Ultrasonic demoulding device and method for using ultrasonic demoulding device to make contact lens

A mold release device and contact lens technology, applied in the field of ultrasonic mold release device and contact lens manufacturing, can solve the problems of time-consuming, affecting detection accuracy, etc., and achieve the effect of reducing the chance of producing defective products and improving the accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Relevant detailed description and technical content of the present invention, now just explain as follows with respect to matching drawing:

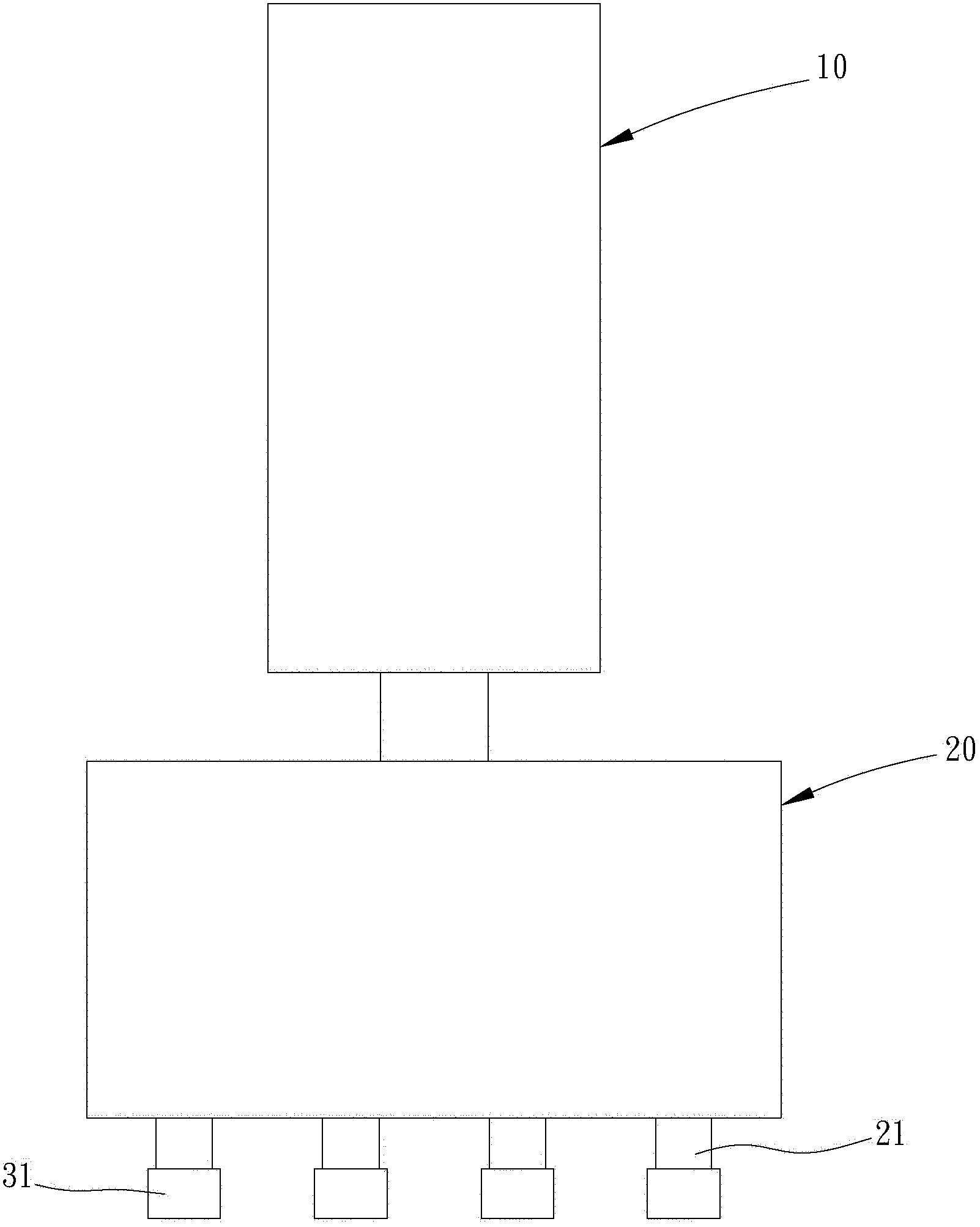

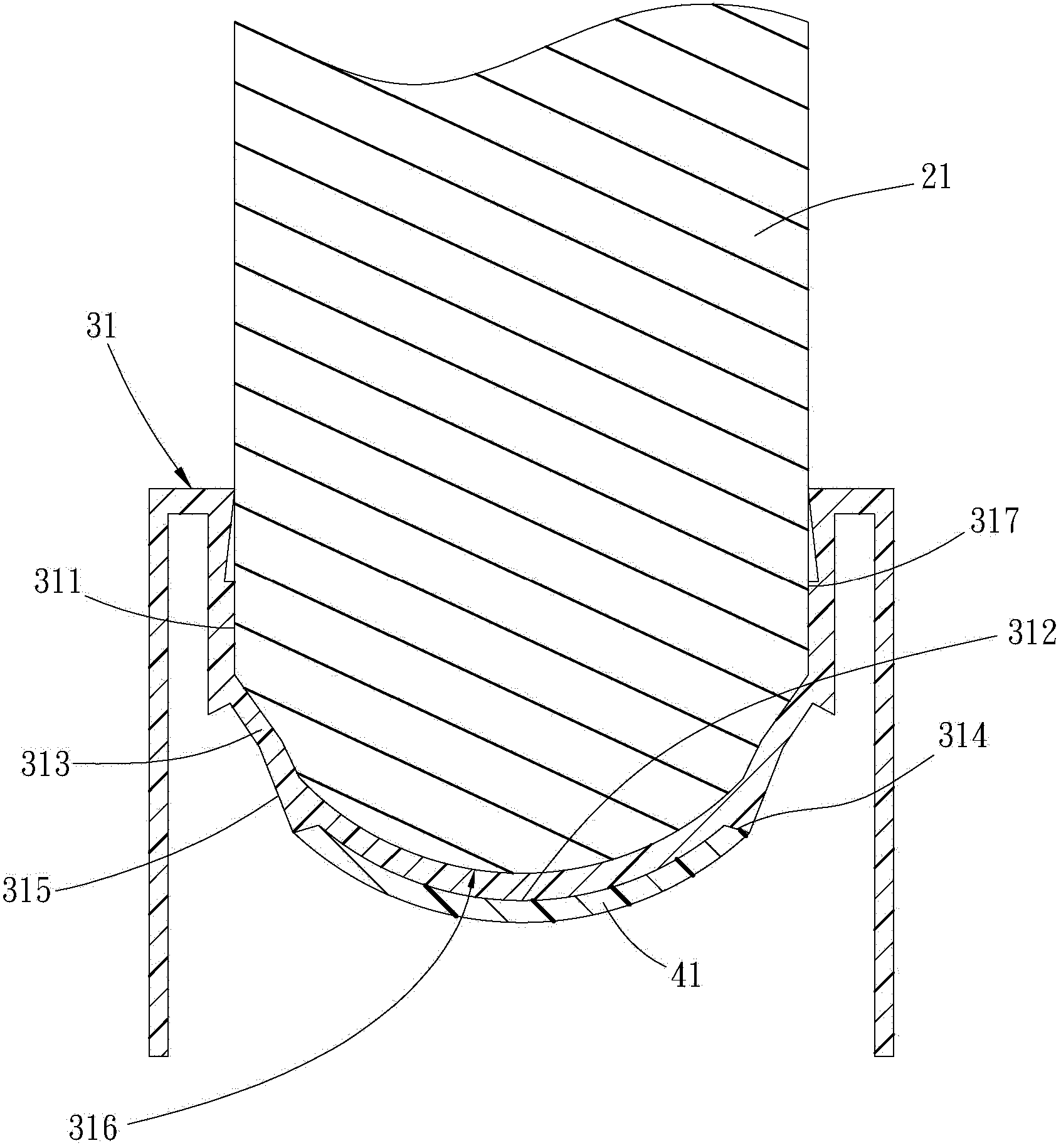

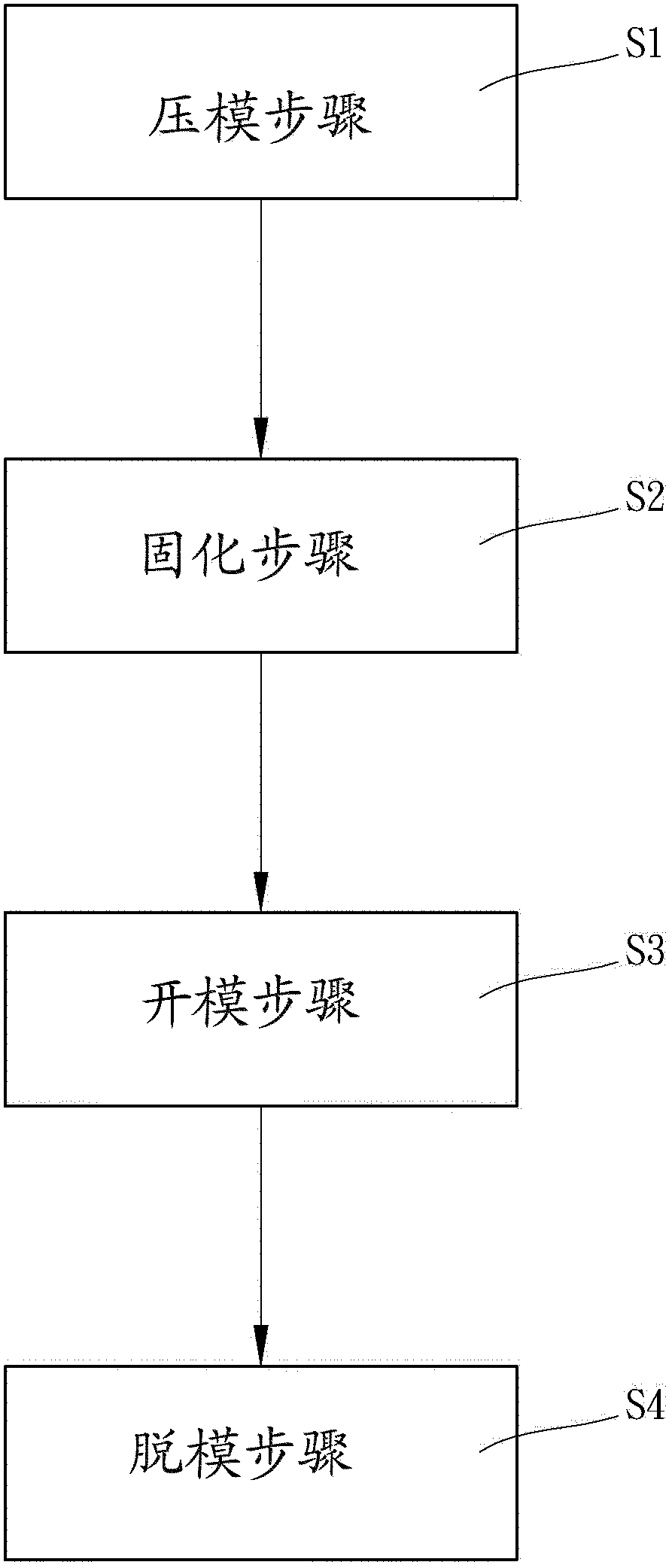

[0022] see Figure 1A and Figure 1B As shown, they are respectively the structure and partial enlarged cross-sectional schematic diagram of an embodiment of the present invention. The present invention provides an ultrasonic demoulding device for demoulding a contact lens 41. The ultrasonic demoulding device includes an ultrasonic wave demoulding device. Oscillator 10, a transmission part 20 and a mould, this mould, in this embodiment, refers to a first mold 31 at this, and can be with a second mold 32 (shown in Figure 3A ) corresponding to meshing. The ultrasonic oscillator 10 is used to generate an ultrasonic wave, and the shock-transmitting member 20 is connected between the ultrasonic oscillator 10 and the first mold 31, and the ultrasonic wave is transmitted from the ultrasonic oscillator 10 to the first mold 31. On a mol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com