Polyurethane microporous elastomer added with alcohol and amine compound, and preparation method and application of polyurethane microporous elastomer added with alcohol and amine compound

A technology of alcohol amine compounds and microporous elastomers, applied in applications, shoe soles, clothing, etc., can solve problems such as consumption of catalysts, hidden dangers of safe use, and easy glue opening, etc., to reduce production costs, improve applicability, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

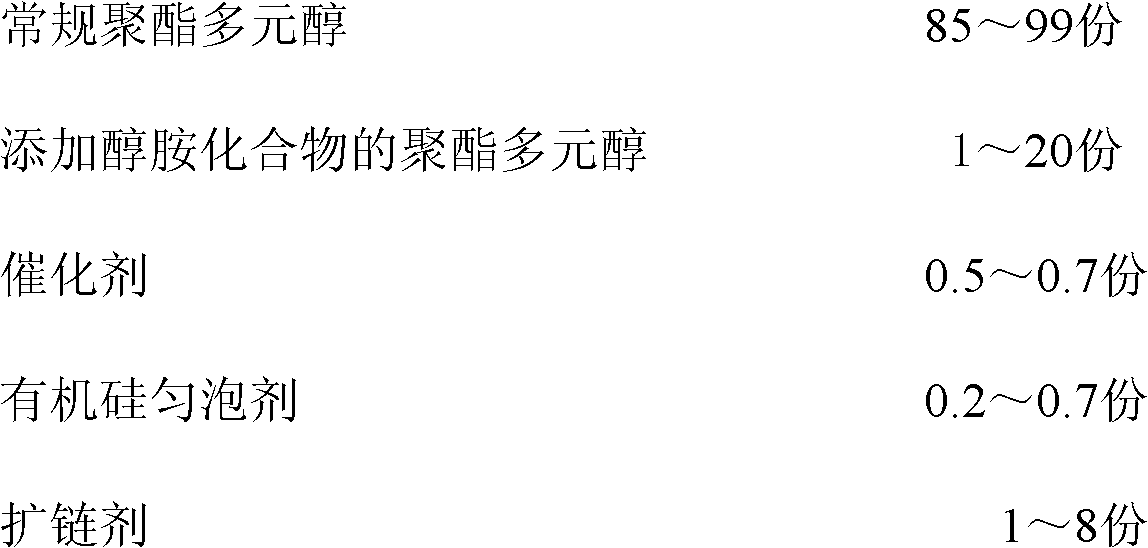

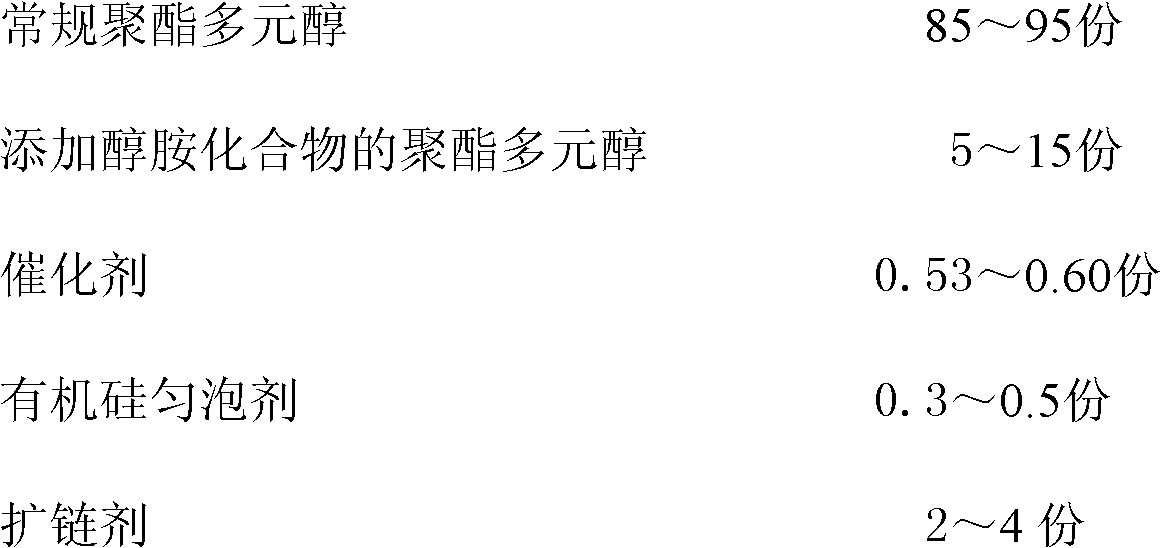

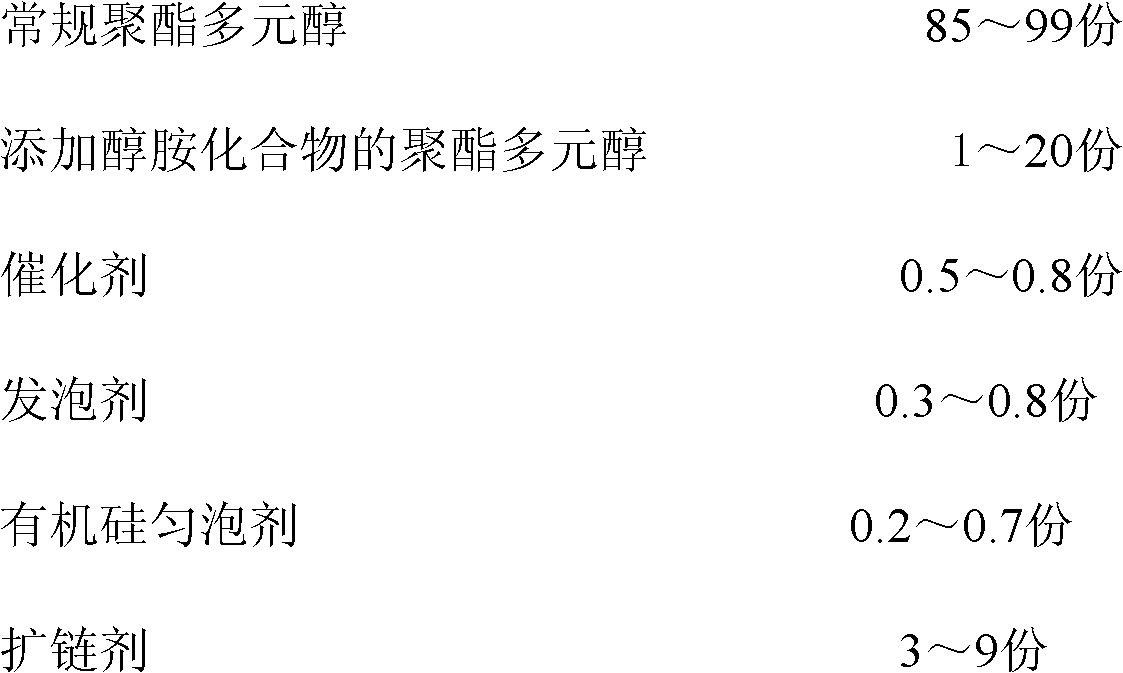

Method used

Image

Examples

Embodiment 1

[0065] Add 11.05kg of adipic acid, 2.36kg of ethylene glycol, 4.03kg of diethylene glycol and 0.89kg of N-methyldiethanolamine in a heatable reactor equipped with a distillation column and a reflux receiver , turn on the stirring device and the nitrogen atmosphere protection device, then raise the temperature to 140°C, and remove the product water by distillation during the reaction process, and the acid value measured at this time is about 40mgKOH / g. Then add 2.0g of catalyst tetraisopropyl titanate TIPT, reduce the pressure to 10-15mbar, raise the temperature to about 220°C, continue the polycondensation reaction, and remove the product water by distillation during the reaction process. Measure the viscosity and acid value of the mixture in the reaction vessel. When the weight-average molecular weight reaches about 2200 and the acid value reaches about 0.4 mgKOH / g, cool the reaction vessel, lower the temperature to room temperature, and terminate the reaction to obtain polyes...

Embodiment 2

[0067] Add 12.51kg of adipic acid, 4.30kg of ethylene glycol, 2.69kg of diethylene glycol and 0.50kg of N-methyldiethanolamine in a heatable reaction kettle equipped with a distillation column and a reflux liquid receiver , turn on the stirring device and the nitrogen atmosphere protection device, then raise the temperature to 160°C, and remove the product water by distillation during the reaction process. At this time, the measured acid value is about 45mgKOH / g. Then add 2.2g of catalyst tetraisopropyl titanate TIPT, reduce the pressure to 10-15mbar, raise the temperature to about 240°C, continue the polycondensation reaction, and remove the product water by distillation during the reaction process. Measure the molecular weight and acid value of the mixture in the reaction vessel. When the weight-average molecular weight reaches about 1800 and the acid value reaches about 0.4 mgKOH / g, cool the reaction vessel, lower the temperature to room temperature, and terminate the reacti...

Embodiment 3

[0070] In a heatable reaction kettle equipped with a distillation column and a reflux liquid receiver, add 11.06kg of adipic acid, then add 2.61kg of ethylene glycol and 4.47kg of diethylene glycol, and turn on the stirring device and the nitrogen atmosphere protection device The temperature was raised to 180°C, and the product water was removed by distillation during the reaction. At this time, the acid value was measured to be about 35 mgKOH / g. Then add 2.2g of catalyst tetraisopropyl titanate TIPT, reduce the pressure to 10-15mbar, raise the temperature to about 230°C, continue the polycondensation reaction, and remove the product water by distillation during the reaction process. Measure the molecular weight and acid value of the mixture in the reaction vessel. When the weight-average molecular weight reaches about 2000 and the acid value reaches about 0.4 mgKOH / g, cool the reaction vessel, lower the temperature to room temperature, and terminate the reaction to obtain poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com