Method of processing fluid distribution housing

A processing method and fluid distribution technology, which is applied in the processing of fluid distribution casings and the field of shell processing, can solve the problems of unqualified shape and size, difficult clamping and easy deformation of spherical surfaces, etc., and achieve the effect of qualified shape and size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

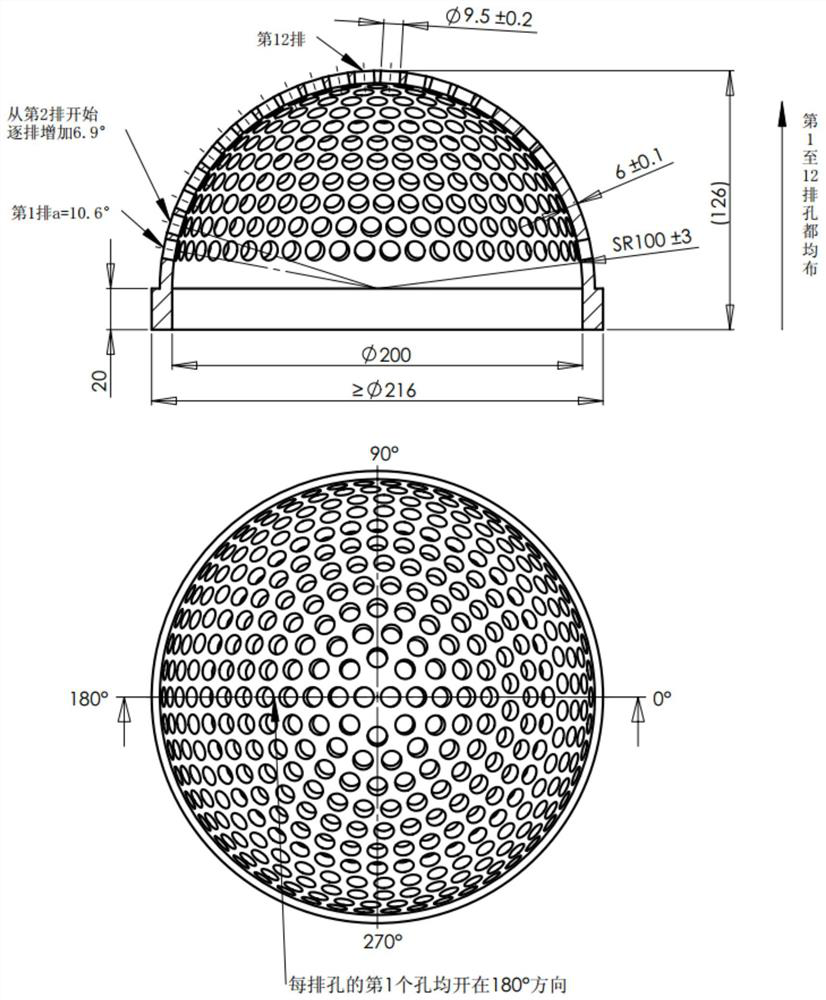

[0025] see Figure 1 to Figure 6 shown.

[0026] A processing method for a fluid distribution casing of the present invention comprises three steps of turning, finishing milling and finishing turning;

[0027] The turning steps performed on the LTC-35CL model CNC horizontal lathe are as follows:

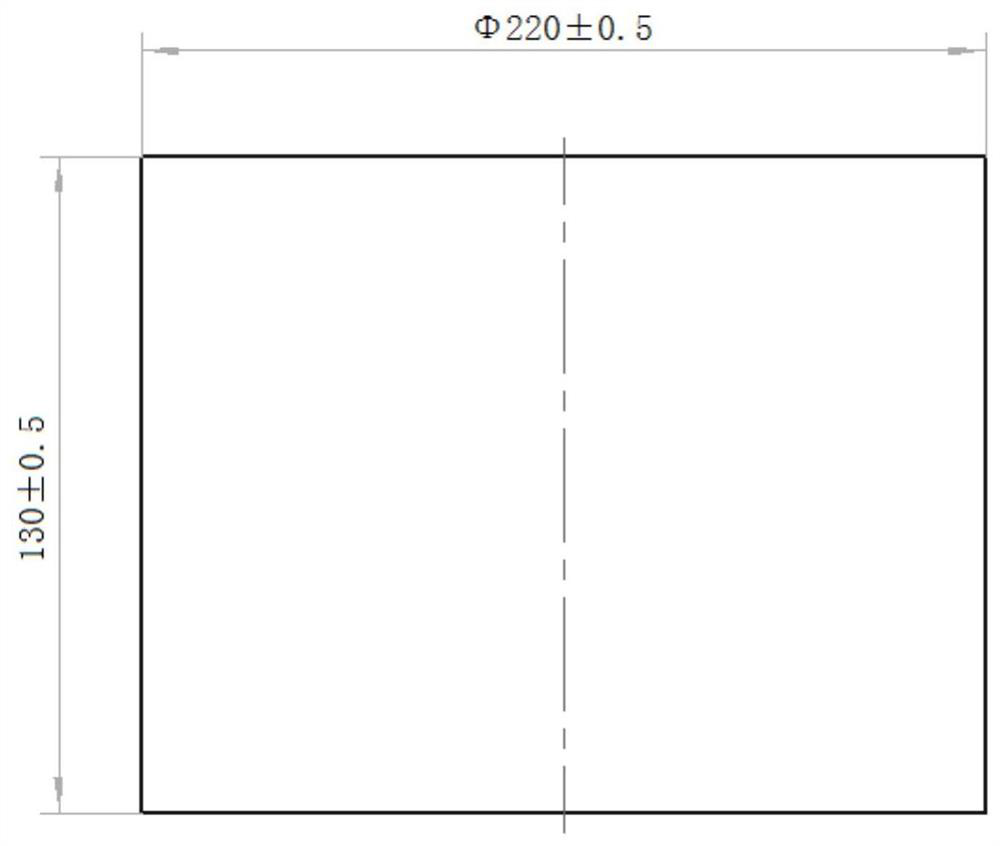

[0028] Step 1, semi-finishing the blank, the blank must meet the requirements of NB / T 47010-2017 level II, the cylindrical blank has a length of 130±0.5, a diameter of 220±0.5, and the blank is as figure 1 As shown, remove the oxidized damage layer on the surface of the axial end face of the car, and the light can be exposed;

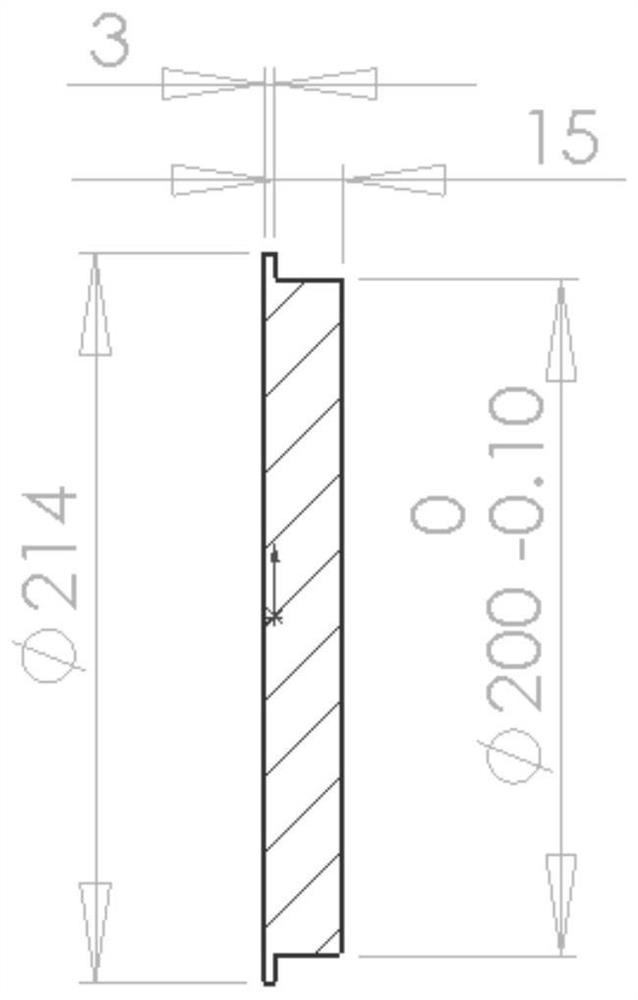

[0029] Step 2, the outer circle of the blank is guaranteed to be 20, and the diameter of the blank is guaranteed to be ≥φ216, such as figure 2 shown;

[0030] Step 3: Drill a φ50 process hole along the axial ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com