Method for Rolling Nickel-based Superalloy Rectangular Ring Blank into Irregular Thin-walled Ring

A technology of nickel-based superalloy and rectangular ring, applied in the field of rolling and forming of rings, can solve the problems of affecting the quality of rings, improper control, intermittent rolling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

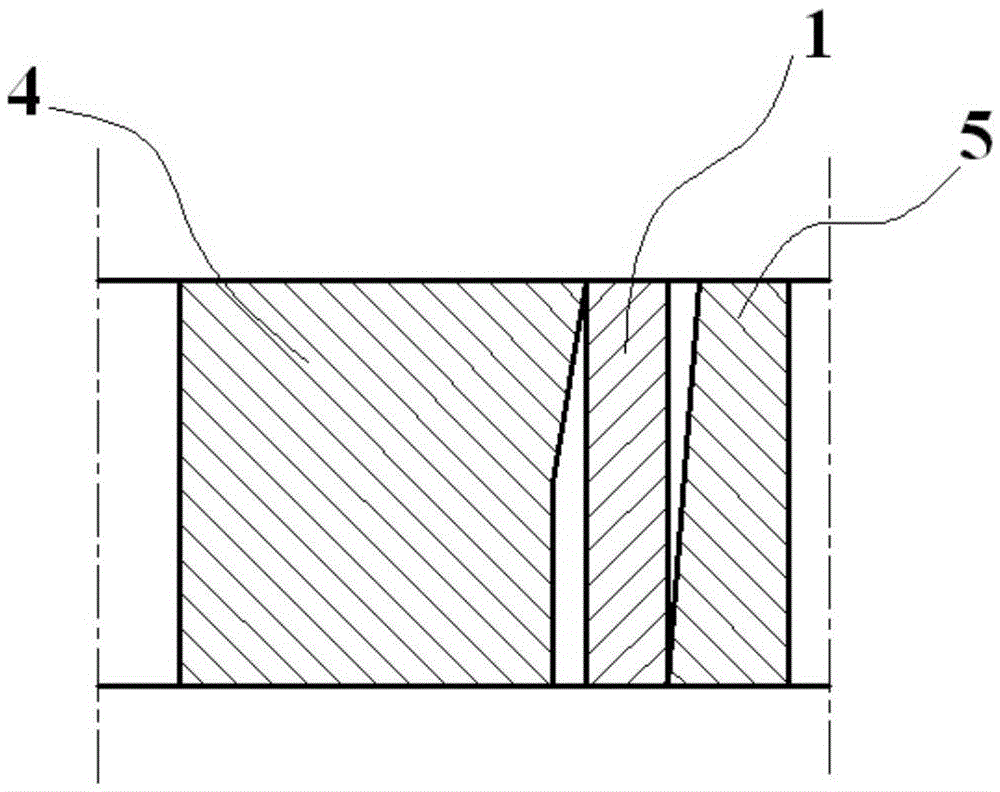

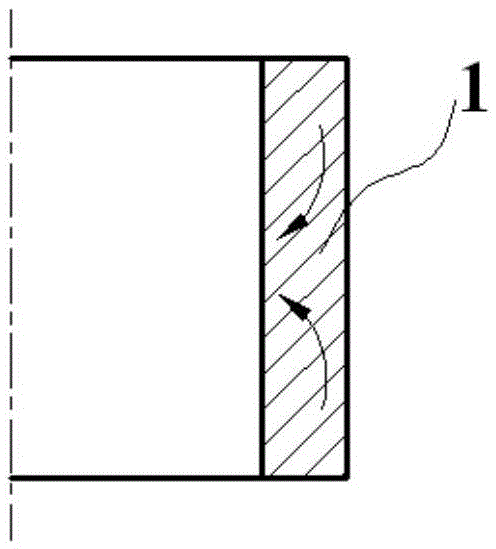

Method used

Image

Examples

specific Embodiment approach

[0038] The main chemical element content (percentage by weight) of the alloy is: C content ≤ 0.08%, Cr content 17.0% ~ 21.0%, Ni content 50.0% ~ 55.0%, Co content ≤ 1.0%, Mo content 2.80% ~3.30%, Al content 0.30%~0.70%, Ti content 0.75%~1.15%, Nb content 4.75%~5.50%, B content ≤0.006%, Mg content ≤0.01%, Mn content ≤0.35 %, Si content ≤0.35%, P content ≤0.015%, S content ≤0.015%, Cu content ≤0.30%, Ca content ≤0.01%, Pb content ≤0.0005%, Se content ≤0.0003% , The balance is Fe.

[0039] The steps of this method are as follows:

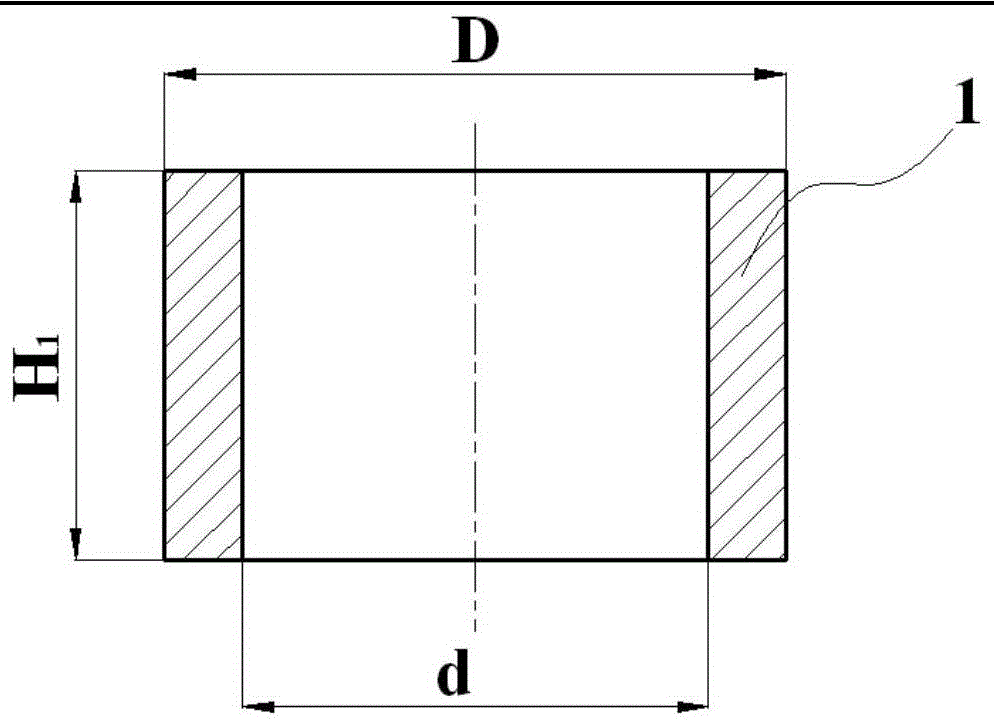

[0040] 1. Design rectangular ring blank 1

[0041] Calculate the rectangular blank dimensions as follows:

[0042] (1) The height of the rectangular ring blank 1 is:

[0043] h 1 =H 2 ;

[0044] Among them: H 1 is the height of the rectangular ring blank 1;

[0045]h 2 is the height of the special-shaped thin-walled ring 3.

[0046] (2) The inner diameter of the rectangular ring blank 1 is:

[0047] d = ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com