Multi-inlet gas-liquid two-phase cyclone feeding downward-spray atomizing nozzle

A technology of atomizing nozzles and inlets, which is applied in the direction of chemical/physical processes, chemical instruments and methods, etc. It can solve the problems of large atomized particle size, material center convergence, and low distribution uniformity, so as to reduce production costs and prevent leakage , Improve the effect of reaction efficiency and reaction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

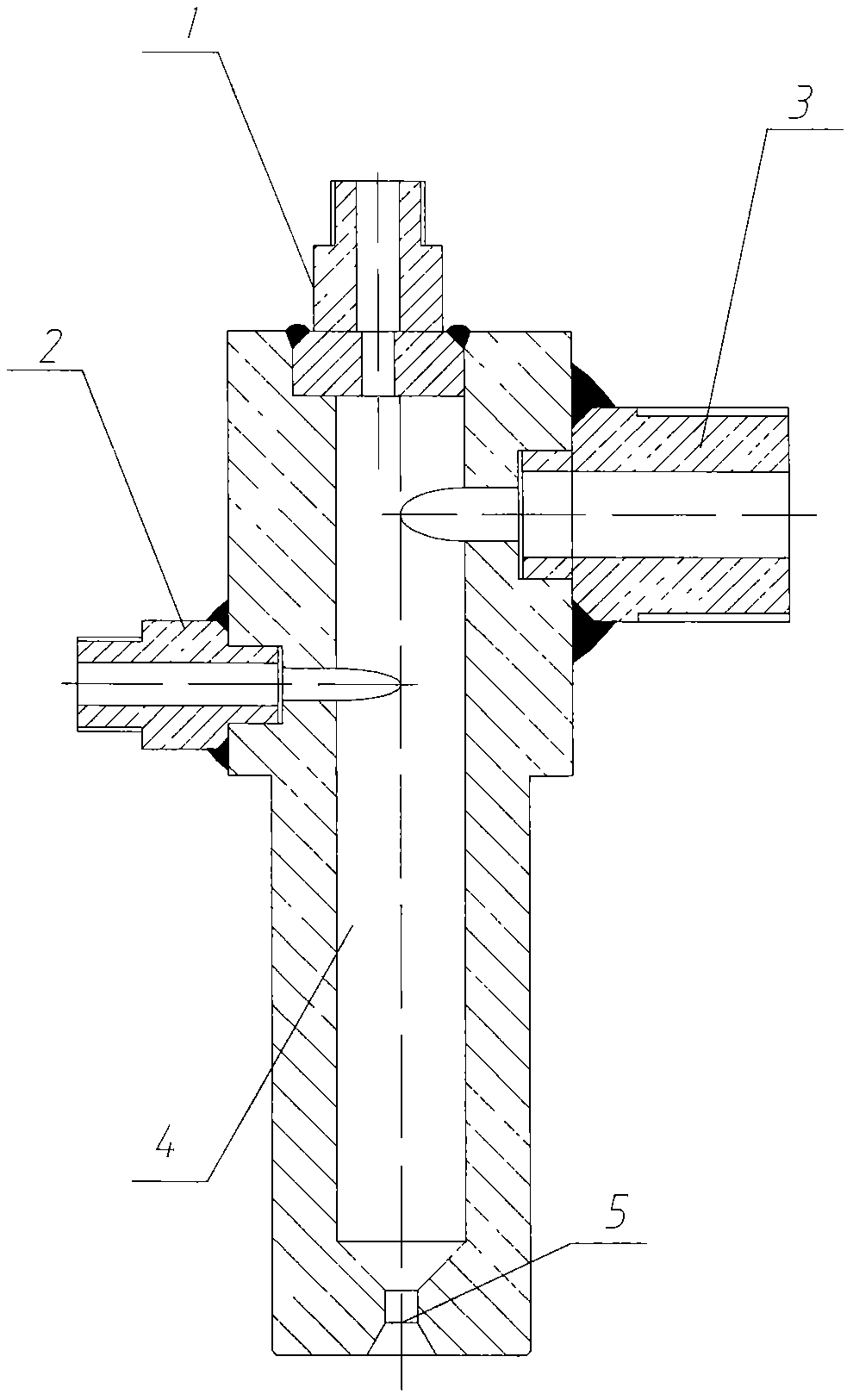

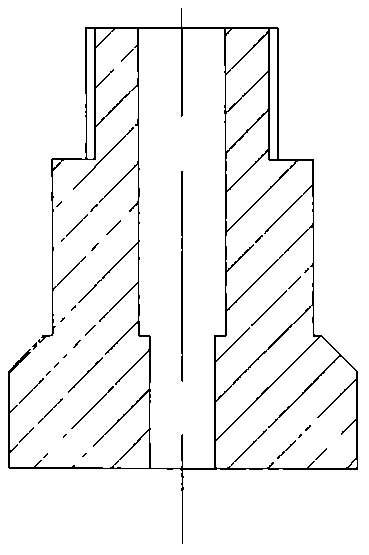

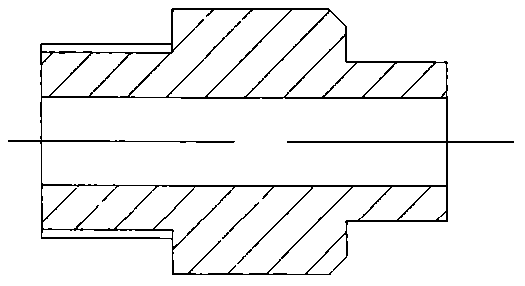

[0021] Figure 1 to Figure 6 Shown is a multi-entrance gas-liquid two-phase swirl feed downspray atomizing nozzle.

[0022] refer to Figure 1 to Figure 6 , the multi-entrance gas-liquid two-phase swirl feed of the present invention is welded on the top of the gas-liquid two-phase mixing chamber (4) from top to bottom by top eccentric liquid phase inlet (1); The tangential gas phase inlet (3) is welded on one side of the gas-liquid two-phase mixing chamber (4); further down is the tangential liquid phase inlet (2) welded on the other side of the gas-liquid two-phase mixing chamber (4) ; Finally, the zoom-type spout (5) and the gas-liquid two-phase mixing chamber (4) are integrally processed. The welding connection method and integrated processing can effectively prevent leakage and increase the safety of the reaction device.

[0023] The multi-inlet gas-liquid two-phase swirl feed spray atomizing nozzle of the present invention has good atomization and distribution effects:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com