Novel layered material composite long glass fiber reinforced polypropylene composite material and preparation method thereof

A technology of layered materials and composite materials, which is applied in the field of polypropylene materials, can solve problems such as bad odor and excessive VOC performance, and achieve the effect of improving impregnation effect, reducing emission ability, and improving emission performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be further explained below in conjunction with implementation, but the embodiments do not limit the present invention in any form.

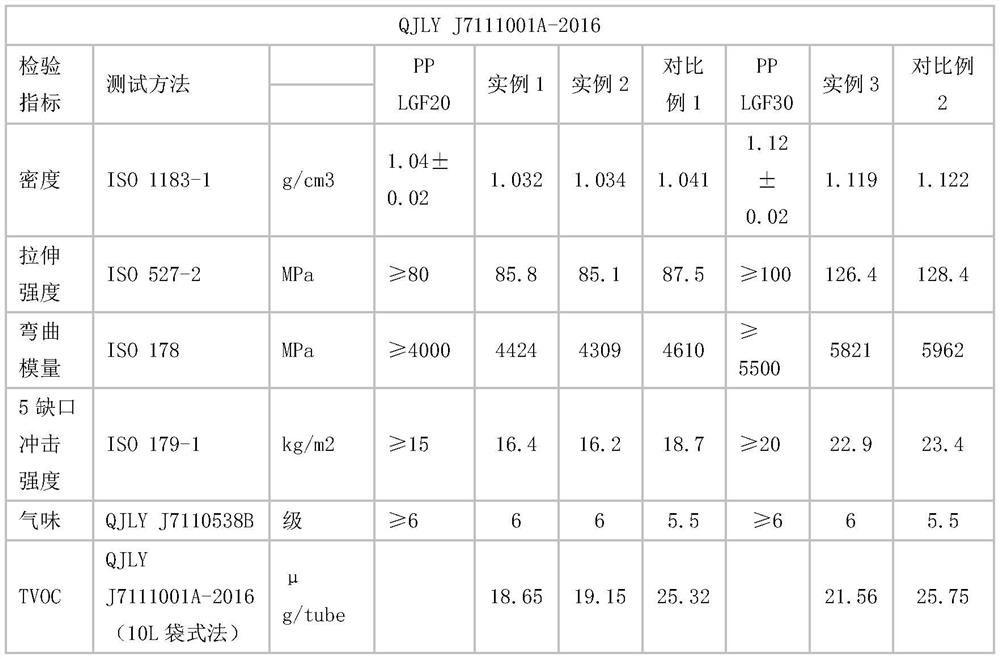

[0021] The composition and mass percentage content of the components contained in the comparative examples and examples of the present invention are shown in the following table 1, table one, the formula composition and content of the examples and comparative examples

[0022] Raw material ratio Example 1 Example 2 Example 3 Comparative example 1 Comparative example 2 layered material powder 10 15 15 0 0 conventional polypropylene 67 62 52 77 67 long glass fiber 20 20 30 20 30 Compatibilizer 2 2 2 2 2 light stabilizer 0.5 0.5 0.5 0.5 0.5 antioxidant 0.5 0.5 0.5 0.5 0.5

[0023] According to the preparation steps of the above table embodiment:

[0024] (1) The sheet material, conventional polypropylene, compatibilizer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com