Polyurethane solid tire material and preparation method thereof

A solid tire and polyurethane technology, applied in the field of polyurethane materials, can solve the problems of easily polluting the environment and containing organic solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

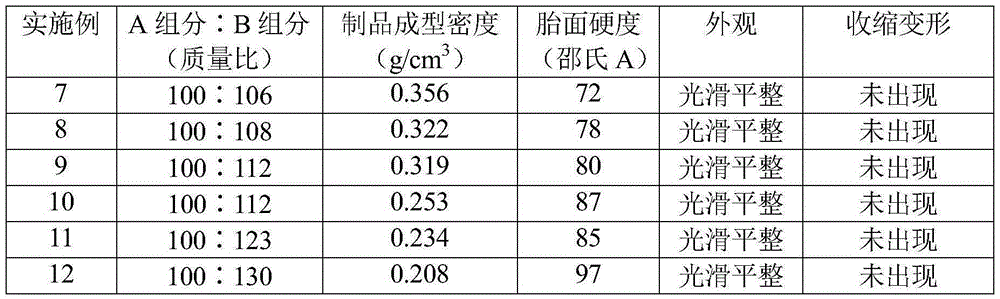

Examples

preparation example Construction

[0014] The preparation method of this polyurethane solid tire material comprises the following steps:

[0015] (1) Polyesterification of dibasic acid and polyol under the action of catalyst B under the protection of nitrogen at 140°C-250°C until the acid value drops below 1mgKOH / g and the hydroxyl value is 30-200mgKOH / g The reaction is stopped at a time of g to obtain a polyester polyol; the functionality of the polyester polyol is controlled at 2 to 2.7.

[0016] (2) Preparation of component A: Add the polyester polyol prepared in step (1), chain extender, foaming agent, catalyst A, and foam stabilizer into the reactor, heat up to 50-80°C and mix evenly, then Cool to 35-40°C and discharge to obtain component A; the final product is liquid at 40-50°C, with a viscosity of about 200-600CPs.

[0017] (3) Preparation of component B: react the polyester polyol prepared in step (1) with polyether polyol and isocyanate in the presence of a side reaction terminator at 70-80°C for 2-3...

Embodiment 1

[0020] Preparation of polyester polyol 1: Mix 518gAA, 222gPTA, 203gEG, 203gDEG, 33.5gTMP and 5g catalyst tetraisobutyl titanate, heat to 240°C under nitrogen protection for polyesterification reaction, react for 20Hr, acid value is 0.3mgKOH / g, hydroxyl value 70mgKOH / g, stop the reaction, and make polyester polyol 960g.

Embodiment 2

[0022] Preparation of polyester polyol 2: Mix 470gAA, 117gPTA, 111gEG, 258gDEG, 22gTMP and 5g catalyst tetraisobutyl titanate, heat to 230°C under nitrogen protection for polyesterification reaction, reaction 18Hr, acid value 0.3mgKOH / g , The reaction was stopped when the hydroxyl value was 56 mgKOH / g, and 960 g of polyester polyol was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com