Short-fluorocarbon-chain acrylate polymer, preparation method thereof and application of short-fluorocarbon-chain acrylate polymer in release agent

A short fluorocarbon chain acrylate and acrylate technology, which is applied in the field of short fluorocarbon chain acrylate polymers and their preparation and application in release agents, can solve the problem of difficult migration of fluorine chains and stable arrangement, and poor surface properties. Good and other questions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

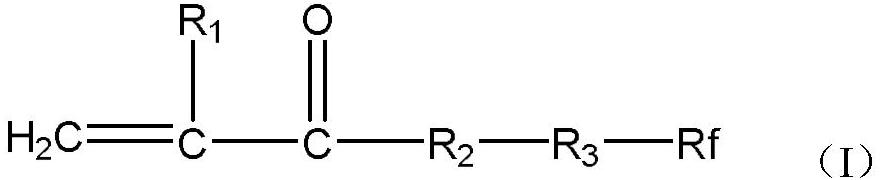

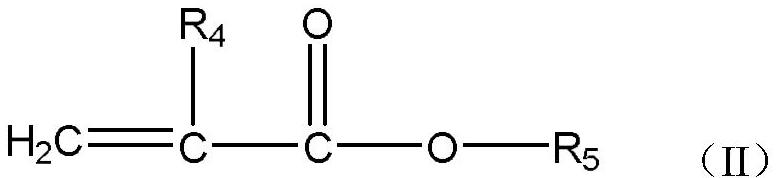

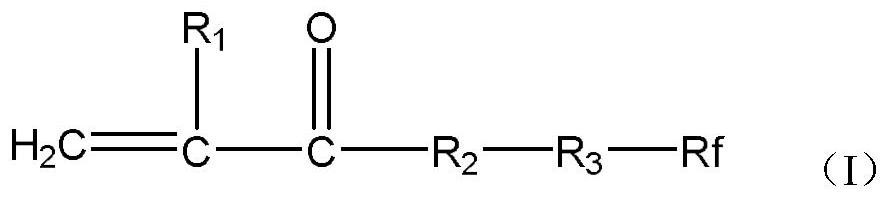

Method used

Image

Examples

Embodiment 1

[0066] N 2 Under the atmosphere, add 30g of octadecyl methacrylate and 5g of acrylic acid to 80g of butyl acetate, start stirring and raise the temperature to 65°C. After all the monomers are dissolved, add 0.2g of azobisisobutyronitrile dropwise to dissolve in 5mL The polymerization initiator solution of butyl acetate, react for 1h after the dropwise addition, and then add 10g CH at 65°C 2 =C(CH 3 )COO(CH 2 ) 2 (CF 2 ) 5 CF 3 React with 5g of vinyltriethoxysilane for 6.0 hours, then raise the temperature to 75°C for 2 hours. Cool to room temperature to obtain a uniform fluorine-containing acrylate copolymer solution.

[0067] Preparation of the release agent composition: take 5.0 g of the above-prepared fluorine-containing acrylate copolymer solution, add 20 g of methyl silicone oil, 70 g of acetone, and 5.0 g of hexafluoroisopropyl methyl ether, mix well and set aside.

[0068] Then use the following test method to test the mold release performance, please refer to T...

Embodiment 2

[0079] N 2 Under the atmosphere, add 20g of octadecyl methacrylate and 5g of acrylic acid to 80g of butyl acetate, start stirring and raise the temperature to 65°C. After all the monomers are dissolved, add 0.2g of azobisisobutyronitrile dropwise to dissolve in 5mL The polymerization initiator solution of butyl acetate, react for 1h after the dropwise addition, and then add 20g CH at 65°C 2 =C(CH 3 )COO(CH 2 ) 2 (CF 2 ) 5 CF 3 React with 5g of vinyltriethoxysilane for 6.0 hours, then raise the temperature to 75°C for 2 hours. Cool to room temperature to obtain a uniform fluorine-containing acrylate copolymer solution.

[0080] The preparation of the release agent composition and the test method of the release performance are the same as in Example 1, and the test results are shown in Table 1.

Embodiment 3

[0082] N 2 Under the atmosphere, add 10g of octadecyl methacrylate and 5g of acrylic acid to 80g of butyl acetate, start stirring and raise the temperature to 65°C. After all the monomers are dissolved, add 0.2g of azobisisobutyronitrile dropwise to dissolve in 5mL Polymerization initiator solution of butyl acetate, react for 1h after dropwise addition, then add 30g CH at 65°C 2 =C(CH 3 )COO(CH 2 ) 2 (CF 2 ) 5 CF 3 React with 5g of vinyltriethoxysilane for 6.0 hours, then raise the temperature to 75°C for 2 hours. Cool to room temperature to obtain a uniform fluorine-containing acrylate copolymer solution.

[0083] The preparation of the release agent composition and the test method of the release performance are the same as in Example 1, and the test results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com