A method for processing the shape of a pcb product with a narrow edge ptfe antenna without internal positioning

A PTFE, shape processing technology, applied in the field of PCB manufacturing, can solve the problems of slow speed, low efficiency, small size does not meet the cleaning requirements of the finished product cleaning machine, etc., to ensure product quality, eliminate large or small size, guarantee Qualified size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] It should be understood that the specific embodiments described herein are merely intended to illustrate the invention and are not intended to limit the invention.

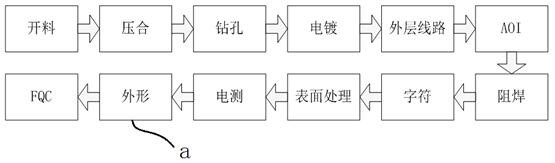

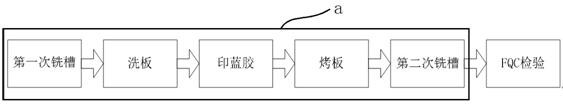

[0026] Such as Figure 1 - Figure 2 In the present invention, the outer shape processing method A of the narrow edge antenna PCB according to an embodiment of the present invention can be applied to the manufacturer of the conventional narrow edge antenna PCB, widely used, and is very versatile. A narrow antenna PCB shape processing method A, including the following steps:

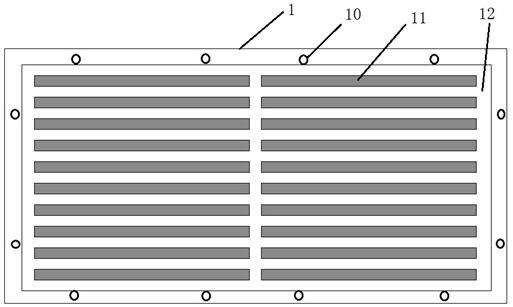

[0027] S1: image 3 As shown, 20 antenna PCB11 is arranged on a matrix, and the upper and lower adjacent antenna PCB11 is disposed as a unit 2, and the antenna PCB11 is surrounded by the portion 12, at the position of the largeboard body 1. Set the positioning hole 10;

[0028] S2: The first milling groove is used to process the processing unit 12 on the large plate body 1 by the CNC machine tool, and the machining direction of the milling gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com