Polyurethane rigid foam combination material

A rigid foam and polyurethane technology, applied in the field of foam plastics, can solve the problems of long demoulding time, lower average core density, capacity constraints, etc., and achieve the effects of saving raw material consumption, low average core density, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 30 parts of sucrose;

[0025] 30 parts of ethylenediamine polyether;

[0026] 40 parts of diethylene glycol polyether;

[0027] 1 part of N,N-dimethylcyclohexylamine;

[0028] Pentamethyldiethylenetriamine 0.2 part;

[0029] 1 part of 1,3,5-tris(dimethylaminopropyl)-hexahydrotriazine;

[0030] 2 parts silicone oil;

[0031] 2.2 parts of water;

[0032] Cyclopentane 12 parts.

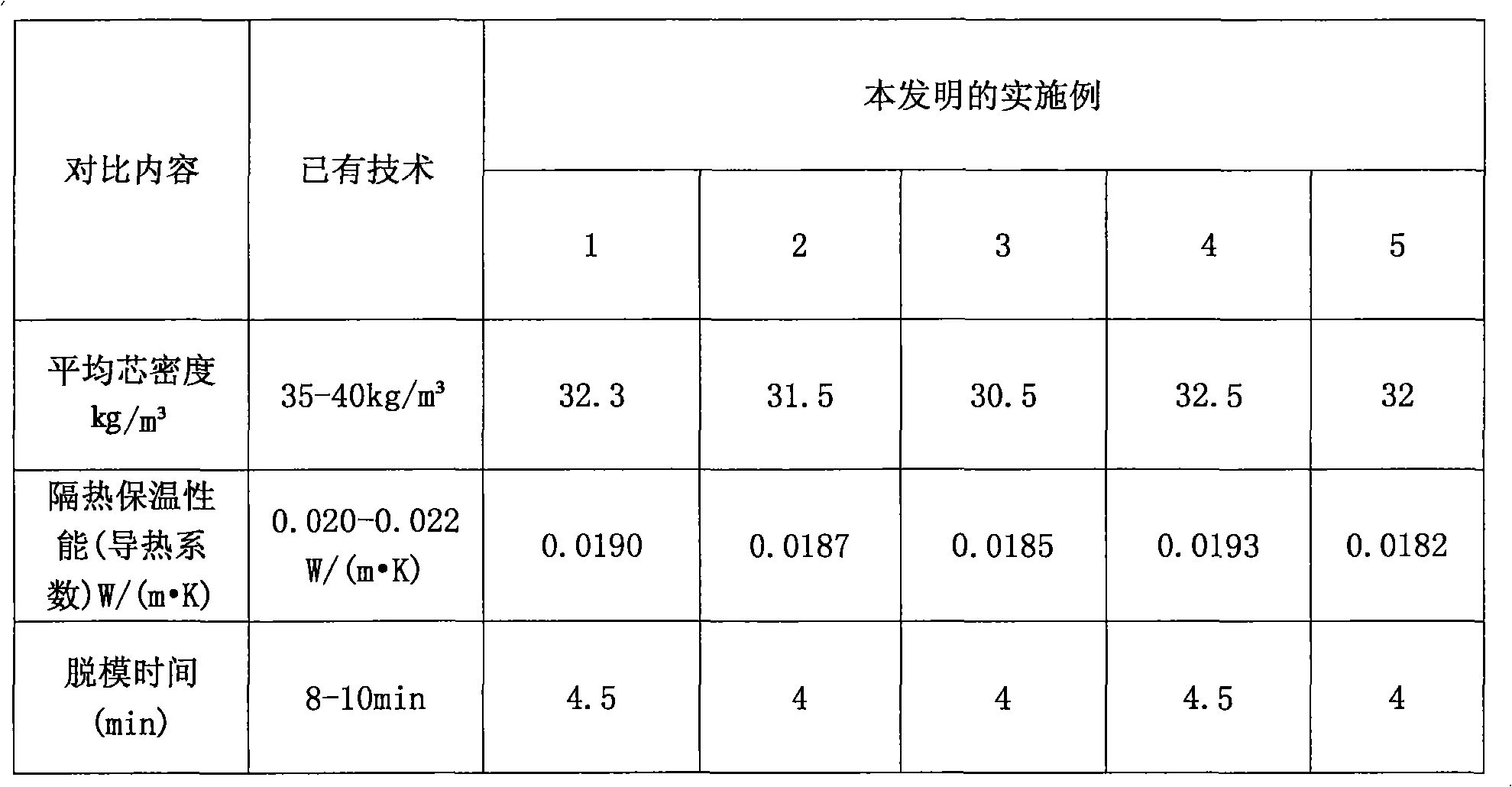

[0033] Put the above-mentioned raw materials into a container and stir evenly to obtain a polyurethane rigid foam composition, and react the polyurethane rigid foam composition with isocyanate to obtain a polyurethane rigid foam with the technical effects shown in the table below.

Embodiment 2

[0035] 35 parts of sucrose;

[0036] 30 parts of o-toluenediamine polyether;

[0037] 35 parts of diethylene glycol polyether;

[0038] 1.2 parts of N, N-dimethylcyclohexylamine;

[0039] 0.4 parts of N, N'-dimethylaniline;

[0040] 1.2 parts of 1,3,5-tris(dimethylaminopropyl)-hexahydrotriazine;

[0041] 2 parts silicone oil;

[0042] 1.8 parts of water;

[0043] Cyclo / isopentane 15 parts.

[0044] Put the above-mentioned raw materials into a container and stir evenly to obtain a polyurethane rigid foam composition, and react the polyurethane rigid foam composition with isocyanate to obtain a polyurethane rigid foam with the technical effects shown in the table below.

Embodiment 3

[0046] 50 parts of sucrose;

[0047] 20 parts of m-phenylenediamine polyether;

[0048] 30 parts of propylene glycol polyether;

[0049] 1.5 parts of 30% 1,4-diazabicyclo[2,2,2]octane solution;

[0050] Pentamethyldiethylenetriamine 0.5 part;

[0051] 0.8 parts of trimethyl-N-ethylhydroxypropyl hexanoic acid;

[0052] 2.2 parts of silicone oil;

[0053] 1.6 parts of water;

[0054] 25 copies of HCFC-141b.

[0055] Put the above-mentioned raw materials into a container and stir evenly to obtain a polyurethane rigid foam composition, and react the polyurethane rigid foam composition with isocyanate to obtain a polyurethane rigid foam with the technical effects shown in the table below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com