High-pressure slurry injector with quick ceramic forming and die releasing functions

A high-pressure grouting machine and molding die technology, which is applied to supply devices, manufacturing tools, etc., can solve the problems of affecting the surface quality of the mud billet, slow mud billet molding, and low pressure of the grouting system, so as to achieve good appearance quality and molding. Fast speed and stable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

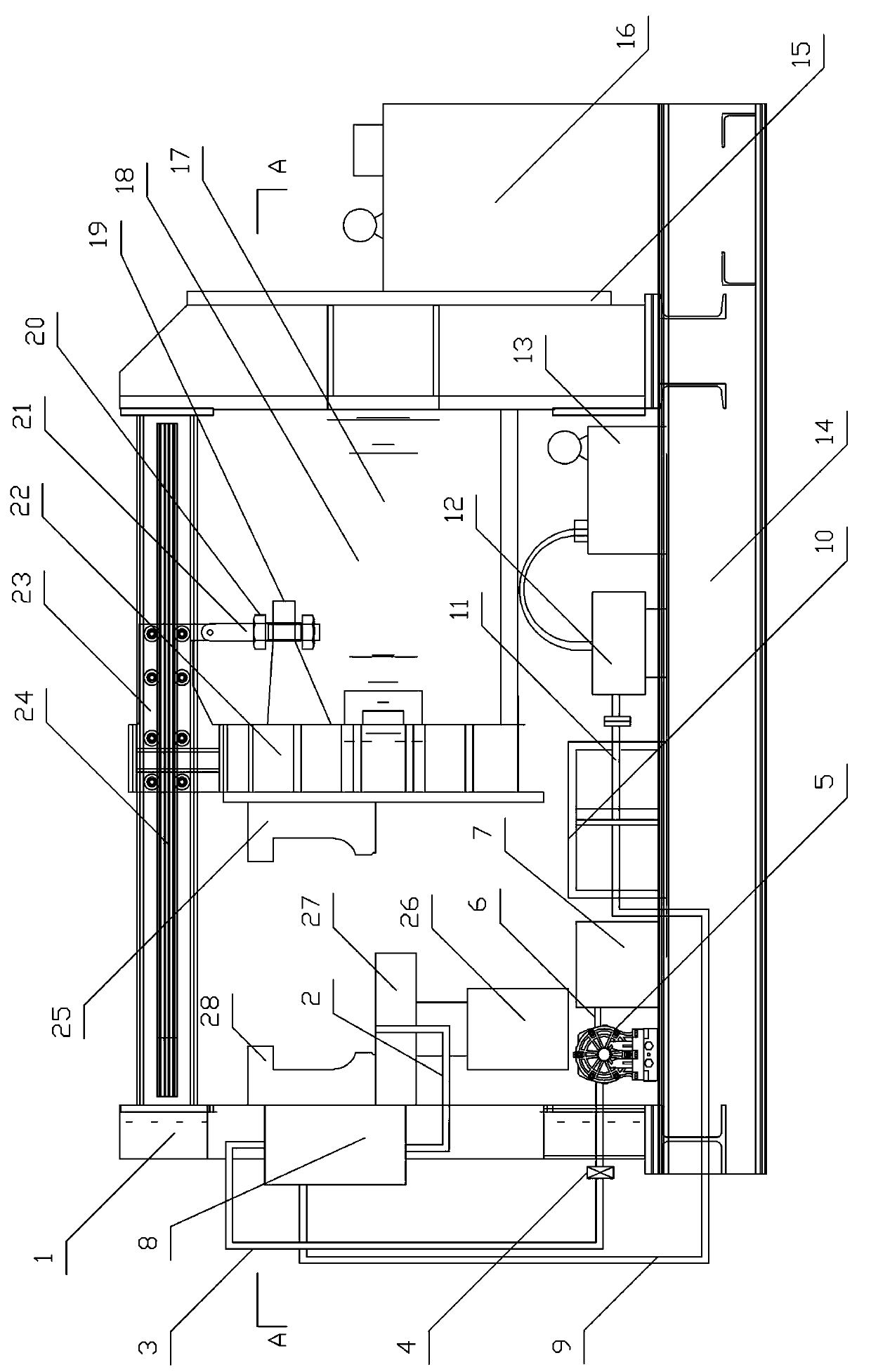

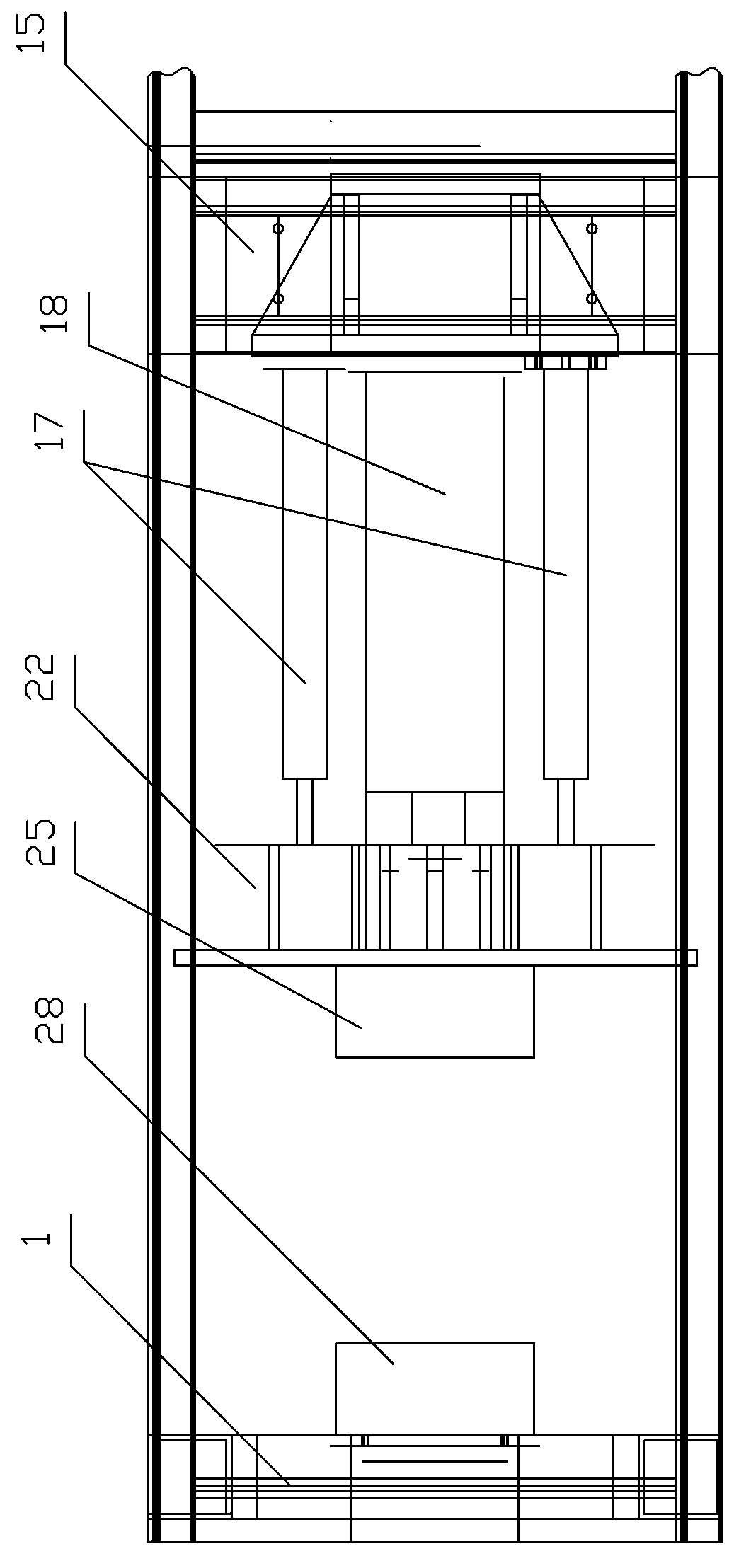

[0014] see figure 1 , 2 , the present invention has frame-shaped frame, and the top of frame 14 is provided with slide rail 24 and is equipped with slide seat 23, and die head 22 is hoisted on slide seat 23, and die head 22 and frame left side support 1 two relatives The right half and the left half ceramic forming molds 25 and 28 are correspondingly installed on the surface, and a bottom mold 27 and a lifting cylinder 26 are installed below the left half ceramic forming mold 28, and a grouting system is installed on the base 14 of the frame 14. And the hydraulic integrated pump station 16 is installed on the right side of the frame 14, especially: between the support 15 on the right side of the frame 14 and the die head 22, a pressurized main oil cylinder 18 and two auxiliary molds for opening and closing are connected. Oil cylinder 17, the grouting system includes a mud blank forming die, a pneumatic diaphragm pump 5 and a grouting pipe 2, the inlet end of the pneumatic dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com