cut into several small sections. The extruded strip is sucked inward or downward; the packaging mechanism 20 is located under the pelletizing mechanism 10, and is used to pack the masterbatches cut by the pelletizing mechanism 10 into packaging bags; due to the variety of masterbatch types and the ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com