Plastic die parting-plane air-admission stripper

A technology of plastic mold and demoulding mechanism, which is applied in the field of plastic products, can solve the problems of shortened mold life, long production cycle, and low production efficiency, and achieve the effects of small mold impact, long service life, and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

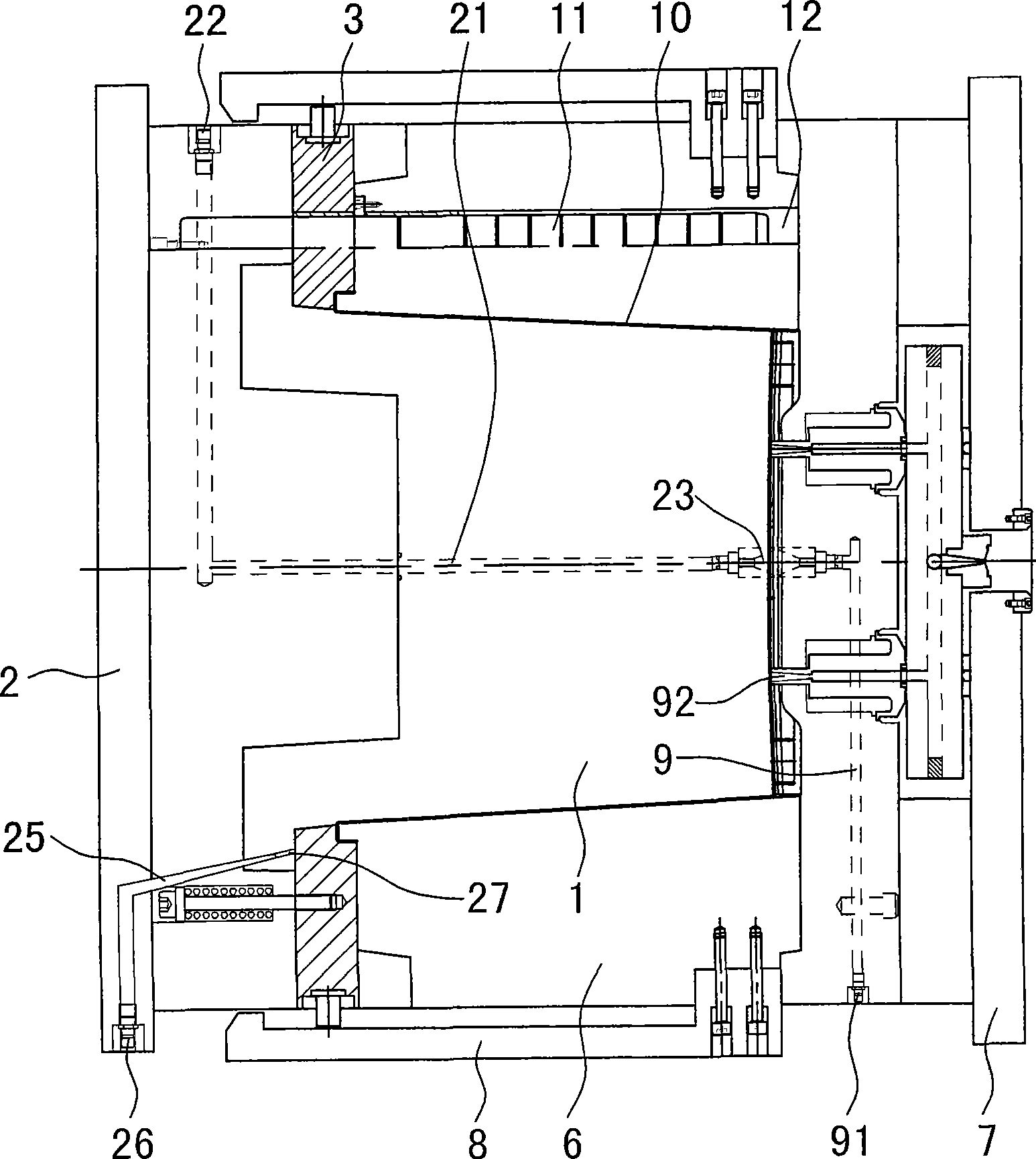

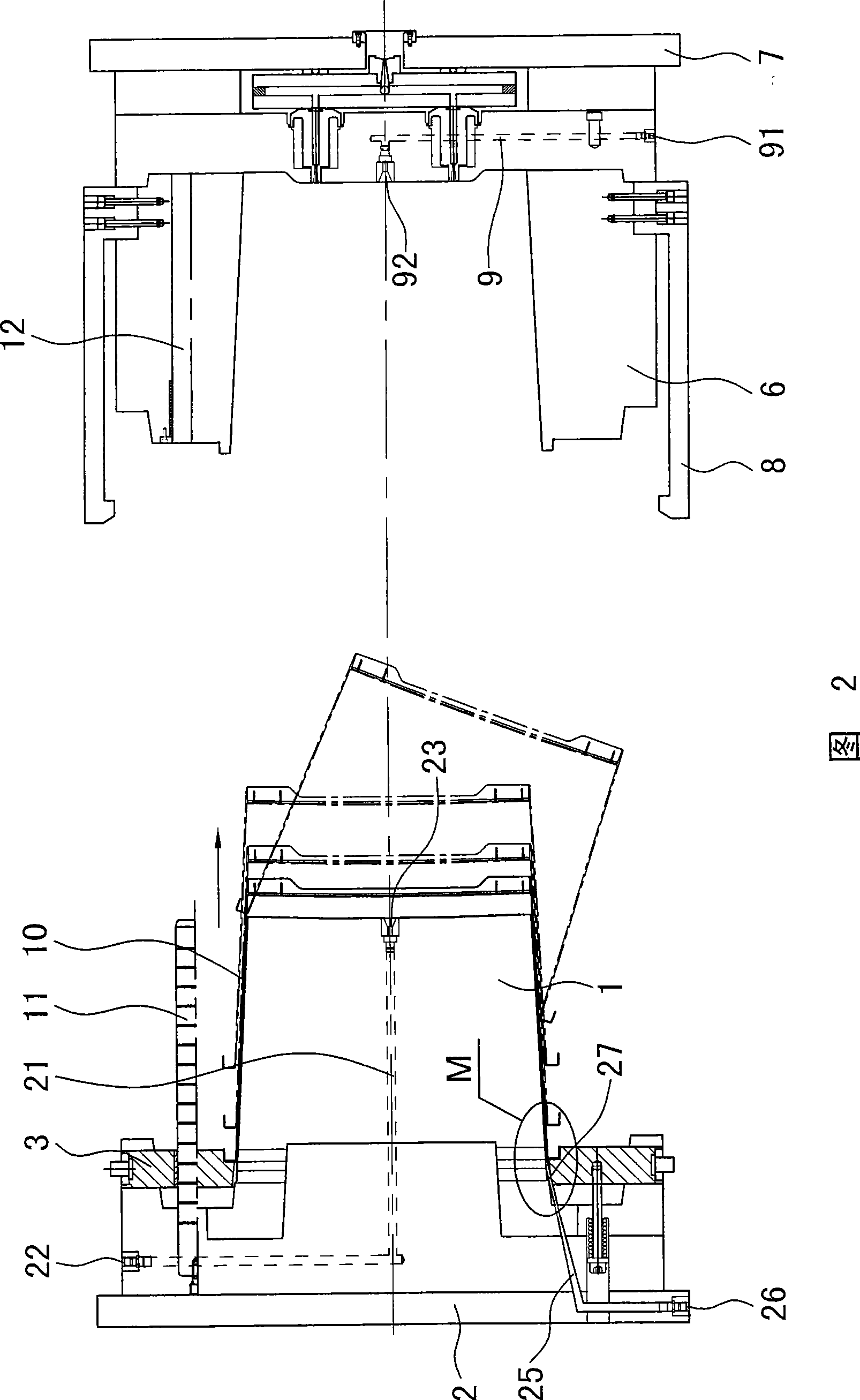

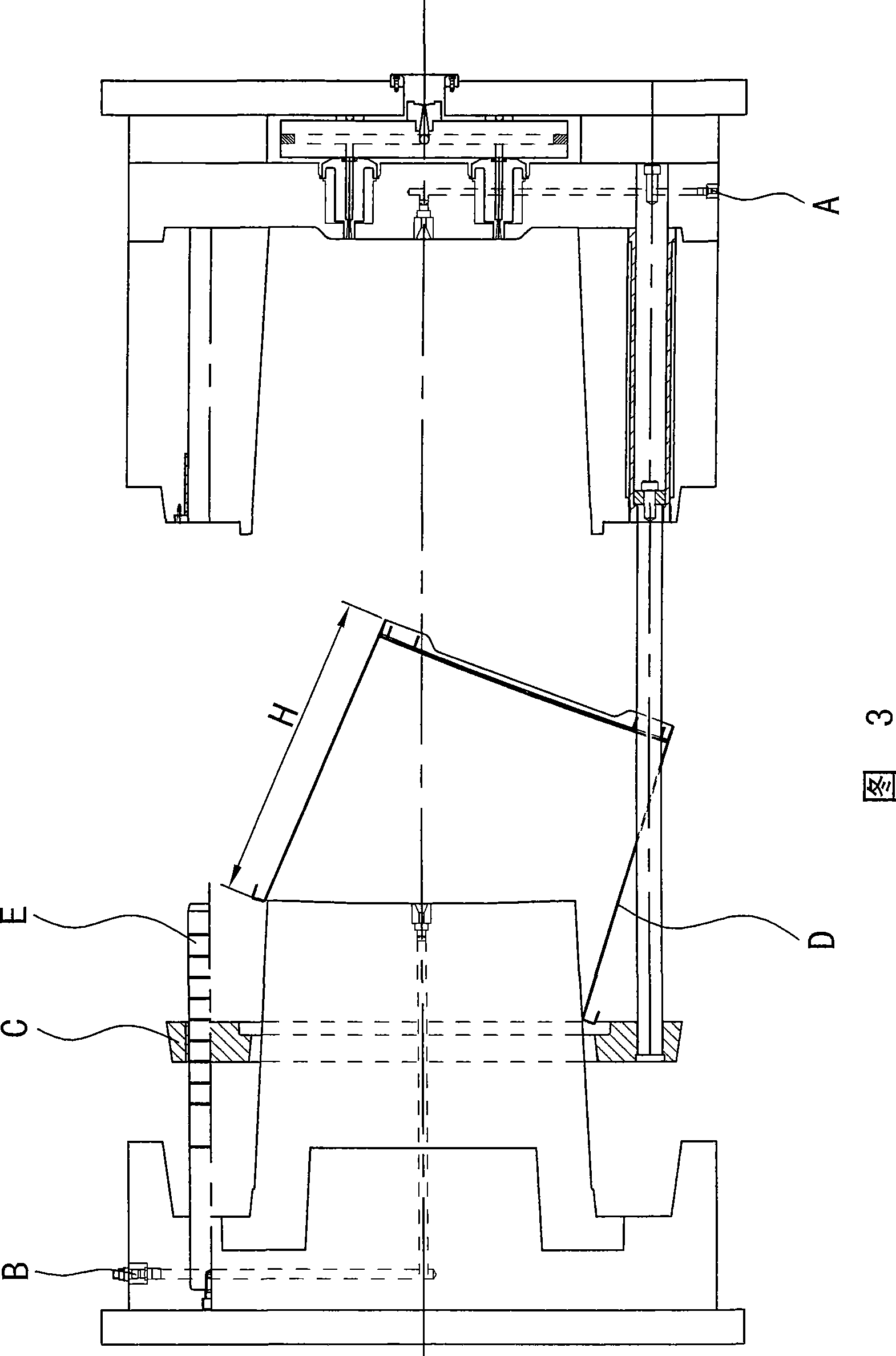

[0011] The invention discloses a plastic mold parting surface air intake and demoulding mechanism, such as figure 1 , shown in Fig. 2, comprise punch 1 and die 6 to form, push plate 3 is housed on punch, draw hook 8 is housed on die, draw hook 8 contacts with push plate 3, it is characterized in that in die 6 A blowing channel 9 is formed, and the blowing channel has an air inlet 91 and an air outlet 92, and a top air channel 21 and a plurality of parting surface air inlet channels 25 are formed in the punch 1, and the top air channel 21 has an air inlet 22 And exhaust port 23, each parting surface air inlet channel 25 has injection port 26 and blowing port 27 respectively, and the air-flow that blowing port 27 produces is positioned at the space between punch 1 and plastic product 10 respectively. The demoulding process is as follows: Before the mold is divided, the air inlet 91 of the air blowing channel 9 is first aired. The air inlet 22 of 21 takes in air, and 2 to 3 seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com