Low-diffusion reactive-type tertiary amine catalyst, and preparation method and application of same

A catalyst and reaction-type technology, which is applied in the field of preparation of low-emission reaction-type tertiary amine catalysts, can solve the problems of weak catalytic gel reaction, small amount of tertiary amine N, high activity of active hydrogen, etc., and achieve good foaming and coagulation Effects of gel balance, viscosity reduction, and catalytic ability enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of 3-dimethylaminopropylurea and N,N'-bis(3-dimethylaminopropylurea):

[0034] First, dissolve 60g of urea in 180g of methanol, add it to a 1L reaction kettle, seal the reaction kettle, replace it with nitrogen three times, then increase the pressure to 1MPa, start stirring at 500 rpm, wait for the temperature to rise to 120°C, and start the reaction In the still, add N, N-dimethylaminopropylamine dropwise with a pump, and the flow rate of the pump is 1g / min. When the feed amount of N, N-dimethylaminopropylamine is 107.1g, stop feeding, and after 10min, the temperature will be reduced. Lower the temperature to 50°C, release the ammonia and nitrogen generated by the reaction, add fresh nitrogen at 2MPa, raise the reaction temperature to 120°C and continue the reaction for 2h, then stop the reaction. The temperature of the reaction liquid was lowered to 30°C, the ammonia in the reaction liquid was removed by a vacuum pump, and then filtered, and the compositio...

Embodiment 2

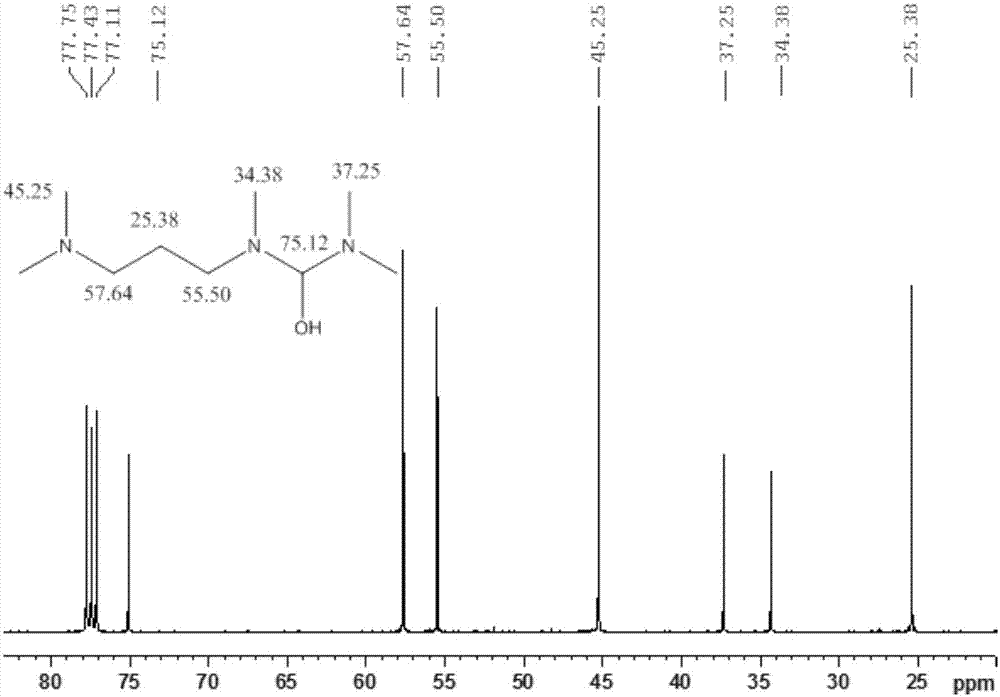

[0036] Preparation of 2,4,8-trimethyl-2,4,8-triazanonan-3-ol and 2,6,8,12-tetramethyl-2,6,8,12-tetraazadeca Trialkan-7-ol:

[0037] The resulting 3-dimethylaminopropyl urea and N,N'-bis(3-dimethylaminopropyl urea) reaction solution was directly transferred to a 1.5L reactor, and a commercial 5% palladium carbon catalyst (Johnson Wanfeng, model: 5ZA503023) 1.5g, seal the reaction kettle, replace it with nitrogen and hydrogen three times respectively, the initial hydrogen pressure is 2 MPa, start stirring at 700 rpm, wait for the reaction temperature to rise to 120 ° C, adjust the hydrogen pressure To 5MPa and continue to flow hydrogen, start to pass 388g of 37% formaldehyde solution into the reactor at a speed of 2g / min with a convection pump, wait until the instantaneous flow rate of the flow meter is lower than 50sccm, close the hydrogen valve, and continue to react for half an hour to stop the reaction . Afterwards, the temperature was lowered, the pressure was released, r...

Embodiment 3

[0039] Prepare polyurethane foam:

[0040] Catalyst composition of the present invention is applied to conventional polyurethane flexible foam flexible foam material, and its basic formula is as follows

[0041]

[0042]

[0043] The amount of polyisocyanate used in the polyurethane formulations of the present invention is not limited, but is typically within the range known to those skilled in the art.

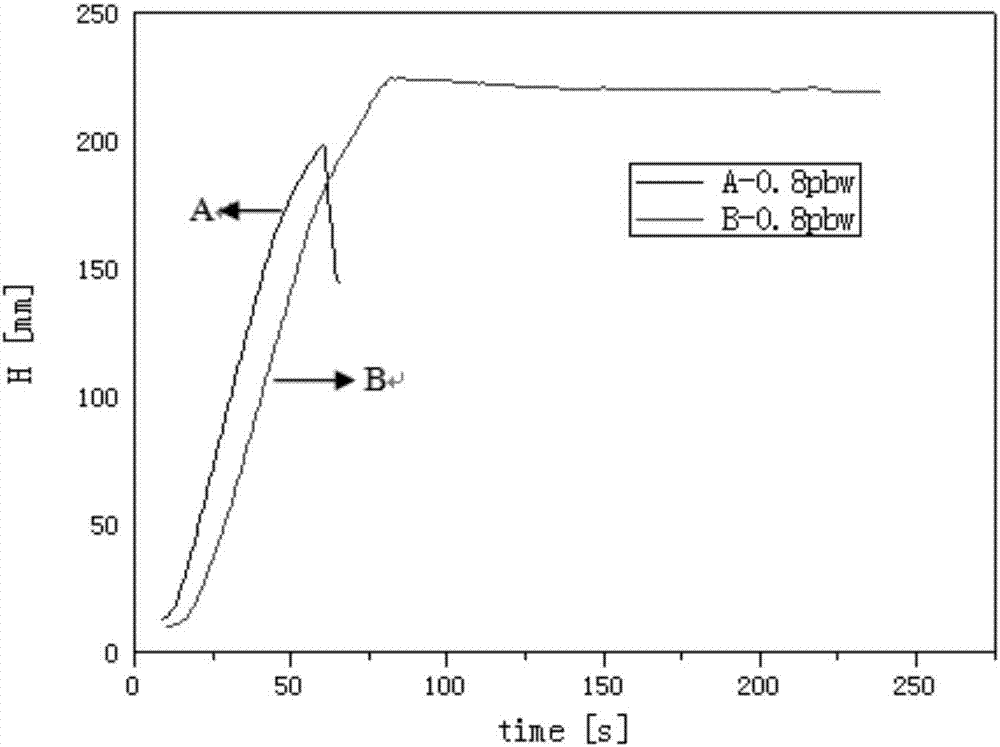

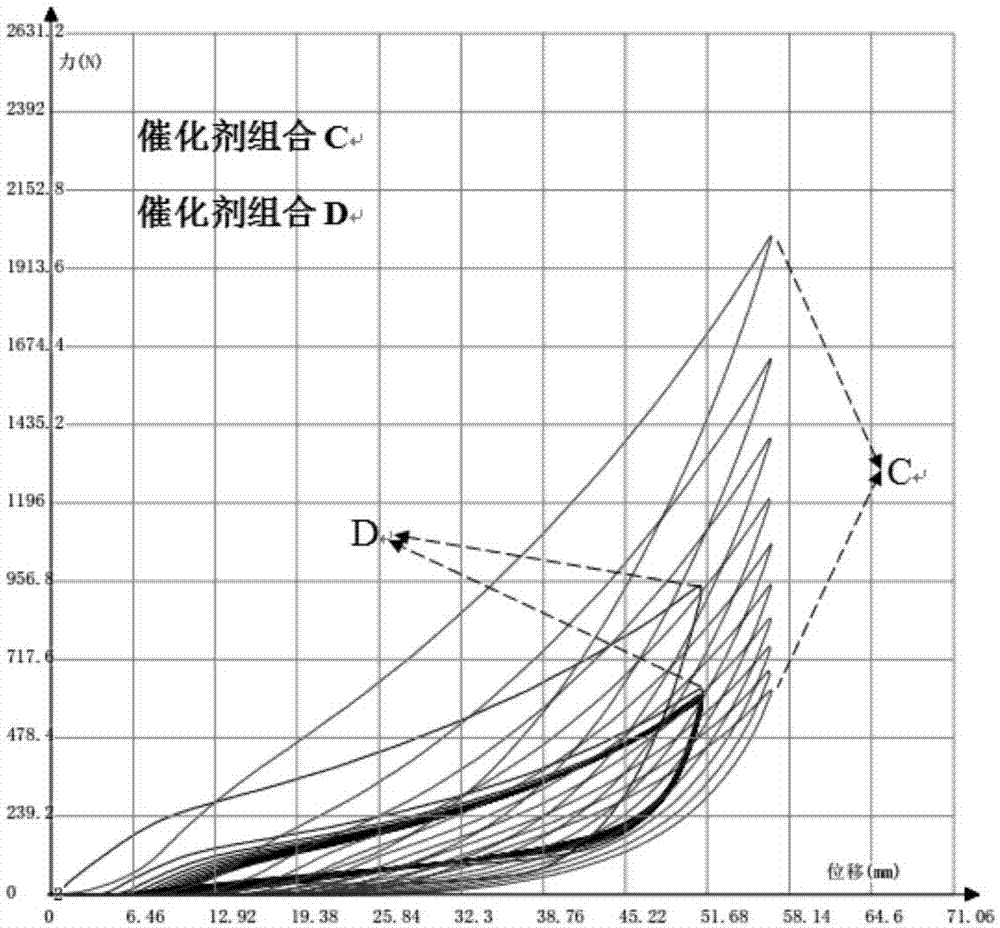

[0044] In the following 50Kg / m3 modified MDI-based automotive high-resilience seat system, 3-dimethylaminopropyl urea and its methylated product 2,4,8-trimethyl-2,4,8 -Triazanonan-3-ol for foaming performance comparison.

[0045]

[0046] One-step manual free foam operation: add polyol, water, cross-linking agent, surfactant and catalyst to the container in proportion and disperse at high speed for 5 minutes to prepare composite material; put composite material and isocyanate into constant temperature culture The box is subjected to constant temperature treatment a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com