Combined polyether, polyurethane raw material composition, wood-like material and preparation methods thereof

A technology of raw material composition and combined polyether, which is applied in the field of combined polyether and polyurethane raw material composition, can solve the problems of low surface hardness, uneven foaming, affecting the appearance of products, etc., and achieve high production efficiency and short demoulding time , the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

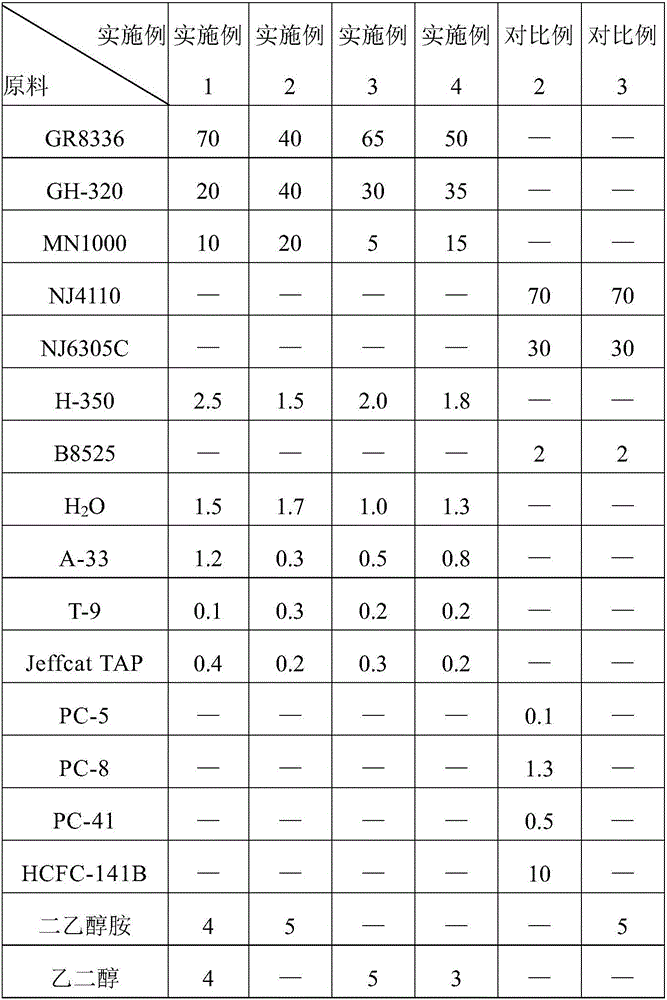

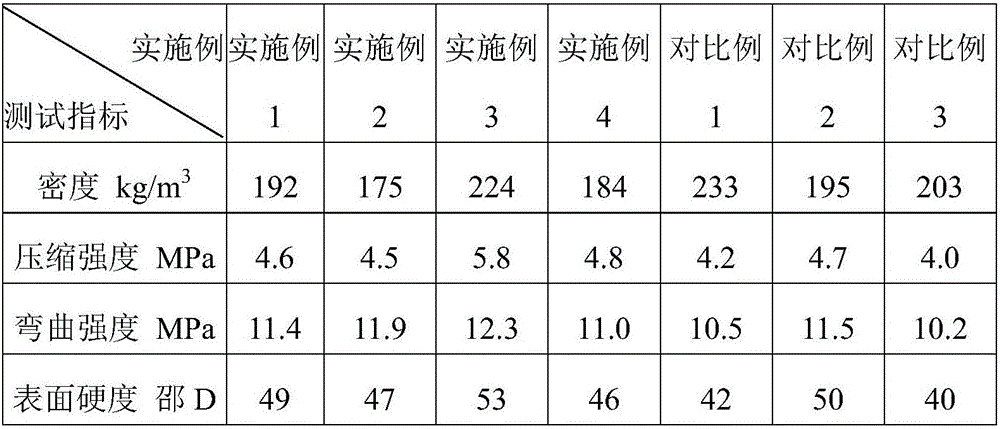

[0040] Table 1

[0041]

[0042] The dosage of each component of the combined polyether in this embodiment is shown in Table 1. The combined polyether can be prepared according to conventional methods in the field. Generally, the above-mentioned components are stirred at room temperature according to their parts by weight and mixed uniformly.

[0043] The preparation method of polyurethane imitation wood material is made up of following steps:

[0044] Control 1 part of combined polyether and 1 part of polymethylene polyphenyl polyisocyanate PM200 at a material temperature of 20±1°C, mix at a speed of 3000r / min and stir well, then pour into a mold with a constant temperature of 30-35°C, and mature Open the mold after 8 minutes, and you get it.

Embodiment 2

[0046] The dosage of each component of the combined polyether in this embodiment is shown in Table 1. The combined polyether can be prepared according to conventional methods in the field. Generally, the above-mentioned components are stirred at room temperature according to their parts by weight and mixed uniformly.

[0047] The preparation method of polyurethane imitation wood material is made up of following steps:

[0048] Control 1 part of combined polyether and 1 part of 44V20 at a material temperature of 20±1°C, mix at a speed of 3000r / min and stir well, pour it into a mold with a constant temperature of 30-35°C, and open the mold after aging for 10 minutes.

Embodiment 3

[0050] The dosage of each component of the combined polyether in this embodiment is shown in Table 1. The combined polyether can be prepared according to conventional methods in the field. Generally, the above-mentioned components are stirred at room temperature according to their parts by weight and mixed uniformly.

[0051] The preparation method of polyurethane imitation wood material is made up of following steps:

[0052] Control 1 part of combined polyether and 1.05 parts of M20S at a material temperature of 20±1°C, mix at a speed of 3000r / min and fully stir evenly, pour into a mold with a constant temperature of 30-35°C, and open the mold after aging for 12 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com